Log in

Search

Latest topics

» Free Flight Radio Assist by GallopingGhostler Today at 12:54 pm

» My N-1R build log

by akjgardner Today at 12:39 pm

» Purchased the last of any bult engines from Ken Enya

by getback Today at 12:05 pm

» Funny what you find when you go looking

by rsv1cox Yesterday at 3:21 pm

» Landing-gear tips

by 1975 control line guy Yesterday at 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» My latest doodle...

by TD ABUSER Mon Nov 18, 2024 11:30 am

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

» Tribute Shoestring build

by amurphy6812 Sun Nov 17, 2024 5:43 pm

Cox Engine of The Month

Skyray 35 Build - Faux Streak look

Page 2 of 9

Page 2 of 9 •  1, 2, 3, 4, 5, 6, 7, 8, 9

1, 2, 3, 4, 5, 6, 7, 8, 9

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

I would say the single most effective option for this wing is to replace the trailing edge with solid stock. Aileron stock could be ripped down to the 1 1/4" width allowing for a much strong trailing edge. A dado could be cut for the ribs using a thin plywood blade on a table saw. If seen many Skyray's where the sheeted trailing edge is most problematic. It has a tendency to droop as it leaves the fuse. This is especially true if one of the pieces is considerably harder than the other. A old free flight trick is to cantilever the wood off the end of the table side by side and take note to see how much they droop comparing both pieces side by side. I do this for full body fuselages. The 1/8" sides can do the same to the fuse. The stronger piece can overpower the lighter weaker piece and dial a bow directly into your fuse. The trailing edge though in my opinion will work fine assuming you get it built straight and covered properly. If you shrink one side more than the other, it will twist the wing at the trailing edge. Having a inverter for your car and a Monokote iron at the field is probably the best thing I ever owned.

I've built many wings that came off the table with a serious curve dialed into them. I've placed it back on the table and used rubber band clamps to hold it down. I take blocks of wood and firmly support the wing in the needed areas and bow it the opposite direction and lay weights on the wing. I have a very fine atomizer which I can spray water from which I use to shrink tissue with. I then dampen the wing and let it sit for a day. I've had good results using this method and have repaired badly warped wings doing so.

I don't know if these are available in your part http://volareproducts.com/BUY/index.php?main_page=product_info&products_id=24 , by a company called Rocket City made these small circular plastic clamps that slide onto T-pins. They work fabulous. No need to stick through the wood just into the table. These go off to the side of the work and these slide down the pin onto the work. They require a lot of force to get them to slide which is a good thing with the exception when you slide them to prepare them to the work. These don't slide on the t-pin easily at first and when you slide them in your hand I always end up putting them through my fingers. Ken

I've built many wings that came off the table with a serious curve dialed into them. I've placed it back on the table and used rubber band clamps to hold it down. I take blocks of wood and firmly support the wing in the needed areas and bow it the opposite direction and lay weights on the wing. I have a very fine atomizer which I can spray water from which I use to shrink tissue with. I then dampen the wing and let it sit for a day. I've had good results using this method and have repaired badly warped wings doing so.

I don't know if these are available in your part http://volareproducts.com/BUY/index.php?main_page=product_info&products_id=24 , by a company called Rocket City made these small circular plastic clamps that slide onto T-pins. They work fabulous. No need to stick through the wood just into the table. These go off to the side of the work and these slide down the pin onto the work. They require a lot of force to get them to slide which is a good thing with the exception when you slide them to prepare them to the work. These don't slide on the t-pin easily at first and when you slide them in your hand I always end up putting them through my fingers. Ken

Ken Cook- Top Poster

- Posts : 5635

Join date : 2012-03-27

Location : pennsylvania

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

Since the weight box will probably end up glued to one or both spars, the strength of the rib is less important than might be thought at first.

There was a guide somewhere (stunt hanger?) that showed using a half rib, sheeting in the box, and using a soft balsa plug that can be sanded exactly fair on the lid, so covering can be attached and the lid completely faired in. Plywood can be faired...but it is not exactly fun.

Phil

There was a guide somewhere (stunt hanger?) that showed using a half rib, sheeting in the box, and using a soft balsa plug that can be sanded exactly fair on the lid, so covering can be attached and the lid completely faired in. Plywood can be faired...but it is not exactly fun.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

Phil, now that the weights are in place, I'm not going to add a box. If it needs more than the one ounce, I'll cut and paste.

Ken, did I see you post sometime in the past, in a Skyray thread, about adding some vertical grain shear webs between the ribs, glued to the face of the TE sheeting? If done on a straight wing, that may help maintain the shape. Otoh, I don't want to add fat, but my light ribs give me some wiggle room in the weight department.

Rusty

The bottom sheet is glued. Now I'mm off to the shop to continue. And to pack my flight box for tomorrow morning's excursion with the old GlueRay. And maybe Wayne's Ukie. My full pattern training begins.

Rusty

Ken, did I see you post sometime in the past, in a Skyray thread, about adding some vertical grain shear webs between the ribs, glued to the face of the TE sheeting? If done on a straight wing, that may help maintain the shape. Otoh, I don't want to add fat, but my light ribs give me some wiggle room in the weight department.

Rusty

The bottom sheet is glued. Now I'mm off to the shop to continue. And to pack my flight box for tomorrow morning's excursion with the old GlueRay. And maybe Wayne's Ukie. My full pattern training begins.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

Rusty, your absolutely correct in the shear webs. In fact that pretty much is the norm for me when it comes to this style of construction. Another option I do is to build the wing per plan, I then go back with a straight edge and slice off approximately 3/8" and glue a piece of spruce or bass onto the trailing edge. I use a razor plane to shape and a very light sanding takes care of the rest. Ken

Ken Cook- Top Poster

- Posts : 5635

Join date : 2012-03-27

Location : pennsylvania

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

Very cool thread! It's hard for me to try to remember all the bits and pieces, tips and so on... but I'm trying to absorb as much as I can; regarding built-up wing construction, reinforcement and straightening warps should they occur. I don't have much experience there. As far as flying precision aerobatics is concerned; I've really enjoyed Rusty's learning experiences through his posts.

Rusty.. after flying that BIG airplane... I imagine you're gonna wring-out that "glue-ray" (I still think you should name it the "Ray-Ray" ) Have fun tomorrow!

) Have fun tomorrow!

Rusty.. after flying that BIG airplane... I imagine you're gonna wring-out that "glue-ray" (I still think you should name it the "Ray-Ray"

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

Thanks guys, glad this thing is on the move now. This wing is going to have tapered fixed flaps attached to the TE. And as I already mentioned, Flite Streak tips. I'm already ruminating over color schemes, and have settled on solvent based urethane clear for the fuselage and stab/elevator.

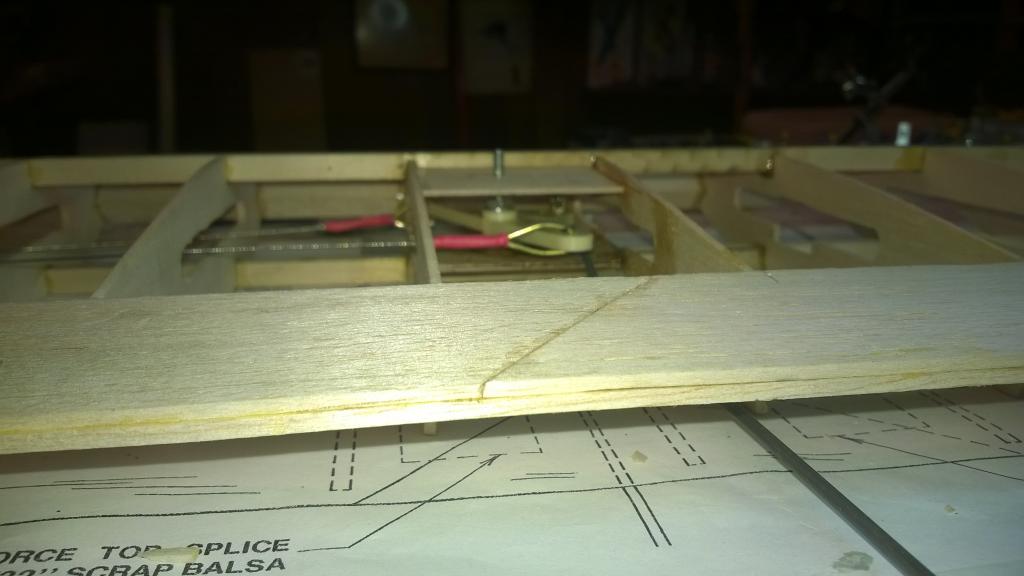

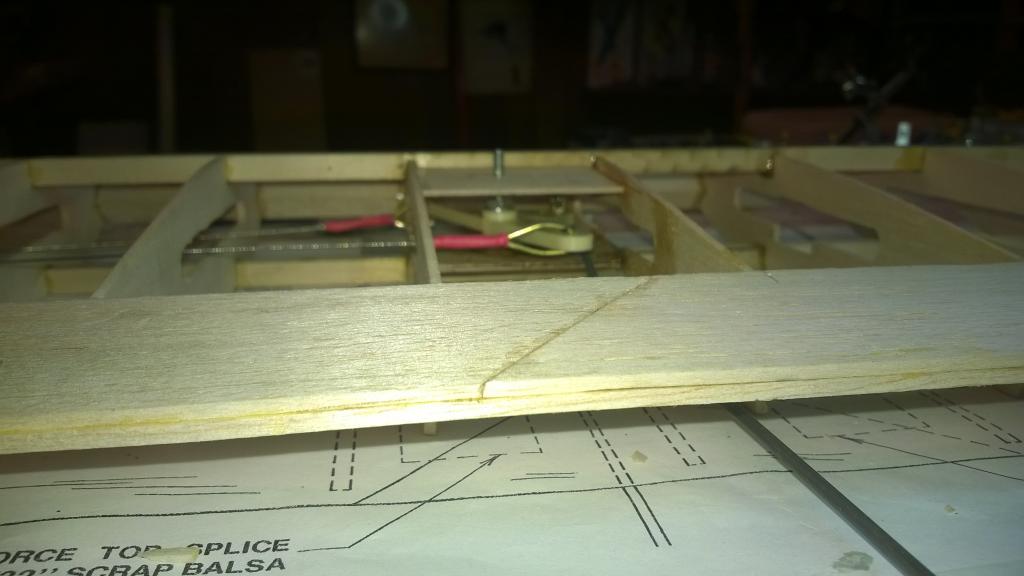

Here are some pictures from tonight.

Bottom sheet glued on. Clothes pins are sanded to an angled flat face that fits the angle... more or less.

Top sheet glued on.

Here are some pictures from tonight.

Bottom sheet glued on. Clothes pins are sanded to an angled flat face that fits the angle... more or less.

Top sheet glued on.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

Nice hammer

Good idea with the cloths pins

Phil

Good idea with the cloths pins

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

Haha, that hammer head is one of my most important tools. I was meaning to get a new handle for it a few decades ago, but I use it as a hand held whammer so much, I think I would miss it if I did. But my favorite tool of all is the 3/4" x 8" square brass bar that can be seen weighting the other end of the wing. I've had it for 40 years and it has countless countless uses. No tool tote of mine is complete without the brass bar and a mini-sledge... and my big channel locks... oh for pete sake... I love tools.pkrankow wrote:Nice hammer

Good idea with the cloths pins

Phil

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

Yeah diggin the clothespins. Much quicker than T pins. On the other hand you have to watch where you glue!

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

Yeah, especially epoxy. I probably have a couple of cloths pin pieces flying from time to time.Cribbs74 wrote:Yeah diggin the clothespins. Much quicker than T pins. On the other hand you have to watch where you glue!

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

That wing is certainly looking good. A very nice achievement. Good luck with it, I also like your thinking. I like the looks of Flite Streak tips. Ken

Ken Cook- Top Poster

- Posts : 5635

Join date : 2012-03-27

Location : pennsylvania

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

Well built wing Rusty. Did you reshape the clothpins so they fit better to the trailing edge and ribs? What happened to your spectacles? I hope that's nothing to do with the "whammer"?

Lieven

Lieven

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

Hi Lieven. Yes, I wrote about that, the clothes pins are sanded flat and angled to fit the TE.OVERLORD wrote:Well built wing Rusty. Did you reshape the clothpins so they fit better to the trailing edge and ribs? What happened to your spectacles? I hope that's nothing to do with the "whammer"?

Lieven

I was cleaning my glasses and they snapped, just broke in the middle of the crossbar. Titanium I think. I was going to try and find a small copper tube to fill with JB Weld and join them. But I guess I'm going to get new ones. At least my old ones work pretty well.

I went flying today, so not much energy for building tonight.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

An addendum to last night's report.

There are removable alignment tabs near the TE on the bottom of every rib to hold them the same height(parallel centerlines) off the table. After gluing and clamping there was a little flex where the ribs at both ends had pulled off the table due to a slight twist in the TE sheeting. With the weights in place, which we discussed above(the hammer whammer and brass bar), after the glue fully dried, I removed the weights and there is no longer any flex. All rib tabs once again sit flat on the table. Just make sure the table is flat. My drywall building board is on top of a 3/8" thick glass, and I even had to shim it in the center to keep it flat on my imperfect wood table. This is all very important fundamental practice for building the closest to perfect wing possible. Remember with balsa, nothing will ever be absolutely perfect. With a small 1/2A plane a flaw may not be noticeable, but with a 46" wing, a little error adds up badly.

Rusty

There are removable alignment tabs near the TE on the bottom of every rib to hold them the same height(parallel centerlines) off the table. After gluing and clamping there was a little flex where the ribs at both ends had pulled off the table due to a slight twist in the TE sheeting. With the weights in place, which we discussed above(the hammer whammer and brass bar), after the glue fully dried, I removed the weights and there is no longer any flex. All rib tabs once again sit flat on the table. Just make sure the table is flat. My drywall building board is on top of a 3/8" thick glass, and I even had to shim it in the center to keep it flat on my imperfect wood table. This is all very important fundamental practice for building the closest to perfect wing possible. Remember with balsa, nothing will ever be absolutely perfect. With a small 1/2A plane a flaw may not be noticeable, but with a 46" wing, a little error adds up badly.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

The wing looks great Rusty

You are a real good builder.

Theo

You are a real good builder.

Theo

Theo Kleynhans- Gold Member

- Posts : 196

Join date : 2013-12-30

Age : 43

Location : South Africa

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

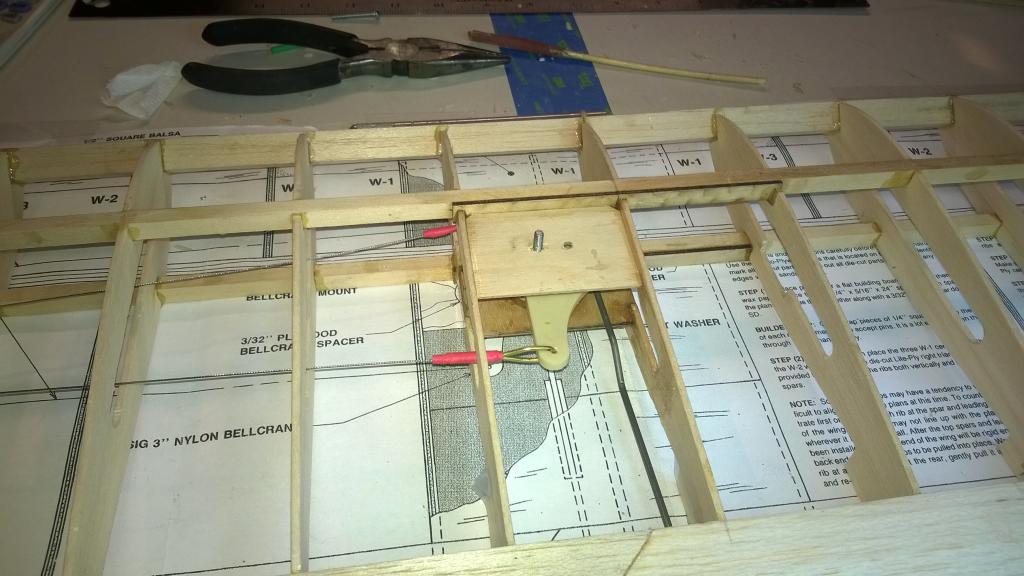

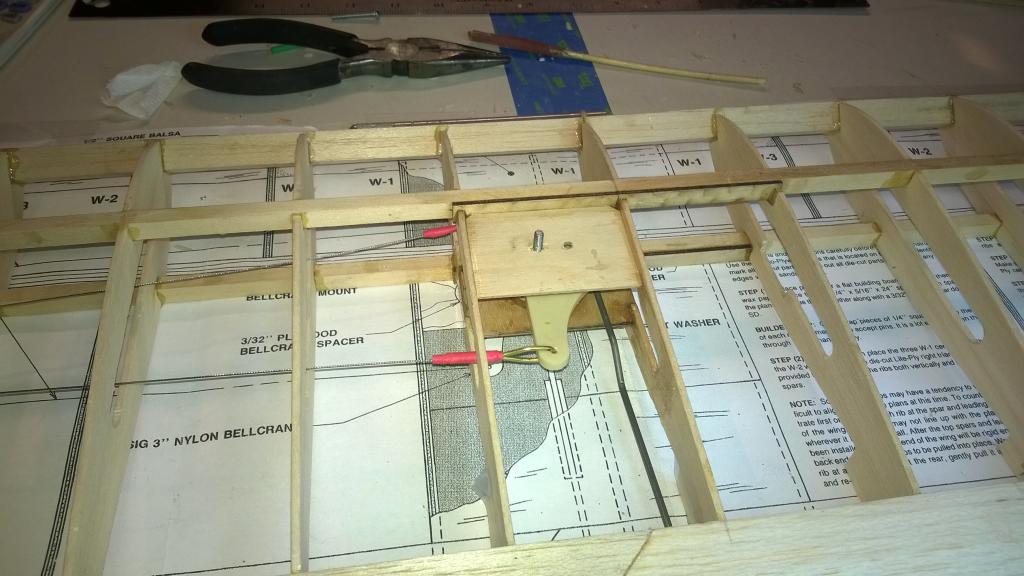

I got some work done tonight before I got run off by a thunder storm.

But not before I had to fix a Black Widow that will never run again.

Now, getting down to business. I epoxied the bellcrank platform into the wing and was not confident in its strength. So I decided to box it in by running a long pivot screw through another platform. It will distribute the load over more area. When the epoxy hardened on the base platform, it really did seem pretty strong but after mistakes on earlier builds, I'm paranoid about underestimating strength. Here's a picture of the beginning of the leadout wrapping job, and the top platform is shown. It will box in the bellcrank and make it as strong as possible. Just like the nut on top of a helicopter prop, it's all that supports the whole machine.

As you can see, the kit did not supply enough wire. My wire is a little thinner, so you can see the difference. The kit wire is on the right. (Well after posting the picture, it's not that obvious)

Here is what I finished before the thunder storm hit. The copper wire wrap is coated with thin 6 minute epoxy.

But not before I had to fix a Black Widow that will never run again.

Now, getting down to business. I epoxied the bellcrank platform into the wing and was not confident in its strength. So I decided to box it in by running a long pivot screw through another platform. It will distribute the load over more area. When the epoxy hardened on the base platform, it really did seem pretty strong but after mistakes on earlier builds, I'm paranoid about underestimating strength. Here's a picture of the beginning of the leadout wrapping job, and the top platform is shown. It will box in the bellcrank and make it as strong as possible. Just like the nut on top of a helicopter prop, it's all that supports the whole machine.

As you can see, the kit did not supply enough wire. My wire is a little thinner, so you can see the difference. The kit wire is on the right. (Well after posting the picture, it's not that obvious)

Here is what I finished before the thunder storm hit. The copper wire wrap is coated with thin 6 minute epoxy.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

You are fine. This is a plane that is getting bashed.

Building the way you, boxed in, double shear on the bolt, are will require enough failures that the bell crank will be the least of your worries. Check for free operation, and use witness marks between the parts. Binding is more of a worry with this technique.

Phil

Building the way you, boxed in, double shear on the bolt, are will require enough failures that the bell crank will be the least of your worries. Check for free operation, and use witness marks between the parts. Binding is more of a worry with this technique.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

Phil

Witness marks? What's that?

What binding are you thinking of?

Rusty

Witness marks? What's that?

What binding are you thinking of?

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

Lay up the parts, carefully. You already drilled the holes so draw (with a pen, pencil, or marker) on the spar and the rib and the plywood (witness marks) so the part gets installed in the correct direction.

If your holes end up not lined up then the axle bolt will be crooked, so the bell crank will not sit properly and potentially bind against the added structure.

It may have been better to NOT drill one part of the box, then drill through after gluing together.

On The Other Hand you are a meticulous builder, and this is a simple problem, so I am probably over blowing it. I might also have missed some sarcasm

I might also have missed some sarcasm

Phil

If your holes end up not lined up then the axle bolt will be crooked, so the bell crank will not sit properly and potentially bind against the added structure.

It may have been better to NOT drill one part of the box, then drill through after gluing together.

On The Other Hand you are a meticulous builder, and this is a simple problem, so I am probably over blowing it.

I might also have missed some sarcasm

I might also have missed some sarcasm

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

Good looking wing Rusty , thanks for the tips, hints , tricks for building a straight wing....Getback

getback- Top Poster

Posts : 10439

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

I gotcha. Okay, here's what I did. Before gluing in the bellcrank's baseplate/ply spacer, I drilled its pivot hole so it(luckily) had a tight fit for the 6-32 screw. When I cut out the top plate, I had to bevel the two leading edge corners so as to fit around the spar/rib glue overflow. See the beveled corners in pic#1. It's upside down, btw. This will assure it only keys into place in one direction. You can also see it has a mistake hole in it too.pkrankow wrote:Lay up the parts, carefully. You already drilled the holes so draw (with a pen, pencil, or marker) on the spar and the rib and the plywood (witness marks) so the part gets installed in the correct direction.

If your holes end up not lined up then the axle bolt will be crooked, so the bell crank will not sit properly and potentially bind against the added structure.

It may have been better to NOT drill one part of the box, then drill through after gluing together.

On The Other Hand you are a meticulous builder, and this is a simple problem, so I am probably over blowing it.I might also have missed some sarcasm

Phil

Next, I turned a threaded rod into the baseplate until it bottomed out on the table. Then I keyed the top plate into it's place firmly flush with the spar and slightly snug between the ribs. Then I Whacked it! The threaded rod left a nice punch mark for drilling its hole. Crude, but it all seems to dry-fit with no need for extra encouragement. I was happy with it at the time, but now, I'll be taking a closer look at it. Thanks for looking out for me.

Rusty

EDIT: Witness marks... now I have a new name for the little alignment marks all over everything I build.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

Hey Rusty, some observations/questions concerning the upper bell-crank platform. Where the lower plate is glued to the lower spar-brace and keyed into slots in the adjacent ribs.. The upper plate will now be sharing the same load.. along with the upper section of the ribs. I am assuming that the upper plate will be glued to the upper spar brace as well as the upper rib sections? Have you provided adequate clearance for the pushrod to move freely between the two plates? I really like the idea.. and it should be a very strong mount, providing that the upper plate is supported equally as well as the bottom one is. Have you considered "glassing" both plates to the spars.. and maybe even the ribs? I realize you used harder balsa on the root ribs.. but they're still only balsa. If either plate were to break loose from the spar, your ribs could crack and fail.

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

roddie wrote:Hey Rusty, some observations/questions concerning the upper bell-crank platform. Where the lower plate is glued to the lower spar-brace and keyed into slots in the adjacent ribs.. The upper plate will now be sharing the same load.. along with the upper section of the ribs. I am assuming that the upper plate will be glued to the upper spar brace as well as the upper rib sections? Have you provided adequate clearance for the pushrod to move freely between the two plates? I really like the idea.. and it should be a very strong mount, providing that the upper plate is supported equally as well as the bottom one is. Have you considered "glassing" both plates to the spars.. and maybe even the ribs? I realize you used harder balsa on the root ribs.. but they're still only balsa. If either plate were to break loose from the spar, your ribs could crack and fail.

The upper plate is nowhere in the vicinity of the pushrod, which passes under the bellcrank and out the bottom of the wing.

I think glass would be needless overkill. Most planes balsa ribs are softer than my center ribs. If you look closely you can see where I did rub some epoxy into the face of the two load bearing ribs. The spar has a pretty good grip on the top plate. Don't forget the sheeting is going to add a great deal of strength to the whole thing too.

Whether or not I make a small bridge to reinforce the bottom plate to the lower spar remains to be seen. I don't want to spend all of my weight savings in one place. But I'll wait until I unpin the wing and look at it from the other side.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

Tonight's progress is a little slim. First I got frustrated with trying to solder a pair of #3 washers on the control rod above and below the bellcrank. I just made a crooked goobery mess, and I sure didn't want to melt the crank. So I cleaned it up and did it another way. I bored a 3/32" hole through a 1/16" wheel collet, dropped a washer over the rod tip and retained it with the collet with a superglued setscrew. I don't think it really needed any retention, but the plans said so. Who am I to ignore the plans.

All boxed in. And per Phil's recommendation, I double checked the fit for any induced stress. It's okay.

Roddie, see what I mean, no interference.

I'll cut off the bolt with plenty of room for the sheeting. I was hoping to sheet it tonight. I had to unpin it from the table before sheeting due to my incorrect order of B/C assembly. It's weighted though, no change in shape that I can see.

All boxed in. And per Phil's recommendation, I double checked the fit for any induced stress. It's okay.

Roddie, see what I mean, no interference.

I'll cut off the bolt with plenty of room for the sheeting. I was hoping to sheet it tonight. I had to unpin it from the table before sheeting due to my incorrect order of B/C assembly. It's weighted though, no change in shape that I can see.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Skyray 35 Build - Faux Streak look

Re: Skyray 35 Build - Faux Streak look

I like it. Looks good and strong.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Page 2 of 9 •  1, 2, 3, 4, 5, 6, 7, 8, 9

1, 2, 3, 4, 5, 6, 7, 8, 9

Similar topics

Similar topics» Scratch build skyray with beam mount for 0.049 teedee

» [solved]Baby Flight Streak build log

» Baby Flite Streak build thread

» Hybrid-Profile Flite Streak/Cox Hyper Viper scratch build

» Great video on building and flying the 1/2A Skyray and Skyray 35

» [solved]Baby Flight Streak build log

» Baby Flite Streak build thread

» Hybrid-Profile Flite Streak/Cox Hyper Viper scratch build

» Great video on building and flying the 1/2A Skyray and Skyray 35

Page 2 of 9

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules