Log in

Search

Latest topics

» Chocolate chip cookie dough.........by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Tee Dee .020 combat model

by rsv1cox Today at 10:07 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

Cox Engine of The Month

Tee Dee .09 rebuild.. and run!

Page 8 of 8

Page 8 of 8 •  1, 2, 3, 4, 5, 6, 7, 8

1, 2, 3, 4, 5, 6, 7, 8

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Good job Roddie, now that it runs....

Only a couple months left to make good on that New Year resolution.

Only a couple months left to make good on that New Year resolution.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Tee Bee- Platinum Member

- Posts : 764

Join date : 2011-08-25

Location : Angleton, TX

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

GOOD SHOW RODDIE

Miller time

Miller time

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

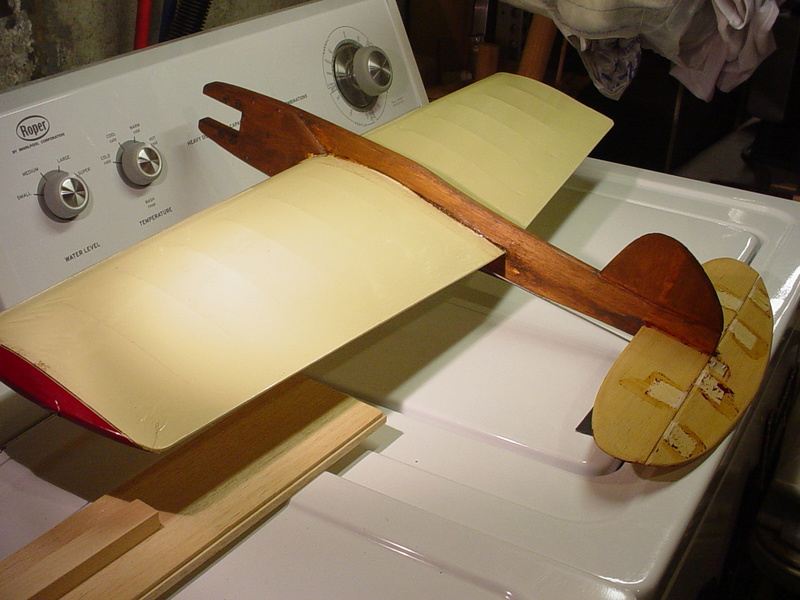

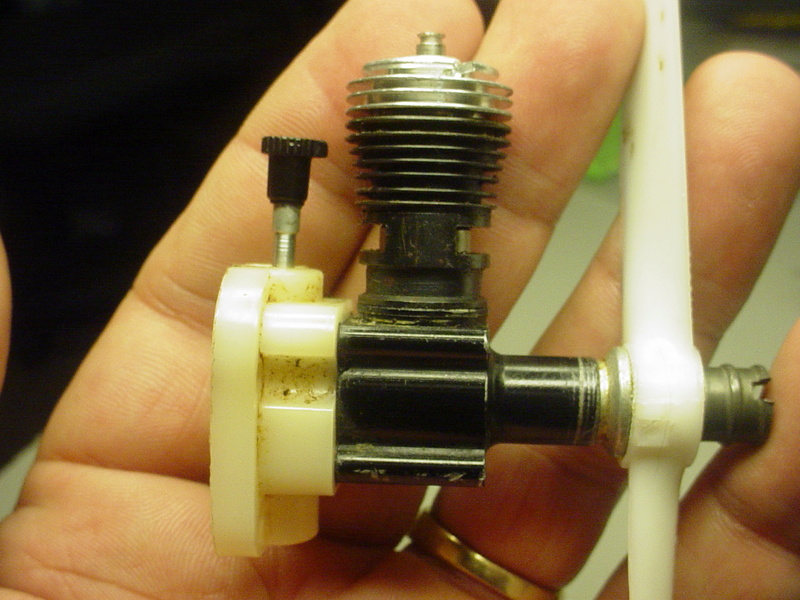

You guys are truly my best friends!!! I'll need to work on some plans for a "home" for this Tee Dee .09 now. It won't be put in a box. It will likely be grafted into the nose of this..

You guys are truly my best friends!!! I'll need to work on some plans for a "home" for this Tee Dee .09 now. It won't be put in a box. It will likely be grafted into the nose of this..

a bit of work for this Winter...

The Jr. Ringmaster... a good choice.. or so I've read. Mine was set-up originally for a Fox .15 steel-fin. I have another home for the Fox engine.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Way To Go Roddie !!! Those TDs are nice but can bee a pain , it will look good on that Jr. Ring.

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

getback wrote:Way To Go Roddie !!! Those TDs are nice but can bee a pain , it will look good on that Jr. Ring.

Thanks Eric, Yes.. this engine took a long time to start. My first vid was so embarrassing

Getting the needle setting correct was the tricky part for me. An "L-bend" rather than the tiny knob on the stock needle would make things a lot easier.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

You're right, Roddie. It can be tough to find that sweet spot on the needle to get her going. Mine usually roars back to life easily at the field on consecutive startups once you arrive at the magic spot. The next time out to the field, the process starts over. I hope to give mine a try later this evening. If she's happy with the Med piston, I'll try to fly her tomorrow.

Tee Bee- Platinum Member

- Posts : 764

Join date : 2011-08-25

Location : Angleton, TX

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Tee Bee wrote:You're right, Roddie. It can be tough to find that sweet spot on the needle to get her going. Mine usually roars back to life easily at the field on consecutive startups once you arrive at the magic spot. The next time out to the field, the process starts over. I hope to give mine a try later this evening. If she's happy with the Med piston, I'll try to fly her tomorrow.

Best of luck with yours Troy. I don't see why you'd have any issues; where you mentioned the piston-fit feeling good in the liner/cylinder. Strange about Doug's (crankbndr) experience with his .15 Medallion pistons not interchanging with a .15 Tee Dee liner..

His Medallion piston wouldn't go past the Tee Dee cylinders' exhaust-ports though. I find that very strange. I wonder if he still has his spent Tee Dee piston to recheck the bore for burrs? I'm not implying that this happened.. but he could have inadvertently turned a burr into his cylinder when he removed it, following the rod-failure.

His Medallion piston wouldn't go past the Tee Dee cylinders' exhaust-ports though. I find that very strange. I wonder if he still has his spent Tee Dee piston to recheck the bore for burrs? I'm not implying that this happened.. but he could have inadvertently turned a burr into his cylinder when he removed it, following the rod-failure. I recently restored two #1 .049 cylinders with bores that were both internally-burred at the exhaust-ports. Ken Cook guided me through the process.. and those two cylinders are now strong-runners. I wouldn't think twice now, about repeating that process on another liner having that issue.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

It's funny how smart this forum is making us. Learning how to troubleshoot and run toy engines that were designed for children. Learning things that do us little good outside of this small niche hobby. I sure enjoy it, though.

Tee Bee- Platinum Member

- Posts : 764

Join date : 2011-08-25

Location : Angleton, TX

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

roddie wrote:

Getting the needle setting correct was the tricky part for me. An "L-bend" rather than the tiny knob on the stock needle would make things a lot easier.

One can take a dremel cutting-disk and make clear groove in the disc part of the nob. That way one can see where the needle is positioned and how much one has turned it etc. I often open up the needle by 1/4-1/2 of a turn for the start and turn it back in ones the engine is running. A visual indication of where one is with the needle, is very useful I think.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Surfer_kris wrote:roddie wrote:

Getting the needle setting correct was the tricky part for me. An "L-bend" rather than the tiny knob on the stock needle would make things a lot easier.

One can take a dremel cutting-disk and make clear groove in the disc part of the nob. That way one can see where the needle is positioned and how much one has turned it etc. I often open up the needle by 1/4-1/2 of a turn for the start and turn it back in ones the engine is running. A visual indication of where one is with the needle, is very useful I think.

I had considered this Kris.. and since you mentioned it, I will likely do it.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

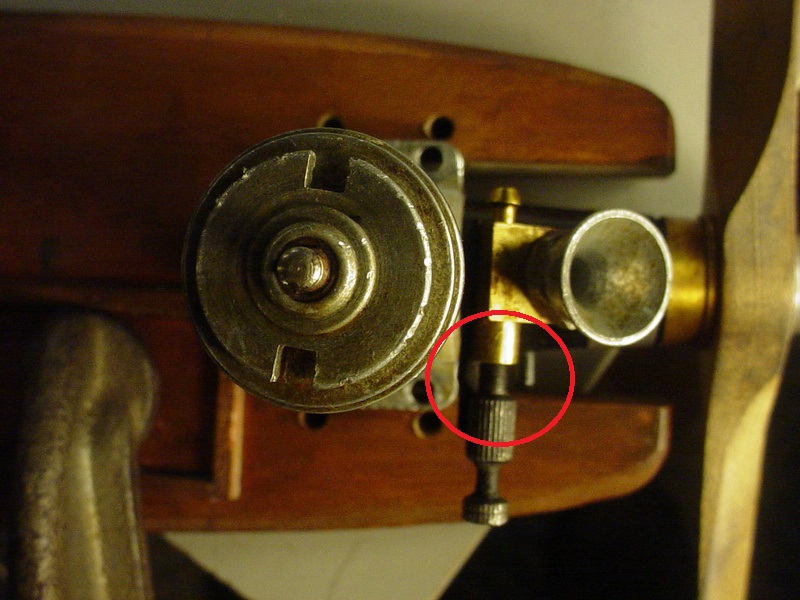

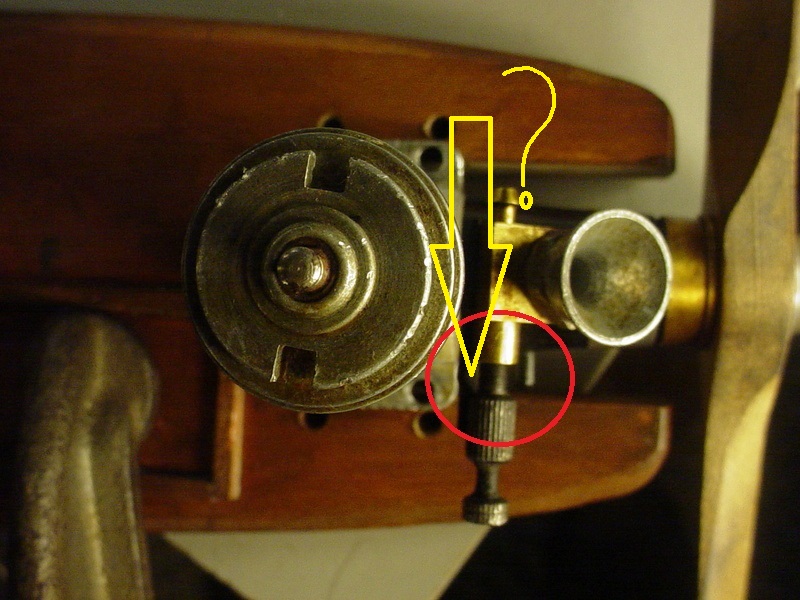

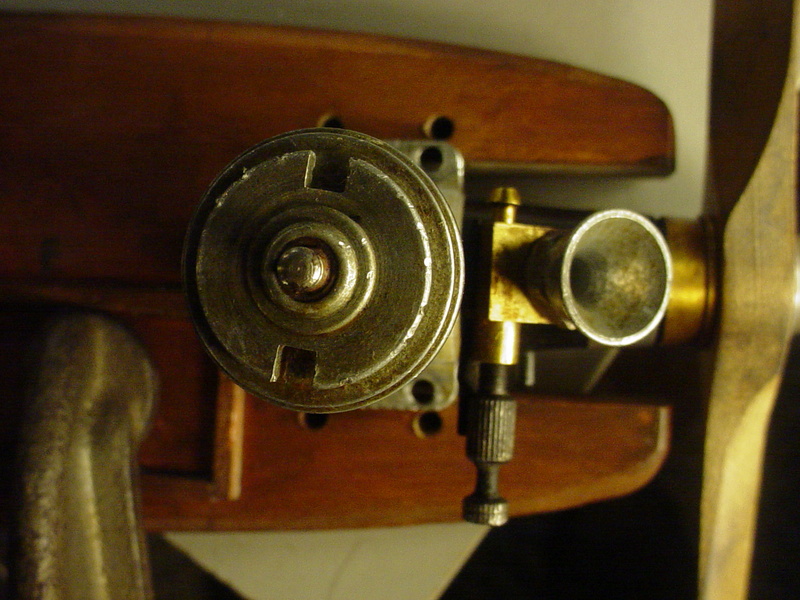

Is there a spring missing Brad? I have a good assortment of compression-springs.. but I thought that the spring-steel "tab" which applies friction to the knurled/grooved shaft of the needle was intended to prevent migration? I can understand the logic behind a coil-spring to help tension the threads against air-leaks. I have used the fuel-line seal method on my reed-valve engines' needles.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Brad may speak for himself but the TDs do use a tab spring on the knurled knob. I'm guessing it's on the bottom where he couldn't see it.

Tee Bee- Platinum Member

- Posts : 764

Join date : 2011-08-25

Location : Angleton, TX

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

The bottom photo was taken before I disassembled the engine. When I reassembled it, I installed the spring upside-down.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

roddie wrote:

The bottom photo was taken before I disassembled the engine. When I reassembled it, I installed the spring upside-down.It seems to function the same.. but could there be an air-leak because of it being installed "over" the valve-body.. rather than under it?

You should not have problems having placed the tongue in the bottom area, look at the photos I put here of my engine, just the tongue is in the bottom, what I have added is a neoprene tube to prevent it from taking air for the threads of the needle, that seals and works correctly.

Try to place a neoprene tube that will hug the needle and the tongue as I show it in my engine.

In my case to prevent the tongue from touching part of the housing, I placed a washer supplement, as the fuel intake is forward and in that position without washer, the carburetor body touches the housing.

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Great morning! Clear skies and 50F.

My TD is breaking in nicely and flying well with the Medallion piston. I test flew it with 3 props. The stiff grey Cox 7x3.5 made the engine happy but just didn't get the airplane up on the step like I wanted. The APC 6x4 flew the airplane nice and fast with good climb authority, but I felt like the engine was crying from the high revs. It had a noticeable darker exhaust residue after running that prop! Next, I tried a MA 7x4. Nice climb. Decent enough speed. Happy engine! That was the setup of the day.

My TD is breaking in nicely and flying well with the Medallion piston. I test flew it with 3 props. The stiff grey Cox 7x3.5 made the engine happy but just didn't get the airplane up on the step like I wanted. The APC 6x4 flew the airplane nice and fast with good climb authority, but I felt like the engine was crying from the high revs. It had a noticeable darker exhaust residue after running that prop! Next, I tried a MA 7x4. Nice climb. Decent enough speed. Happy engine! That was the setup of the day.

Tee Bee- Platinum Member

- Posts : 764

Join date : 2011-08-25

Location : Angleton, TX

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

MauricioB wrote:

You should not have problems having placed the tongue in the bottom area, look at the photos I put here of my engine, just the tongue is in the bottom, what I have added is a neoprene tube to prevent it from taking air for the threads of the needle, that seals and works correctly.

Try to place a neoprene tube that will hug the needle and the tongue as I show it in my engine.

In my case to prevent the tongue from touching part of the housing, I placed a washer supplement, as the fuel intake is forward and in that position without washer, the carburetor body touches the housing.

Hi Mauricio! Thank You for taking the time to show me. It seems that Cox built-in some versatility to the arrangement.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Tee Bee wrote:Great morning! Clear skies and 50F.

My TD is breaking in nicely and flying well with the Medallion piston. I test flew it with 3 props. The stiff grey Cox 7x3.5 made the engine happy but just didn't get the airplane up on the step like I wanted. The APC 6x4 flew the airplane nice and fast with good climb authority, but I felt like the engine was crying from the high revs. It had a noticeable darker exhaust residue after running that prop! Next, I tried a MA 7x4. Nice climb. Decent enough speed. Happy engine! That was the setup of the day.

That's GREAT NEWS Troy! I'm sure that you're as happy now, as the engine is! Thanks for the performance info on the different props. What were you using for fuel? When the Cox fuels became unavailable (very soon after I got seriously into the hobby..) I switched to the Sig "Champion" 25 and 35 blends.. and they're all I've ever used since.

I used to run the Cox stiff-grey 6 x 3's and 6 x 4's on my reed-valve .049's. I bought wood-props in those sizes too. They're the sizes I have the most of, in my stock of props. I didn't know back in those days, that I was over-loading those reed-valve engines. I did have (and still have..) some Cox 3-blade 5 x 3's.. and 5 x 3.5's.. but didn't like the way they looked on my models.

Most of my self-designed 1/2A size C/L models were/are a bit large for the reed-valve engines that I was running.. which made matters worse.. although I didn't realize it at the time. Those airplanes flew on lines that were at least 10' shorter than the normal 35' to accommodate the area (at home) that I had to fly in. I had 52' of clear-space.. and rarely flew anywhere else.. so I never made-up a longer set of lines. It will be interesting to see how both; me and my models fly, with an extra 10-12 feet of line. I'm sure that it will be "liberating" to say the least..

I now have one of each; Tee Dee's .049 and .051 which I could mount on those airplanes.. and effectively use those 6 x 3's and 6 x 4's. My last parts-order included two "radial" mounts for the engines.

My "Custom Triplane" may be a good candidate for the Tee Dee .049 engine.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

One of my favorite setups is a nice running TD .049 w/Cox 5x3 rubber ducky prop. I fly that combo a lot. Yeah, a lot of factors in choosing a prop for an engine/airframe and the end results aren't always what you thought they would be beforehand. It's a good thing I like test flying.  My heavy Minnie Mambo with a throttled reedie Surestart .049 flies and runs best with a Cox 6x3 but my speedier/lighter 1/2A sport planes usually do better with a 5x3. I'm not looking to break the sound barrier like guys such as 1/2A Nut, so I don't like to rev the engines too much these days, preferring for them to last for hours of runtime/years of service. I used to fly my Skydrill with a highly modded reedie and an APC 4.2x4. It went fast and revved hard but usually needed a clearance reset every few runs. With a Cox 5x3, it's usually fast enough for me and goes the distance. As for fuel, I almost always run Sig Champion 25 with 1.5oz added castor to a quart bottle. That's a decent enough mix that I run all my Cox engines with it. My planes aren't the fastest and my flying skills are limited, but I sure have fun! I'm typing this from the flying field, BTW.

My heavy Minnie Mambo with a throttled reedie Surestart .049 flies and runs best with a Cox 6x3 but my speedier/lighter 1/2A sport planes usually do better with a 5x3. I'm not looking to break the sound barrier like guys such as 1/2A Nut, so I don't like to rev the engines too much these days, preferring for them to last for hours of runtime/years of service. I used to fly my Skydrill with a highly modded reedie and an APC 4.2x4. It went fast and revved hard but usually needed a clearance reset every few runs. With a Cox 5x3, it's usually fast enough for me and goes the distance. As for fuel, I almost always run Sig Champion 25 with 1.5oz added castor to a quart bottle. That's a decent enough mix that I run all my Cox engines with it. My planes aren't the fastest and my flying skills are limited, but I sure have fun! I'm typing this from the flying field, BTW.

My heavy Minnie Mambo with a throttled reedie Surestart .049 flies and runs best with a Cox 6x3 but my speedier/lighter 1/2A sport planes usually do better with a 5x3. I'm not looking to break the sound barrier like guys such as 1/2A Nut, so I don't like to rev the engines too much these days, preferring for them to last for hours of runtime/years of service. I used to fly my Skydrill with a highly modded reedie and an APC 4.2x4. It went fast and revved hard but usually needed a clearance reset every few runs. With a Cox 5x3, it's usually fast enough for me and goes the distance. As for fuel, I almost always run Sig Champion 25 with 1.5oz added castor to a quart bottle. That's a decent enough mix that I run all my Cox engines with it. My planes aren't the fastest and my flying skills are limited, but I sure have fun! I'm typing this from the flying field, BTW.

My heavy Minnie Mambo with a throttled reedie Surestart .049 flies and runs best with a Cox 6x3 but my speedier/lighter 1/2A sport planes usually do better with a 5x3. I'm not looking to break the sound barrier like guys such as 1/2A Nut, so I don't like to rev the engines too much these days, preferring for them to last for hours of runtime/years of service. I used to fly my Skydrill with a highly modded reedie and an APC 4.2x4. It went fast and revved hard but usually needed a clearance reset every few runs. With a Cox 5x3, it's usually fast enough for me and goes the distance. As for fuel, I almost always run Sig Champion 25 with 1.5oz added castor to a quart bottle. That's a decent enough mix that I run all my Cox engines with it. My planes aren't the fastest and my flying skills are limited, but I sure have fun! I'm typing this from the flying field, BTW.

Tee Bee- Platinum Member

- Posts : 764

Join date : 2011-08-25

Location : Angleton, TX

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Tee Bee wrote:One of my favorite setups is a nice running TD .049 w/Cox 5x3 rubber ducky prop. I fly that combo a lot. Yeah, a lot of factors in choosing a prop for an engine/airframe and the end results aren't always what you thought they would be beforehand. It's a good thing I like test flying.My heavy Minnie Mambo with a throttled reedie Surestart .049 flies and runs best with a Cox 6x3 but my speedier/lighter 1/2A sport planes usually do better with a 5x3. I'm not looking to break the sound barrier like guys such as 1/2A Nut, so I don't like to rev the engines too much these days, preferring for them to last for hours of runtime/years of service. I used to fly my Skydrill with a highly modded reedie and an APC 4.2x4. It went fast and revved hard but usually needed a clearance reset every few runs. With a Cox 5x3, it's usually fast enough for me and goes the distance. As for fuel, I almost always run Sig Champion 25 with 1.5oz added castor to a quart bottle. That's a decent enough mix that I run all my Cox engines with it. My planes aren't the fastest and my flying skills are limited, but I sure have fun! I'm typing this from the flying field, BTW.

TOO COOL Troy! Hope you're having fun flying today! I remember now; you stating what your preferred fuel-blend is. I've never mixed my own fuel or added castor. I really should source some more 1/2A fuel. Back when (several years ago..) I "last" ordered fuel from Sig Manufacturing, they sold separately; "Baker's AA castor" and the "Klotz" synthetic oils that they used in their "Champion-1/2A" fuel-formulations. I often considered buying the castor.. but never did.

The Sig fuel that I've been using.. is at least 15 years old..

I share your current opinion on engine-longevity. I've never flown a model-airplane that had a "hot" engine. The closest I've come to that is "bench-running" my 2014/15 CEF Speed-Contest reedie.. which was cantankerous.. starting/running on a suction-feed/hard-tank when equipped with a pseudo-"Killer-Bee" backplate, Tee Dee cylinder/head and APC 4.75 x 4 propeller. When I finally worked-out the fuel-feed issues.. and got the engine to run continuously.. it was scary. I actually stood-back.. and thought; holy crap!!!

More recently; I ran an engine given to me by "Bob" (rsv1cox) that came in a box of parts-engines that he graciously mailed to me.. to help get a Testors/McCoy engine running. There were several engines in that box! One was a Cox .049 reedie-configuration having a black-anodized case with round drive-plate that appeared to be from an early "Black Widow".. a #1 cylinder, standard glow-head, a white/Delrin horseshoe backplate with aluminum needle.. and copper-star reed. There was a nice white nylon 6 x 3 "Tornado" propeller mounted.

The reed was partially-stuck to its seat.. but I was able to lift it free without creasing it. I used a toothpick. There was the all too common "green-goo" present.. so I cleaned the Delrin seat and circlip using a cotton-swab soaked in thinner.. and cleaned the copper reed by placing it flat on a square of 600 grit abrasive-paper.. and "swirled it around" on both sides using the point of my index-finger. I then gently wiped it clean; flat over a facial-tissue in the same way.. swirling it until no traces of residue could be seen. I then reinstalled the reed/circlip into the backplate.. and confirmed proper operation using the blow/suck method with my mouth. It was "ready to run" as far as I knew.

The NVA's "spray-hole" was discovered to be facing rearward.. noticed by Brad.. (1/2A Nut) through photos I'd posted.. so I proceeded to press it out and reinstall it "frontward".. (a first for me...)

Here's the vid of it running..

https://www.youtube.com/watch?v=fkZAZmPB_CE

I first tried running it with the Tornado propeller.. but the engine ran "backward" on every attempt.. so I removed the prop and installed a R/H zero-drag starter-spring.. and the APC 4.75 x 4 prop that Ron had sent back from the Tach-race. It was all set to mount with a prop-screw, flat-washer and a fuel-line hub-bushing. The fuel-tank used was a Perfect #2 wedge of 3oz. capacity attached to the backside of the mount.

Page 8 of 8 •  1, 2, 3, 4, 5, 6, 7, 8

1, 2, 3, 4, 5, 6, 7, 8

Similar topics

Similar topics» Cox .020 PeeWee/TeeDee prop-screw

» Cox Tee Dee .049 Rebuild ...

» Ez Bee rebuild

» TD rebuild .049

» Engine rebuild help please

» Cox Tee Dee .049 Rebuild ...

» Ez Bee rebuild

» TD rebuild .049

» Engine rebuild help please

Page 8 of 8

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules