Log in

Search

Latest topics

» Landing-gear tipsby roddie Today at 4:22 pm

» It's the X Wing that has a canard

by rdw777 Today at 3:21 pm

» My current avatar photo

by GallopingGhostler Yesterday at 7:02 pm

» Cox 020 PeeWee rebuild questions

by LooseSpinner99 Yesterday at 4:38 pm

» music vids.. some of your favorites

by Kim Yesterday at 3:28 pm

» New Model Build

by bsadonkill Yesterday at 1:19 pm

» Kofuku Maru Fishing Boat Model

by Levent Suberk Yesterday at 11:39 am

» Free Flight Radio Assist

by rdw777 Yesterday at 11:24 am

» TEE DEE Having issues

by GallopingGhostler Wed Nov 13, 2024 11:38 pm

» Pathé Modeling Videos

by Levent Suberk Wed Nov 13, 2024 2:10 pm

» My latest doodle...

by layback209 Wed Nov 13, 2024 1:20 am

» Drones, pretty nifty...........

by rsv1cox Tue Nov 12, 2024 6:55 pm

Cox Engine of The Month

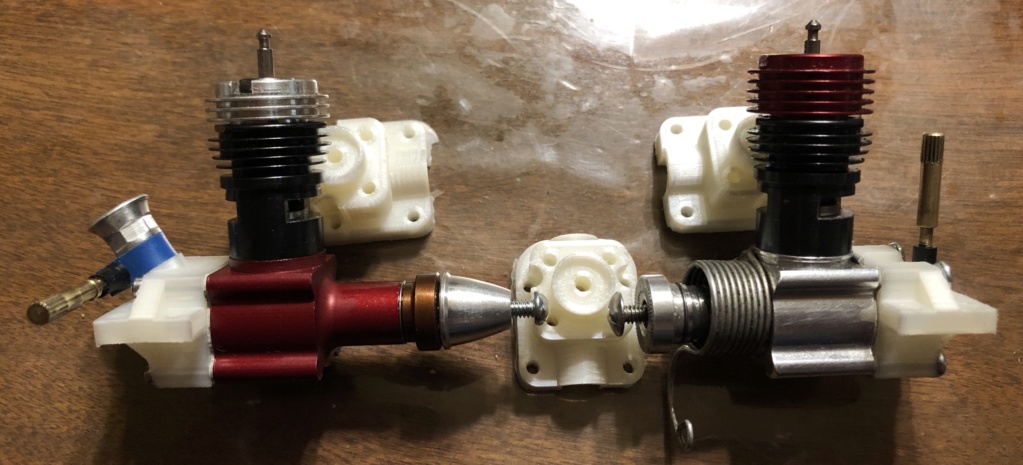

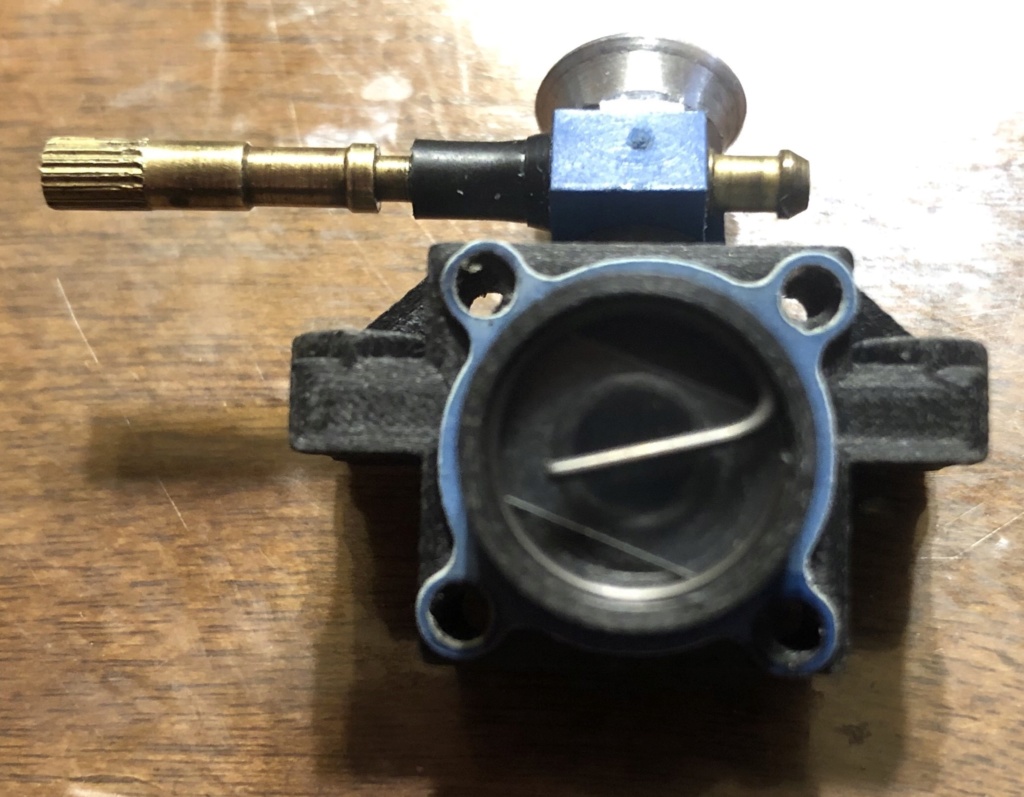

3D printed beam mount .049 backplate

Page 4 of 5

Page 4 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

Need some more screws so ordered 20 of these type would be

nice if they were half threaded smooth through the backplate.

#2-56 - Stainless Steel Socket Head Caps Screws SAE Coarse Allen / Hex

https://www.ebay.com/itm/2-56-Stainless-Steel-Socket-Head-Caps-Screws-SAE-Coarse-Allen-Hex-18-8-A2/123516129112?ssPageName=STRK%3AMEBIDX%3AIT&var=424067098058&_trksid=p2060353.m2749.l2649

Funfly RC with a .049 can produce enough thrust for a solid 4ch plane if the size is right.

nice if they were half threaded smooth through the backplate.

#2-56 - Stainless Steel Socket Head Caps Screws SAE Coarse Allen / Hex

https://www.ebay.com/itm/2-56-Stainless-Steel-Socket-Head-Caps-Screws-SAE-Coarse-Allen-Hex-18-8-A2/123516129112?ssPageName=STRK%3AMEBIDX%3AIT&var=424067098058&_trksid=p2060353.m2749.l2649

Funfly RC with a .049 can produce enough thrust for a solid 4ch plane if the size is right.

1/2A Nut- Top Poster

- Posts : 3534

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

getback- Top Poster

Posts : 10431

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

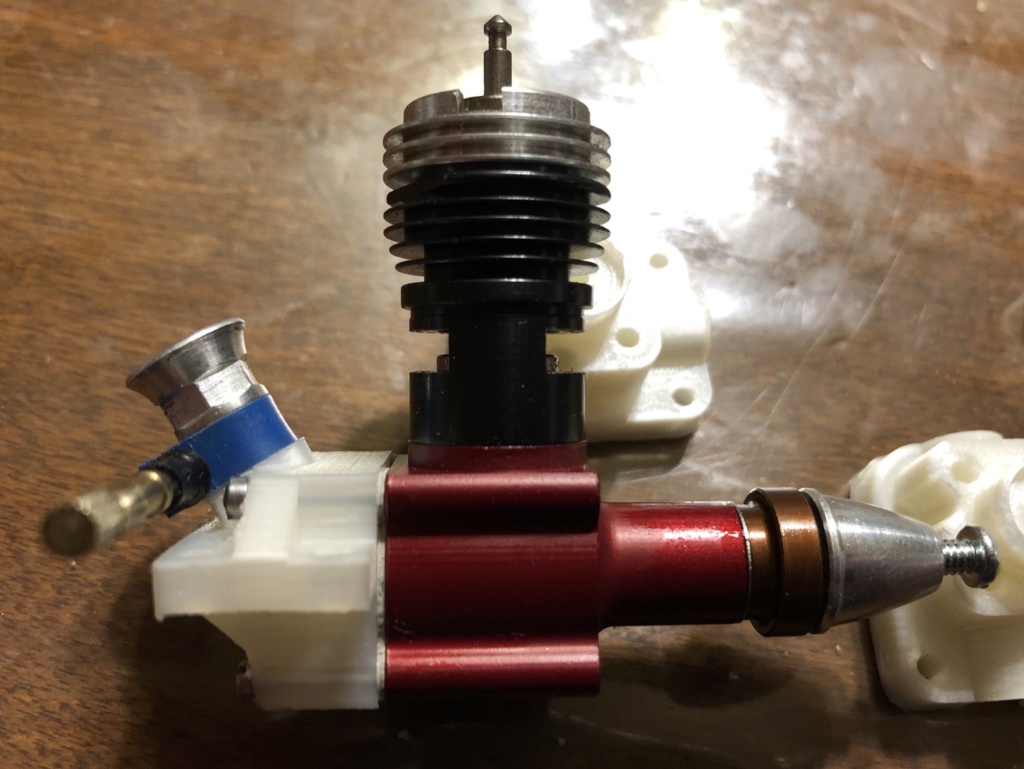

Welp the socket head bolts showed up so I can assemble the next version.

So much faster to install the screws compared to the flat heads making for

easy non slip removal / maintenance much quicker and it looks good.

With a handle type wrench it is easy to gauge the torque applied.

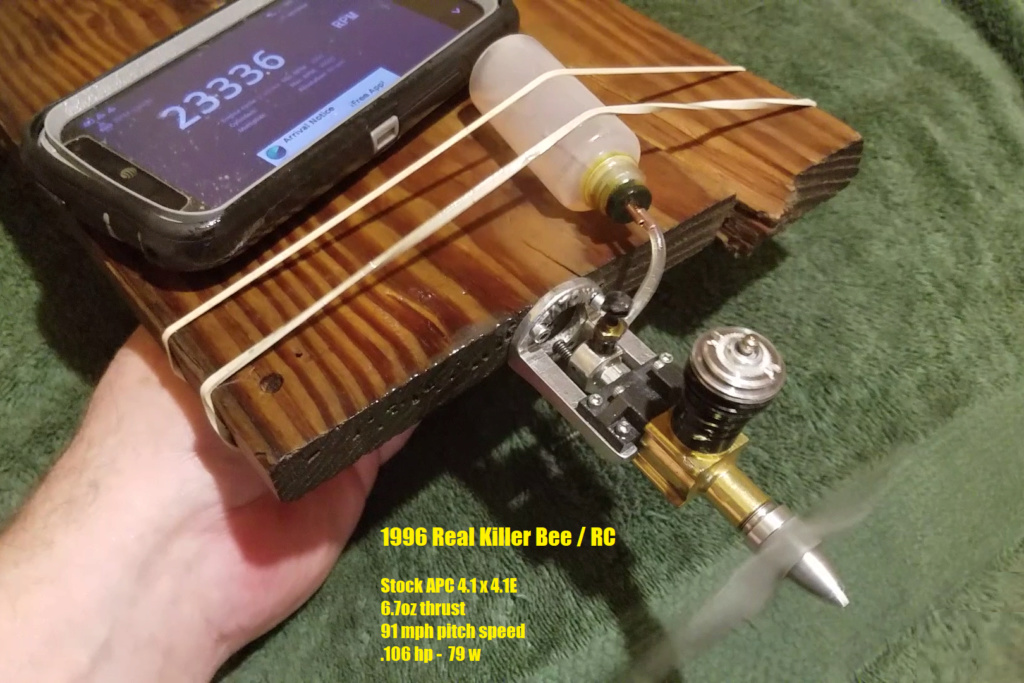

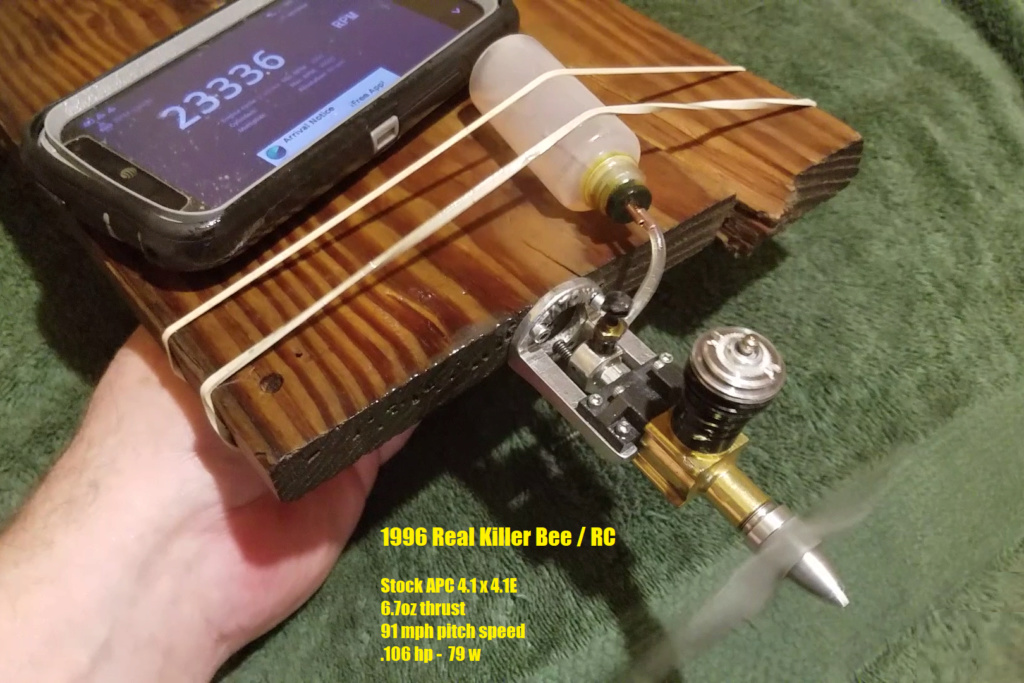

1996 Real Killer Bee .049 RC

So much faster to install the screws compared to the flat heads making for

easy non slip removal / maintenance much quicker and it looks good.

With a handle type wrench it is easy to gauge the torque applied.

1996 Real Killer Bee .049 RC

1/2A Nut- Top Poster

- Posts : 3534

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

Looks fantastic, Brad...I guess it may take an engine cowl with the carb fully embedded in the plane's nose behind the firewall, and only the NV sticking out , so that the CG should stay aft. I mean having the rear mounted carb completely exposed in front of the firewall would pull the CG too much to the front?

balogh- Top Poster

Posts : 4957

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

Thank you Andras

The RX battery will be enough to correct the CG should you use a cowled engine.

The wonderful transition of it all is turning a reed engine into a RC engine.

Throttle rings is one way of course, this version allows a muffler or header etc.

If used with a profile plane the plane itself has it's incorporated beam mounts.

Could have a access hatch for a scale planes to set the NV / hide the engine.

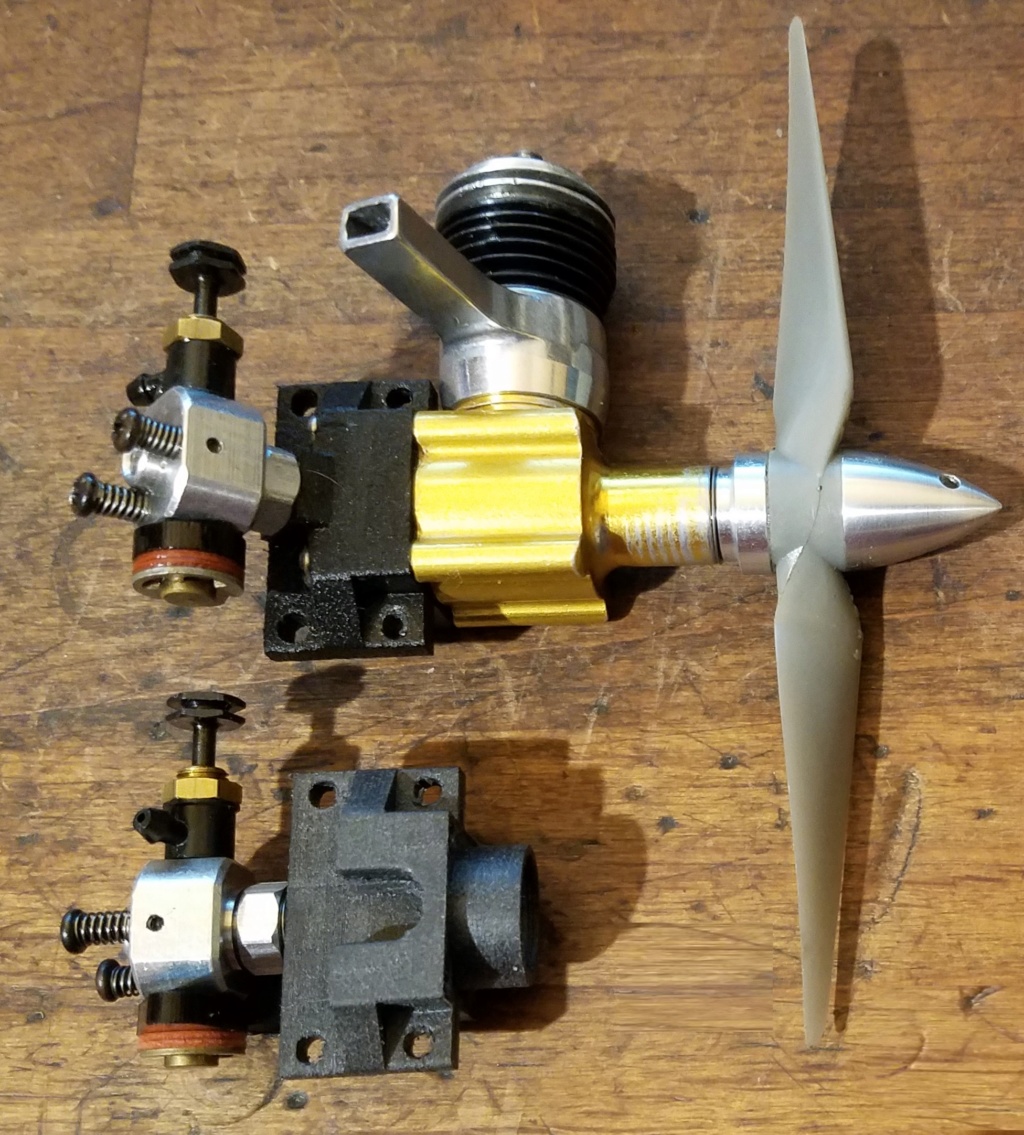

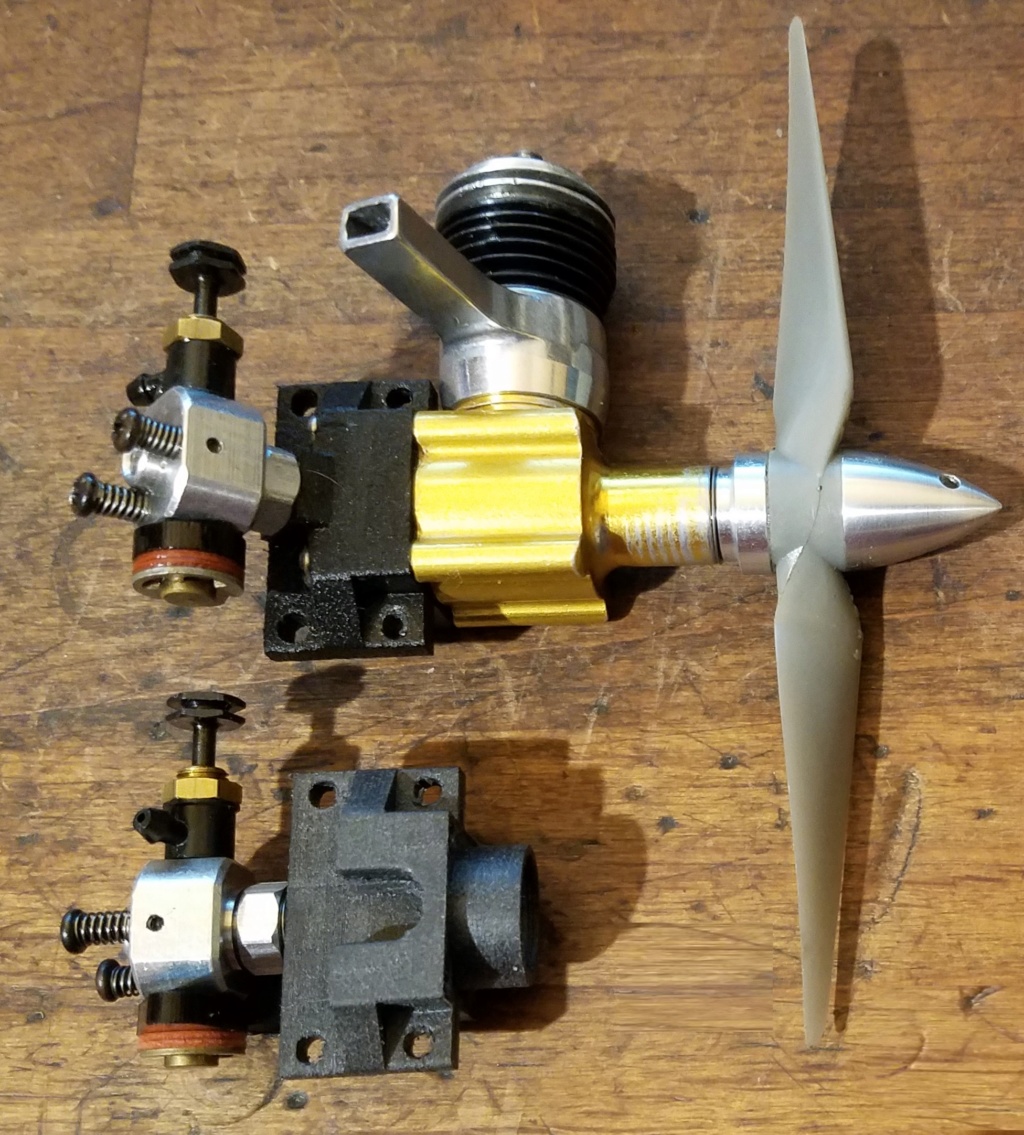

I prefer to expose the engine for all for it's beauty a most unique Cox KB engine and assembly!

Ultimately for me the power plant is a big part of the hobby interest I want to see it running / pulling

the plane fast and slow passes.

A mere 67g as shown / major eye candy encourages me to use it in a project!

The 65 degree mount should allow the use of a typical engine mount I don't have one to check this.

Here shown would need to remove a bit of material for it to clear and set fully on the beams.

The RX battery will be enough to correct the CG should you use a cowled engine.

The wonderful transition of it all is turning a reed engine into a RC engine.

Throttle rings is one way of course, this version allows a muffler or header etc.

If used with a profile plane the plane itself has it's incorporated beam mounts.

Could have a access hatch for a scale planes to set the NV / hide the engine.

I prefer to expose the engine for all for it's beauty a most unique Cox KB engine and assembly!

Ultimately for me the power plant is a big part of the hobby interest I want to see it running / pulling

the plane fast and slow passes.

A mere 67g as shown / major eye candy encourages me to use it in a project!

The 65 degree mount should allow the use of a typical engine mount I don't have one to check this.

Here shown would need to remove a bit of material for it to clear and set fully on the beams.

1/2A Nut- Top Poster

- Posts : 3534

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

Update

Ran the engine see results APC 4.1x4.1E / 23,336 rpm.

The E prop unloaded well providing stellar static power.

This prop is better than the APC 4.2x4 due to the thinner

blades and weight. Idle was checked to 9.2k rpm then

pushed it too far and the engine stopped. Will take some

setup efforts to get if functioning down to 7k with small

speed props, with a larger 6x3 idle would be easy to obtain.

Ran the engine see results APC 4.1x4.1E / 23,336 rpm.

The E prop unloaded well providing stellar static power.

This prop is better than the APC 4.2x4 due to the thinner

blades and weight. Idle was checked to 9.2k rpm then

pushed it too far and the engine stopped. Will take some

setup efforts to get if functioning down to 7k with small

speed props, with a larger 6x3 idle would be easy to obtain.

1/2A Nut- Top Poster

- Posts : 3534

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

Great performance with that COX RC carb..I have never really been able to tame that carb to a really low idle. Maybe a hot turbo plug will help keep the flame even at lower idle in your Killa Bee?

balogh- Top Poster

Posts : 4957

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

Yes true a turbo plug #3 would provide the best possible idle.

Really for what I do anything under 10k is enough to have it slow

enough for landing then kill the engine when it is close to the ground.

The carb is nice for safety if the radio starts acting up. The SPI

engine in conjunction with a reed induction valve makes it snap

and bark as the fuel and air gets choked down. My Nano X

low idle purrs on a #6 and the Tarno Carb without a pressure tap.

Really for what I do anything under 10k is enough to have it slow

enough for landing then kill the engine when it is close to the ground.

The carb is nice for safety if the radio starts acting up. The SPI

engine in conjunction with a reed induction valve makes it snap

and bark as the fuel and air gets choked down. My Nano X

low idle purrs on a #6 and the Tarno Carb without a pressure tap.

1/2A Nut- Top Poster

- Posts : 3534

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

Jason,

Do you plan to make these in black, and release some to Bernie and Matt for resale?

Would be nice to have one in .049 size, to match the .020 size I have yet to run.

Bill

Do you plan to make these in black, and release some to Bernie and Matt for resale?

Would be nice to have one in .049 size, to match the .020 size I have yet to run.

Bill

smooth_bill- Gold Member

- Posts : 229

Join date : 2012-02-19

Age : 87

Location : Beaverton, OR

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

Would a 25% or so glass filled nylon alleviate any strain on the nozzles?

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

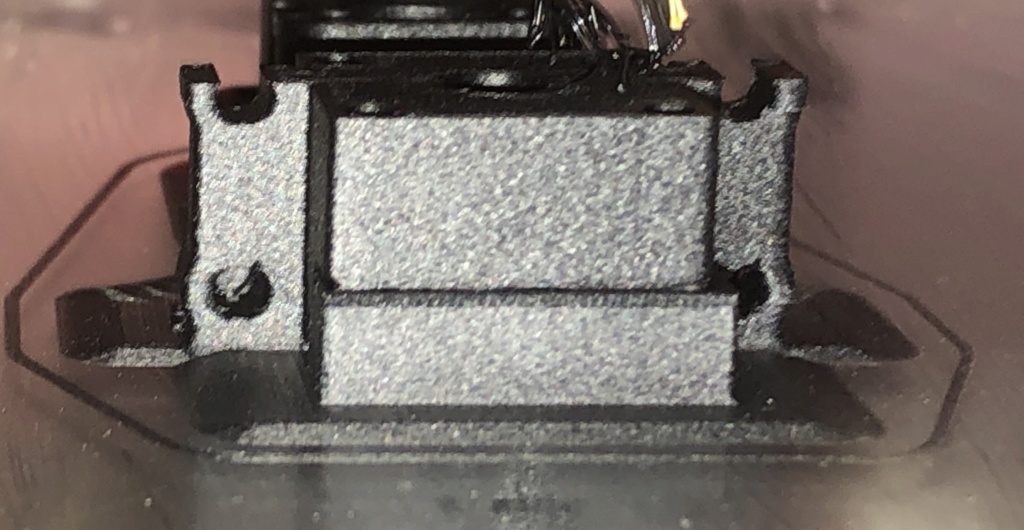

I have a sample spool of GFR zytel. It has an even more porous finish than the carbon fiber zytel and it is just as abrasive.

I have had pretty good luck printing direct to glass using Dimafix. First layer height is critical. Once the bed cools down the parts pop easily off the glass.

https://www.matterhackers.com/store/l/dimafix-3d-printing-adhesive-pen/sk/MR0VKNJY?rcode=GAT9HR&rcode=PPCADS&gclid=Cj0KCQjw-Mr0BRDyARIsAKEFbediPPW3Se6WuugKvfPxfxpE7rRjVzGDpaFxaFf3hllpXKnaxCmyBIIaAqKKEALw_wcB

I have had pretty good luck printing direct to glass using Dimafix. First layer height is critical. Once the bed cools down the parts pop easily off the glass.

https://www.matterhackers.com/store/l/dimafix-3d-printing-adhesive-pen/sk/MR0VKNJY?rcode=GAT9HR&rcode=PPCADS&gclid=Cj0KCQjw-Mr0BRDyARIsAKEFbediPPW3Se6WuugKvfPxfxpE7rRjVzGDpaFxaFf3hllpXKnaxCmyBIIaAqKKEALw_wcB

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

That's really cool Jason. Looks strong.

Dave P.- Gold Member

- Posts : 477

Join date : 2017-07-31

Age : 67

Location : Durham, NC

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

Simply amazing Jason. I cannot believe at how smooth it looks. So you mention that there was about an hour left from where you posted the picture, how long does it take to print out a single part from start overall? Is the time also affected by what materials you choose to use?

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

Beautiful pieces, congratulations Jason.

balogh- Top Poster

Posts : 4957

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

60 degrees looks right does not waste space should do well on the bench with a venturi or rc carb.

1/2A Nut- Top Poster

- Posts : 3534

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

Can't wait. You're not just helping the hobby survive, but advancing it.

Thanks Jason.

Bob

Thanks Jason.

Bob

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

That looks great! Fantastic design. I hope it runs even better than it looks!

fit90- Diamond Member

- Posts : 1341

Join date : 2011-08-11

Location : Naples, Florida

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

NEW222 wrote:Simply amazing Jason. I cannot believe at how smooth it looks. So you mention that there was about an hour left from where you posted the picture, how long does it take to print out a single part from start overall? Is the time also affected by what materials you choose to use?

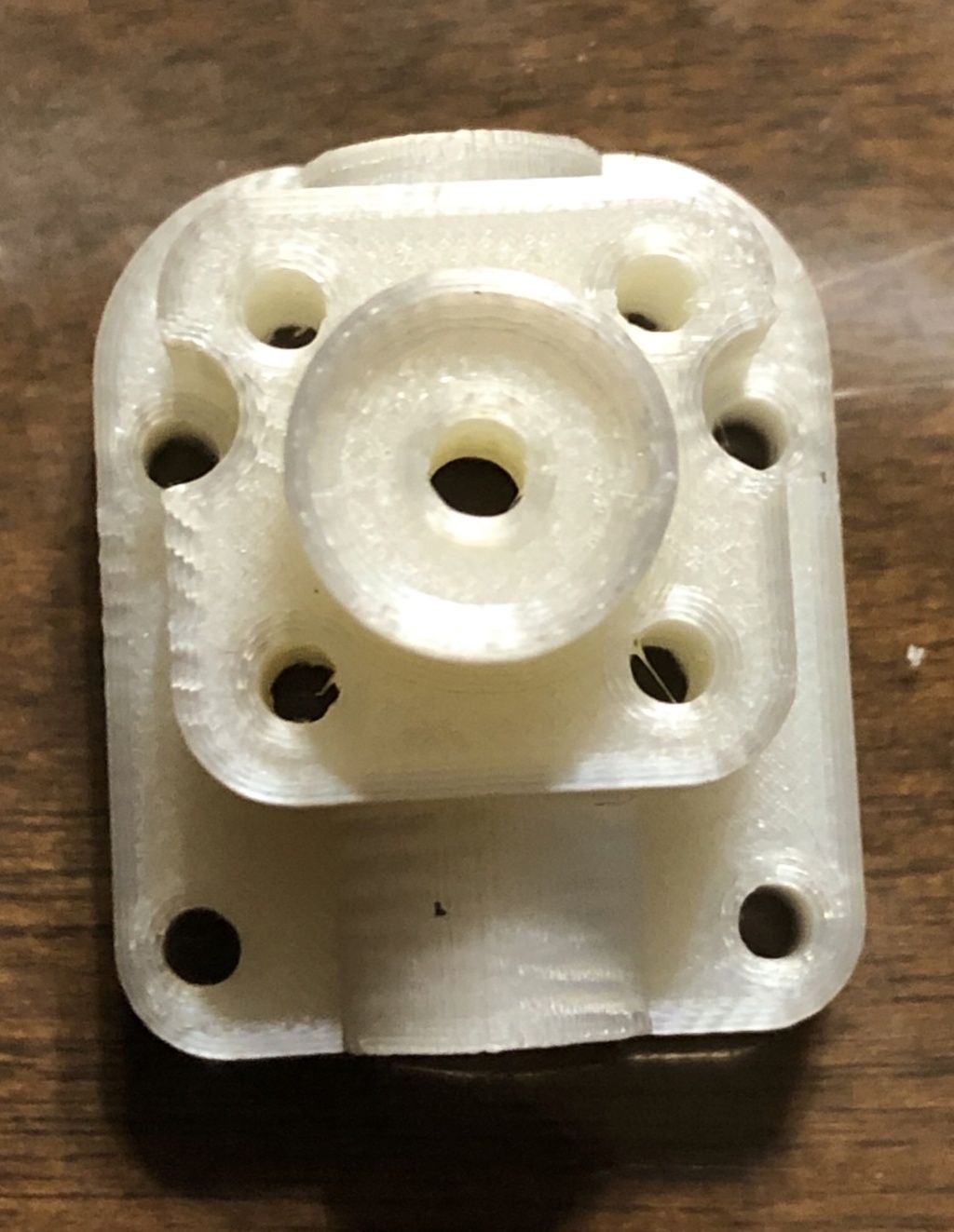

It takes ~ 3 hours and 40 minutes to print one of them.

Material plays a factor in how fast you can print but the 100 micron layer height is the biggest factor. 10 layers per mm with a .25mm nozzle diameter.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

Looks great Jason!

I'll be watching for the release and saving my coins.

Bill

I'll be watching for the release and saving my coins.

Bill

smooth_bill- Gold Member

- Posts : 229

Join date : 2012-02-19

Age : 87

Location : Beaverton, OR

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

Ok so I printed 6 of each and contacted 2 interested parties already. So there are 4 sets available for testing. I say testing as I want feedback to see how they perform. All I ask is you run them. Treat them like a rented mule. I wanna see where the faults are.

I will include gasket, reed, circlip, and screws for easy installation. You just need to add the front half of an engine of your choice and either a needle valve assembly or TD venturi/NVA, tarno carb, Cox RC05 carb, or carb of your choice that’s threader for 1/4-32.

Send me a PM if you’re interested.

I will include gasket, reed, circlip, and screws for easy installation. You just need to add the front half of an engine of your choice and either a needle valve assembly or TD venturi/NVA, tarno carb, Cox RC05 carb, or carb of your choice that’s threader for 1/4-32.

Send me a PM if you’re interested.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Page 4 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Similar topics

Similar topics» 3D printed PeeWee .020 tank backplate

» beam mount question

» 3D printed R/C Pee Wee backplate

» Are these Cox red beam mount tanks ok for diesel?

» Dragonfly/Medallion 049 RC Muffler

» beam mount question

» 3D printed R/C Pee Wee backplate

» Are these Cox red beam mount tanks ok for diesel?

» Dragonfly/Medallion 049 RC Muffler

Page 4 of 5

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules