Log in

Search

Latest topics

» Duende V model from RC Model magazine 1983.by MauricioB Yesterday at 10:22 pm

» My current avatar photo

by roddie Yesterday at 9:05 pm

» Funny what you find when you go looking

by GallopingGhostler Yesterday at 7:32 pm

» My N-1R build log

by rdw777 Yesterday at 5:24 pm

» My latest doodle...

by TD ABUSER Yesterday at 11:30 am

» Landing-gear tips

by 1975 control line guy Yesterday at 10:07 am

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

» Free Flight Radio Assist

by rdw777 Sun Nov 17, 2024 6:03 pm

» Tribute Shoestring build

by amurphy6812 Sun Nov 17, 2024 5:43 pm

» Cox 020 PeeWee rebuild questions

by LooseSpinner99 Sun Nov 17, 2024 5:17 pm

» It's the X Wing that has a canard

by rdw777 Fri Nov 15, 2024 6:58 pm

» music vids.. some of your favorites

by Kim Thu Nov 14, 2024 3:28 pm

Cox Engine of The Month

Lead Out Wire

Page 1 of 2

Page 1 of 2 • 1, 2

Lead Out Wire

Lead Out Wire

The Jr. Satan is calling for 2" Bellcrank...should I do a nylon or steel crank? The lead-out wire..should I be looking to make a tear drop shape?...do I get the brass crimp up as close to the hole as possible? Solder? Heat shrink? All the above? Any sites that show making lead-outs at the bellcrank? Thanks Guys!

ZACATTACK- Gold Member

- Posts : 328

Join date : 2012-04-15

Re: Lead Out Wire

Re: Lead Out Wire

The AMA rulebook for general controlline competition has several pages on line construction for both steel cable and spectra lines.

http://www.modelaircraft.org/files/2011-2012CLGeneral4.pdf

http://www.modelaircraft.org/files/2011-2012CLGeneral4.pdf

Re: Lead Out Wire

Re: Lead Out Wire

Zat answer your question?

Oh, and metal vs, plastic is a matter of opinion. The mylar is just as indestructible and lighter. I like the way the bushing through the mounting hole stabilizes it.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Lead Out Wire

Re: Lead Out Wire

From what I read steel bellcranks tend to cut through the wire. I would solder the copper wraps.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Lead Out Wire

Re: Lead Out Wire

ZACATTACK wrote: The Jr. Satan is calling for 2" Bellcrank...should I do a nylon or steel crank? The lead-out wire..should I be looking to make a tear drop shape?...do I get the brass crimp up as close to the hole as possible? Solder? Heat shrink? All the above? Any sites that show making lead-outs at the bellcrank? Thanks Guys!

Nylon bellcranks have alway worked well for me on my small planes like 1/2A's; on larger planes I go with aluminum bellcranks and fine solid wire leadouts.

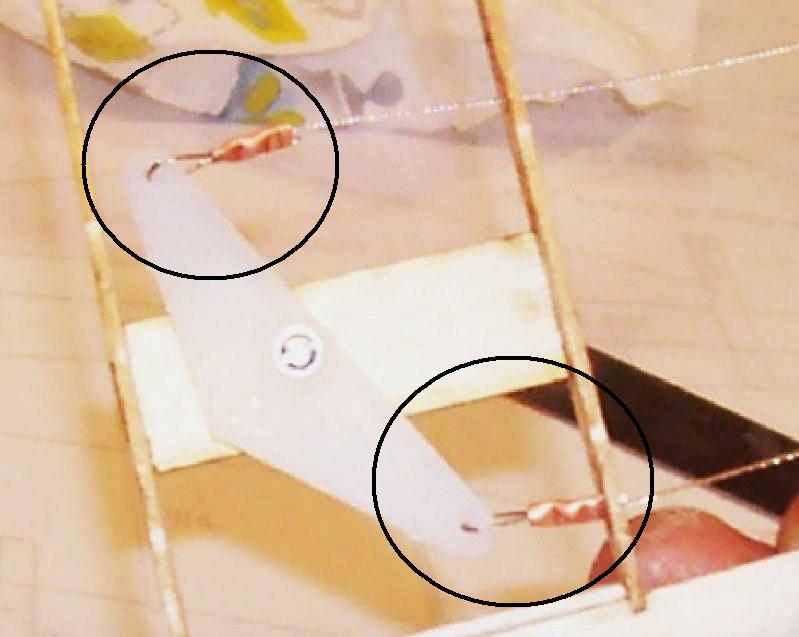

When using cable lead-outs there should be enough radius in the "tear drop" attachment to allow free movement of the bellcrank both ways without restriction. (Too little radius will blind the bellcrank) I use small copper tube to crimp and secure the lead-outs then solder them firmly in place.

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: Lead Out Wire

Re: Lead Out Wire

There is a building tip on Stunthanger.com that suggests using 1/16 brass tube to sleeve/bushing the portion of the cable through the bell crank. The tip suggests using a long enough piece to bend over and support the wire and joint, which also protects the ribs some from snagging.

I haven't tried it myself yet.

Phil

I haven't tried it myself yet.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Lead Out Wire

Re: Lead Out Wire

I've seen that too but haven't tried it. I think it's more useful for larger planes, and all of mine are 1/2A. I haven't worn through the holes in a nylon crank yet.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Lead Out Wire

Re: Lead Out Wire

On my exposed hardware airplanes I am tempted to just go to Spectra or Dacron with proper knots and skip the soldering all together. I like the thought of steel inside a sealed wing for some reason.

Phil

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Lead Out Wire

Re: Lead Out Wire

On my recent BRM build I used the provided cable leadouts, nylon bellcrank and copper sleeves secured with solder. The instructions recommend making two passes through the sleeves with the cables but the sleeves simply weren't wide enough to accomodate two passes ergo the solder.

I also enlarged the holes in the ribs closest to the bellcrank to accomadate passage of the loops without obstruction.

I'm now thinking on future builds to use something other than cable lead-outs especially on 1/2A planes. Braided dacron secured with bowline knots?

I also enlarged the holes in the ribs closest to the bellcrank to accomadate passage of the loops without obstruction.

I'm now thinking on future builds to use something other than cable lead-outs especially on 1/2A planes. Braided dacron secured with bowline knots?

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: Lead Out Wire

Re: Lead Out Wire

I use figure-8 loops in Dacron. I also use surgeon loops in Dacron. Both of these loop knots have surprising knot strength in Dacron and mono-filament.

I don't know what knot to suggest for a loop in Spectra. I used Palomar knots for terminating the Power Pro Spectra fishing line I am using for my control lines. I am also using snaps from snap swivels for my connectors, but plan to change that soon. I have "#4 thick small OD" washers for terminating now, and ordered clips from Cox to re-terminate my Spectra control lines.

http://www.powerpro.com/publish/content/global_fish/en/us/power_pro_v2/info/using_powerpro/knots/palomar_knot_.html

Bowlines can shake out under certain circumstances. (Never use a bowline knot on an anchor, use an anchor hitch, with the tail restrained. The bowline WILL shake out underwater all on its own, but that is a separate topic for another forum).

Phil

I don't know what knot to suggest for a loop in Spectra. I used Palomar knots for terminating the Power Pro Spectra fishing line I am using for my control lines. I am also using snaps from snap swivels for my connectors, but plan to change that soon. I have "#4 thick small OD" washers for terminating now, and ordered clips from Cox to re-terminate my Spectra control lines.

http://www.powerpro.com/publish/content/global_fish/en/us/power_pro_v2/info/using_powerpro/knots/palomar_knot_.html

Bowlines can shake out under certain circumstances. (Never use a bowline knot on an anchor, use an anchor hitch, with the tail restrained. The bowline WILL shake out underwater all on its own, but that is a separate topic for another forum).

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Lead Out Wire

Re: Lead Out Wire

I'd stay away from the dacron, look at Rustys set up, .018-.021 steel cable is still your best bet.

Re: Lead Out Wire

Re: Lead Out Wire

Mark Boesen wrote:I'd stay away from the dacron, look at Rustys set up, .018-.021 steel cable is still your best bet.

I fly my Lil Wizard on 30 year old Dacron lead outs. They pass pull test and do not look worn. OK, it sat for the last 20 years in my parents attic...

I would not seal Dacron in a wing though.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Lead Out Wire

Re: Lead Out Wire

Which setup are you referring to, Mark?

When I built my Li'l Satan I used dacron leadouts, and now I regret it. Because the other day I popped a dacron leadout on my Stuntman23. It did about 5 outside loops while I trotted backwards and finally hit the ground. But it's not enclosed like the Satan, so no problem to replace. That leadout was a lot older too, but I can't help thinking about it since I souped the Satan up with a Tee Dee .049. I bought some plastic covered stainless steel at the fishing store the other day. I'll try that on the Stuntman and if I like it, I'll perform surgery on the Satan.

I use Spectra and Spiderwire for the control lines with fishing clips to hook to the rings on the leadouts. I use the clips with no protruding tang to get caught up with the other line. Some people cut off the swivel but I've never had one break. I take pliers and tighten the brass where it grips the spring wire so it can't slip. That's a home made line length adjuster made with a cotter pin, stiff tube and a washer. At first I put it in the front center and the lines caught on it so I moved it to the corner.

When I built my Li'l Satan I used dacron leadouts, and now I regret it. Because the other day I popped a dacron leadout on my Stuntman23. It did about 5 outside loops while I trotted backwards and finally hit the ground. But it's not enclosed like the Satan, so no problem to replace. That leadout was a lot older too, but I can't help thinking about it since I souped the Satan up with a Tee Dee .049. I bought some plastic covered stainless steel at the fishing store the other day. I'll try that on the Stuntman and if I like it, I'll perform surgery on the Satan.

I use Spectra and Spiderwire for the control lines with fishing clips to hook to the rings on the leadouts. I use the clips with no protruding tang to get caught up with the other line. Some people cut off the swivel but I've never had one break. I take pliers and tighten the brass where it grips the spring wire so it can't slip. That's a home made line length adjuster made with a cotter pin, stiff tube and a washer. At first I put it in the front center and the lines caught on it so I moved it to the corner.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Lead Out Wire

Re: Lead Out Wire

Mark Boesen wrote:I'd stay away from the dacron, look at Rustys set up, .018-.021 steel cable is still your best bet.

Ditto. Stay away from something that can break, wear or deteriorate over time.

I use 1/64" music wire. I prefer wire to cable for leadouts --- it's smooth and I think is less abrasive on nylon bellcranks. Once bent, sleeved and soldered with small brass tubing, you never have to worry about it pulling loose.

Re: Lead Out Wire

Re: Lead Out Wire

Oh, yeah, I forgot I had posted that.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Lead Out Wire

Re: Lead Out Wire

Remember it's the solder applied in the crimp that secures the connection. Solder bonds only to copper and not steel cable. Solder only binds steel cable in place.

In my larger Class C stunters of the past I used 1/32" music wire for lead outs and never had a problem with them.

Personally I believe steel cable lead outs in 1/2 planes are "overkill" as the strength of steel is not required.

BTW, the virtue of bowline knot is the it is simple to tie and will not loosen. I used bowlines to secure my boats for many years without a problem. They also may be untied easily.

In my larger Class C stunters of the past I used 1/32" music wire for lead outs and never had a problem with them.

Personally I believe steel cable lead outs in 1/2 planes are "overkill" as the strength of steel is not required.

BTW, the virtue of bowline knot is the it is simple to tie and will not loosen. I used bowlines to secure my boats for many years without a problem. They also may be untied easily.

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: Lead Out Wire

Re: Lead Out Wire

SuperDave wrote:Remember it's the solder applied in the crimp that secures the connection. Solder bonds only to copper and not steel cable. Solder only binds steel cable in place.

...

BTW, the virtue of bowline knot is the it is simple to tie and will not loosen. I used bowlines to secure my boats for many years without a problem. They also may be untied easily.

Properly cleaned and fluxed steel accepts solder readily, and not much different than cleaned and fluxed copper. Copper may have a little more affinity for solder than steel does, and flux seems to clean copper more effectively.

I have been using copper wrapped cable terminations since I find them easier than sourcing the correct tubing for crimping. I live in a modeling wasteland it seems, an hour drive each way to get the goods is unpleasant.

Bowline is one of my favorite knots too for essentially the same reasons (I am currently without a boat though), but it does have limitations and should not be used where not appropriate.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Lead Out Wire

Re: Lead Out Wire

Phil:

I'm still "pumped" about my Weller Parasol butane soldering torch and it's many applications in modeling, automotive/motorcycle work and and around the house. It not only solders but features various supplied adapters like a mini-blowtorch and a heat deflector.

I've written so much about this tool here on CECF that some have

Bye, bye electric soldering irons!

I too live distant from any modeling hobby shop. Just about everything I buy is from on-line sources. Suggest that you do the same.

I'm still "pumped" about my Weller Parasol butane soldering torch and it's many applications in modeling, automotive/motorcycle work and and around the house. It not only solders but features various supplied adapters like a mini-blowtorch and a heat deflector.

I've written so much about this tool here on CECF that some have

Bye, bye electric soldering irons!

I too live distant from any modeling hobby shop. Just about everything I buy is from on-line sources. Suggest that you do the same.

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: Lead Out Wire

Re: Lead Out Wire

I think that is my brother's soldering torch of choice. He doesn't always have the correct form of electricity at his job.

I prefer electric since I don't burn the tips up (been there, done that!). I use a Craftsman 150W/230W soldering gun for terminations and if I am inclined to build a fuel tank (or pop-pop motor boats, the reason I bought it). I also have a selection of Radio Shack electric soldering pencil irons, buying a really nice Weller adjustable soldering station would have been cheaper, except the collection of pencils tool years to acquire.

I broke down and ordered plywood from BalsaUSA.com, pumped my order up considerably because of their non-trivial shipping charge, and a whole stack of material enough to build a couple planes cost less than buying from "local" places.

Fuel is worth the drive though to save haz-mat shipping.

Phil

I prefer electric since I don't burn the tips up (been there, done that!). I use a Craftsman 150W/230W soldering gun for terminations and if I am inclined to build a fuel tank (or pop-pop motor boats, the reason I bought it). I also have a selection of Radio Shack electric soldering pencil irons, buying a really nice Weller adjustable soldering station would have been cheaper, except the collection of pencils tool years to acquire.

I broke down and ordered plywood from BalsaUSA.com, pumped my order up considerably because of their non-trivial shipping charge, and a whole stack of material enough to build a couple planes cost less than buying from "local" places.

Fuel is worth the drive though to save haz-mat shipping.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Lead Out Wire

Re: Lead Out Wire

Phil:

My Weller Portasol soldering torch is a model P2KC. BTW, the heat deflector works great on heat-shrink tubing and I use the mini-blowtorch to free up "frozen" Cox engines (after a good soaking in Hoppes #9 gun cleaning solvent of course)

Yes I know Hoppes is flammable but I dry the engine throughly before I apply small amounts of heat. Further I don't use excessive force when freeing up a frozen engine. I'm VERY carefull not to leave the dreaded "tool marks" I use the appropriate Cox wrenches too.

I use the appropriate Cox wrenches too.

My Weller Portasol soldering torch is a model P2KC. BTW, the heat deflector works great on heat-shrink tubing and I use the mini-blowtorch to free up "frozen" Cox engines (after a good soaking in Hoppes #9 gun cleaning solvent of course)

Yes I know Hoppes is flammable but I dry the engine throughly before I apply small amounts of heat. Further I don't use excessive force when freeing up a frozen engine. I'm VERY carefull not to leave the dreaded "tool marks"

I use the appropriate Cox wrenches too.

I use the appropriate Cox wrenches too. Last edited by SuperDave on Wed Oct 17, 2012 4:44 pm; edited 1 time in total

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: Lead Out Wire

Re: Lead Out Wire

That's exactly how I do it Dave, except I use my wife's creme brulee torch(don't tell her).

Works like a charm and I swear by Hoppe's #9.

Oh, and I use a home-made strap wrench.

Bob

Works like a charm and I swear by Hoppe's #9.

Oh, and I use a home-made strap wrench.

Bob

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: Lead Out Wire

Re: Lead Out Wire

Bob:

Since I enjoy creme brulee I don't mess with my wife's torch so no deception is necessary lest I break it.

I keep my Weller butane torch right here with my other modeling tools.

BTW, I use butane cannisters from an Asian food market. My torch "fuels" quite easily from them with no problems.

Since I enjoy creme brulee I don't mess with my wife's torch so no deception is necessary lest I break it.

I keep my Weller butane torch right here with my other modeling tools.

BTW, I use butane cannisters from an Asian food market. My torch "fuels" quite easily from them with no problems.

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: Lead Out Wire

Re: Lead Out Wire

How does solid wire compare to cables? Does it have the same range of motion? They do look good, but I was wondering if they limit bellcrank movement.

Ron

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Lead Out Wire

Re: Lead Out Wire

Ron:

When I flew Class stunters I used 1/32" music wire for lead outs with never a problem. If they are installed correct they do not bind metal bellcranks. (I use aluminum rather than steel bellcranks)

The trick is to carefully bend and secure the loops to allow freedom of movement of the bellcrank.

When I flew Class stunters I used 1/32" music wire for lead outs with never a problem. If they are installed correct they do not bind metal bellcranks. (I use aluminum rather than steel bellcranks)

The trick is to carefully bend and secure the loops to allow freedom of movement of the bellcrank.

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Line Connectors and Lead-Outs

» P-38 Lightning-Roddie style..

» Baby Ringmaster fever

» Ring Master Gold KIt

» Ebay Ringmaster Resto (finishing pics!)

» P-38 Lightning-Roddie style..

» Baby Ringmaster fever

» Ring Master Gold KIt

» Ebay Ringmaster Resto (finishing pics!)

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules