Log in

Search

Latest topics

» Tribute Shoestring buildby 1/2A Nut Today at 2:24 pm

» Cox 020 PeeWee rebuild questions

by TD ABUSER Today at 2:17 pm

» Landing-gear tips

by 1975 control line guy Today at 9:28 am

» My current avatar photo

by GallopingGhostler Yesterday at 7:39 pm

» It's the X Wing that has a canard

by rdw777 Yesterday at 6:58 pm

» music vids.. some of your favorites

by Kim Thu Nov 14, 2024 3:28 pm

» New Model Build

by bsadonkill Thu Nov 14, 2024 1:19 pm

» Kofuku Maru Fishing Boat Model

by Levent Suberk Thu Nov 14, 2024 11:39 am

» Free Flight Radio Assist

by rdw777 Thu Nov 14, 2024 11:24 am

» TEE DEE Having issues

by GallopingGhostler Wed Nov 13, 2024 11:38 pm

» Pathé Modeling Videos

by Levent Suberk Wed Nov 13, 2024 2:10 pm

» My latest doodle...

by layback209 Wed Nov 13, 2024 1:20 am

Cox Engine of The Month

Prop hub nut

Page 1 of 1

jbanes1961- Bronze Member

- Posts : 47

Join date : 2019-10-29

Age : 63

Location : NW Indiana...30min south of Chicago

Re: Prop hub nut

Re: Prop hub nut

I'm assuming this is the prop hub nut. I'm also assuming that this needs to be removed to service engine. The problem I'm seeing here, is when u try to loosen the nut, it just spins the engine. Am I missing something here?

jbanes1961- Bronze Member

- Posts : 47

Join date : 2019-10-29

Age : 63

Location : NW Indiana...30min south of Chicago

Re: Prop hub nut

Re: Prop hub nut

Yep! Gotta remove the backplate (or tank and backplate if so equipped) first. Second, remove the piston and cylinder assembly (don't ask me how I know this one). From there, there are a couple of options. Option one is to pad the jaws of a vice, re-install the propeller screw, then insert into the vice and slowly and carefully tighten up the vise until the crankshaft pushes free from teh drive washer. Option two is to simply put the propeller screw back in, then lay the engine pointing up on a solid flat surface and strike the propeller screw carefully, and the drive washer will again seperate from the crankshaft. I personally prefer and do the first one in a vice, but have done it both ways without any damage. There are a few threads here explaining this if you want to search 'how to remove drive washer'. Hope this helps.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Prop hub nut

Re: Prop hub nut

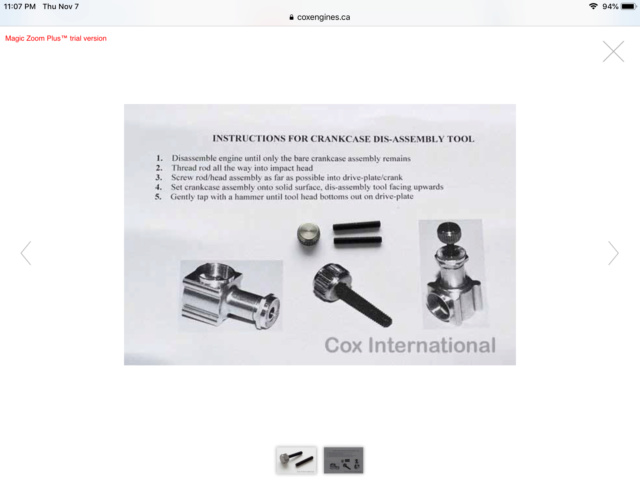

Forgot to add that a coupel of our sponsors here sell tools specific to doing this particular task, as well as put it back on.

Speaking of putting it back on. Very easy as well. Just insert crankshaft into the crankcase, line up the splines of the drive washer and crankshaft up (you can feel it when it is in place), then using your propeller screw with a propeller on it, put it in and start tightning it up. It will naturally follow its way back onto the crankshaft.

Speaking of putting it back on. Very easy as well. Just insert crankshaft into the crankcase, line up the splines of the drive washer and crankshaft up (you can feel it when it is in place), then using your propeller screw with a propeller on it, put it in and start tightning it up. It will naturally follow its way back onto the crankshaft.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: Prop hub nut

Re: Prop hub nut

Very good...one last question, can i safely assume that the hub will never just fall off, when u dont want it to? Sounds kinda like a press fit deal...nothing is wrong with engine, I saw in the 50 yr old instructions that u were supposed to check hub for tightness every time before u fly it. Which got me to looking at the set up and seeing possible problems

jbanes1961- Bronze Member

- Posts : 47

Join date : 2019-10-29

Age : 63

Location : NW Indiana...30min south of Chicago

Re: Prop hub nut

Re: Prop hub nut

Sir,

What you are showing us on your engine is the prop drive plate, not a prop hub nut. Some drive plates are hex-shaped, and some are round. They press onto the crank.

The prop hub nut is the black barrel that is being used to re-assemble the drive plate onto the crankshaft on the above image. They are usually used with a spinner. They can work loose through use, so it is prudent to check the prop hub nut to ensure the prop doesn't come flying off the crank.

Go to Cox International and look for the spinners. Each one shows the prop hub nut. The spinner slips over the prop hub nut and snaps into the groove around the prop hub nut's mid-section.

Not every engine will.use a prop hub nut. Some people will use a 5-40 screw and washer to retain the prop. Another spinner (the aluminum.one) is drilled through with a screw securing the spinner onto the prop. Again, look at Cox International's site for that example. Even prop screws can work loose. Check your prop mounting often. Props taste awful.

Enjoy the hobby! Have you got a plane picked yet?

Jim in MS

What you are showing us on your engine is the prop drive plate, not a prop hub nut. Some drive plates are hex-shaped, and some are round. They press onto the crank.

The prop hub nut is the black barrel that is being used to re-assemble the drive plate onto the crankshaft on the above image. They are usually used with a spinner. They can work loose through use, so it is prudent to check the prop hub nut to ensure the prop doesn't come flying off the crank.

Go to Cox International and look for the spinners. Each one shows the prop hub nut. The spinner slips over the prop hub nut and snaps into the groove around the prop hub nut's mid-section.

Not every engine will.use a prop hub nut. Some people will use a 5-40 screw and washer to retain the prop. Another spinner (the aluminum.one) is drilled through with a screw securing the spinner onto the prop. Again, look at Cox International's site for that example. Even prop screws can work loose. Check your prop mounting often. Props taste awful.

Enjoy the hobby! Have you got a plane picked yet?

Jim in MS

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Prop hub nut

Re: Prop hub nut

Yes I have a plane picked out. P40 Warhawk. Soon as I find one in my price range

jbanes1961- Bronze Member

- Posts : 47

Join date : 2019-10-29

Age : 63

Location : NW Indiana...30min south of Chicago

Re: Prop hub nut

Re: Prop hub nut

Plastic , balsa , RTF , build ur own , scratch builds ?? and RC / CL ?jbanes1961 wrote:Yes I have a plane picked out. P40 Warhawk. Soon as I find one in my price range

getback- Top Poster

Posts : 10432

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Prop hub nut

Re: Prop hub nut

Probably start with plastic CL

jbanes1961- Bronze Member

- Posts : 47

Join date : 2019-10-29

Age : 63

Location : NW Indiana...30min south of Chicago

Re: Prop hub nut

Re: Prop hub nut

Take Jim up on that J Balsa flys better and is easier to repair , cost less than Plastic .. The P40 is pretty sought after and can demand some $$$ for fun !!

getback- Top Poster

Posts : 10432

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Prop hub nut

Re: Prop hub nut

Here you go if you must .... https://www.ebay.com/sch/i.html?_from=R40&_trksid=p2380057.m570.l1313.TR3.TRC1.A0.H0.Xcox+p40.TRS0&_nkw=cox+p40&_sacat=0

getback- Top Poster

Posts : 10432

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Prop hub nut

Re: Prop hub nut

I just built this Carl Goldberg 1/2A P-40 in about a week off and on. I traced all the part from the originals, still leaving me a complete kit. Nice easy build just have to add the paint and decals. Bought the decals from Brodak, looks just like the original ones. JBanes you can order the complete kit from Brodak also.

Canso07.

Canso07.

Canso07- Gold Member

- Posts : 104

Join date : 2016-12-12

Age : 43

Location : Calgary, Canada

Canso07- Gold Member

- Posts : 104

Join date : 2016-12-12

Age : 43

Location : Calgary, Canada

Re: Prop hub nut

Re: Prop hub nut

thanks for all the info....

jbanes1961- Bronze Member

- Posts : 47

Join date : 2019-10-29

Age : 63

Location : NW Indiana...30min south of Chicago

Re: Prop hub nut

Re: Prop hub nut

Canso07,

Any chance you scanned the parts into full size PDFs?

I'd like a copy.

I usually scan the plans/build sheet in overlapping sections, and then use stitching software to digitally assemble the prints. From there, print to PDF as different size Iimages to create a full size PDF (just a little math to check percentage scale-up or down).

The CG P-40 begs to be wrapped around a jumping bean wing!

Any chance you scanned the parts into full size PDFs?

I'd like a copy.

I usually scan the plans/build sheet in overlapping sections, and then use stitching software to digitally assemble the prints. From there, print to PDF as different size Iimages to create a full size PDF (just a little math to check percentage scale-up or down).

The CG P-40 begs to be wrapped around a jumping bean wing!

Last edited by 944_Jim on Sun Nov 10, 2019 12:40 pm; edited 1 time in total

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Prop hub nut

Re: Prop hub nut

no, i didn't scan them, don't have the scanner and i"m not very computer saavy

jbanes1961- Bronze Member

- Posts : 47

Join date : 2019-10-29

Age : 63

Location : NW Indiana...30min south of Chicago

Re: Prop hub nut

Re: Prop hub nut

JBanes,

That was for Canso. If he digitized the patterns, they can be used to scratchbuild.one fairly quickly.

If you wanted to buy a kit like his, then here you go. Brodak reproduces the very same kit with their name on it:

https://brodak.com/catalog/product/view/id/3045/category/900/

You still need to supply your finishing supplies.

That was for Canso. If he digitized the patterns, they can be used to scratchbuild.one fairly quickly.

If you wanted to buy a kit like his, then here you go. Brodak reproduces the very same kit with their name on it:

https://brodak.com/catalog/product/view/id/3045/category/900/

You still need to supply your finishing supplies.

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Prop hub nut

Re: Prop hub nut

Ok, thanks Jim, I check it out

jbanes1961- Bronze Member

- Posts : 47

Join date : 2019-10-29

Age : 63

Location : NW Indiana...30min south of Chicago

Re: Prop hub nut

Re: Prop hub nut

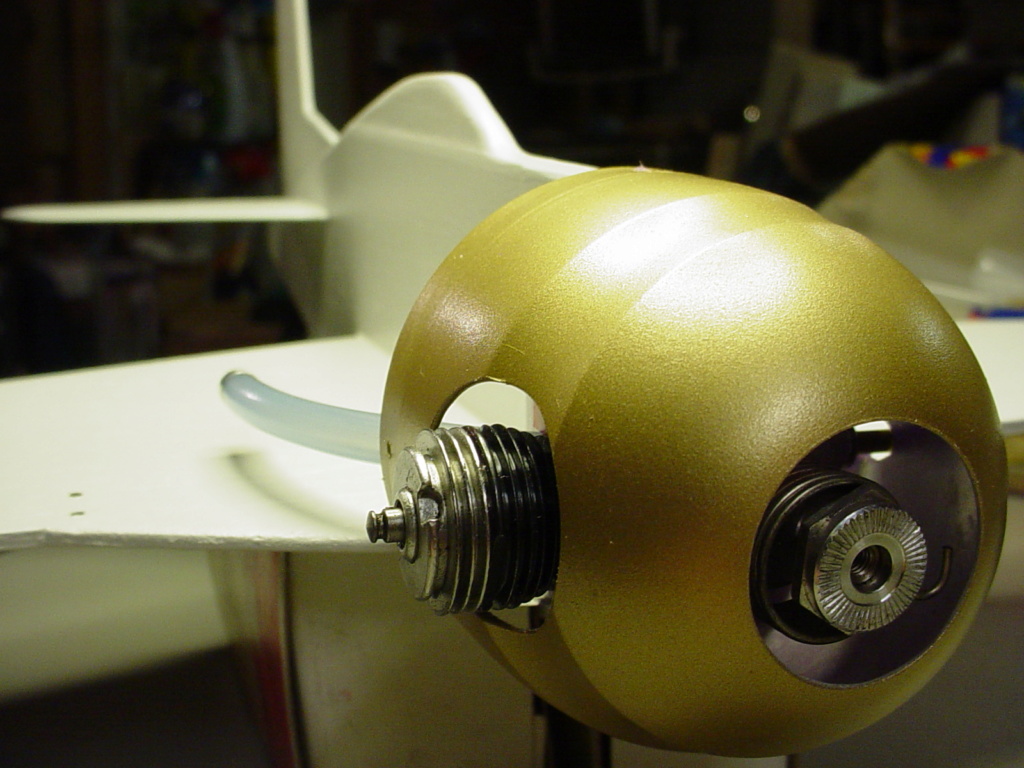

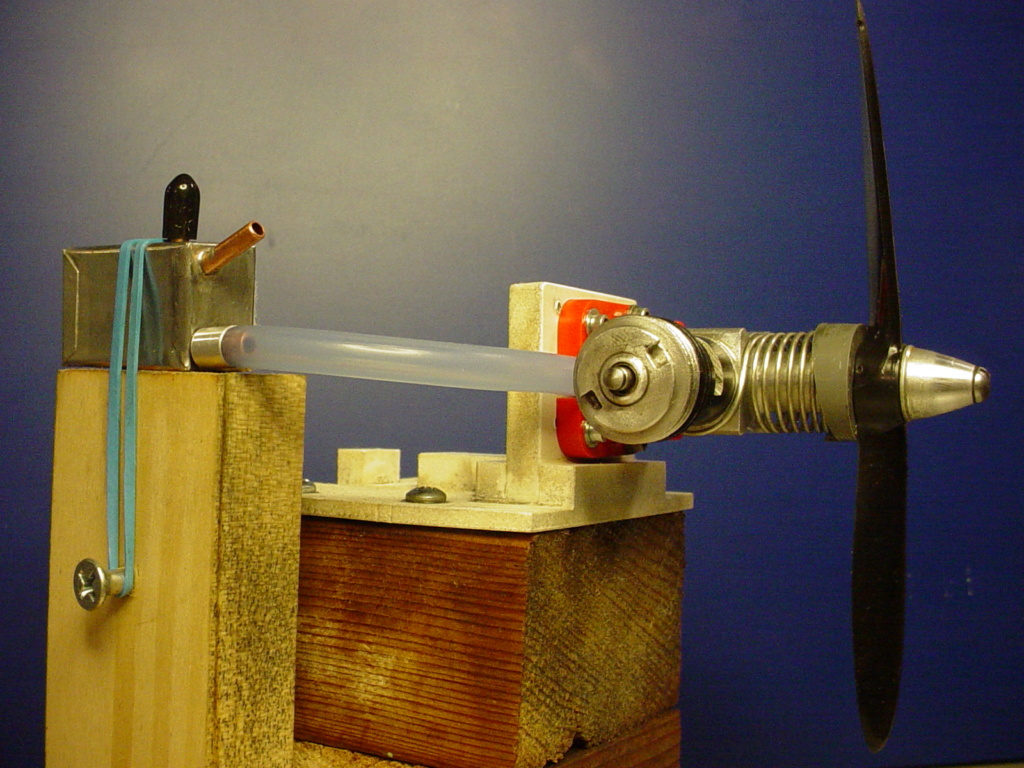

Hello jbanes, I like the photo. I LOVE Cox engines! I see that you now have some info. to work with. The Cox .049/.051 engines (all) utilize a female size 5-40 machine-screw thread for mounting a propeller or drive to the crankshaft.

Your photo shows a nice brass prop. drive-plate. You're correct in that it's splined and a press-fit onto the output-end of the crankshaft. For "Pusher" applications; a thrust-washer (currently available part) can be placed between the drive-plate and the front of the case. This lessens the wear on the front of the case from friction. Installing a thrust-washer is also a smart idea if an electric-starter is ever used on the engine.

I use an electric starter.. and usually apply a drop of oil to the drive-plate/case junction. The Cox Tee Dee .049/.051 aluminum spinner works well for using an electric starter. It's a cone with a through-hole for a longer (approx. 1"L.) 5-40 prop-screw.

Here are two .049 engines with the Tee Dee-style spinner installed (Tee Dee .049 on top/Medallion .049 below)

A 1"L. black-oxide 5-40 cap-screw on this one... (I got mine through Fastenal Co.)

The spinner's taper ranges approximately .300 to .400" or 7 to 10mm diameter. My homemade electric starter uses 5/16" ID (.312") rubber fuel-tubing to engage this type of spinner.

You may want to use a "starter-spring" (currently available part). The hex/cam type is designed for the engine in your photo.. because of its' hex drive-plate. The cam-style spring assy. is Cox's 2nd generation design and does NOT hook-around the propeller blade root, like the 1st generation does. It was designed to work with the hex drive-plate by "keying-into it".. with a plastic cam piece which the spring automatically engages when the propeller is wound backward.

Here's a photo of the cam-style assy. that I used on a model..

note the hex-shaped drive-plate (like yours..)

... installed on the engine..

The spring-coil is of a larger diameter on this (cam-style) type.. in order to fit-over the larger hex drive-plate. This design also induces a slight "drag" on the crankshaft.. because of the "ratchet" effect that allows automatic-operation when winding backwards for starting the engine. It's handy on an engine that has a cowling.

The 1st generation (1-piece) spring however is a referred to as a "zero-drag" type.. that hooks around the propeller and has a smaller diameter to fit-over the smaller/round drive-plate. It must be manually hooked-over the propeller each time an attempt is made to start the engine. It then retracts back out of the way when released.

Re: Prop hub nut

Re: Prop hub nut

Roddie,

I love your tanks...mine look like they are hand-formed with a brick!

I love your tanks...mine look like they are hand-formed with a brick!

Last edited by 944_Jim on Mon Nov 11, 2019 7:16 am; edited 1 time in total

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Prop hub nut

Re: Prop hub nut

Most members in this forum are master craftsmen and working like Cox engineers. Here is a thread to make masterful metal fuel tanks:

https://www.coxengineforum.com/t9455-wedge-tank-build

https://www.coxengineforum.com/t9455-wedge-tank-build

Levent Suberk- Diamond Member

- Posts : 2263

Join date : 2017-12-24

Location : Türkiye

Re: Prop hub nut

Re: Prop hub nut

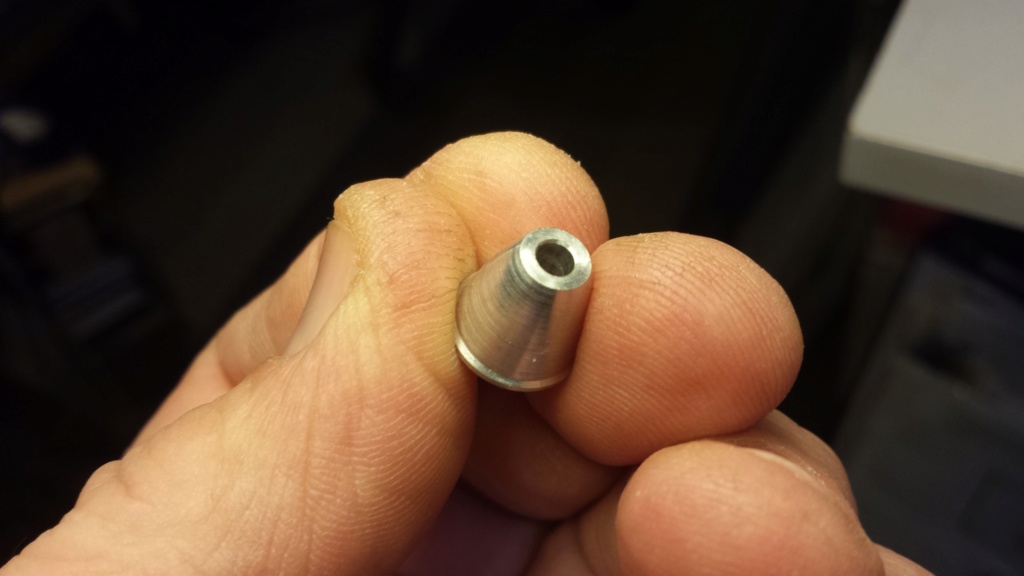

Cox did make prop hub nuts for some of their engines/models that used spinners. I'll site some examples of my own.. which fit the .049 engine's 5-40 threaded prop-screw (actually a stub-screw)

This more common type came stock with my PT-19 Flight Trainer..

Those are 5-40 stub-screws that thread-into those hub-nuts.. through the propeller hub-hole and into the crankshaft. Notice the "slot" across the face of the hub nut. The edge of a Cox .049 engine wrench fits into that slot for installing/removing the propeller.

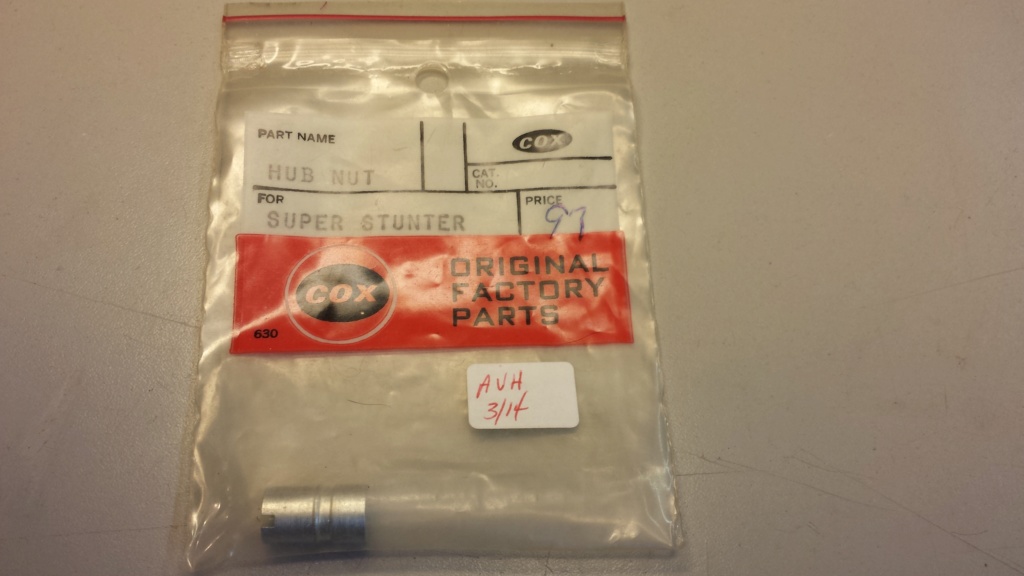

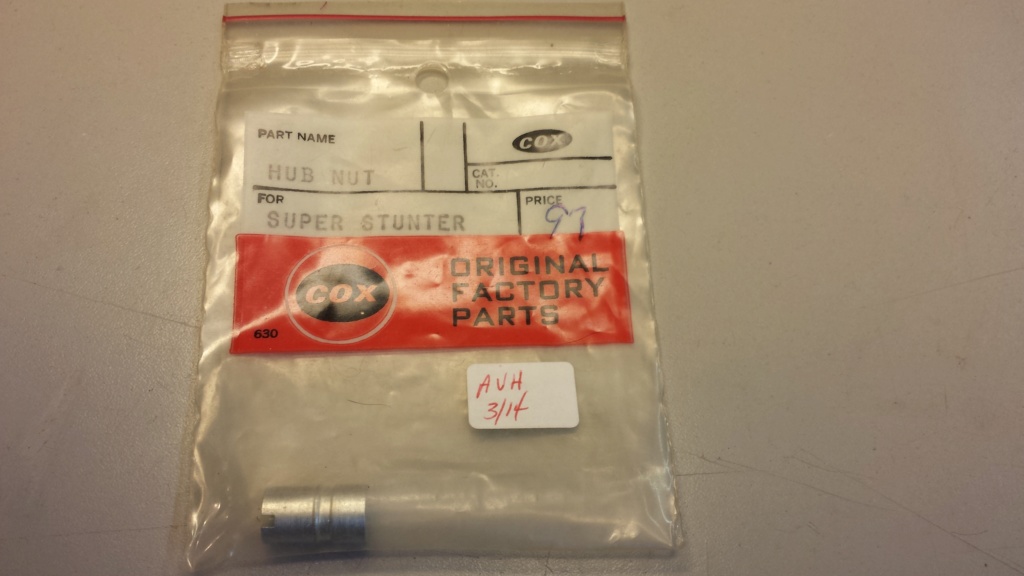

I sourced a couple of NOS Cox "Super Stunter" hub nuts from a local hobby shop that closed a few years ago.

They're solid and heavy. Much heavier than the common type shown above. They're actually a nice flight-trimming tool for that certain model that needs just a tad more nose-weight..

This more common type came stock with my PT-19 Flight Trainer..

Those are 5-40 stub-screws that thread-into those hub-nuts.. through the propeller hub-hole and into the crankshaft. Notice the "slot" across the face of the hub nut. The edge of a Cox .049 engine wrench fits into that slot for installing/removing the propeller.

I sourced a couple of NOS Cox "Super Stunter" hub nuts from a local hobby shop that closed a few years ago.

They're solid and heavy. Much heavier than the common type shown above. They're actually a nice flight-trimming tool for that certain model that needs just a tad more nose-weight..

Re: Prop hub nut

Re: Prop hub nut

Thanks Roddy, that's what I saw in the original instructions for my engine..

jbanes1961- Bronze Member

- Posts : 47

Join date : 2019-10-29

Age : 63

Location : NW Indiana...30min south of Chicago

Similar topics

Similar topics» [The Traveling Prop] Who wants to be the one to send the prop overseas?

» Cox Prop Rod

» Cox prop rod

» Prop rod....

» cox 4x2.5 prop?

» Cox Prop Rod

» Cox prop rod

» Prop rod....

» cox 4x2.5 prop?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules