Log in

Search

Latest topics

» Promote the forum with flyers!by Admin Today at 1:35 am

» Roger Harris revisited

by rsv1cox Yesterday at 7:34 pm

» Engine choice

by GallopingGhostler Yesterday at 4:03 pm

» A Little 400 Mile Hop for Some Memory Lane Stuff, and to Hit a Swap Meet.

by roddie Yesterday at 4:01 pm

» My N-1R build log

by roddie Yesterday at 9:19 am

» Night flying at Walters RC park

by 1975 control line guy Sun Nov 24, 2024 7:29 pm

» Happy 77th birthday Andrew!

by GallopingGhostler Sun Nov 24, 2024 7:10 pm

» Cox films/videos...

by GallopingGhostler Sun Nov 24, 2024 7:07 pm

» Cox 020 PeeWee rebuild questions

by LooseSpinner99 Sun Nov 24, 2024 6:13 pm

» Did you spot the Cox engine in this NASA research video?

by balogh Sun Nov 24, 2024 5:08 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Sun Nov 24, 2024 2:54 pm

» Tee Dee .020 combat model

by 1/2A Nut Sun Nov 24, 2024 10:34 am

Cox Engine of The Month

Tee Dee .09 rebuild.. and run!

Page 6 of 8

Page 6 of 8 •  1, 2, 3, 4, 5, 6, 7, 8

1, 2, 3, 4, 5, 6, 7, 8

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

roddie wrote:MauricioB wrote:Roddie, I do not like the connecting rod being bent, there is a risk that something undesirable might happen and ruin the engine. Do you have a chance to straighten it out ... ... that works properly in your efforts?

I don't know if the con-rod is bent Mauricio.. but something seems strange to me. I've never had a problem fitting a cylinder/piston to a crankcase before this one. I'd also never removed and replaced a crankshaft before. I thought I might have done something wrong in the re-installation of the crankshaft.. but I was careful. Why else would the rod fit on the crankpin one-way and not the other? I wouldn't know how to check for a bent-rod.. unless it was really obvious.

Maybe I shouldn't try running it without some closer inspection?

Roddie, I can not see the picture from here but it seems to have a "big deviation" ... everything can happen, but if something is wrong and detected in time, then if the correct decision is made, the risks decrease and the result will be happy.

I would like you to enjoy the engine, but in your place, I would be concerned to make sure the connecting rod is properly centered.

I would not run it until I got the engine in shape

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

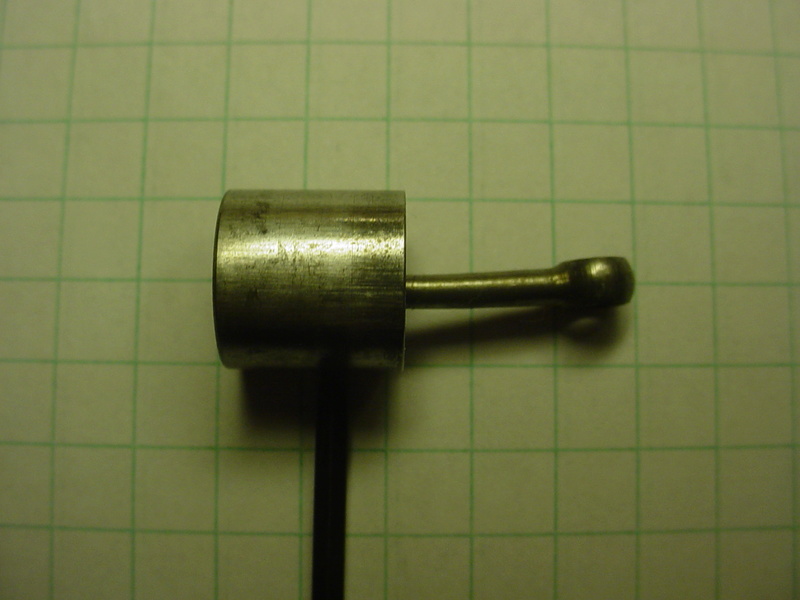

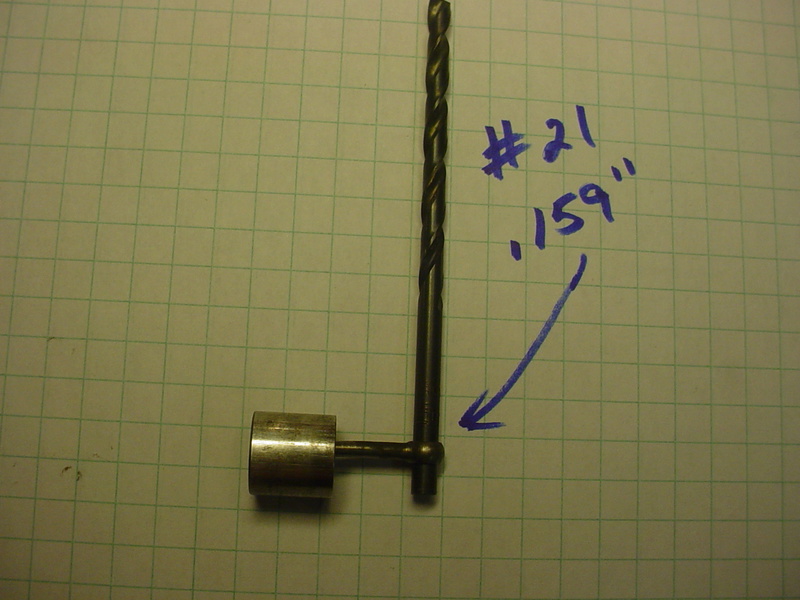

Since you can not for sure tell if it is bent just run it and see if there are any issues

with vibrations or low compression. These simple engines can still function due to

the ball socket design allowing some fudge factor. Do you own a reset tool? Is there slop

in the ball socket? Super fine #0000 steel wool will brighten up the aluminum parts when

dissembled if you don't have a buffing wheel and some rouge. Oil while lightly scrubbing

off the corrosion followed by a good rinse then hand polish with metal polish wadding to

a bright shine. Only if you wish of course it is time consuming.

with vibrations or low compression. These simple engines can still function due to

the ball socket design allowing some fudge factor. Do you own a reset tool? Is there slop

in the ball socket? Super fine #0000 steel wool will brighten up the aluminum parts when

dissembled if you don't have a buffing wheel and some rouge. Oil while lightly scrubbing

off the corrosion followed by a good rinse then hand polish with metal polish wadding to

a bright shine. Only if you wish of course it is time consuming.

1/2A Nut- Top Poster

- Posts : 3540

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

MauricioB wrote:

Roddie, I can not see the picture from here but it seems to have a "big deviation" ... everything can happen, but if something is wrong and detected in time, then if the correct decision is made, the risks decrease and the result will be happy.

I would like you to enjoy the engine, but in your place, I would be concerned to make sure the connecting rod is properly centered.

I would not run it until I got the engine in shape

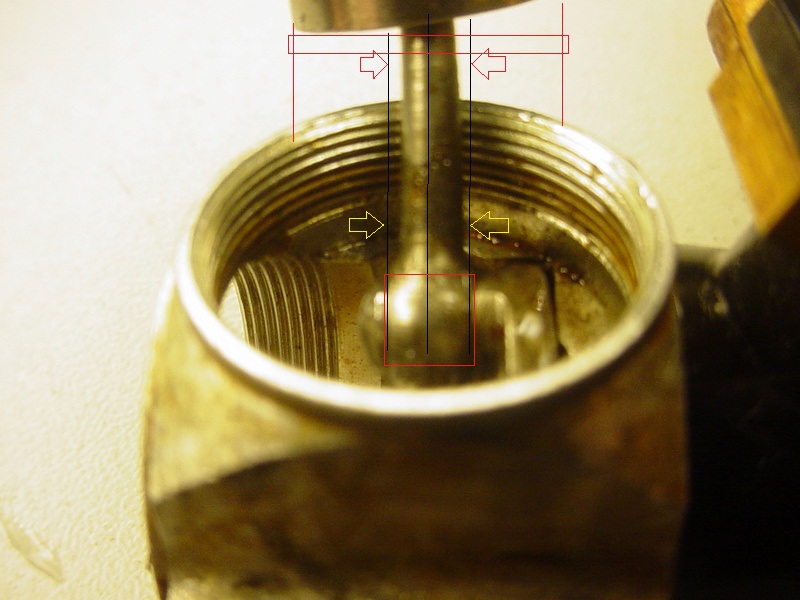

Mauricio, Thank you for your time editing my photo to show the bend. I disassembled the engine to inspect further..

Yes.. the rod is bent and no amount of polishing will straighten it...

Has anyone had any luck straightening a bent conrod held captive in the piston? Probably not..

The bend is such that it can be bowing upward with the pin-end laying flat.

... maybe.. just maybe..

... maybe.. just maybe..

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

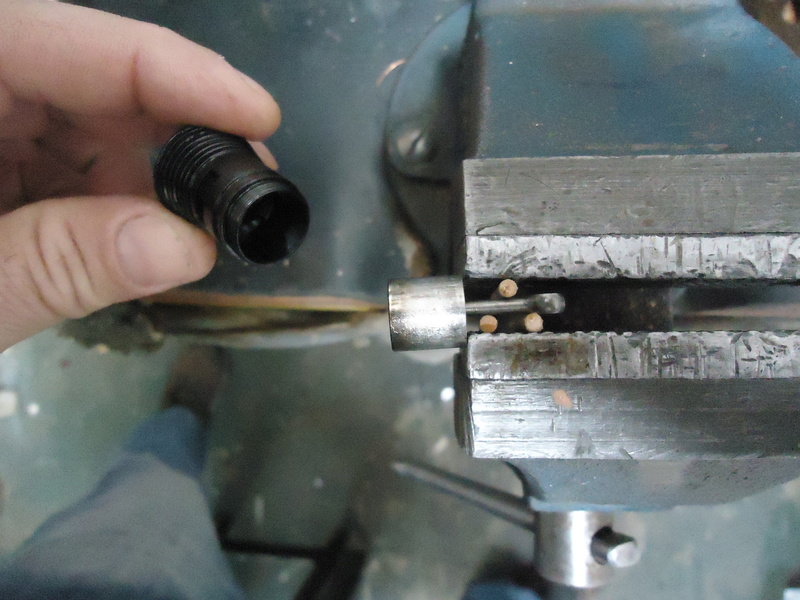

no go... pin-diameter too large. Jaws won't fit inside the piston-skirt. Smaller music-wire pins might work.. but the plier-jaws will likely grip the rod-eye before the pins can do their work. Maybe a single-pin might do it.. with the opposite jaw padded with tape? I'm probably wasting my time.. but right now I have plenty of it..

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

"Nothin but time on your hands!" Then don't rush this repair. I have not had any success in attempting to straighten con-rods. Maybe if you add heat ( flame or soldering iron tip) to the bend and take tiny taps to con rod on a anvil, it might help. Don't try and bend it cold or you'll end up with this:

Looking for pic....,up top now..

Last edited by Marleysky on Fri Oct 13, 2017 12:44 pm; edited 1 time in total (Reason for editing : Pic add)

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

roddie wrote:no go... pin-diameter too large. Jaws won't fit inside the piston-skirt. Smaller music-wire pins might work.. but the plier-jaws will likely grip the rod-eye before the pins can do their work. Maybe a single-pin might do it.. with the opposite jaw padded with tape? I'm probably wasting my time.. but right now I have plenty of it..

Roddie, do not remove the piston rod, the curve is below the piston skirt, therefore I would make a tightening as I show in the photos, as you thought, but with a bench morza, thing to go squeezing smoothly , and inspecting that it fits well.

Do not heat anything, just a small touch will surely suffice. I'd like to be there, just to get [bleep] up if something goes wrong! and to give us a hug if we succeed !!

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

I managed to tweak the rod straighter.

I gripped the rod up-high near the socket with taped-jaws on my needle-nose.. and pressed hard with my thumb a couple times on the pin-end.

It's not perfectly straight.. but I can now install the cylinder with the rod-eye on the crank-pin either way.. so I know that it's straighter than it was. As far as which way is best to orient the rod on the crankpin.. I have no clue. Either way; I'm sure there will be uneven wear over time.

I gripped the rod up-high near the socket with taped-jaws on my needle-nose.. and pressed hard with my thumb a couple times on the pin-end.

It's not perfectly straight.. but I can now install the cylinder with the rod-eye on the crank-pin either way.. so I know that it's straighter than it was. As far as which way is best to orient the rod on the crankpin.. I have no clue. Either way; I'm sure there will be uneven wear over time.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Well that's a bummer...

Just out of curiosity, have you used and electric starter on this engine?

I have straightened an aluminium rod once on an Enya engine that I got second hand. It worked well, so I guess you fix will too, just avoid bending it again.

As the next time it might simply break...

Just out of curiosity, have you used and electric starter on this engine?

I have straightened an aluminium rod once on an Enya engine that I got second hand. It worked well, so I guess you fix will too, just avoid bending it again.

As the next time it might simply break...

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

For future reference - these do come up on eBay - here's a right-priced one, ended at a reasoable price, vs the other one I saw on eBay for $40 with shipping

http://www.ebay.com/itm/new-cox-piston-cylinder-amp-rod-for-r-c-09-on-org-package-/201989545222?hash=item2f0783dd06%3Ag%3AxCwAAOSwdAxZbBNj&nma=true&si=ZRyJ%252F7Slyro3OtKfvtpVZyCM18A%253D&orig_cvip=true&rt=nc&_trksid=p2047675.l2557

http://www.ebay.com/itm/new-cox-piston-cylinder-amp-rod-for-r-c-09-on-org-package-/201989545222?hash=item2f0783dd06%3Ag%3AxCwAAOSwdAxZbBNj&nma=true&si=ZRyJ%252F7Slyro3OtKfvtpVZyCM18A%253D&orig_cvip=true&rt=nc&_trksid=p2047675.l2557

PeterJGregory- Gold Member

- Posts : 144

Join date : 2014-07-28

Age : 61

Location : Hudson Valley, New York

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Surfer_kris wrote:Well that's a bummer...

Just out of curiosity, have you used and electric starter on this engine?

I have straightened an aluminium rod once on an Enya engine that I got second hand. It worked well, so I guess you fix will too, just avoid bending it again.

As the next time it might simply break...

Kris, I got this engine second-hand earlier in the Summer. I do have a "homemade" elec. starter. Its' stock 05 "can-motor" doesn't have enough torque to bend a rod. It will barely crank my .049's. I only attempted to start this engine one time.. and couldn't get it to run. I was hand-propping. It did flood a few times.. but I don't think that I bent the rod. It doesn't matter now anyway.

There's an oil-hole in the bottom of the rod.. so I checked it to make sure it's clean/open.

I think it's gonna' be ok.. the bend is now barely noticeable when I rotate the rod.

I will try to run again.. and we'll see what happens.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

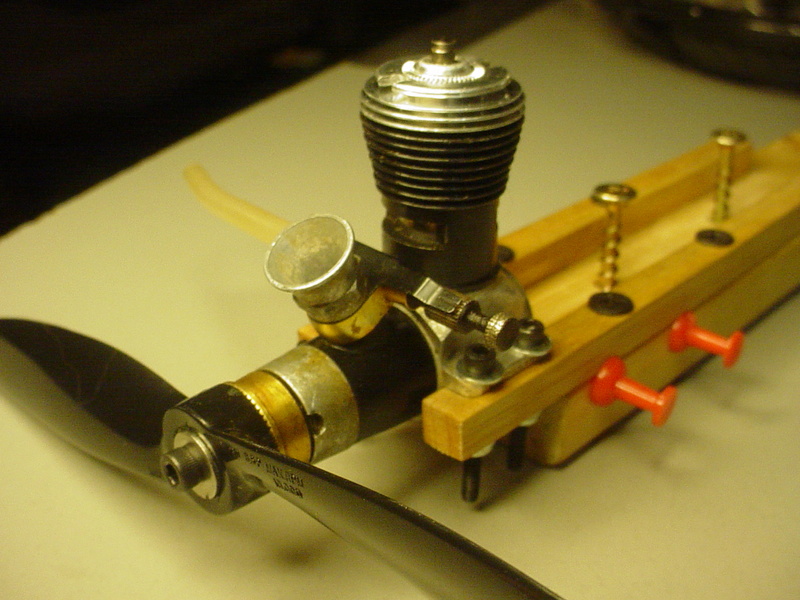

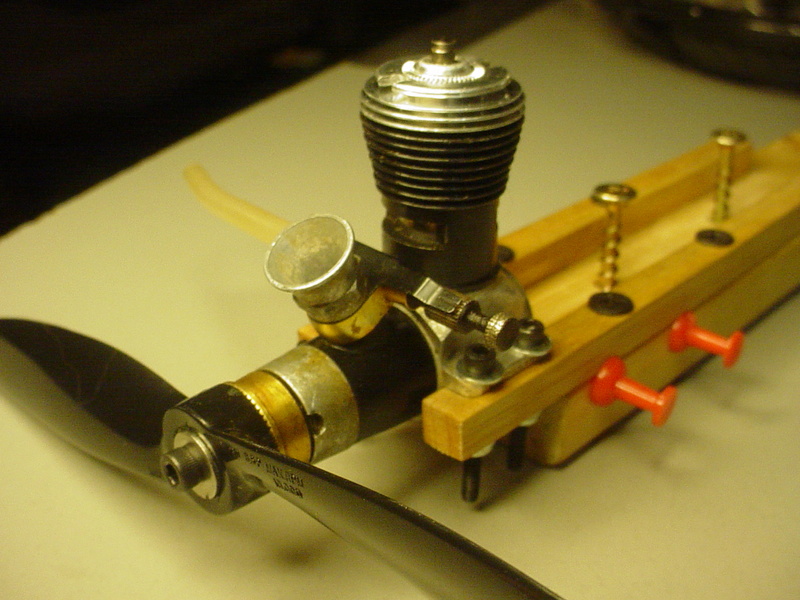

I reassembled the Tee Dee .09 tonight.. and plan to bench-run it tomorrow.

The mount has been upgraded with 4-40 machine-screws with lock-nuts. I'll be running the Cox 7 x 3.5 prop and Tee Dee H/C glow-head that Bob Dickerson generously mailed me from New York. I swapped-out the 6-32 slotted prop-screw and TD aluminum spinner for a 6-32 cap-screw and flat-washer. Work on this engine was made possible by Ron Cribbs' generous contribution of a pair of Cox .09 wrenches mailed-out to me from Oklahoma. Thanks again to Bob and Ron. Without their generous contributions; I wouldn't have been able to get this engine back to its' stock configuration.

I'm confident that the engine will run this time. I'm hoping that the slight bend in the piston-rod won't be a problem. The mounting is rigid.. so I don't know if I'll be able to detect any vibration. I plan to run the engine "rich" initially.. and see how it behaves during the transition to being leaned-out.

While reassembling the engine tonight; the cylinder screwed-easily into the case.. where it hadn't.. before I tweaked the rod, so I think that it's going to be ok.

The mount has been upgraded with 4-40 machine-screws with lock-nuts. I'll be running the Cox 7 x 3.5 prop and Tee Dee H/C glow-head that Bob Dickerson generously mailed me from New York. I swapped-out the 6-32 slotted prop-screw and TD aluminum spinner for a 6-32 cap-screw and flat-washer. Work on this engine was made possible by Ron Cribbs' generous contribution of a pair of Cox .09 wrenches mailed-out to me from Oklahoma. Thanks again to Bob and Ron. Without their generous contributions; I wouldn't have been able to get this engine back to its' stock configuration.

I'm confident that the engine will run this time. I'm hoping that the slight bend in the piston-rod won't be a problem. The mounting is rigid.. so I don't know if I'll be able to detect any vibration. I plan to run the engine "rich" initially.. and see how it behaves during the transition to being leaned-out.

While reassembling the engine tonight; the cylinder screwed-easily into the case.. where it hadn't.. before I tweaked the rod, so I think that it's going to be ok.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Good luck with the testing. I'm hoping to fly a TD .09 on Thurs if I can get some time in the morning. They generally run really well, for a Cox engine.

Tee Bee- Platinum Member

- Posts : 764

Join date : 2011-08-25

Location : Angleton, TX

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Have fun, Pal.

Bob

Bob

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Hope the run goes well Roddie keep us updated .

getback- Top Poster

Posts : 10443

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Thanks guys.. I'm getting ready to fit the fuel-tank to the mount again.. and will head George's (gcb) advice on lowering the tank. I'll also NOT connect the fuel-line until I can get the engine to start and run-off a priming.

It's a beautiful Fall day here in RI... Sunny/clear 68 degrees F.. with a light breeze.

It's a beautiful Fall day here in RI... Sunny/clear 68 degrees F.. with a light breeze.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Roddie.

I haven't tried running off a tank yet, but my recently gifted Tee Dee 09, once freed up, started and ran out the prime easily. One drip on the side of the piston and one or two (no more) down the chute. Mine started real easy. I'd say it's had next-to no use. Your efforts might inspire me to mount it up with a tank attached and see if it actually keeps running properly.

I haven't tried running off a tank yet, but my recently gifted Tee Dee 09, once freed up, started and ran out the prime easily. One drip on the side of the piston and one or two (no more) down the chute. Mine started real easy. I'd say it's had next-to no use. Your efforts might inspire me to mount it up with a tank attached and see if it actually keeps running properly.

Oldenginerod- Top Poster

- Posts : 4019

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

As one of the recent active TD09 users here I can confirm that if the fuel tank is positioned not quite far from, or too much below the carb level, the TD09 is a terrific runner that starts easily and reacts to NV settings very reliably.

With an R/C carb and plug type head it also idles well...stock heads do not support low idle run.

Good luck Roddie.. I cannot wait to see yours running and splashing hot castor..

With an R/C carb and plug type head it also idles well...stock heads do not support low idle run.

Good luck Roddie.. I cannot wait to see yours running and splashing hot castor..

balogh- Top Poster

Posts : 4960

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Roddie, this probably won't make you feel any better, but after many awesome flights this year, my TD .09 got a bent a rod today during a startup attempt. I was having trouble hand starting it, so against my best judgment I bumped it with my little Sullivan Hornet 1/2A starter. I guess it flooded because after attempting to bump it just one time, I could feel resistance while turning it by hand. I removed the cylinder and found the rod bent inside of the piston skirt. I don't think I'll be able to straighten it. It really bummed me out because I was really looking forward to flying my plane this morning. Now I guess I'll be on the near-impossible quest of finding a TD .09 piston/rod assembly. I have lots of experience running Medallion .09s with an occasional electric start and have never had a problem like this. I'm wondering now what the difference is between a Med and TD piston and if I can interchange them. A teardown and inspection coming soon. I hope your day went better than mine. No more electric starters on my Cox engines! I've said it before but now I mean it.

Tee Bee- Platinum Member

- Posts : 764

Join date : 2011-08-25

Location : Angleton, TX

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Tee Bee wrote:Roddie, this probably won't make you feel any better, but after many awesome flights this year, my TD .09 got a bent a rod today during a startup attempt. I was having trouble hand starting it, so against my best judgment I bumped it with my little Sullivan Hornet 1/2A starter. I guess it flooded because after attempting to bump it just one time, I could feel resistance while turning it by hand. I removed the cylinder and found the rod bent inside of the piston skirt. I don't think I'll be able to straighten it. It really bummed me out because I was really looking forward to flying my plane this morning. Now I guess I'll be on the near-impossible quest of finding a TD .09 piston/rod assembly. I have lots of experience running Medallion .09s with an occasional electric start and have never had a problem like this. I'm wondering now what the difference is between a Med and TD piston and if I can interchange them. A teardown and inspection coming soon. I hope your day went better than mine. No more electric starters on my Cox engines! I've said it before but now I mean it.

That SUCKS Troy.... Is it bent real bad? See below; the photo that Mauricio posted, on making a fixture with three offset pins in a vise. If the bend is below the piston-skirt, you might be able to straighten it.

I'm sorry man... I don't see why a Medallion piston wouldn't work. The SPI design I believe is in the cylinder's exhaust-port height.. and not in the length of the piston-skirt.

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

I haven't pulled the piston from the engine, just peered at it after unscrewing the cylinder but it appears to be bent inside the piston skirt best I can tell. Later on, I'll remove it and compare with the Med piston/rod. I have a few of those so fingers are crossed that it's compatible.

Tee Bee- Platinum Member

- Posts : 764

Join date : 2011-08-25

Location : Angleton, TX

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Tee Bee I once bent the rod in a 051 with electric starter the same way but then managed to straighten it with a narrow nosed flat plyer that went inside the piston skirt. It was not perfectly straight at the end but the piston is functional again. The 09 rod is thicker but you can also use a larger plyer on it.

While the smallest bend may cause the rod to buckle in operation, my piston is still alive and kicking.

While the smallest bend may cause the rod to buckle in operation, my piston is still alive and kicking.

balogh- Top Poster

Posts : 4960

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Now for the good news: I tore the TD down along with an old Medallion .09 and compared the pistons. They look the same to me. The funny thing is that 2 out of my 3 Medallions had SPI when I checked them. One did not. That's a subject for another thread.  Anyway, I installed the Med piston and it fits great with nice compression in the TD cylinder. The great flying Shark XV awaits the chance to redeem herself in the air. I may be able to straighten the bent rod but I doubt it and am not in the mood to try it today. On a side note, one of my fellow club flyers was ribbing me about bending my rod and not getting to fly today just before he bonked a landing with his electric plane and bent the motor shaft.

Anyway, I installed the Med piston and it fits great with nice compression in the TD cylinder. The great flying Shark XV awaits the chance to redeem herself in the air. I may be able to straighten the bent rod but I doubt it and am not in the mood to try it today. On a side note, one of my fellow club flyers was ribbing me about bending my rod and not getting to fly today just before he bonked a landing with his electric plane and bent the motor shaft.

How goes it, Roddie? Sorry to steal your thread.

Anyway, I installed the Med piston and it fits great with nice compression in the TD cylinder. The great flying Shark XV awaits the chance to redeem herself in the air. I may be able to straighten the bent rod but I doubt it and am not in the mood to try it today. On a side note, one of my fellow club flyers was ribbing me about bending my rod and not getting to fly today just before he bonked a landing with his electric plane and bent the motor shaft.

Anyway, I installed the Med piston and it fits great with nice compression in the TD cylinder. The great flying Shark XV awaits the chance to redeem herself in the air. I may be able to straighten the bent rod but I doubt it and am not in the mood to try it today. On a side note, one of my fellow club flyers was ribbing me about bending my rod and not getting to fly today just before he bonked a landing with his electric plane and bent the motor shaft.

How goes it, Roddie? Sorry to steal your thread.

Tee Bee- Platinum Member

- Posts : 764

Join date : 2011-08-25

Location : Angleton, TX

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

That is good news Troy. Strange regarding the SPI issue among the Medallions..  I was wondering if the Medallion pistons have an "oil-hole" in the crank-pin end? My Tee Dee's piston has one.. but I don't know if all the Cox .09's did. If your Tee Dee is all put back together.. maybe you could check one of your other two Medallions.. or maybe you noticed this when swapping the piston. I don't know.. and I don't want to worry you.. but you just can't assume these things with Cox engines. The Tee Dee runs at a higher rpm.. and if there's no oil-hole on that rod... well.. you wouldn't want to risk shearing the crank-pin.

I was wondering if the Medallion pistons have an "oil-hole" in the crank-pin end? My Tee Dee's piston has one.. but I don't know if all the Cox .09's did. If your Tee Dee is all put back together.. maybe you could check one of your other two Medallions.. or maybe you noticed this when swapping the piston. I don't know.. and I don't want to worry you.. but you just can't assume these things with Cox engines. The Tee Dee runs at a higher rpm.. and if there's no oil-hole on that rod... well.. you wouldn't want to risk shearing the crank-pin.

I haven't done squat with my engine.. but that shouldn't surprise anybody. Tomorrow's another day.. and the weather is forecast to be beautiful through next Tuesday.. so I'm psyched about that. We've still got tomatoes ripening on the vine! I still have some work to do, to prepare for my bench-run. I want to wire an alternate glow-clip.. and make sure that I can adjust the bench-tank to stay in varying positions.. in case there's issues drawing fuel.

What fuel-blend are you running in your engine?

I was wondering if the Medallion pistons have an "oil-hole" in the crank-pin end? My Tee Dee's piston has one.. but I don't know if all the Cox .09's did. If your Tee Dee is all put back together.. maybe you could check one of your other two Medallions.. or maybe you noticed this when swapping the piston. I don't know.. and I don't want to worry you.. but you just can't assume these things with Cox engines. The Tee Dee runs at a higher rpm.. and if there's no oil-hole on that rod... well.. you wouldn't want to risk shearing the crank-pin.

I was wondering if the Medallion pistons have an "oil-hole" in the crank-pin end? My Tee Dee's piston has one.. but I don't know if all the Cox .09's did. If your Tee Dee is all put back together.. maybe you could check one of your other two Medallions.. or maybe you noticed this when swapping the piston. I don't know.. and I don't want to worry you.. but you just can't assume these things with Cox engines. The Tee Dee runs at a higher rpm.. and if there's no oil-hole on that rod... well.. you wouldn't want to risk shearing the crank-pin.

I haven't done squat with my engine.. but that shouldn't surprise anybody. Tomorrow's another day.. and the weather is forecast to be beautiful through next Tuesday.. so I'm psyched about that. We've still got tomatoes ripening on the vine! I still have some work to do, to prepare for my bench-run. I want to wire an alternate glow-clip.. and make sure that I can adjust the bench-tank to stay in varying positions.. in case there's issues drawing fuel.

What fuel-blend are you running in your engine?

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

I checked and neither the TD or Med piston had an oil passage hole like yours. Maybe it's a year thing?

While I was at it, I went ahead and attempted to straighten the rod just as you did. With just a bit of pressure, it snapped in two. It probably already had a stress crack. It was worth a try, though. The engine has been remounted to the plane for another go next week when I get another day off. A perfectly good Medallion has been relegated to the spare parts box until I stumble onto another piston. As for fuel, I use Sig Champion 25. I buy it in quart bottles and add 1.5 fl.oz. extra Klotz castor oil. It has served me well for many years in all my Cox engines for sport flying and I don't think the rod failure had anything to do with the mix.

While I was at it, I went ahead and attempted to straighten the rod just as you did. With just a bit of pressure, it snapped in two. It probably already had a stress crack. It was worth a try, though. The engine has been remounted to the plane for another go next week when I get another day off. A perfectly good Medallion has been relegated to the spare parts box until I stumble onto another piston. As for fuel, I use Sig Champion 25. I buy it in quart bottles and add 1.5 fl.oz. extra Klotz castor oil. It has served me well for many years in all my Cox engines for sport flying and I don't think the rod failure had anything to do with the mix.

Tee Bee- Platinum Member

- Posts : 764

Join date : 2011-08-25

Location : Angleton, TX

Re: Tee Dee .09 rebuild.. and run!

Re: Tee Dee .09 rebuild.. and run!

Strange about the oil-hole in my rod..  I don't know much about these engines Troy. Maybe the previous-owner of mine drilled the oil-hole? That sucks that your rod broke. I guess I was lucky with straightening mine. That doesn't imply that my engine won't "grenade" when I try to run it though..

I don't know much about these engines Troy. Maybe the previous-owner of mine drilled the oil-hole? That sucks that your rod broke. I guess I was lucky with straightening mine. That doesn't imply that my engine won't "grenade" when I try to run it though..  I'm prepared for that. If it happens.. it happens.

I'm prepared for that. If it happens.. it happens.

I've run Sig Champion 25 and 35 exclusively in my Cox engines.. and it has served them well too. Sig used to sell "Bakers AA castor oil" as an additive.. but I don't see it listed anymore. I never added castor to the Sig fuel I ran in my Cox engines. Please let us know how your piston-swap works out.

I don't know much about these engines Troy. Maybe the previous-owner of mine drilled the oil-hole? That sucks that your rod broke. I guess I was lucky with straightening mine. That doesn't imply that my engine won't "grenade" when I try to run it though..

I don't know much about these engines Troy. Maybe the previous-owner of mine drilled the oil-hole? That sucks that your rod broke. I guess I was lucky with straightening mine. That doesn't imply that my engine won't "grenade" when I try to run it though.. I've run Sig Champion 25 and 35 exclusively in my Cox engines.. and it has served them well too. Sig used to sell "Bakers AA castor oil" as an additive.. but I don't see it listed anymore. I never added castor to the Sig fuel I ran in my Cox engines. Please let us know how your piston-swap works out.

Page 6 of 8 •  1, 2, 3, 4, 5, 6, 7, 8

1, 2, 3, 4, 5, 6, 7, 8

Similar topics

Similar topics» Cox .020 PeeWee/TeeDee prop-screw

» Cox Tee Dee .049 Rebuild ...

» Ez Bee rebuild

» TD rebuild .049

» Engine rebuild help please

» Cox Tee Dee .049 Rebuild ...

» Ez Bee rebuild

» TD rebuild .049

» Engine rebuild help please

Page 6 of 8

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules