Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

Cox Engine of The Month

Tee Dee .09 rebuild.. and run!

Page 4 of 8

Page 4 of 8 •  1, 2, 3, 4, 5, 6, 7, 8

1, 2, 3, 4, 5, 6, 7, 8

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

balogh wrote:Good point, Roddie, I use brake cleaning spray, connecting its sprayer with a silicon tube to the bottom spout of the venturi, and by sealing the intake side with my finger, pressure-flush the 3 orifices.

TD-s are easy to diagnose with orifice clogging problems if they run weakly and do not seem to want to react to needle valve adjustment. When I notice that - although rather seldom, because I use, as a rule, filter in the fuel line - I immediately remove and clean the venturi including the 3 orifices, and blow through the anodized spray-ring too to make sure its single orifice is also clog-free.

Brake-cleaner spray is one of the chemicals missing from my arsenal. There isn't much that I "don't have".. but that's one.. along with carburetor-cleaner. I haven't done a brake-job in decades.. but I should get some carb-cleaner spray. General Motors parts department used to sell the best penetrant that I've ever used. "Heat-Valve Penetrant" was what it was called.. and it was specifically formulated to lubricate the heat-riser valve associated with the automatic-chokes on GM's pre-fuel injection engines of the early 1980's. It contained colloidal-graphite.. and would penetrate where nothing else could.

Actually; the only aerosol spray-solvent that I have on hand is WD-40, an old can of TV-tuner cleaner and a very small container of a product called "De-Ox-it Gold".. which is/was a better cleaner/spray for rheostats associated with audio-systems.. more for "carbon-residue" than anything else. Now that everything is "electronic".. these special physical-lubricants/penetrants are getting harder to find.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

dckrsn wrote:That's a big one.

Way ta go Roddie.

Bob

Thanks Bob. I'm learning as I go here. The plastic carb looks ok.. though I know that they can be prone to cracks causing air-leaks. I'm hoping for the best naturally. I'll again; flush the NVA while it's off the engine to be sure that it's clean. I've never removed the crank from a model engine. This engine will be the guinea-pig. If it's relatively "clean".. I'll just reinstall it. Some of my Bee engine's cases have sticky cranks that I know could use a de-varnishing. I just need to be more comfortable with the dis-assembly process.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Removing the drive washer is not a difficult task. As Ron mentioned, he taps on the prop screw. I don't use the prop screw because it can bend. I use a allen socket screw. Most of the time I place the crank in a vise between two wood blocks and press the screw out. Loosening the collet retainer is the easiest however the tool can do damage to the collet and or the threads of the case if not careful. Putting the drive washer back on is the problematic part. It can go on out of square. I use the same allen socket head and place a nut on it. Screw the allen socket head back into the crank and holding the socket with a allen key, back the nut back down onto the drive washer. This goes easier with a washer and or spacers under the nut due to the .09 having the centering extension on the front. Don't forget the thrust washer in between the case and the drive washer. If a older TD it's phenolic. I don't make a habit of removing this part unless absolutely necessary. The splines will cut again on install and this can be problematic if it's not tight.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Roddie, Ken's advice is spot on as always. I would like to add that be sure to turn the bolt all the way to the bottom of the prop bolt hole. Snug, but not tight. That will make the life of the threads easier as the tapping impacts are then transferred mostly via the end of the bolt to the bottom of the hole instead of to the threads.

Also when re-installing the drive plate, use the bolt and a nut as Ken suggests, again to preserve the threads on the crankshaft. Since the bolt is stationary in the hole, the process only causes static axial force to the threads. Hard to explain but anyway it is much easier to damage threads while turning than with an axial pull. So if you use a nut and bolt, the possible damage will occur to the nut and the area of the bolt where the nut is, instead of damaging the thread in the crank. Ouch my head hurts because of all the science Also remember to lubricate the thread before tightening the nut.

Also remember to lubricate the thread before tightening the nut.

Sorry if this is all "basic" to you, but maybe it is useful to some future readers anyway

Also when re-installing the drive plate, use the bolt and a nut as Ken suggests, again to preserve the threads on the crankshaft. Since the bolt is stationary in the hole, the process only causes static axial force to the threads. Hard to explain but anyway it is much easier to damage threads while turning than with an axial pull. So if you use a nut and bolt, the possible damage will occur to the nut and the area of the bolt where the nut is, instead of damaging the thread in the crank. Ouch my head hurts because of all the science

Also remember to lubricate the thread before tightening the nut.

Also remember to lubricate the thread before tightening the nut. Sorry if this is all "basic" to you, but maybe it is useful to some future readers anyway

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Removal of the backplate is the "easy" part, just be careful with the last tap as there is a risk that the crankpin will hit the support as the crank comes out free. The tougher part is indeed to get it back on properly, with the prop-plate perpendicular to the axis of the crank. It doesn't take much error at the prop-plate to have a prop that is not tracking well. The prop-plate tends to deform at the back, deformed by the spline on the crank, and I usually deburr that before putting it back on.

I rarely find a real reason to remove it though. An engine that has been sitting for some time can feel a little tight (from old oil) but this will go away quite easily as soon as you run it again. So it only need to come off if one has to replace the thrust washer, or if there is another serious problem.

I rarely find a real reason to remove it though. An engine that has been sitting for some time can feel a little tight (from old oil) but this will go away quite easily as soon as you run it again. So it only need to come off if one has to replace the thrust washer, or if there is another serious problem.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Thanks once more.. guys! I appreciate this guidance/advice very much. I removed the crank last night.

I sat the rear of the case flat on my bench-vises' anvil, installed the slotted prop-screw fully.. and tapped gently using a small "tack-hammer" to avoid bending the screw. The crank came out of the case with no issue. I don't see much in way of "varnishing" on the crank. The crank "bore" looks very clean. This is as far as I've gotten.. as of this post.

When I reinstall the thrust-washer and drive-plate later; I assume that I should try to match-up the original grooves that the spline cut into the drive-plate if possible. I can feel the splines engaging with the two pieces apart from the engine. Common-sense tells me that re-fitting in this way would insure the drive-plate goes back-on to the crankshaft squarely.. and with less effort than if randomly located causing new grooves to be cut into the aluminum.

The thrust-washer is a phenolic one. Its' thickness measures .019" across the center.. but thins-out to .017" at the outer-edges. It has some significant wear.. and looks like the engine might have seen a good share of electric-starter use?

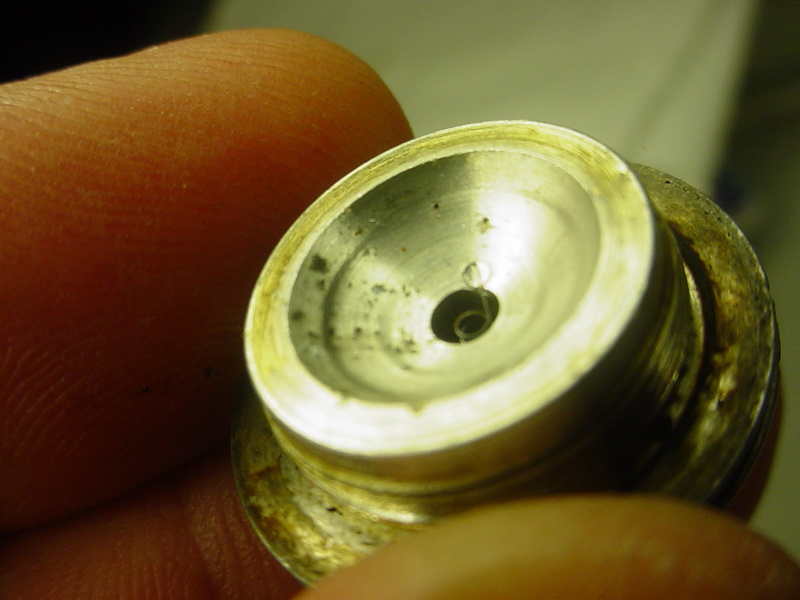

Here's a photo of the side (I assume..) facing the case/collar-ring..

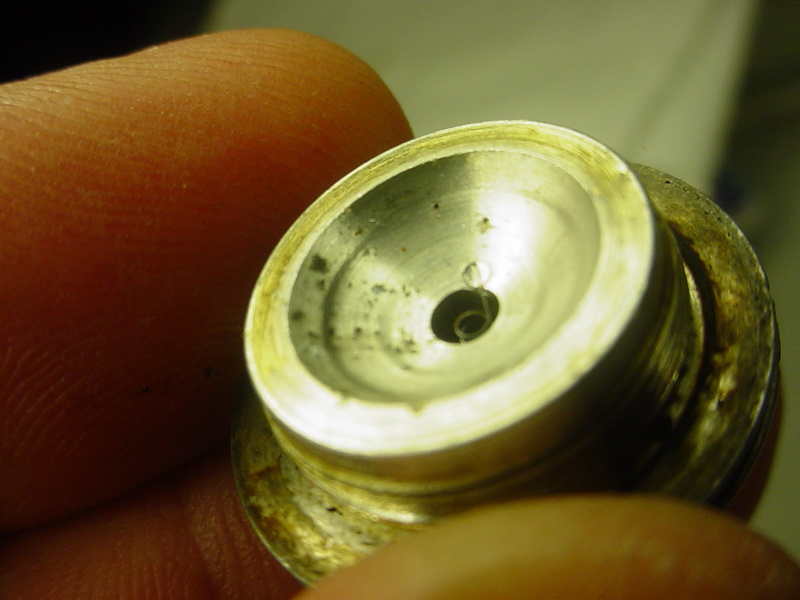

and the side facing the drive-plate..

Should this part be replaced before re-assembly? If so; what would an alternate material be.. and its' approximate thickness?

I sat the rear of the case flat on my bench-vises' anvil, installed the slotted prop-screw fully.. and tapped gently using a small "tack-hammer" to avoid bending the screw. The crank came out of the case with no issue. I don't see much in way of "varnishing" on the crank. The crank "bore" looks very clean. This is as far as I've gotten.. as of this post.

When I reinstall the thrust-washer and drive-plate later; I assume that I should try to match-up the original grooves that the spline cut into the drive-plate if possible. I can feel the splines engaging with the two pieces apart from the engine. Common-sense tells me that re-fitting in this way would insure the drive-plate goes back-on to the crankshaft squarely.. and with less effort than if randomly located causing new grooves to be cut into the aluminum.

The thrust-washer is a phenolic one. Its' thickness measures .019" across the center.. but thins-out to .017" at the outer-edges. It has some significant wear.. and looks like the engine might have seen a good share of electric-starter use?

Here's a photo of the side (I assume..) facing the case/collar-ring..

and the side facing the drive-plate..

Should this part be replaced before re-assembly? If so; what would an alternate material be.. and its' approximate thickness?

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Roddie

Matt sells stainless steel thrust washers for 09-s.

Matt sells stainless steel thrust washers for 09-s.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

If you are not going to use an electric starter, then the phenol washer one will be okey. Once running the prop will keep the crank in the forward position anyway. It is only on throttled engines that the crank will move back and forth at low carb settings. If you replace the washer, don't make it too tight, there should be some play, fore and aft, to allow for a proper lubrication of the crank.

And yes, do try to match the splines with the previously made grooves in the thrust-plate. Good luck!

And yes, do try to match the splines with the previously made grooves in the thrust-plate. Good luck!

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

This exactly ^^^^

If it were me I would give it a light sanding of 1000grit and re-assemble. It's a runner. The crescent shaped cutout on the wrench will remove the carb body collar, but not really needed at this point as you can get to everything now.

Ron

If it were me I would give it a light sanding of 1000grit and re-assemble. It's a runner. The crescent shaped cutout on the wrench will remove the carb body collar, but not really needed at this point as you can get to everything now.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Roddie,

good luck, you are almost there. Looking forward to hearing the first brrrrrrrppppoooouuuuiiiiiiiiiiiiiiiiiiii...from your bench-run video!

Until then here is a vid I just shot today and youtube-d on my 09 in action with the Cosmic Wind minus its landing gear - as a precaution for the deep grass on the only accessible field. (The Sony headcam will not be better than that... ). Sorry I did not want to poach your thread, just to give some more inspiration to a.s.a.p. fire up your 09

). Sorry I did not want to poach your thread, just to give some more inspiration to a.s.a.p. fire up your 09

K

good luck, you are almost there. Looking forward to hearing the first brrrrrrrppppoooouuuuiiiiiiiiiiiiiiiiiiii...from your bench-run video!

Until then here is a vid I just shot today and youtube-d on my 09 in action with the Cosmic Wind minus its landing gear - as a precaution for the deep grass on the only accessible field. (The Sony headcam will not be better than that...

K

Last edited by balogh on Sat Sep 09, 2017 2:35 pm; edited 5 times in total

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Put it back together, there's nothing wrong with it.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Surfer_kris wrote:If you are not going to use an electric starter, then the phenol washer one will be okey. Once running the prop will keep the crank in the forward position anyway. It is only on throttled engines that the crank will move back and forth at low carb settings. If you replace the washer, don't make it too tight, there should be some play, fore and aft, to allow for a proper lubrication of the crank.

And yes, do try to match the splines with the previously made grooves in the thrust-plate. Good luck!

Thanks Kris. I will likely be hand-propping this engine.. unless I can wind a coil of music-wire to make a starter-spring for it. I really LOVE the cam-spring that you made and recently posted!

I just looked at ExModel Engines Tee Dee .09 parts.. and it might make good sense to place an order for the SS thrust-washers, a pkg. of head-gaskets and needle/spring while they're still available. I'll have to see how and if this engine is a runner beforehand. If it runs good.. I might also consider the aluminum carb. This is an older engine and its plastic-carb is on borrowed-time. With shipping/sales tax from nearby CT.. I'd be looking at $30-35 for all of those parts.

A few years ago I scored some OEM Cox parts from a LHS that was closing after 70+ years in business (since 1939!). Amongst two small boxes of parts.. there were "two" Tee Dee .09 mufflers at 40% off the marked price of $5.. making them $3 ea. One package was open and missing a few small parts. CEF member Mark McRiley (batjack) wanted them both.. so I mailed them out to him. There was also some Aero-Gloss dope.. which I mailed-off to Ron Cribbs.

I wish I'd gotten the HS owner's personal phone#.. because he was certain that he had another box of Cox parts stowed-away in the backroom somewhere. I gave him "my" phone#.. but never heard back from him. The HS phone is no longer in service. I can only imagine what might have been in that last box which he couldn't find.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

balogh wrote:Roddie,

good luck, you are almost there. Looking forward to hearing the first brrrrrrrppppoooouuuuiiiiiiiiiiiiiiiiiiii...from your bench-run video!

Until then here is a vid I just shot today and youtube-d on my 09 in action with the Cosmic Wind minus its landing gear - as a precaution for the deep grass on the only accessible field. (The Sony headcam will not be better than that...). Sorry I did not want to poach your thread, just to give some more inspiration to a.s.a.p. fire up your 09.

Nice flight Andras! Plenty of power there.. and the tuning seemed to sound a bit on the "rich-side"?? No worries with posting that here my friend!

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

roddie wrote:

Thanks Kris. I will likely be hand-propping this engine.. unless I can wind a coil of music-wire to make a starter-spring for it. I really LOVE the cam-spring that you made and recently posted!

I just looked at ExModel Engines Tee Dee .09 parts.. and it might make good sense to place an order for the SS thrust-washers, a pkg. of head-gaskets and needle/spring while they're still available. I'll have to see how and if this engine is a runner beforehand. ...............

Roddie you bet it WILL be a runner...you'd better stock parts still available from Matt, Bernie, ebay and elsewhere because the TD09 was one of the smallest production run COX engines, and it slowly goes extinct..unlike your obsession that will certainly grow the more you run it...

and yes, it was slightly on the rich side, I just want to avoid lean-runs when the tank nears to empty, as best as I can.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Ken Cook wrote: Put it back together, there's nothing wrong with it.

I still have to remove that Medallion head and install the Tee Dee one that Bob sent me. That'll be sometime this afternoon..

No one commented on what I mentioned about the "fluttering" of the ammeter needle on my panel while trying to start this engine previously...

Anyone ever experience that? I thought it might be a sign of poor continuity.. or a coil/element that might be on it's way out...

Anyone ever experience that? I thought it might be a sign of poor continuity.. or a coil/element that might be on it's way out...  Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Roddie the well-used COX clips - if you use one - are infamous of their tricky habit of popping off the head when you flip the prop...maybe yours did not hop off, just loses contact with the head...I could not think of anything else than that..I experienced that on bench starting even when the bench is held down on a table or something fixed...let alone in an airplane that you hold with one hand only while flipping the prop with the other. The COX clip best likes to hop off most often when the engine fires up and then the prop will hit the clip wire just to make the biggest damage possible...Murphy's law.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Removal of the Medallion head

Removal of the Medallion head

First use of my Wagner heat-gun since I bought it a few years ago (on sale..  ) I used the low (750 degrees F) setting and heated the cylinder and head for about one minute.

) I used the low (750 degrees F) setting and heated the cylinder and head for about one minute.

A gasket had been installed..

doesn't look too bad..

comparison; Medallion head "left"-Tee Dee head (from Bob)-"right". Notice the light-reflection showing the difference in the combustion-chamber shape..

I'm glad to finally get that old head off.. slow progress I know.. but it's better than rushing and breaking a part that can't be replaced.

A gasket had been installed..

doesn't look too bad..

comparison; Medallion head "left"-Tee Dee head (from Bob)-"right". Notice the light-reflection showing the difference in the combustion-chamber shape..

I'm glad to finally get that old head off.. slow progress I know.. but it's better than rushing and breaking a part that can't be replaced.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

I've been watching this one from the sidelines. Has it run successfully yet? I just flew one of my TD .09s a few days ago. I always enjoy running it but now that I see how problematic they are, I'm scared to try it again.

Seriously, I thought it looked sorted out once the venture holes were unclogged. It just HAS to run now.

FWIW, I ran a Med .09 for years on a 2 channel Pong 2, hundreds of flights. During that time, I used Cox Medallion heads, TD heads, a standard glow plug conversion head, and a Turbo Plug conversion head all with success. The RPM performance changed with compression ratio changes but the engine was happy to run with any of those heads. Much more forgiving in the variations compared to the smaller Cox engines. The current TD .09 that I'm flying has only been run with a TD head but I'm assuming that any of those heads would run just fine if peak performance wasn't an issue.

Seriously, I thought it looked sorted out once the venture holes were unclogged. It just HAS to run now.

FWIW, I ran a Med .09 for years on a 2 channel Pong 2, hundreds of flights. During that time, I used Cox Medallion heads, TD heads, a standard glow plug conversion head, and a Turbo Plug conversion head all with success. The RPM performance changed with compression ratio changes but the engine was happy to run with any of those heads. Much more forgiving in the variations compared to the smaller Cox engines. The current TD .09 that I'm flying has only been run with a TD head but I'm assuming that any of those heads would run just fine if peak performance wasn't an issue.

Tee Bee- Platinum Member

- Posts : 764

Join date : 2011-08-25

Location : Angleton, TX

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

balogh wrote:Roddie,

good luck, you are almost there. Looking forward to hearing the first brrrrrrrppppoooouuuuiiiiiiiiiiiiiiiiiiii...from your bench-run video!

Until then here is a vid I just shot today and youtube-d on my 09 in action with the Cosmic Wind minus its landing gear - as a precaution for the deep grass on the only accessible field. (The Sony headcam will not be better than that...). Sorry I did not want to poach your thread, just to give some more inspiration to a.s.a.p. fire up your 09

K

Very cute András video and enjoy your 09 friend! .... congratulations!

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Thank you Mauricio,

unfortunately the Sony headcam is really not the best to show how well this Cosmic Wind flies in reality...

unfortunately the Sony headcam is really not the best to show how well this Cosmic Wind flies in reality...

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Tee Bee wrote:I've been watching this one from the sidelines. Has it run successfully yet? I just flew one of my TD .09s a few days ago. I always enjoy running it but now that I see how problematic they are, I'm scared to try it again.

Seriously, I thought it looked sorted out once the venture holes were unclogged. It just HAS to run now.

FWIW, I ran a Med .09 for years on a 2 channel Pong 2, hundreds of flights. During that time, I used Cox Medallion heads, TD heads, a standard glow plug conversion head, and a Turbo Plug conversion head all with success. The RPM performance changed with compression ratio changes but the engine was happy to run with any of those heads. Much more forgiving in the variations compared to the smaller Cox engines. The current TD .09 that I'm flying has only been run with a TD head but I'm assuming that any of those heads would run just fine if peak performance wasn't an issue.

Hi Troy, Truth be known... I haven't put the engine back together yet. I certainly could have done that by now.. but I'm somewhat "immobile" with back-trouble. I've had issues before.. but never this bad or for this length of time. I just started a new job last week and am already out on injury. Doc referred me for steroid spinal-injections. The weather here has been damp.. which doesn't help matters.

I also need to scrounge-up some 4-40 machine-screws and lock-nuts to safely mount the engine. I was surprised at how scarce 4-40 screws are (good ones anyway..) at several hardware stores. I wanted to find the black cap-screws.. or button-heads.. but could only find them in 6-32 size and larger. I may have a package of DuBro 4-40 mounting-screws.. but their length needs to be at least 3/4".

News-flash..

I'll ream-out my bench-mounts' beams to accept them.

I just double-checked the pressure-nipple on the carb by connecting a pc. of fuel-line and blowing/sucking to confirm that it wasn't drilled-open. It wasn't. The carb and collar are the only pieces that I haven't removed from the case.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Sorry about your back problems. Take care of that first! These cantankerous toys we love to play with can sure bring joy to your life when they work well but a bit of misery when they don't. It's little wonder why the rest of the world has moved on to brushless electric motors for powering their models. Earlier this week, at our club flying field, a fellow club member was ribbing me about my stubborn starting glow engine. It was all in fun since he's been flying models for about 40yrs or so and has lived those struggles. He now 86yrs old and flies electrics exclusively to keep his life simpler. I pulled out a couple of boxes of various old Cox engines that have all been restored and showed him my parts stash which is organized neatly in little bins by engine type. He enjoyed looking at everything and admitted that owning, running, and maintaining a collection of Cox engines was a pretty neat hobby in itself. There will always be an elusive engine you'd like to have or a hard-to-find part needed to get one running again. There will always be a new plane in the back of your mind that you'd like to build for a particular engine in your stash.

Rest up and get well, Roddie.

Rest up and get well, Roddie.

Tee Bee- Platinum Member

- Posts : 764

Join date : 2011-08-25

Location : Angleton, TX

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Hi Roddie, sorry about your back problems. I too have suffered from severe back pain for 30 years. I can feel when it pops out and know to get horizontal fast on heat. Soma is a muscle relaxer that works with heat to stop pain and can move after a few days. If you try to work through the pain makes it much worse, 10 fold. If your doc won't write Soma find a new one.

crankbndr- Top Poster

- Posts : 3109

Join date : 2011-12-10

Location : Homestead FL

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Hi Roddie it looks like our generation is plagued with this back problem. Had one myself earlier this year when an abrupt move pinched a nerve between my vertebrae. Had a chiropractor work on it who said the muscles around the waist must be strengthened.

Get well soon. The TeeDee09 will also wait for you.

One way to strengthen my muscles is running after my RC planes landing not exactly where planned

Get well soon. The TeeDee09 will also wait for you.

One way to strengthen my muscles is running after my RC planes landing not exactly where planned

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Just screwing with you Roddie///// pay attention

From my MC accident I KNOW BACK PAIN

GIT off ass.... go put cuts on your finger and smell/ hear the damned Cox .09

I did it a lot of times recouping from a wheel chair or walker..... quite a few times with augmented dope n booze....

stop being a wussie... prime it in your hand, add 1.5 Vdc, and hold on tight

NO OH NO !!!

seriously !!!!

With a .09 that is very very bad advice.... I was just kidding!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

DO NOT fire a Cox .09 in your hand... it will eat your nose right off your ugly mug and you will be pist at me for life

From my MC accident I KNOW BACK PAIN

GIT off ass.... go put cuts on your finger and smell/ hear the damned Cox .09

I did it a lot of times recouping from a wheel chair or walker..... quite a few times with augmented dope n booze....

stop being a wussie... prime it in your hand, add 1.5 Vdc, and hold on tight

NO OH NO !!!

seriously !!!!

With a .09 that is very very bad advice.... I was just kidding!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

DO NOT fire a Cox .09 in your hand... it will eat your nose right off your ugly mug and you will be pist at me for life

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Page 4 of 8 •  1, 2, 3, 4, 5, 6, 7, 8

1, 2, 3, 4, 5, 6, 7, 8

Similar topics

Similar topics» Cox .020 PeeWee/TeeDee prop-screw

» Cox Tee Dee .049 Rebuild ...

» Ez Bee rebuild

» TD rebuild .049

» Engine rebuild help please

» Cox Tee Dee .049 Rebuild ...

» Ez Bee rebuild

» TD rebuild .049

» Engine rebuild help please

Page 4 of 8

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules