Log in

Search

Latest topics

» Landing-gear tipsby rdw777 Today at 4:49 pm

» It's the X Wing that has a canard

by rdw777 Today at 3:21 pm

» My current avatar photo

by GallopingGhostler Yesterday at 7:02 pm

» Cox 020 PeeWee rebuild questions

by LooseSpinner99 Yesterday at 4:38 pm

» music vids.. some of your favorites

by Kim Yesterday at 3:28 pm

» New Model Build

by bsadonkill Yesterday at 1:19 pm

» Kofuku Maru Fishing Boat Model

by Levent Suberk Yesterday at 11:39 am

» Free Flight Radio Assist

by rdw777 Yesterday at 11:24 am

» TEE DEE Having issues

by GallopingGhostler Wed Nov 13, 2024 11:38 pm

» Pathé Modeling Videos

by Levent Suberk Wed Nov 13, 2024 2:10 pm

» My latest doodle...

by layback209 Wed Nov 13, 2024 1:20 am

» Drones, pretty nifty...........

by rsv1cox Tue Nov 12, 2024 6:55 pm

Cox Engine of The Month

3D printed beam mount .049 backplate

Page 5 of 5

Page 5 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

the wasp carb is a great idea

fit90- Diamond Member

- Posts : 1341

Join date : 2011-08-11

Location : Naples, Florida

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

What size thread did you use to cut the AP Wasp carb?

Did it require any reduction first?

Good to see you are using socket head bolts too,

easy to adjust just the right amount of torque.

I use socket head wood screws for the beam mounts the hole

size you currently use is a bit big / smaller hole would help on

strength / splitting / cracks.

Did it require any reduction first?

Good to see you are using socket head bolts too,

easy to adjust just the right amount of torque.

I use socket head wood screws for the beam mounts the hole

size you currently use is a bit big / smaller hole would help on

strength / splitting / cracks.

1/2A Nut- Top Poster

- Posts : 3534

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

I turned it down on the lathe for 1/4-32 pitch thread size. I ran the die on the normal way to get a few threads started the turned the die around to cut threads to the bottom. Not much meat left. These carbs were cheap when they were readily available. It needs a thin nut to tighten the carb down tight to the carb body.

I have taps for the .020 venturi, .049 venturi and the TD 15 venturi. Also a cox cylinder tap. All the venturi tools from Ridenfligh on eBay. Piston reset tools for all engines and the .15 reset tool I made. All kept in a handy case.

I did model the hole size of the mounting ears after the TD but they get egged out a little printing vertically. I did buy #2 small diameter washers for the wood screws I have. I still have a boatload of the wood screws left over from the horseshoe backplates.

I just got in over $100 worth of small screws from McMaster Carr. I didn’t like the thread engagement with the 2-56 x 1/2” hex screws. I bought 2-56 x 9/16” screws. Gives a few extra threads.

I have taps for the .020 venturi, .049 venturi and the TD 15 venturi. Also a cox cylinder tap. All the venturi tools from Ridenfligh on eBay. Piston reset tools for all engines and the .15 reset tool I made. All kept in a handy case.

I did model the hole size of the mounting ears after the TD but they get egged out a little printing vertically. I did buy #2 small diameter washers for the wood screws I have. I still have a boatload of the wood screws left over from the horseshoe backplates.

I just got in over $100 worth of small screws from McMaster Carr. I didn’t like the thread engagement with the 2-56 x 1/2” hex screws. I bought 2-56 x 9/16” screws. Gives a few extra threads.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

Last edited by 1/2A Nut on Thu Jun 11, 2020 1:19 am; edited 1 time in total

1/2A Nut- Top Poster

- Posts : 3534

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

Brad just have one question, have you had any problem with the Cox .049 .05 Tee Dee RC Carburetor Assembly fuel barb. Ive cracked or broke the barb off two of them. It seems to me the plastic is just old.the plastic seems to be very brittle on mine. I'm thinking about just building them out of brass with tubing. Basswood

Basswood- Gold Member

- Posts : 141

Join date : 2020-02-19

Age : 68

Location : Phoenix, Az.

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

I guess my point is what is this 3D printed material made from?

Basswood

Basswood

Basswood- Gold Member

- Posts : 141

Join date : 2020-02-19

Age : 68

Location : Phoenix, Az.

Any left?

Any left?

Jason_WI wrote:Still 3 left for testing yet.

I have one of each carb type for testing. I won’t need anymore for that. Thanks for the lead though.

Are there any left for testing? I just started reading this thread. I have been looking for this kind of carb for a few years. I even talked to bob Beecroft about building me one, but he had too many other priority jobs a ahead of that one.

Happydad

Edited to add data

P.s. I have a 1/4-32 tap

happydad- Rest In Peace

- Posts : 1592

Join date : 2012-05-28

Age : 79

Location : Escondido, CA

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

Basswood, the version I have to test has a carbon blend to it.

1/2A Nut- Top Poster

- Posts : 3534

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

wit wasp carb y sugest use 051 size cylinder is porting wil fit beter ventury to jet size of wasp carb neadle set up is bit diferent y made my wit couple mod to get right amount of fuel to hard to explain wat is ur test result on wasp carb how u tuned carb for 049 ? my is tee dee 051

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

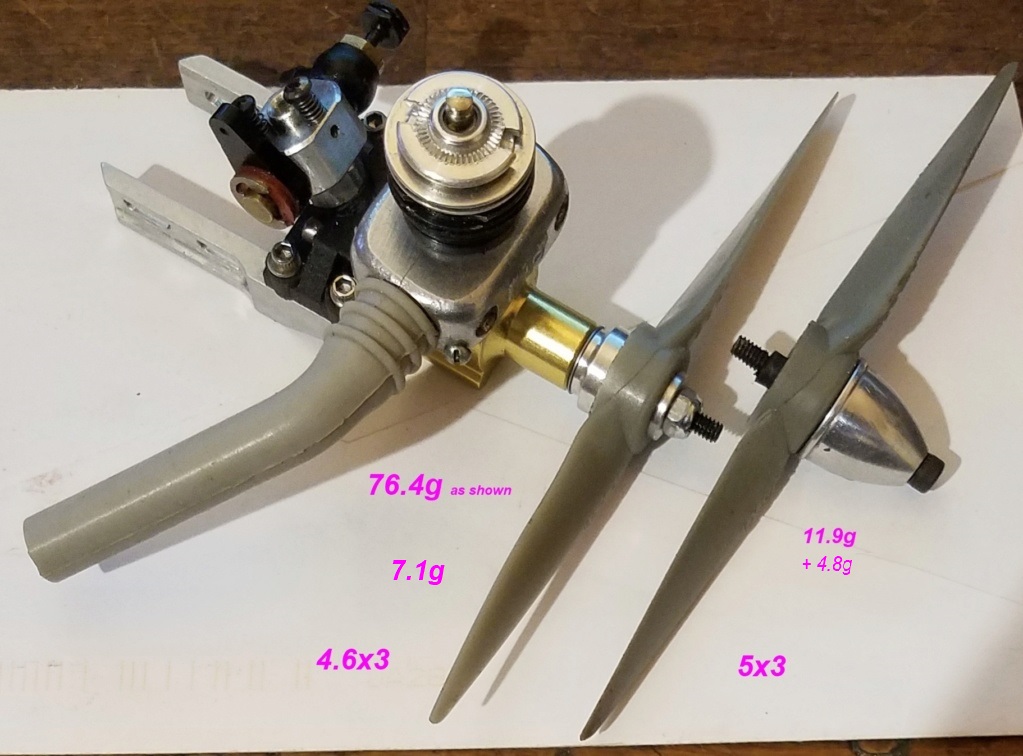

Killer Bee .049 with 3D Printed Backplate for RC Carb 65 deg.

Testing with muffler and exhaust deflector made reasonable

power considering not open exhaust / very easy on the ears.

SPI engine seemed to breath reasonably for bench testing.

APC 4.6x3 / 20,914 rpm peak / 60 mph pitch speed / 8.9oz thrust.

Stop screw needs to be set for low idle looks like it can handle 6.8k

with a larger prop much lower perhaps 5k I would expect.

25% nitro / 20% castor / 3 shims Cox High Compression Plug.

Engine ran well side mounted the exhaust system may have helped

with the steady running. Butter on the ears will make a great RC

engine project as is or open exhaust for full power. Aluminum mounting

brackets for bench testing ease and to acquire side mounting test.

3D mount was clean no air leaks great design for fuss free use!

Improved 65 deg. angle made access a breeze with the RC carb.

Absolutely zero vibrations with this set up very pleased with the low weight centered stud / nut method.

The engine did great with the bulky robust combat prop.

Last edited by 1/2A Nut on Wed Jun 10, 2020 2:32 pm; edited 3 times in total

1/2A Nut- Top Poster

- Posts : 3534

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

Brad my Tarno carb got loose in the 3D backplate despite the contra-nut. I did not want to overtighten for fears I might cut the threads in the backplate. How did you keep the carb vibe-free?

balogh- Top Poster

Posts : 4957

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

It all starts with a perfectly centered prop. I use fuel tube that

is a snug fit when the stud bolt went thru it sets the stage for

a centered prop. The trick is not to mess it up with a spinner

that slides / kicks out of center when tighten. Threaded bullet

spinners work great. The nut and stud method worked very

well today low mass tucked up close to the prop hub is another

factor to help reduce vibrations. I used a small crescent wrench

to tighten the locking nut no fear of stripping the threads. I put

about 6-7 lbs of torque on the nut.

is a snug fit when the stud bolt went thru it sets the stage for

a centered prop. The trick is not to mess it up with a spinner

that slides / kicks out of center when tighten. Threaded bullet

spinners work great. The nut and stud method worked very

well today low mass tucked up close to the prop hub is another

factor to help reduce vibrations. I used a small crescent wrench

to tighten the locking nut no fear of stripping the threads. I put

about 6-7 lbs of torque on the nut.

1/2A Nut- Top Poster

- Posts : 3534

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

For the threads you should be able to tighten it down as much as you would with a delrin carb body on a TD 049.

I’m also going to use a tapping machine with custom mounting blocks for the parts to get the tap perpendicular to the hole and have perfectly formed threads from the start. These first few samples were hand tapped.

I’ll see if I can run some torque tests on these to see what the threshold is. Destructive testing is fun.

I’m also going to use a tapping machine with custom mounting blocks for the parts to get the tap perpendicular to the hole and have perfectly formed threads from the start. These first few samples were hand tapped.

I’ll see if I can run some torque tests on these to see what the threshold is. Destructive testing is fun.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

Thanks for the advice Brad and Jason.. I also make sure the prop is well balanced and use the fuel tube on studs for APC props that come with larger screw holes than the COX prop stud diameter. Because of the US thread size, I do not have too many options to replace the aluminum spinner with something lighter. I do not often use even the small COX rubber spinners because they tend to fly away from the stud hub and get lost.

Maybe I will also wrap some plumber silicon tape on the carb neck to increase tightness in fitting, then span the contra-nut cautiously a bit more than before.

Maybe I will also wrap some plumber silicon tape on the carb neck to increase tightness in fitting, then span the contra-nut cautiously a bit more than before.

balogh- Top Poster

Posts : 4957

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: 3D printed beam mount .049 backplate

Re: 3D printed beam mount .049 backplate

Thank you Andras, have a few of these backplates and thus far the ones with RC

carbs on them have held up well with the locking nut. None have gotten loose on

me / no air leaks observed. Fuel draw has been good although if I use a muffler

I tend to go with a pressure tap to improve steady top end rpm.

carbs on them have held up well with the locking nut. None have gotten loose on

me / no air leaks observed. Fuel draw has been good although if I use a muffler

I tend to go with a pressure tap to improve steady top end rpm.

1/2A Nut- Top Poster

- Posts : 3534

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Page 5 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Similar topics

Similar topics» 3D printed PeeWee .020 tank backplate

» beam mount question

» 3D printed R/C Pee Wee backplate

» Are these Cox red beam mount tanks ok for diesel?

» Dragonfly/Medallion 049 RC Muffler

» beam mount question

» 3D printed R/C Pee Wee backplate

» Are these Cox red beam mount tanks ok for diesel?

» Dragonfly/Medallion 049 RC Muffler

Page 5 of 5

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules