Log in

Search

Latest topics

» Cox 020 PeeWee rebuild questions by balogh Today at 4:01 pm

» music vids.. some of your favorites

by Kim Today at 3:28 pm

» It's the X Wing that has a canard

by rsv1cox Today at 2:23 pm

» New Model Build

by bsadonkill Today at 1:19 pm

» My current avatar photo

by rsv1cox Today at 12:33 pm

» Kofuku Maru Fishing Boat Model

by Levent Suberk Today at 11:39 am

» Free Flight Radio Assist

by rdw777 Today at 11:24 am

» TEE DEE Having issues

by GallopingGhostler Yesterday at 11:38 pm

» Pathé Modeling Videos

by Levent Suberk Yesterday at 2:10 pm

» My latest doodle...

by layback209 Yesterday at 1:20 am

» Drones, pretty nifty...........

by rsv1cox Tue Nov 12, 2024 6:55 pm

» Project Cox .049 r/c & Citabrian Champion

by roddie Tue Nov 12, 2024 6:20 pm

Cox Engine of The Month

And she started up with a mighty roar....

Page 1 of 2

Page 1 of 2 • 1, 2

And she started up with a mighty roar....

And she started up with a mighty roar....

Got out a box of used OK Cubs and selected five to start up and evaluate.

An .09, .074, and three .049's.

The red tanked .049 was pretty well locked up, so I let it soak in penetrating oil and started with the .074. Not much prep except cleaning the needle valve. Filled the tank, primed and applied voltage. Using an electric starter she started up with a mighty roar.

But whoa, the vibration shook off the glow plug clip and she sputtered to a stall. I tightened the already tight mounting screws and tried again.

This time she was running on the tank and shaking violently. I shut it down and changed the prop from a 7/3 to a 5/3. Started it up with the same result. I have never seen an engine vibrate like this.

I removed the back plate and could see no reason for the shaking. The crankshaft is tight in the case and everything looks normal. I put it aside for further evaluation and started on the red tank .049 which hadn't loosened up. Because of the fuel tubing I did not want to apply heat.

Hoping that the penetrating oil had loosened up the head I used a 6 point #16 metric socket (perfect size) and started to remove the head when I heard the dreaded crack. The head remained on the cylinder and the cylinder separated from the case snapping the connecting rod off the piston. Darn. But I did discover that the connecting rod uses a wrist pin connection rather than the ball joint of the Cox engines.

Oh well, I have many OK Cub parts engines one will have to cough up a piston. So, my first experience with running these Cubs has not been a happy one. Hopefully the other three will fair better.

An .09, .074, and three .049's.

The red tanked .049 was pretty well locked up, so I let it soak in penetrating oil and started with the .074. Not much prep except cleaning the needle valve. Filled the tank, primed and applied voltage. Using an electric starter she started up with a mighty roar.

But whoa, the vibration shook off the glow plug clip and she sputtered to a stall. I tightened the already tight mounting screws and tried again.

This time she was running on the tank and shaking violently. I shut it down and changed the prop from a 7/3 to a 5/3. Started it up with the same result. I have never seen an engine vibrate like this.

I removed the back plate and could see no reason for the shaking. The crankshaft is tight in the case and everything looks normal. I put it aside for further evaluation and started on the red tank .049 which hadn't loosened up. Because of the fuel tubing I did not want to apply heat.

Hoping that the penetrating oil had loosened up the head I used a 6 point #16 metric socket (perfect size) and started to remove the head when I heard the dreaded crack. The head remained on the cylinder and the cylinder separated from the case snapping the connecting rod off the piston. Darn. But I did discover that the connecting rod uses a wrist pin connection rather than the ball joint of the Cox engines.

Oh well, I have many OK Cub parts engines one will have to cough up a piston. So, my first experience with running these Cubs has not been a happy one. Hopefully the other three will fair better.

rsv1cox- Top Poster

Posts : 11225

Join date : 2014-08-18

Location : West Virginia

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

Is the crank bent?

Is the spinner screw or spinner askew? Sorry about the busted rod.

Is the spinner screw or spinner askew? Sorry about the busted rod.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

Another thing while it's kinda a long shot, the crank could be ms-balanced or piston could be heavier than normal for that engine

also more RPM than usule can cause excessive vibration too but that probably isn't the case here. (Bandit)

also more RPM than usule can cause excessive vibration too but that probably isn't the case here. (Bandit)

TDbandit- Platinum Member

- Posts : 897

Join date : 2014-12-01

Age : 52

Location : Riverdale Georgia

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

That's strange , not the vibration , that you would try and start those with out cleaning first , Why ? that's just setting your self up for disappointment ( I Think ) Heck I have enough fun trying to get clean engines to run right  This engine I working up for Roger has been giving me a fit , but I did find out I needed a difft. tank set up cause it kept siphouring the fuel out the vent

This engine I working up for Roger has been giving me a fit , but I did find out I needed a difft. tank set up cause it kept siphouring the fuel out the vent

This engine I working up for Roger has been giving me a fit , but I did find out I needed a difft. tank set up cause it kept siphouring the fuel out the vent

This engine I working up for Roger has been giving me a fit , but I did find out I needed a difft. tank set up cause it kept siphouring the fuel out the vent

getback- Top Poster

Posts : 10431

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

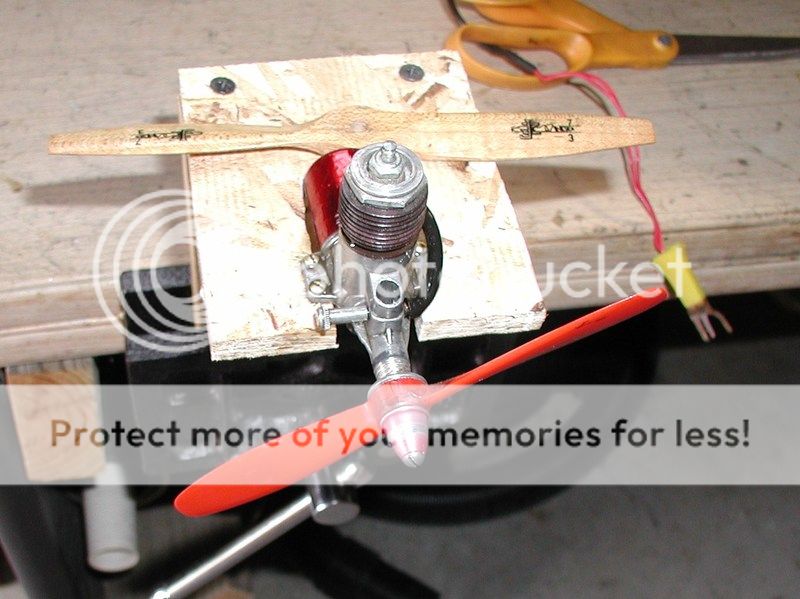

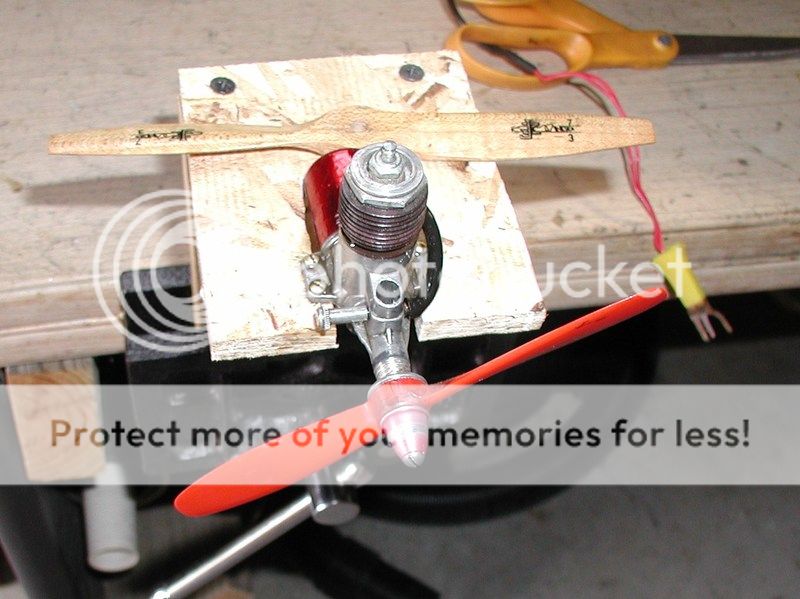

That sucks about the broken conn-rod Bob. As for the vibration.. I'd actually try putting two fender-washers under the drywall screw-heads on your mount. Is the butt-joint between the upright piece in the vice and the wafer-board nice and square? You could have some spring-boarding taking place.

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

Very observant roddie...They are dry wall screws and they do sit a little proud, I had actually thought of counter-sinking them but didn't. The engine sits tight in the mount and I had thought about relieving it a bit. But, it's more than that. Were it mounted in an less secure balsa airframe it would have shaken it apart. It's the only time I have been afraid of an engine.

It was running really lean on the first (or second) start so after it stopped on it's own (no way I was reaching in there to adjust the NV) I richened it out a couple of turns. It started right up again shaking just as bad but running better.

I had swapped the OK Cub spinner for a smaller Cox spinner as the original was to large for the machine screw to fit through it with enough turns to secure the prop to the engine. I do not like this arraingment, would rather see a threaded shaft and a securing nut.

I will find a better prop, check the crank, perhaps sand the rails so they don't fit as tight to the case and try it again.

Eric, the engine was already clean, no hint of caster anywhere and it turned freely. But yes, it's very unlike me not to disassemble and clean before running.

It was running really lean on the first (or second) start so after it stopped on it's own (no way I was reaching in there to adjust the NV) I richened it out a couple of turns. It started right up again shaking just as bad but running better.

I had swapped the OK Cub spinner for a smaller Cox spinner as the original was to large for the machine screw to fit through it with enough turns to secure the prop to the engine. I do not like this arraingment, would rather see a threaded shaft and a securing nut.

I will find a better prop, check the crank, perhaps sand the rails so they don't fit as tight to the case and try it again.

Eric, the engine was already clean, no hint of caster anywhere and it turned freely. But yes, it's very unlike me not to disassemble and clean before running.

rsv1cox- Top Poster

Posts : 11225

Join date : 2014-08-18

Location : West Virginia

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

To tell you the truth Bob.. that wafer-board could be amplifying normal vibration and resonating across the whole thin sheet. Hard-beams would be worth a try.. or cut the existing notch back closer to the joint, re-drill the lug-holes and trim-off the front-edge to length. I suspect the mount before the engine.

Last edited by roddie on Sun Jun 28, 2015 4:22 pm; edited 1 time in total

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

With your musical background roddie you probably understand harmonics better than I do. I will stiffen things up a bit and try again.

Bob

Bob

rsv1cox- Top Poster

Posts : 11225

Join date : 2014-08-18

Location : West Virginia

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

Another thing to try for a beam-mount.. is cut a short length of 1" x 2" stock.. about 6" long. Use a spade drill-bit or hole-saw that's closest to (without being under) the size of your engine's case diameter.. and bore a through-hole; close to one of the short edges and on-center. Cross-cut through the hole (you can gage the cut to suit the width) and you now have something more rigid to mount in a vise. You may have to hog out a little with a round rasp to clear case webbing.. but that's still a quickie job.

This Tee Dee fits real easily..

This Tee Dee fits real easily..

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

Hardwood, if you have it.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

Are you sure the shaker is an 074. The 074 had beam and radial mounts. The 099 had only beam mounts. The size will be cast on the bottom of the case. A 5" prop on that engine would be exciting. Is the prop centered over the spigot at the center of the thrust washer. Is the hole in the prop snug, not oversize? Is the prop balanced? The particle board cantilevered way over the rather narrow vertical board doesn't look too solid.

GWILLIEFOX- Rest In Peace

- Posts : 304

Join date : 2014-12-23

Age : 81

Location : Beaver Falls, PA

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

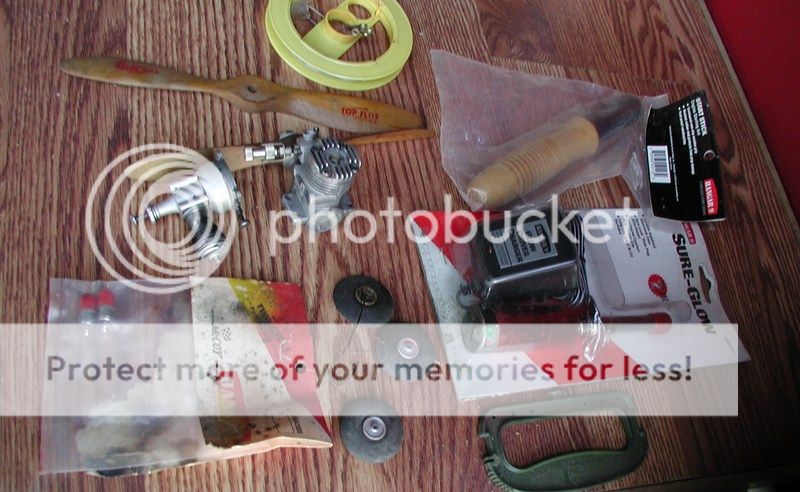

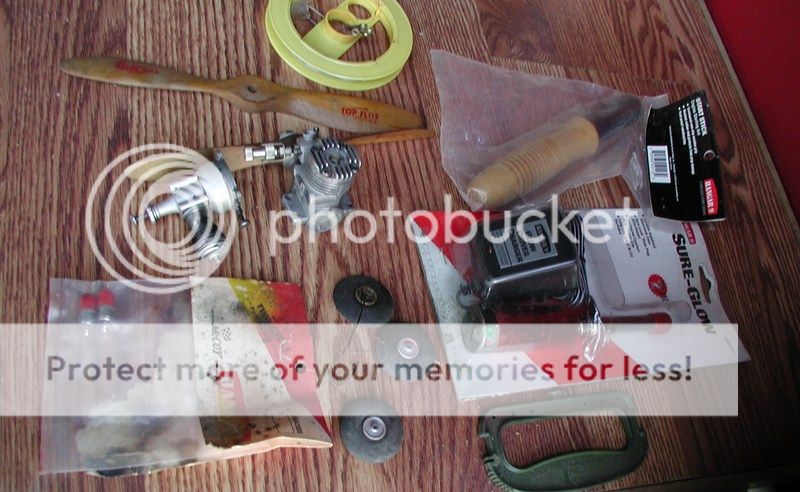

The top engine looks to be an 049A and the bottom right an 049A without its tank. These engines use the same piston/cylinder/rod as the rod you snapped.

GWILLIEFOX- Rest In Peace

- Posts : 304

Join date : 2014-12-23

Age : 81

Location : Beaver Falls, PA

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

Not sure what happened to my reply I sent before. Can't find it here.

Anyway, it was to say that I have had similar vibration problems with Cubs and they must be mounted very solid. Main problem I've had has been with the A model, with some flex in the plastic tank. I don't think I've had the same problem with my beam mount attempts.

To support what GWILLIEFOX said, the engine pictured is definitely an .099 and should be using at least a 7"X3" prop. I certainly wouldn't be using an old red KaySun that they supplied with these engines- dangerous. I had a "new" one break in half just by tightening the prop screw. Never got to try it.

Also, I would suggest that there is no .074 engine in the picture of 5 engines. The two larger engines look like an .099 and a .149. They used both radial and beam on the .149, but not on the .099. There was a square back .099 also.

Rod.

Anyway, it was to say that I have had similar vibration problems with Cubs and they must be mounted very solid. Main problem I've had has been with the A model, with some flex in the plastic tank. I don't think I've had the same problem with my beam mount attempts.

To support what GWILLIEFOX said, the engine pictured is definitely an .099 and should be using at least a 7"X3" prop. I certainly wouldn't be using an old red KaySun that they supplied with these engines- dangerous. I had a "new" one break in half just by tightening the prop screw. Never got to try it.

Also, I would suggest that there is no .074 engine in the picture of 5 engines. The two larger engines look like an .099 and a .149. They used both radial and beam on the .149, but not on the .099. There was a square back .099 also.

Rod.

Oldenginerod- Top Poster

- Posts : 4017

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

Busted!!! I knew I shouldn't try to get anything by you guys.

Not wanting to go back out to the garage I ID'ed the engines from the picture I posted above, coming close but no cigar. They are in fact:

One .149

One .099

Two .049A's (one missing the fuel tank) and

One .049 B - the one with the broken connecting rod.

I always thought it neat that they cast the name, displacement, and casting # into the crankcase. I'm building a new mount ala roddie, and finding a different prop. But the 7/3 prop I used is new and should have worked well, but I did not balance it prior to trying.

I have about a dozen more OK's NIB and hung on my display wall, I seriously doubt that they will all be as troublesome.

More later......

Bob

Not wanting to go back out to the garage I ID'ed the engines from the picture I posted above, coming close but no cigar. They are in fact:

One .149

One .099

Two .049A's (one missing the fuel tank) and

One .049 B - the one with the broken connecting rod.

I always thought it neat that they cast the name, displacement, and casting # into the crankcase. I'm building a new mount ala roddie, and finding a different prop. But the 7/3 prop I used is new and should have worked well, but I did not balance it prior to trying.

I have about a dozen more OK's NIB and hung on my display wall, I seriously doubt that they will all be as troublesome.

More later......

Bob

rsv1cox- Top Poster

Posts : 11225

Join date : 2014-08-18

Location : West Virginia

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

Good Morning Bob. Ron mentioned "hardwood" which is a better choice. If you use fir.. try to find long screws (3/4" if you have them) because they're going into end-grain. In either case; I would also pre-drill 4 pilot holes for the screws.. (you'll have to if you use hardwood.. ) Good luck!

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

Man, even with the new style mount this thing shakes like a leaf in a hurricane.....

Kidding..... Solid as a rock.

Solid as a rock.

Old prop, but solid on the peg, much better than the original 7/3.

I guess I will have to use this style mounting for the larger displacement engines. Thanks roddie for the guidance. I tried the spade bit route, but finally just cut it out on the band saw. I didn't have any hardwood but found some hard pine packing crate wood. Works fine.

This is apparently a new or newer engine, notice no wear on the piston or discoloration. I thought at first that the con rod was bent, but she’s running fine now. I did replace the neoprene tubing, the old stuff was deteriorating and did not provide a good seal around the spray bars nipple.

Thanks everybody for your help.

Bob

Kidding.....

Old prop, but solid on the peg, much better than the original 7/3.

I guess I will have to use this style mounting for the larger displacement engines. Thanks roddie for the guidance. I tried the spade bit route, but finally just cut it out on the band saw. I didn't have any hardwood but found some hard pine packing crate wood. Works fine.

This is apparently a new or newer engine, notice no wear on the piston or discoloration. I thought at first that the con rod was bent, but she’s running fine now. I did replace the neoprene tubing, the old stuff was deteriorating and did not provide a good seal around the spray bars nipple.

Thanks everybody for your help.

Bob

rsv1cox- Top Poster

Posts : 11225

Join date : 2014-08-18

Location : West Virginia

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

Hey Bob, I'm glad the mount worked out. I wish I had a band-saw. I suggested cross-drilling the relief for the case because most modelers would have a set of spade-bits around the shop. Maybe not a drill-press.. but any electric hand-drill would work fine. I actually like the radius that's formed on the inside of the beams. It leaves more "meat" for the wood-screws. The case-webbing clearance on some engines becomes a consideration though.

Everything I build at home here is done with minimalist tools. I'm dreaming of tools that I'd love to have in my shop.. I also try to make things/parts.. rather than buy them. I have a table-saw that was my Grandfather's. It's tiny (16" x 20" table) and weighs a small ton. The miter-gage is missing.. and the rip-fence needs to be set with a framing-square.. My drill-press is rudimentary/red-neck. It's a bench-top cast-iron oldie.. with a replacement motor that runs in the wrong direction.

I also try to make things/parts.. rather than buy them. I have a table-saw that was my Grandfather's. It's tiny (16" x 20" table) and weighs a small ton. The miter-gage is missing.. and the rip-fence needs to be set with a framing-square.. My drill-press is rudimentary/red-neck. It's a bench-top cast-iron oldie.. with a replacement motor that runs in the wrong direction.  I have the belt twisted into a figure-eight between the pulleys. I not only have balsa dust.. but I have rubber dust too! It's sad really..

I have the belt twisted into a figure-eight between the pulleys. I not only have balsa dust.. but I have rubber dust too! It's sad really..

Everything I build at home here is done with minimalist tools. I'm dreaming of tools that I'd love to have in my shop..

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

Good thread, Bob. This is the first one of my catching up on the forums.

Everything I was itching to jump in and say was covered. But I would re-iterate, stay away from putting mounting screws into the end grain of any kind of wood. Underestimating the strength of materials required to hold these babies down reliably was one of my early dangerous mistakes. When mounting engines, always err on the side of overkill.

Rusty

Everything I was itching to jump in and say was covered. But I would re-iterate, stay away from putting mounting screws into the end grain of any kind of wood. Underestimating the strength of materials required to hold these babies down reliably was one of my early dangerous mistakes. When mounting engines, always err on the side of overkill.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

Thanks guys,

roddie, my band saw is a $40 yard sale cheapy, but for the type of work that I do it's adequate. Save for a metal working lathe I have about every power/hand tool imaginable. Nothing expensive, Craftsman mostly but I have had years to accumulate.

I have four major workshops, loft, gun room, two and four car garages and that can be a problem as the tool I need at the moment always seems to be someplace else. Some days I spend more time travelling between shops than I spend on the project.

It's apparent now that the wood I used and the design of the mount contributed greatly to the vibration I experienced with this engine. I usually use 1X4 or 1X2 pine to mount and test my Cox reed engines, but now moving to beam mounts I will have to come up with a better system. Mounting an engine in an airplane is a different story. I usually use machine screws and locking nuts epoxied in behind the firewall. Never lost an engine yet on a test stand or in an airplane....other than in a crash that is.

I will clean up this engine, preserve with after run oil and put it away until I can find a suitable airplane to mount it on. Moving on to one of the other Cubs today.

roddie, my band saw is a $40 yard sale cheapy, but for the type of work that I do it's adequate. Save for a metal working lathe I have about every power/hand tool imaginable. Nothing expensive, Craftsman mostly but I have had years to accumulate.

I have four major workshops, loft, gun room, two and four car garages and that can be a problem as the tool I need at the moment always seems to be someplace else. Some days I spend more time travelling between shops than I spend on the project.

It's apparent now that the wood I used and the design of the mount contributed greatly to the vibration I experienced with this engine. I usually use 1X4 or 1X2 pine to mount and test my Cox reed engines, but now moving to beam mounts I will have to come up with a better system. Mounting an engine in an airplane is a different story. I usually use machine screws and locking nuts epoxied in behind the firewall. Never lost an engine yet on a test stand or in an airplane....other than in a crash that is.

I will clean up this engine, preserve with after run oil and put it away until I can find a suitable airplane to mount it on. Moving on to one of the other Cubs today.

rsv1cox- Top Poster

Posts : 11225

Join date : 2014-08-18

Location : West Virginia

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

glad you got her straightened out Bob, you can use hard wood and cross cut with a dado blade or make small cuts as deep as you need to go for the beam mount , and clap to the bench or table is what i use, for the larger engines 10,15,29 ect. I use my mount as seen in some pics I have posted ( sq. bed post works well ) nothing worst than a running loose engine wide open most time

getback- Top Poster

Posts : 10431

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

My understanding is a 099 with beam mount only is a 1949, after that they had beam and radial. This is the same engine I have on a ringmaster and need a crankcase for. My main bearing got taken out by a out of balance spinner.

chevyiron420- Gold Member

- Posts : 251

Join date : 2015-01-28

Age : 66

Location : Barney Georgia

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

I tipped the .099 on it's side and ran the fuel tank dry. Set it aside to clean and preserve.

And started on the .149.

Pre-run check included removing the needle valve, squirting some Remoil spray through the spray bar and cleaning with a tiny bristle brush then blowing it out with compressed air. Engine turns freely, glow plug is good and the cylinder/head are tight with compression.

Gassed up with 25% Cox fuel primed and flipped to start. Got a weak response. Primed again and opened the needle valve a turn. Repeat this many times, needle from full in to full out a turn at a time. Went through the procedure again this time using the electric starter. Single burps then nothing. Lot's of spark, lots of compression, lots of fuel. I even primed the fuel line. It would burn the prime then nothing. In the picture it looks like the fuel tank is above the engine, but it's actually level with the venturi. I know many are saying “I could have that engine running in five minutes” maybe so. But this is the first engine that I haven’t been able to start that did not have an obvious problem. But hints are invited.

Set it side for a later look and started on the red fuel tanked .049. Checking it over pre run I noticed that the cylinder was slightly loose on the crankcase. I finger tightened it only to discover that the crank case threads are stripped. Oh well, I found the piston for the metal red tanked .049

My first operational impressions of these Herkimer's is not good. It seems they are made from sub prime materials and have design faults. The design of the head precludes the use of a four way wrench inviting the use of needle nosed pliers as evidenced by the damaged glow plugs on these examples. Also, I do not like the use of a machine screw and boss on the thrust washer for the propeller even though the Cox .049's use the same design.

Thankfully I got this box of stuff in yesterday, another "make an offer" bid that was accepted. It contained an early Thimble Drome stamped .049 with an actually good glow plug and an Enya 19. Two of my favorite engines.

I have got to clean that Cox up and run it just to clear my head of these Cubs.. Thank goodness for COX engines.

And started on the .149.

Pre-run check included removing the needle valve, squirting some Remoil spray through the spray bar and cleaning with a tiny bristle brush then blowing it out with compressed air. Engine turns freely, glow plug is good and the cylinder/head are tight with compression.

Gassed up with 25% Cox fuel primed and flipped to start. Got a weak response. Primed again and opened the needle valve a turn. Repeat this many times, needle from full in to full out a turn at a time. Went through the procedure again this time using the electric starter. Single burps then nothing. Lot's of spark, lots of compression, lots of fuel. I even primed the fuel line. It would burn the prime then nothing. In the picture it looks like the fuel tank is above the engine, but it's actually level with the venturi. I know many are saying “I could have that engine running in five minutes” maybe so. But this is the first engine that I haven’t been able to start that did not have an obvious problem. But hints are invited.

Set it side for a later look and started on the red fuel tanked .049. Checking it over pre run I noticed that the cylinder was slightly loose on the crankcase. I finger tightened it only to discover that the crank case threads are stripped. Oh well, I found the piston for the metal red tanked .049

My first operational impressions of these Herkimer's is not good. It seems they are made from sub prime materials and have design faults. The design of the head precludes the use of a four way wrench inviting the use of needle nosed pliers as evidenced by the damaged glow plugs on these examples. Also, I do not like the use of a machine screw and boss on the thrust washer for the propeller even though the Cox .049's use the same design.

Thankfully I got this box of stuff in yesterday, another "make an offer" bid that was accepted. It contained an early Thimble Drome stamped .049 with an actually good glow plug and an Enya 19. Two of my favorite engines.

I have got to clean that Cox up and run it just to clear my head of these Cubs.. Thank goodness for COX engines.

rsv1cox- Top Poster

Posts : 11225

Join date : 2014-08-18

Location : West Virginia

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

Bob, I wouldn't concern yourself with tank height. Make it higher than centerline so gravity will continuously feed. I keep pinchers with me to stop fuel flow. Your fuel line however is extremely long. and I personally would have the tank mounted the other way directly behind the engine on top of the block. I would also slip fuel tubing over the needle valve side and allow it to but up against the case. Those needle valves are absolute crap. The fuel tubing your using which appears to be the medium generally fits the spraybar nipple poorly. If that's a Perfect tank, the tubing is usually undersized and the medium tubing fits it very poorly. What I'm saying is you essentially have 3 air leaks, the tank, the spraybar nipple and the needle valve side due to poor threads and fit of the assembly onto the spraybar. Combine these with the very long fuel tubing and your really taxiing the fuel draw.

I personally would refrain from the use of electic starters. The rods are too weak in these engines and your essentially grinding the drive washer into the case not to mention pushing the crank pin into the backplate. Use clear fuel tubing and pull a choke through manually by covering the venturi with a finger. If fuel isn't coming down the line continue opening the needle until it does. When you say Cox 25% fuel, are you referring to nitro content? That's a bit much for the .149 and I would use caution especially with that 8x6 on there. The crank could break. The engine is much happier with a 7x6 and it lessens the strain if that's the only fuel you have. I made mention of using higher nitro but that's with the smaller mills. I wouldn't feed that old timer anything more than 15% nitro . I hope some of this helps, I really do like the .149 but I highly recommend wearing hearing protection. Ken

I personally would refrain from the use of electic starters. The rods are too weak in these engines and your essentially grinding the drive washer into the case not to mention pushing the crank pin into the backplate. Use clear fuel tubing and pull a choke through manually by covering the venturi with a finger. If fuel isn't coming down the line continue opening the needle until it does. When you say Cox 25% fuel, are you referring to nitro content? That's a bit much for the .149 and I would use caution especially with that 8x6 on there. The crank could break. The engine is much happier with a 7x6 and it lessens the strain if that's the only fuel you have. I made mention of using higher nitro but that's with the smaller mills. I wouldn't feed that old timer anything more than 15% nitro . I hope some of this helps, I really do like the .149 but I highly recommend wearing hearing protection. Ken

Ken Cook- Top Poster

- Posts : 5634

Join date : 2012-03-27

Location : pennsylvania

Re: And she started up with a mighty roar....

Re: And she started up with a mighty roar....

Thanks for the pointers Ken. My SOP is to thumb the venturi and pull the fuel through but I must admit with my eyes and poor lighting I couldn't tell for sure if it was happening.

The tubing connection to the spray bars nipple is tight, but the little Perfect tank not so. I have trouble finding the clear tubing in the smaller sizes. I have some 20% nitro, will try that. I can move the tank closer, perhaps beveling the back of the mount so the triangle tanks feed is positioned to pick up the fuel. I had filled the tank to overflowing before attempting to start the Cub.

I did disassemble the Cox .049. It was clean but refused to move the crank, so I heated it to no help. I finally removed the tank and sprayed it with RemOil and let it sit. Still, with a prop it wouldn't budge. As the prop drive washer already had been damaged I got it to move by using pliers gently applied with a leather buffer. I have new thrust washers and will replace it.

The gum wasn't so much on the cylinder/piston as inside the forward crankcase. I took a lot of Remoil and patience to finally fully free it. Works fine now I'm sure but I have yet to start it. Comforting knowing that it will run.

Always wanted one of these, got it with the stuff pictured above. I didn't know if the nicad would accept a charge, but it did. This one has a good/bad plug meter.

Oh yes, and Rod check that red prop at the hub just to the left of the screwdriver handle. It's cracked right through. I didn't notice it until I cleaned all the gunk from it. Wiil have to magic marker it X and use for display only.

The tubing connection to the spray bars nipple is tight, but the little Perfect tank not so. I have trouble finding the clear tubing in the smaller sizes. I have some 20% nitro, will try that. I can move the tank closer, perhaps beveling the back of the mount so the triangle tanks feed is positioned to pick up the fuel. I had filled the tank to overflowing before attempting to start the Cub.

I did disassemble the Cox .049. It was clean but refused to move the crank, so I heated it to no help. I finally removed the tank and sprayed it with RemOil and let it sit. Still, with a prop it wouldn't budge. As the prop drive washer already had been damaged I got it to move by using pliers gently applied with a leather buffer. I have new thrust washers and will replace it.

The gum wasn't so much on the cylinder/piston as inside the forward crankcase. I took a lot of Remoil and patience to finally fully free it. Works fine now I'm sure but I have yet to start it. Comforting knowing that it will run.

Always wanted one of these, got it with the stuff pictured above. I didn't know if the nicad would accept a charge, but it did. This one has a good/bad plug meter.

Oh yes, and Rod check that red prop at the hub just to the left of the screwdriver handle. It's cracked right through. I didn't notice it until I cleaned all the gunk from it. Wiil have to magic marker it X and use for display only.

rsv1cox- Top Poster

Posts : 11225

Join date : 2014-08-18

Location : West Virginia

Page 1 of 2 • 1, 2

Similar topics

Similar topics» AMF Wen-Mac parts or help

» The Mighty Thor Slag engine

» Where I started

» [solved]Is cox still in business? I cant find anything on their site!

» help! it wont start

» The Mighty Thor Slag engine

» Where I started

» [solved]Is cox still in business? I cant find anything on their site!

» help! it wont start

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules