Log in

Search

Latest topics

» Tee Dee .020 combat modelby roddie Today at 1:34 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

Cox Engine of The Month

Tee Dee .09 rebuild.. and run!

Page 2 of 8

Page 2 of 8 •  1, 2, 3, 4, 5, 6, 7, 8

1, 2, 3, 4, 5, 6, 7, 8

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Well... I had delusions of grandeur for my 5000th post.. but it was not to be. The old Tee Dee .09 wouldn't run. I got a few "pops" out of it this afternoon.. but that's it.

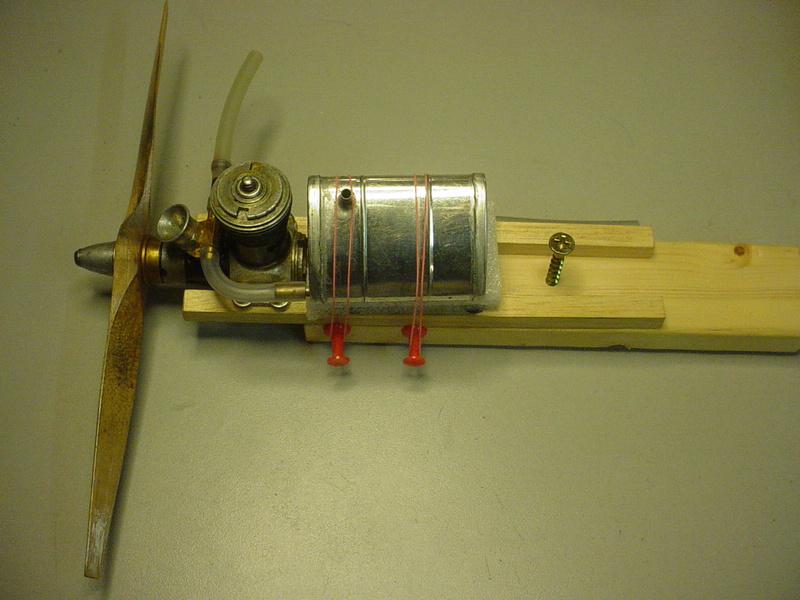

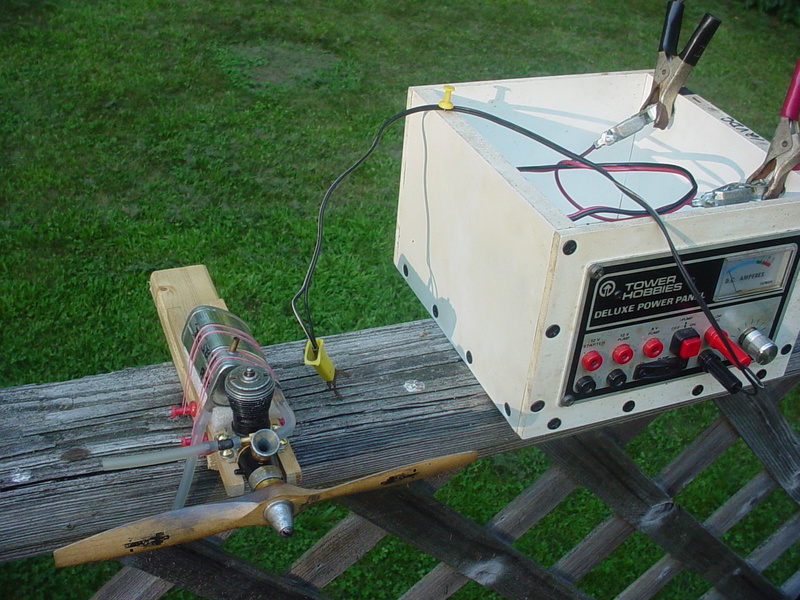

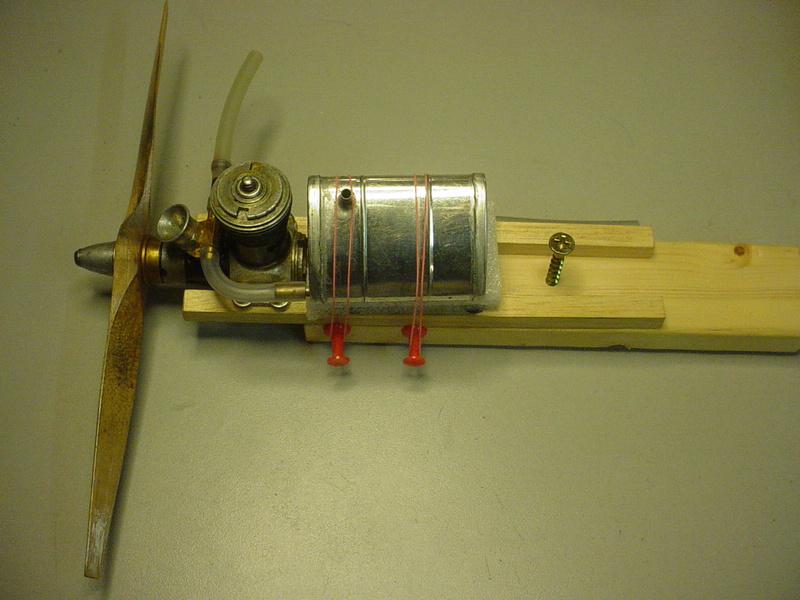

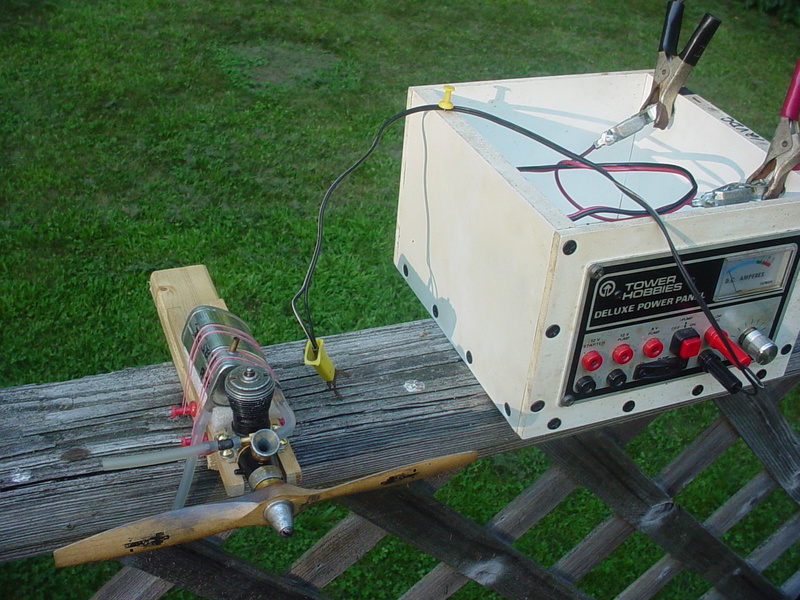

Yesterday I was ill-prepared.. and wasn't feeling well. I also hadn't made a tank-mount to bench-run it. Today I spent some time at the chalkboard going-over figures... (LOL Ron..) and devised a secondary-mount to secure a tank at what I thought was a good level.

K... so.. I bring all the support-gear outside and mount everything up.. and fuel-up with Sig Champion 25..

Needle-open 3.75 turns.. venturi-choked.. exhaust-prime.. glow-head is SIZZLING with 3A on the meter.... flip.. flip.. flip.. "pop" flip.. flip.. flip.. prime again.. flip.. flip.. flip.. flip.. flip.. flip.. flip.. "pop".. close needle-valve and blow-through exhaust-ports.. flip.. flip.. flip.. flip.. flip.. flip.. prime exhaust-port again.. flip.. "pop"... flip.. flip.. flip..

flip.. flip.. flip.. prime again.. flip.. flip.. flip.. flip.. flip.. flip.. flip.. "pop".. close needle-valve and blow-through exhaust-ports.. flip.. flip.. flip.. flip.. flip.. flip.. prime exhaust-port again.. flip.. "pop"... flip.. flip.. flip..

OK.. maybe I should try some different fuel.. so I fetch a bottle of Sig Champion "35".. evacuate the tank and refill. Choke/prime Flip.. pop.. flip.. flip.. flip.. "pop" flip.. flip..

By this time; I'm getting "flipped-out".. but at least I gave it a try.

but at least I gave it a try.

My diagnosis; the engine has a Medallion (low-compression) plug installed.. and since I don't have a wrench.. I don't know if there's even a head-gasket under it. Compression could feel stronger.. but I don't have another engine to compare it to.

So.. I'll try to source a Tee Dee glow-head before I try to run the engine again.

Yesterday I was ill-prepared.. and wasn't feeling well. I also hadn't made a tank-mount to bench-run it. Today I spent some time at the chalkboard going-over figures... (LOL Ron..) and devised a secondary-mount to secure a tank at what I thought was a good level.

K... so.. I bring all the support-gear outside and mount everything up.. and fuel-up with Sig Champion 25..

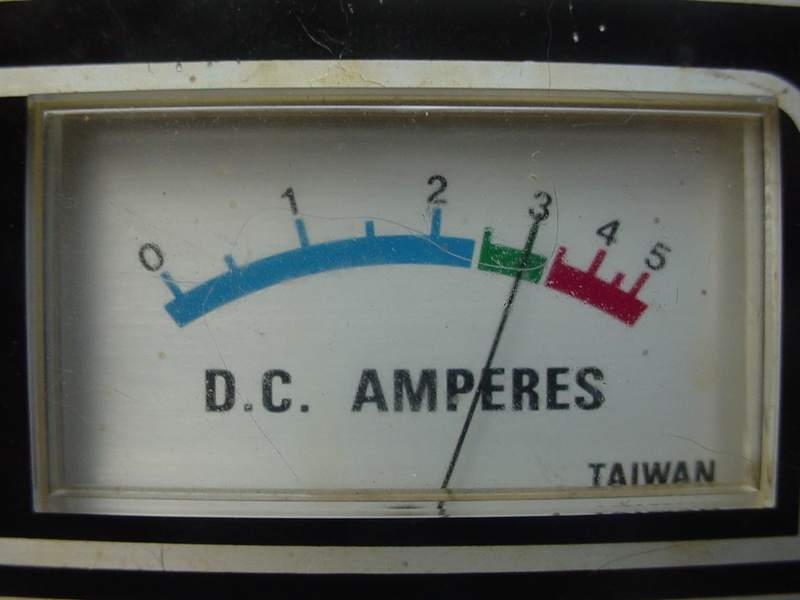

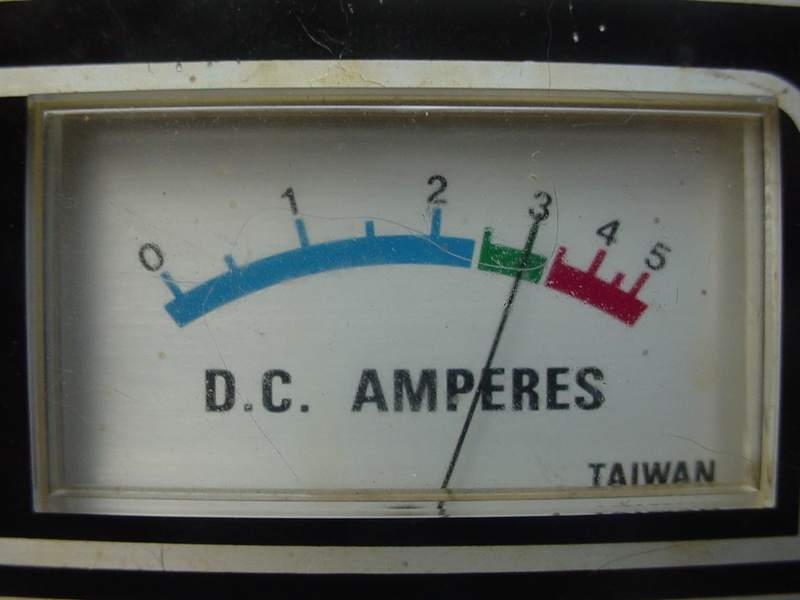

Needle-open 3.75 turns.. venturi-choked.. exhaust-prime.. glow-head is SIZZLING with 3A on the meter.... flip.. flip.. flip.. "pop"

OK.. maybe I should try some different fuel.. so I fetch a bottle of Sig Champion "35".. evacuate the tank and refill. Choke/prime Flip.. pop.. flip.. flip.. flip.. "pop" flip.. flip..

By this time; I'm getting "flipped-out"..

My diagnosis; the engine has a Medallion (low-compression) plug installed.. and since I don't have a wrench.. I don't know if there's even a head-gasket under it. Compression could feel stronger.. but I don't have another engine to compare it to.

So.. I'll try to source a Tee Dee glow-head before I try to run the engine again.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

What an anticlimax...

Try a smaller prop, a 7x3-7x4 is better suited for the engine and a plastic one will give you a little better inertia. If the plug is sizzling and it wont't run appart from some minor pops, my guess is that it is overprimed. Try without the fuel tank connected, prime the side of the piston only with the port closed and you should get a brief run each time.

Try a smaller prop, a 7x3-7x4 is better suited for the engine and a plastic one will give you a little better inertia. If the plug is sizzling and it wont't run appart from some minor pops, my guess is that it is overprimed. Try without the fuel tank connected, prime the side of the piston only with the port closed and you should get a brief run each time.

Last edited by Surfer_kris on Tue Aug 22, 2017 12:29 am; edited 1 time in total

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Probably the fuel Roddie. Not the head.

I've run many a engine without gaskets. Lower compression head will start better than a high compression every time. That prop is a little large bud.

Shoot me a PM.

I've run many a engine without gaskets. Lower compression head will start better than a high compression every time. That prop is a little large bud.

Shoot me a PM.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Roddie

the Medallion head in itself should not be a problem if it glows. My TD09 runs fine with low normal and high compression heads both. If it is a gasket problem, you will hear the air escaping from under the head when turning the crankshaft towards compression. If the piston/cylinder fit is worn, you will see extensive bubble formation at the exhaust port when turning the crank into compression.

I agree a large prop will not help start the engine up, but again, - sorry for giving unsolicited advice on this - you may want to check the fuel supply:

1. Check the small holes (3) on the venturi neck for plugging

2. Check the crank radial play...if excessive because abuse by the previous owner(s) on unbalanced props, the crank will not have the proper sealing.

3. Check the plastic carb body at the venturi connection area for cracks - a typical issue with TD-s of long previous history

4. Check again the nv threads..if loose, slip the silicone tube over them and the carb...

the Medallion head in itself should not be a problem if it glows. My TD09 runs fine with low normal and high compression heads both. If it is a gasket problem, you will hear the air escaping from under the head when turning the crankshaft towards compression. If the piston/cylinder fit is worn, you will see extensive bubble formation at the exhaust port when turning the crank into compression.

I agree a large prop will not help start the engine up, but again, - sorry for giving unsolicited advice on this - you may want to check the fuel supply:

1. Check the small holes (3) on the venturi neck for plugging

2. Check the crank radial play...if excessive because abuse by the previous owner(s) on unbalanced props, the crank will not have the proper sealing.

3. Check the plastic carb body at the venturi connection area for cracks - a typical issue with TD-s of long previous history

4. Check again the nv threads..if loose, slip the silicone tube over them and the carb...

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

roddie wrote:Well... I had delusions of grandeur for my 5000th post.. but it was not to be. The old Tee Dee .09 wouldn't run. I got a few "pops" out of it this afternoon.. but that's it.

Roddie, take a look at your installation. You have installed the tank so it will gravity feed into the crankcase and flood your engine. Disconnect the tank until you get it to run off a prime.

All the rest should work...not necessarily optimum, but it should work. Make sure you drain ALL of the fuel from the crankcase before trying again. When it is all set up again try starting without using a prime. There may be enough residual fuel left to start it.

When you can successfully run off a few primes, then you can try the tank again. I would suggest reinstalling the tank lower so the top is below the needle valve.

If you still have some castor in the fuel jets you may find the engine getting richer as they get

flushed. It happened to me.

Good luck.

George

gcb- Platinum Member

- Posts : 908

Join date : 2011-08-11

Location : Port Ewen, NY

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Thanks for the comments guys. I do have some 7 x 4's but they're wood (Zinger-brand.. and really lightweight). I'm a little puzzled.. because I've gotten 8 x 3's to run on reed-valve engines.

I think I may have flooded it a few times.. so I closed the needle and blew-through the exhaust-ports to clear the upper-cylinder of fuel. Maybe there was still too much down in the bottom?

This morning, I can hear some "air-hissing" when turning through compression.. but it's hard to tell where it's coming from.. and I can't see any bubbling. It's a strange hiss though, that stops abruptly mid-stroke. I thought maybe the seal in the plug might be bad.. but again; no evidence of bubbles.

The crankshaft is good and snug.. no side-play at all.

I may have caused an issue by mounting the engine a way's back on the beams so that the front-screws wouldn't be too close to the end, for fear of splitting the wood. In doing this; I now just noticed that the carb's pressure-nipple is bent-upward from contacting the beam.

When removing the engine, the right-front wood-screw's "head" sheared-off! I was able to remove the stub from the beam with locking-pliers.

Stupid of me to use soft-brass screws. I'm actually lucky that the engine didn't run.. or they all could have broken or loosened. They came-out a lot easier than they went in. Lesson learned.

I can't see any cracks in the carb.. but wonder if it's sealing with the case was compromised when the engine was torqued-down on the right-side against the pressure-nipple?

Can I use an ignition-wrench to remove the venturi? I have no experience with these engines. I'm assuming that's the only way to observe the 3-holes in the spray-bar flowing properly.

I didn't experience any lock-up due to flooding yesterday.. but after removing the engine this morning, there's an intermittent lock-up when flipping the prop.. I think there may be something amiss inside.

I think there may be something amiss inside.

I may try to remove the cylinder with my strap-wrench. I tried previously.. but the webbed-strap has a waxy-coating that won't grip the cylinder. I will try wrapping a piece of rubber around the cylinder to see if that helps.

I think I may have flooded it a few times.. so I closed the needle and blew-through the exhaust-ports to clear the upper-cylinder of fuel. Maybe there was still too much down in the bottom?

This morning, I can hear some "air-hissing" when turning through compression.. but it's hard to tell where it's coming from.. and I can't see any bubbling. It's a strange hiss though, that stops abruptly mid-stroke. I thought maybe the seal in the plug might be bad.. but again; no evidence of bubbles.

The crankshaft is good and snug.. no side-play at all.

I may have caused an issue by mounting the engine a way's back on the beams so that the front-screws wouldn't be too close to the end, for fear of splitting the wood. In doing this; I now just noticed that the carb's pressure-nipple is bent-upward from contacting the beam.

When removing the engine, the right-front wood-screw's "head" sheared-off! I was able to remove the stub from the beam with locking-pliers.

Stupid of me to use soft-brass screws. I'm actually lucky that the engine didn't run.. or they all could have broken or loosened. They came-out a lot easier than they went in. Lesson learned.

I can't see any cracks in the carb.. but wonder if it's sealing with the case was compromised when the engine was torqued-down on the right-side against the pressure-nipple?

Can I use an ignition-wrench to remove the venturi? I have no experience with these engines. I'm assuming that's the only way to observe the 3-holes in the spray-bar flowing properly.

I didn't experience any lock-up due to flooding yesterday.. but after removing the engine this morning, there's an intermittent lock-up when flipping the prop..

I think there may be something amiss inside.

I think there may be something amiss inside. I may try to remove the cylinder with my strap-wrench. I tried previously.. but the webbed-strap has a waxy-coating that won't grip the cylinder. I will try wrapping a piece of rubber around the cylinder to see if that helps.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

An old piece of leather belt and some Chanel locks will get the cylinder off.

I don't have much experience with tee dee .09s but I know mine likes to be damn near flooded to start.

Jim

I don't have much experience with tee dee .09s but I know mine likes to be damn near flooded to start.

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

gcb wrote:roddie wrote:Well... I had delusions of grandeur for my 5000th post.. but it was not to be. The old Tee Dee .09 wouldn't run. I got a few "pops" out of it this afternoon.. but that's it.

Roddie, take a look at your installation. You have installed the tank so it will gravity feed into the crankcase and flood your engine. Disconnect the tank until you get it to run off a prime.

All the rest should work...not necessarily optimum, but it should work. Make sure you drain ALL of the fuel from the crankcase before trying again. When it is all set up again try starting without using a prime. There may be enough residual fuel left to start it.

When you can successfully run off a few primes, then you can try the tank again. I would suggest reinstalling the tank lower so the top is below the needle valve.

If you still have some castor in the fuel jets you may find the engine getting richer as they get

flushed. It happened to me.

Good luck.

George

Hi George, yes.. you're right. The tank was sitting on a piece of rubber-foam which I can slice-thinner to lower it's height. I mentioned an "air-hiss" that stops-abruptly mid-stroke.. but just realized that it only happens when turning the prop in reverse-rotation. I hope that doing this hasn't hurt anything. I'm so used to reedies that run in either direction. When trying to start; I was cranking in the proper-rotation..

I probably just need to get used-to running Tee Dee's.. I've heard that they require a bit more finesse.

Thanks for your input.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

JPvelo wrote:An old piece of leather belt and some Chanel locks will get the cylinder off.

I don't have much experience with tee dee .09s but I know mine likes to be damn near flooded to start.

Jim

Hi Jim, I took your advice.. and got the cylinder off without much trouble. I gripped-it up "high" in hopes that the glowhead would loosen .. but the cylinder broke-free first. It was tight.. but didn't require a lot of pressure to loosen it. I'll have to wait until I get the proper wrenches to get the head off.

The engine looks pretty clean inside, considering how dirty it was on the outside.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

roddie wrote:..........

This morning, I can hear some "air-hissing" when turning through compression.. but it's hard to tell where it's coming from.. and I can't see any bubbling. It's a strange hiss though, that stops abruptly mid-stroke. I thought maybe the seal in the plug might be bad.. but again; no evidence of bubbles.

..........

Roddie,

All TD09-s were built with tapered piston/cylinder fit. Even if the piston top shows little runtime of your engine, the first section of the compression stroke occurs with the piston and cylinder being slightly loose-fit, where some escape of air is unavoidable/normal. When the piston moves further up the fit becomes tighter - the tightest at the TDC pinch - and no further escape of compressed air occurs. This may be the reason of hearing the hiss up until the piston reaches midway in the compression cycle

In actual running conditions with high rpm/piston velocity the escape of air is negligable and have no meaningful effect on compression as the time for air escape is really very short and the amount of air escaping is minimal.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

It is possible that the pressure nipple was drilled through into the crankcase. In that case you might only get a "pop" when trying to start and might account for the hiss you are hearing. No real way to tell until you get the wrench.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Well Shoot i was hoping for something more exciting !!!  But thats OK i understand completely .. My only advice from looking at the pics is where me (((( Take engine apart and CLEAN Up good , Hobbies #9 will clean the gunk out of it (( Not the Plastic )) But that way you will know the engine a lot better yes remove the crankshaft too LOL , It's not that bad after you do a few

But thats OK i understand completely .. My only advice from looking at the pics is where me (((( Take engine apart and CLEAN Up good , Hobbies #9 will clean the gunk out of it (( Not the Plastic )) But that way you will know the engine a lot better yes remove the crankshaft too LOL , It's not that bad after you do a few  You will get it running and bee proud of it !!

You will get it running and bee proud of it !!  My Brother !!

My Brother !!

But thats OK i understand completely .. My only advice from looking at the pics is where me (((( Take engine apart and CLEAN Up good , Hobbies #9 will clean the gunk out of it (( Not the Plastic )) But that way you will know the engine a lot better yes remove the crankshaft too LOL , It's not that bad after you do a few

But thats OK i understand completely .. My only advice from looking at the pics is where me (((( Take engine apart and CLEAN Up good , Hobbies #9 will clean the gunk out of it (( Not the Plastic )) But that way you will know the engine a lot better yes remove the crankshaft too LOL , It's not that bad after you do a few  You will get it running and bee proud of it !!

You will get it running and bee proud of it !!

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Eric knows of which he speaketh.

I picked up an .09 Medallion and an .09 TeeDee

as a lot. Took a little coin to do, but

worked out well. Don't forget the ear plugs.

These babies bark.

Bob

I picked up an .09 Medallion and an .09 TeeDee

as a lot. Took a little coin to do, but

worked out well. Don't forget the ear plugs.

These babies bark.

Bob

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

roddie wrote:

I may have caused an issue by mounting the engine a way's back on the beams so that the front-screws wouldn't be too close to the end, for fear of splitting the wood. In doing this; I now just noticed that the carb's pressure-nipple is bent-upward from contacting the beam.

Sorry, I warned you about that earlier, or at least tried to, but perhaps I wasn't clear enough.

Check the hissing sound, it could just be the regular intake that your hear (from the intake port as it opens) but it could also be from the pressure nipple if it has been drilled trough, as others have mentioned.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Surfer_kris wrote:roddie wrote:

I may have caused an issue by mounting the engine a way's back on the beams so that the front-screws wouldn't be too close to the end, for fear of splitting the wood. In doing this; I now just noticed that the carb's pressure-nipple is bent-upward from contacting the beam.

Sorry, I warned you about that earlier, or at least tried to, but perhaps I wasn't clear enough.

Check the hissing sound, it could just be the regular intake that your hear (from the intake port as it opens) but it could also be from the pressure nipple if it has been drilled trough, as others have mentioned.

Hi Kris, I just looked back to the first thread-page.. and see that I totally missed your post.

I checked the pressure-nipple by probing inside it with a small pin. It has not been drilled-out. There's no sign of cracks anywhere on the carb.. at least none that I can see.

I trimmed the hardwood beams back with a razor-saw to clear the nipple and will re-drill their holes for 4-40 machine-screws and lock-nuts. I do have some thin aluminum-stock that I can use for plates.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Roddie,

on my fairly used 09 serving the Cosmic Wind I hear the same hissing sound just after the piston closes the exhaust port and moves up on the compression stroke, but the hissing stops soon afterwards....where the fit of the tapered piston and cylinder is already tight enough to seal perfectly. I believe you may experience the same.

On my NIB TD09-s as well as tapered-bore NIB 049/051 TD-s this hissing is not yet experienced though, because the tapered fit at the cylinder bottom/piston top encounter is still relatively tight/untouched by engine runtime . .

on my fairly used 09 serving the Cosmic Wind I hear the same hissing sound just after the piston closes the exhaust port and moves up on the compression stroke, but the hissing stops soon afterwards....where the fit of the tapered piston and cylinder is already tight enough to seal perfectly. I believe you may experience the same.

On my NIB TD09-s as well as tapered-bore NIB 049/051 TD-s this hissing is not yet experienced though, because the tapered fit at the cylinder bottom/piston top encounter is still relatively tight/untouched by engine runtime . .

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

balogh wrote:Roddie,

on my fairly used 09 serving the Cosmic Wind I hear the same hissing sound just after the piston closes the exhaust port and moves up on the compression stroke, but the hissing stops soon afterwards....where the fit of the tapered piston and cylinder is already tight enough to seal perfectly. I believe you may experience the same.

On my NIB TD09-s as well as tapered-bore NIB 049/051 TD-s this hissing is not yet experienced though, because the tapered fit at the cylinder bottom/piston top encounter is still relatively tight/untouched by engine runtime . .

Hi again Andras, This Tee Dee .09 is probably fine. I just need to learn it's habits. I was a bit aggressive with my starting technique.. and as George pointed-out; my tank's feed-line was too high. I had a baseline for setting the needle but other than that.. I was in unfamiliar territory. I'd power-flushed the NVA with questionable fuel.. and there may have been a surplus of that fuel still in the case. The engine was drawing-fuel from the tank when I choked the venturi.. so I figured I was good to go.. when in fact; the engine was probably choked-down with fuel in the bottom-end. I even primed the venturi.. (more than once..) which was likely a big mistake.

I've taken steps to lower the tank.. and will proceed with a fully-closed needle and priming the "piston" when it's covering the exhaust-port.. so as not to flood the engine. That's criteria #1.. although Jim Roselle mentioned his engine needing to be flooded to start..

I'll be happy to get it to run past a "pop".. and we'll take it from there!

I'll be happy to get it to run past a "pop".. and we'll take it from there!  Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

With the fuel line disconnected and you are only getting a pop on prime then something is wrong Roddie. I alluded to a potential issue a few posts back.

Every engine ever made should be able to run on a prime. Get it to run on prime first and then hook up fuel. A snort of fuel in the exhaust port and a couple drops in the intake should get it to run.

If you aren't building case pressure all you will get is a pop. Been there.

Every engine ever made should be able to run on a prime. Get it to run on prime first and then hook up fuel. A snort of fuel in the exhaust port and a couple drops in the intake should get it to run.

If you aren't building case pressure all you will get is a pop. Been there.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Cribbs74 wrote:With the fuel line disconnected and you are only getting a pop on prime then something is wrong Roddie. I alluded to a potential issue a few posts back.

Every engine ever made should be able to run on a prime. Get it to run on prime first and then hook up fuel. A snort of fuel in the exhaust port and a couple drops in the intake should get it to run.

If you aren't building case pressure all you will get is a pop. Been there.

Will send a PM Ron.. thanks!

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

I received a pair of needed wrenches from Ron C. today in the mail.. and a Tee Dee head and 7 x 3.5 Cox prop from Bob D. about a week ago! Thanks guys!

I need to apply a little heat to get the Medallion head off the cylinder.. and then we can give it another shot for a bench-run.

I need to apply a little heat to get the Medallion head off the cylinder.. and then we can give it another shot for a bench-run.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

The suspense is killing me!

I might just have to go out in the backyard and fire up my own...

I might just have to go out in the backyard and fire up my own...

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Surfer_kris wrote:The suspense is killing me!

I might just have to go out in the backyard and fire up my own...

Not sure why you drew a negative vote Kris. I gave you a "Greenie" to compensate.

Roddie, without reading back over the entire thread, I gather you suspect that it's losing compression, but I've had Ciox engines react like that when they had too much compression. Maybe stick another head gasket in and try it once you get it apart. Who knows, you might find it has no gasket.

Rod.

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

It was only meant as a joke, I thought that would be okey in this thread.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Kris if you do fire yours up post the rpms / prop size

I have this data thus far:

- Best pass 128 mph / APC 4.75x5.5E / 24,467 rpm

- Static MA 5.5x4.5 / 17.3k / 12.34oz / 74mph prior to launch

Unloaded 24,467 rich

- Best level pass 143mph / per prop calc / APC 5.25x6.25E

down wind / 21,960rpm

Temp 96F Static: (16.9k to 17.1k rpm at launch)

- Idle with throttle sleeve:

6,400 to 7,400 range MA 5.5x4.5

All the above was done with 20% oil / 30% nitro

I have this data thus far:

- Best pass 128 mph / APC 4.75x5.5E / 24,467 rpm

- Static MA 5.5x4.5 / 17.3k / 12.34oz / 74mph prior to launch

Unloaded 24,467 rich

- Best level pass 143mph / per prop calc / APC 5.25x6.25E

down wind / 21,960rpm

Temp 96F Static: (16.9k to 17.1k rpm at launch)

- Idle with throttle sleeve:

6,400 to 7,400 range MA 5.5x4.5

All the above was done with 20% oil / 30% nitro

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Oldenginerod wrote:Surfer_kris wrote:The suspense is killing me!

I might just have to go out in the backyard and fire up my own...

Not sure why you drew a negative vote Kris. I gave you a "Greenie" to compensate.

Roddie, without reading back over the entire thread, I gather you suspect that it's losing compression, but I've had Ciox engines react like that when they had too much compression. Maybe stick another head gasket in and try it once you get it apart. Who knows, you might find it has no gasket.

Rod.

I've never given anyone a neg. point.. and I can't see how Kris's comment would have warranted one.

Rod, you might be correct about the possibility of a missing head gasket. The head that came installed on it is TIGHT. With cylinder removed from the engine; I locked the wrench (with forks for holding it..) in my bench-vise and tried to remove the head with the spanner on the other wrench. It wouldn't budge.. and I was afraid to go "gorilla" on it for fear of damaging the cylinder or the wrench.

As for the previous starting issues.. Ron mentioned the possibility of a failing element in that plug. I haven't actually observed the intensity of its "glow" with the cylinder removed from the engine.

There's one thing I forgot to mention. During my previous attempts to start the engine, I noticed the needle on my panel's ammeter was "fluttering". I've witnessed this before with other engines/plugs, but not as excessive as this one. Could this be an indicator of poor continuity and/or a failing coil?

Page 2 of 8 •  1, 2, 3, 4, 5, 6, 7, 8

1, 2, 3, 4, 5, 6, 7, 8

Similar topics

Similar topics» Cox .020 PeeWee/TeeDee prop-screw

» Cox Tee Dee .049 Rebuild ...

» Ez Bee rebuild

» TD rebuild .049

» Engine rebuild help please

» Cox Tee Dee .049 Rebuild ...

» Ez Bee rebuild

» TD rebuild .049

» Engine rebuild help please

Page 2 of 8

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules