Log in

Search

Latest topics

» Free Flight Radio Assist by MauricioB Today at 5:25 pm

» Cox 020 PeeWee rebuild questions

by LooseSpinner99 Today at 5:17 pm

» Landing-gear tips

by roddie Today at 11:27 am

» Brushless motors?

by rsv1cox Today at 10:45 am

» Tribute Shoestring build

by Ken Cook Today at 7:07 am

» My current avatar photo

by GallopingGhostler Fri Nov 15, 2024 7:39 pm

» It's the X Wing that has a canard

by rdw777 Fri Nov 15, 2024 6:58 pm

» music vids.. some of your favorites

by Kim Thu Nov 14, 2024 3:28 pm

» New Model Build

by bsadonkill Thu Nov 14, 2024 1:19 pm

» Kofuku Maru Fishing Boat Model

by Levent Suberk Thu Nov 14, 2024 11:39 am

» TEE DEE Having issues

by GallopingGhostler Wed Nov 13, 2024 11:38 pm

» Pathé Modeling Videos

by Levent Suberk Wed Nov 13, 2024 2:10 pm

Cox Engine of The Month

Balance propellers.

Page 1 of 1

Balance propellers.

Balance propellers.

Balance propellers.

While setting up my aircraft from .15 cubic inches glow to 60 cc of gasoline, I have always balanced the propellers, but at this stage of building small models, I mean from .010 onwards, I have not balanced propellers Of Cox 010/020/049/051, and I'm thinking of starting to check them and see if I need to balance them.

My question is: Do you balance propellers for Cox and other brands of engines in cylinder sizes from 0.010 to 0.074?

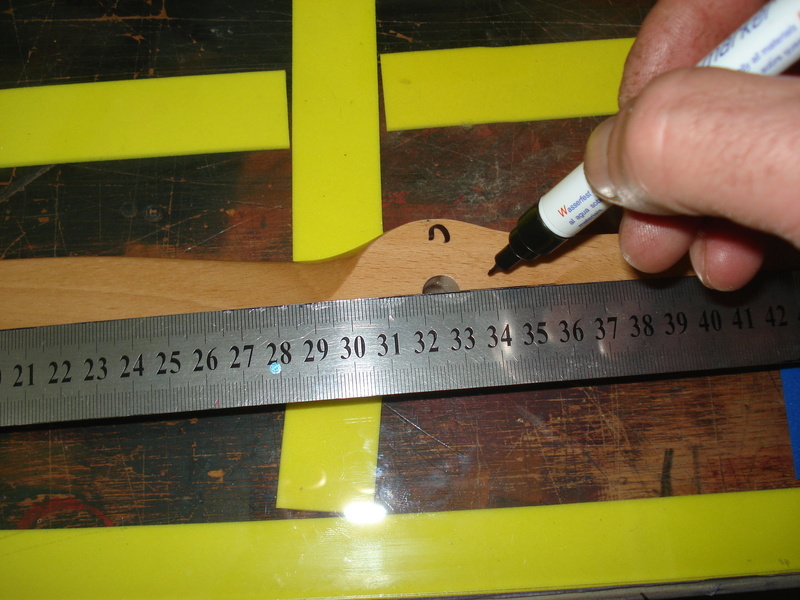

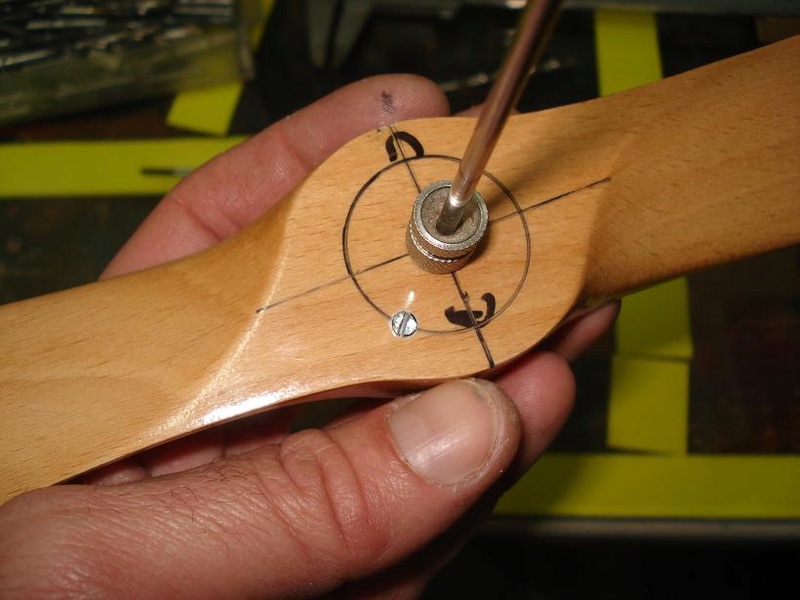

These are some old photos of me in the process of balance, in the case of the photos is for a motor of .20 cubic inches.

The propeller is fully balanced when turning it stops in different positions slowly and without rebounds

I look forward to your experiences, thank you!

While setting up my aircraft from .15 cubic inches glow to 60 cc of gasoline, I have always balanced the propellers, but at this stage of building small models, I mean from .010 onwards, I have not balanced propellers Of Cox 010/020/049/051, and I'm thinking of starting to check them and see if I need to balance them.

My question is: Do you balance propellers for Cox and other brands of engines in cylinder sizes from 0.010 to 0.074?

These are some old photos of me in the process of balance, in the case of the photos is for a motor of .20 cubic inches.

The propeller is fully balanced when turning it stops in different positions slowly and without rebounds

I look forward to your experiences, thank you!

MauricioB- Top Poster

- Posts : 3710

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Balance propellers.

Re: Balance propellers.

Mauricio the 010 thru the 09 size COX engines I have are very sensitive to propeller balance, see e.g the 010 owner's manual.

Apart from performance issues, unbalanced propellers will destroy the aluminum journal bearing in the crankcase nose, and I saw such engines I bought used from ebay simply not starting up because of crankcase leakage along the crankshaft.

I regularly check propellers for balance especially when new.

Most COX propeller hubs have hollow backside and the gaps offer themselves to putting balancing material like steel wire chips or plastic particles inside. I have never tried it but now that we talk about it and I saw you drill balancing holes in the hub, I will try instead of sanding the blades or adding Scotch tape for balancing.

Apart from performance issues, unbalanced propellers will destroy the aluminum journal bearing in the crankcase nose, and I saw such engines I bought used from ebay simply not starting up because of crankcase leakage along the crankshaft.

I regularly check propellers for balance especially when new.

Most COX propeller hubs have hollow backside and the gaps offer themselves to putting balancing material like steel wire chips or plastic particles inside. I have never tried it but now that we talk about it and I saw you drill balancing holes in the hub, I will try instead of sanding the blades or adding Scotch tape for balancing.

balogh- Top Poster

Posts : 4957

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Balance propellers.

Re: Balance propellers.

Here I have balanced a Cox propeller, with very good result.

Check the original state of the blade.

I add an ammunition in the right place.

Check with balancer the state of the blade.

Remove material if necessary by means of a wick.

Finally check the blade until it is in a state of equilibrium. (The blade must rotate freely on the balancer, slow down slowly and remain in any position without revotes).

Check the original state of the blade.

I add an ammunition in the right place.

Check with balancer the state of the blade.

Remove material if necessary by means of a wick.

Finally check the blade until it is in a state of equilibrium. (The blade must rotate freely on the balancer, slow down slowly and remain in any position without revotes).

MauricioB- Top Poster

- Posts : 3710

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Balance propellers.

Re: Balance propellers.

There have been a few props that my typical blade sanding did not work so I determined the Hub was one side heavy....always settled blades horizontal with same side down every time

That is the ONLY time I drilled smallish holes in a hub, and I seem to recall PMing Rockn Rusty on the subject cuz he was concerned screwing with the HUB on some of his props...I assured him the HUB drilled prop was on a bad assed combat motor and held up to the abuse

That said....be very very cautious about reducing material in the HUB of propellers

AND especially with APC props the HUB Hole was drilled off center ...that is eventually what I determine was wrong with the heavy side HUB ones I had... there are two fixes... trash can, or centering fixture to drill out center over sized and sleeve down for prop stud/screw.....grrr

I love many APC props, but too frequently some new ones get cut off to use as paint stirrers or fillet shapes

On most of my wood props I smear a layer of full dope on the back side light blade with my finger---dries quick...I do not sand away any of the finish...If I go too far I add a light smear to the now lighter blade

BTW I am a proponent of the magnetic balancers....I had a ball bearing one that gave me fits

That is the ONLY time I drilled smallish holes in a hub, and I seem to recall PMing Rockn Rusty on the subject cuz he was concerned screwing with the HUB on some of his props...I assured him the HUB drilled prop was on a bad assed combat motor and held up to the abuse

That said....be very very cautious about reducing material in the HUB of propellers

AND especially with APC props the HUB Hole was drilled off center ...that is eventually what I determine was wrong with the heavy side HUB ones I had... there are two fixes... trash can, or centering fixture to drill out center over sized and sleeve down for prop stud/screw.....grrr

I love many APC props, but too frequently some new ones get cut off to use as paint stirrers or fillet shapes

On most of my wood props I smear a layer of full dope on the back side light blade with my finger---dries quick...I do not sand away any of the finish...If I go too far I add a light smear to the now lighter blade

BTW I am a proponent of the magnetic balancers....I had a ball bearing one that gave me fits

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Do you need to balance Cox props?

Do you need to balance Cox props?

From a previous discussion, I copied it. The answer: YES, one needs to balance props used on 1/2A's (Cheers, Paul aka Mr. Mouse)

Fom: Paul Gibeault [mailto@shaw.ca]

Sent: November-03-14 12:02 PM

To: Cox International Support

Cc: aerorich80@comcast.net

Subject: Re: Cox Engines Quarterly

Hi Bernie & Rich,

Rich, you raise an interesting question. The very bottom line is top of the blade airfoil (on many production props) like Cox,Top Flite, Grish, Master Air Screw, and others is not overly critical. In an ideal world (which we don't have with models), one has to live with "the best compromise". You also have to ask yourself why is a perfectly looking molded prop out of balance? One reason is that the blade thicknesses are slightly different. Not a lot, but some... SOoo, it's worse to have a prop out of static balance than to have both blade top airfoils identical. Of course there are limits to blade thickness asymmetry. A blade .060" thinner than another will run quite poorly. Often I find I can improve the blade balance by removing (often less) but not more than~ ten thousandths of material. In other words just a few minutes with fine sandpaper/file. Anything requiring more than a few minutes rework (in my view) is cause for rejection. Removing material from the blade bottom is much more critical as that can change the pitch or induce undercamber which we don't want to do. So most of our model prop rework is confined to:

1st: blade diameter,

2nd: blade shape, equalization in that order. Then

3rd: blade thickness. This assumes the hub is OK (which it may not be...APC's are notorious for being off here).

Re-reading your question Rich: I really don't do anything to make sure the blade airfoils & thicknesses are the same. I just assume they are. The reason: It is extremely difficult to measure 1/2A prop blade airfoils with any degree of accuracy, especially on plastic or nylon. I can use a micrometer to determine thickness, but again there are inaccuracies trying to measure on a curved surface. So much so that again the best compromise is to try & achieve a reasonable 360 degree static balance & go flying. My own experience indicates this is quite acceptable.

Note: Competition modellers at the world C/L championship level all use carbon fibre re-inforced plastic (CFRP) moulded propellors. They have found that even from the same mould, in a batch of 10 props, 1-2 will be dogs, 6-7 will be OK, & 1-2 will be superior in performance!

This shows that moulding props is not an exact repeatable & consistent process. Even a full size pylon racer told me that.

The British gold medal speed team have small metal templates (top & bottom) EDM machined, 10 templates per 3" blade with which to measure/shape their blade profiles with along each station. Each 3" (single blade) carbon prop needs 30-40 hours of hand sanding / filing / polishing before it is considered competition ready! These people understand fully what you're talking about. But I'm willing to bet that you do not know of anybody, who goes to that extreme for their model airplane

props even at the National level...

P.S. That's an excellent idea adding balance weight to the hub area

Fom: Paul Gibeault [mailto@shaw.ca]

Sent: November-03-14 12:02 PM

To: Cox International Support

Cc: aerorich80@comcast.net

Subject: Re: Cox Engines Quarterly

Hi Bernie & Rich,

Rich, you raise an interesting question. The very bottom line is top of the blade airfoil (on many production props) like Cox,Top Flite, Grish, Master Air Screw, and others is not overly critical. In an ideal world (which we don't have with models), one has to live with "the best compromise". You also have to ask yourself why is a perfectly looking molded prop out of balance? One reason is that the blade thicknesses are slightly different. Not a lot, but some... SOoo, it's worse to have a prop out of static balance than to have both blade top airfoils identical. Of course there are limits to blade thickness asymmetry. A blade .060" thinner than another will run quite poorly. Often I find I can improve the blade balance by removing (often less) but not more than~ ten thousandths of material. In other words just a few minutes with fine sandpaper/file. Anything requiring more than a few minutes rework (in my view) is cause for rejection. Removing material from the blade bottom is much more critical as that can change the pitch or induce undercamber which we don't want to do. So most of our model prop rework is confined to:

1st: blade diameter,

2nd: blade shape, equalization in that order. Then

3rd: blade thickness. This assumes the hub is OK (which it may not be...APC's are notorious for being off here).

Re-reading your question Rich: I really don't do anything to make sure the blade airfoils & thicknesses are the same. I just assume they are. The reason: It is extremely difficult to measure 1/2A prop blade airfoils with any degree of accuracy, especially on plastic or nylon. I can use a micrometer to determine thickness, but again there are inaccuracies trying to measure on a curved surface. So much so that again the best compromise is to try & achieve a reasonable 360 degree static balance & go flying. My own experience indicates this is quite acceptable.

Note: Competition modellers at the world C/L championship level all use carbon fibre re-inforced plastic (CFRP) moulded propellors. They have found that even from the same mould, in a batch of 10 props, 1-2 will be dogs, 6-7 will be OK, & 1-2 will be superior in performance!

This shows that moulding props is not an exact repeatable & consistent process. Even a full size pylon racer told me that.

The British gold medal speed team have small metal templates (top & bottom) EDM machined, 10 templates per 3" blade with which to measure/shape their blade profiles with along each station. Each 3" (single blade) carbon prop needs 30-40 hours of hand sanding / filing / polishing before it is considered competition ready! These people understand fully what you're talking about. But I'm willing to bet that you do not know of anybody, who goes to that extreme for their model airplane

props even at the National level...

P.S. That's an excellent idea adding balance weight to the hub area

Paulgibeault- Gold Member

- Posts : 259

Join date : 2011-09-24

Location : Leduc, Alberta Canada

Re: Balance propellers.

Re: Balance propellers.

Thanks for the information that everyone brings here.

I do not speak English, I manage with the translator of google and I hope to transmit my experience and that the translation that google grants, is the best possible.

Clarified this then say the following:

In my opinion, the profile of a blade should never be modified by means of a sandpaper in order to be able to balance, this damages the profile of the propeller itself, turning that sector sanded into a profile different from that of the other blade.

For this reason, I understand that the best way is to preserve the original design of the propeller and work on the hub or center of it, it is there where one can achieve a good result without modifying the propeller.

Remember that the propeller is a "rotary wing" and that the profiles of the blades should always be perfectly identical, which if you modify by sanding or adding material such as varnish or paint, you will be adding those profiles, making a blade turn Air in a different way from the other blade and will generate a turbulence to be different from one another.

I share with you two own videos, which I did a few years ago, to convey safety in the use of propellers.

I do not speak English, I manage with the translator of google and I hope to transmit my experience and that the translation that google grants, is the best possible.

Clarified this then say the following:

In my opinion, the profile of a blade should never be modified by means of a sandpaper in order to be able to balance, this damages the profile of the propeller itself, turning that sector sanded into a profile different from that of the other blade.

For this reason, I understand that the best way is to preserve the original design of the propeller and work on the hub or center of it, it is there where one can achieve a good result without modifying the propeller.

Remember that the propeller is a "rotary wing" and that the profiles of the blades should always be perfectly identical, which if you modify by sanding or adding material such as varnish or paint, you will be adding those profiles, making a blade turn Air in a different way from the other blade and will generate a turbulence to be different from one another.

I share with you two own videos, which I did a few years ago, to convey safety in the use of propellers.

MauricioB- Top Poster

- Posts : 3710

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Balance propellers.

Re: Balance propellers.

I have to lean towards the law of diminishing returns. While you can do whatever you need to do balancing the prop, the engine is still out of balance. One of two things are going to happen, either it works, it works very well or it doesn't. In regards to props with one blade which is supposedly out of true vs the other. This can be beneficial as it now allows both blades to grab clean air. This is the sole purpose of a single bladed prop. Speed flyers know this and timing the flight is the ONLY way to tell. Listening to engine rpm's and trying to check by eye can offer poor and ineffective results. I firmly believe this is being over analyzed and it's not entirely necessary. There are so many other limiting factors that dictate engine life and model efficiency. I'm not suggesting not to balance a prop but based on what I'm reading here and from personal experiences I can say it's not a do or die situation. From the age of 10 to my mid 20's I never balanced a prop, you bolted or screwed it on and flew. I still own and fly those engines from my youth. What I'm conveying is that while some go to great strides to balance a prop, it doesn't mean that it's going to work well on the model. In theory it does assist with the gyroscopic action at the end of the shaft but the crank will still and always will be out of balance.

Looking at the picture where the hub is being drilled could result in a serious injury. My flying partner while setting the needle one afternoon had a Master Airscrew throw a blade and the blade went through the side of his face through his cheek and into his mouth. This was due to the hollow voids in the hub area just like on the Cox hubs. I would never drill the hub on one of those props. I have to admit, not a time when I'm using those props nowadays that I don't think of that incident. He has a serious scar from his ear to his lower chin about 5" long now. Certain engines offer radical pulses to the shaft and this is due to the mass on the crank itself. I feel this is totally responsible for what happened that day. For example, a Fox .35 vs a OS FP .35. While the Fox is timid compared to the FP in terms of power offerings, the Fox is pretty brutal on it's components. Don't feel that due to the fact the engine is not high performance that the above couldn't happen.

In reading the posts, I saw no mention of blade length until Paul posted in his list #1 thing to check first. This is the first step which needs to be checked prior to balancing the props. I have measured Master Airscrew props and have found them to be off as much as 1/8" and then some due to flash. I rarely find a APC prop that's radically out of balance. Master Airscrew props are horrid and I usually remove the wording which is painted onto the face of the prop on the heavier side prior to doing any major sanding. The next step is the mold lines down the leading and trailing edge of the prop. These are dangerous to leave on and will cut you instantly if left on the prop edges and these can easily be removed by continuous scraping. This isn't changing the airfoil which by the way is not an easy task to do anyhow. The GF series props are extremely tough to sand and while you do get minor sanding dust from sanding, one really needs to spend a lot of time to reshape the airfoil. Essentially one is banking on the fact that the airfoil is correct in the first place. Molds are produced in a fashion to compensate for shrinkage when released. One prop to the next can ultimately be different due to the way the material cools after release.

Looking at the picture where the hub is being drilled could result in a serious injury. My flying partner while setting the needle one afternoon had a Master Airscrew throw a blade and the blade went through the side of his face through his cheek and into his mouth. This was due to the hollow voids in the hub area just like on the Cox hubs. I would never drill the hub on one of those props. I have to admit, not a time when I'm using those props nowadays that I don't think of that incident. He has a serious scar from his ear to his lower chin about 5" long now. Certain engines offer radical pulses to the shaft and this is due to the mass on the crank itself. I feel this is totally responsible for what happened that day. For example, a Fox .35 vs a OS FP .35. While the Fox is timid compared to the FP in terms of power offerings, the Fox is pretty brutal on it's components. Don't feel that due to the fact the engine is not high performance that the above couldn't happen.

In reading the posts, I saw no mention of blade length until Paul posted in his list #1 thing to check first. This is the first step which needs to be checked prior to balancing the props. I have measured Master Airscrew props and have found them to be off as much as 1/8" and then some due to flash. I rarely find a APC prop that's radically out of balance. Master Airscrew props are horrid and I usually remove the wording which is painted onto the face of the prop on the heavier side prior to doing any major sanding. The next step is the mold lines down the leading and trailing edge of the prop. These are dangerous to leave on and will cut you instantly if left on the prop edges and these can easily be removed by continuous scraping. This isn't changing the airfoil which by the way is not an easy task to do anyhow. The GF series props are extremely tough to sand and while you do get minor sanding dust from sanding, one really needs to spend a lot of time to reshape the airfoil. Essentially one is banking on the fact that the airfoil is correct in the first place. Molds are produced in a fashion to compensate for shrinkage when released. One prop to the next can ultimately be different due to the way the material cools after release.

Ken Cook- Top Poster

- Posts : 5635

Join date : 2012-03-27

Location : pennsylvania

Re: Balance propellers.

Re: Balance propellers.

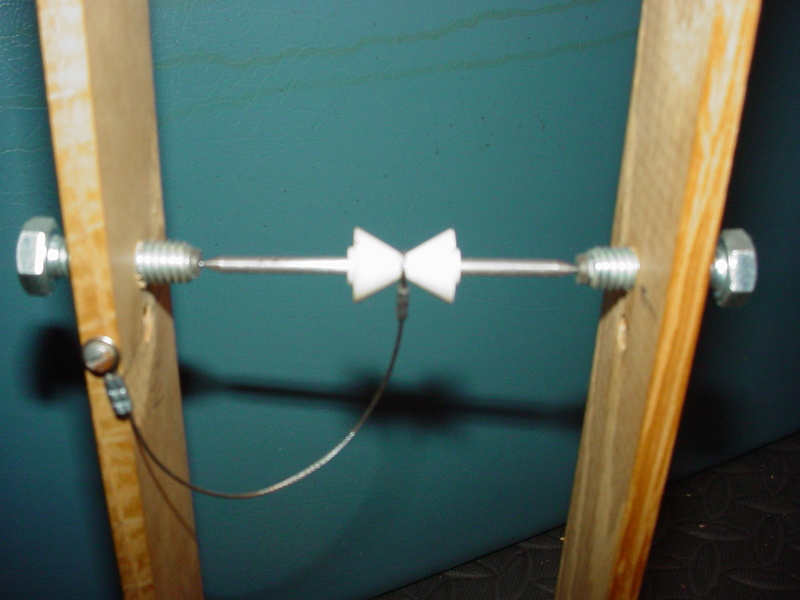

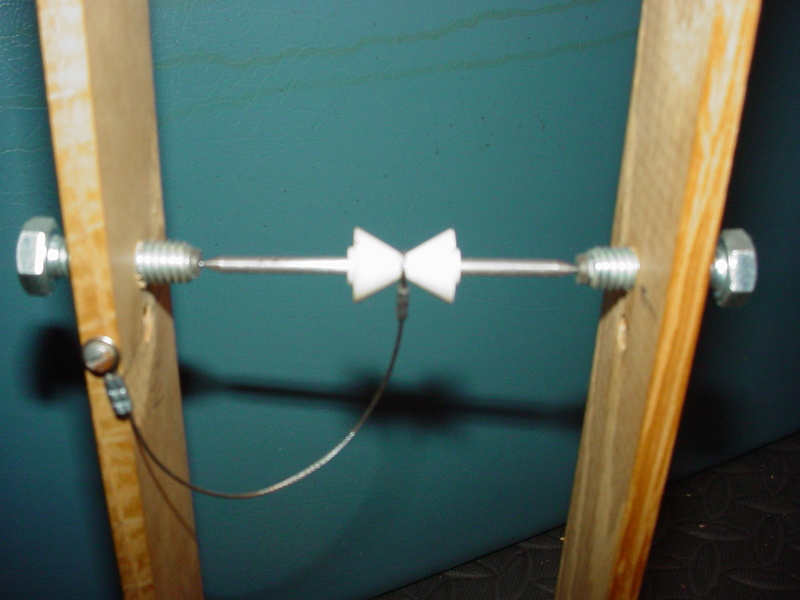

I've only generally run 1/2A aero-engines.. and I never used to check the prop-balance. Then I decided to buy a "Kavan" balance-shaft with hub-cones, to check the balance of my props. I basically "copied" the design of a magnetic-balancer (Top-Flite's?) and made my own by building a wooden-frame with adjustment-screws having small powerful (rare-earth) magnets to hold the balance-shaft. One end of the pointed balance-shaft "floats" in the magnetic-field.

A picture is worth a thousand words..

The screws (5/16-18 bolts actually..) can be adjusted for sensitivity.. or to compensate for frame-bowing. I tapped the wood uprights to accept them.

Thinking about the commentary thus far.. I'd still balance my props to get them close.. but wouldn't go too far beyond that. I'll definitely pay more attention to blade-length differences now, after reading. I'd never considered that factor.

Interesting that the engine itself (crank) can be out of balance.. Therefore it would make a difference in overall balance; where the prop is "indexed" in relation to the crank.. correct? I can't imagine an accurate way to measure that.. other than trial and error with every different prop used. I'm in the habit of indexing my props to "windmill" horizontally up-against cylinder-compression when the engine stops, to lessen the possibility of a prop-strike when landing.. and I'm not about to change that practice.

Therefore it would make a difference in overall balance; where the prop is "indexed" in relation to the crank.. correct? I can't imagine an accurate way to measure that.. other than trial and error with every different prop used. I'm in the habit of indexing my props to "windmill" horizontally up-against cylinder-compression when the engine stops, to lessen the possibility of a prop-strike when landing.. and I'm not about to change that practice.

A picture is worth a thousand words..

The screws (5/16-18 bolts actually..) can be adjusted for sensitivity.. or to compensate for frame-bowing. I tapped the wood uprights to accept them.

Thinking about the commentary thus far.. I'd still balance my props to get them close.. but wouldn't go too far beyond that. I'll definitely pay more attention to blade-length differences now, after reading. I'd never considered that factor.

Interesting that the engine itself (crank) can be out of balance..

Re: Balance propellers.

Re: Balance propellers.

Ohh Roddie, very good your balancer, great work buddy! ... that is ideal for small propellers since there is no friction of the shaft with the discs.

Yesterday I went to fly and tried different propellers, balanced and unbalanced, notoriously improves engine speed and vibrations in general, for example you can see in the fuel tank, that when the propeller is balanced, it is beat less generating less foam And a more stable fuel to run the engine!

regards

Yesterday I went to fly and tried different propellers, balanced and unbalanced, notoriously improves engine speed and vibrations in general, for example you can see in the fuel tank, that when the propeller is balanced, it is beat less generating less foam And a more stable fuel to run the engine!

regards

MauricioB- Top Poster

- Posts : 3710

Join date : 2016-02-16

Age : 53

Location : ARG

balogh- Top Poster

Posts : 4957

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Balance propellers.

Re: Balance propellers.

András, I think that what you show is an excellent solution to the "beat" of the fuel, giving the engine a constant, coupled and reliable.

MauricioB- Top Poster

- Posts : 3710

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Balance propellers.

Re: Balance propellers.

Yes, Mauricio,

I like these ballon tanks, because

1. The tank adjusts itself to any tank compartment shape in the engine nose

2. There is no air over the fuel, so even in inverted flights the engine sucks fuel and not air

3. No heavy clunk at the end of the pick-up line is needed to keep the suction line end always under the fuel level, like in hard-walled tanks

4. No foaming of fuel

5. Just one inlet (filling) and one outlet(supply) line, no air-vent line is needed

6. Very cheap, and easy to install

I like these ballon tanks, because

1. The tank adjusts itself to any tank compartment shape in the engine nose

2. There is no air over the fuel, so even in inverted flights the engine sucks fuel and not air

3. No heavy clunk at the end of the pick-up line is needed to keep the suction line end always under the fuel level, like in hard-walled tanks

4. No foaming of fuel

5. Just one inlet (filling) and one outlet(supply) line, no air-vent line is needed

6. Very cheap, and easy to install

balogh- Top Poster

Posts : 4957

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Balance propellers.

Re: Balance propellers.

András, interesting and to take into account these points in favor that you mention, Thank you !!balogh wrote:Yes, Mauricio,

I like these ballon tanks, because

1. The tank adjusts itself to any tank compartment shape in the engine nose

2. There is no air over the fuel, so even in inverted flights the engine sucks fuel and not air

3. No heavy clunk at the end of the pick-up line is needed to keep the suction line end always under the fuel level, like in hard-walled tanks

4. No foaming of fuel

5. Just one inlet (filling) and one outlet(supply) line, no air-vent line is needed

6. Very cheap, and easy to install

MauricioB- Top Poster

- Posts : 3710

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Balance propellers.

Re: Balance propellers.

FWIIW

I have a pretty comprehensive collection of props...mostly cuz when I did not know better-- I did the shotgun approach to buying what was / were the suggested props for each engine

The down side of that was--- I was NOT asking the right question...

What is a good prop for THIS engine and This Plane at This weight flying on this line length...??

And like Ken or others ...way back in the 50/60/70s we just bought nylon or wood props and bolted them on...

I/we did know about prop balancing

That was a craft the 36,000+ RPM speed guys had to do

I do think it a good practice to :

Check equal blade length and adjust

Check hub centering hole and discard or correct

*Check general balance and correct

*In this area I started being real OCD and anal about "perfect balance"

Then I met a real good stunt flier who helps me fly and trim my planes... he has never balanced a prop in his life

If he does not like the "feel" of a certain prop...in the air... he shifts it 90 degrees first... and if it still sux... a new different prop is installed

Yes some props--- OUT of the Package-- as new---- need-- to BE ----cleaned up

I still hang every prop on my mag balance,,,BUT that sucker has to REALLY be way out of whack to get me concerned and fussing now a days...

HEY I am a HACK sport flyer.... ...

You wanna win the WC or NATS...balance you prop to within .0000007 grams

You wanna fly this Sunday...

I believe ANY store bought 9X4 mounted on your OS 20 FP will work right our of the package...just fine

MNSHO

I have a pretty comprehensive collection of props...mostly cuz when I did not know better-- I did the shotgun approach to buying what was / were the suggested props for each engine

The down side of that was--- I was NOT asking the right question...

What is a good prop for THIS engine and This Plane at This weight flying on this line length...??

And like Ken or others ...way back in the 50/60/70s we just bought nylon or wood props and bolted them on...

I/we did know about prop balancing

That was a craft the 36,000+ RPM speed guys had to do

I do think it a good practice to :

Check equal blade length and adjust

Check hub centering hole and discard or correct

*Check general balance and correct

*In this area I started being real OCD and anal about "perfect balance"

Then I met a real good stunt flier who helps me fly and trim my planes... he has never balanced a prop in his life

If he does not like the "feel" of a certain prop...in the air... he shifts it 90 degrees first... and if it still sux... a new different prop is installed

Yes some props--- OUT of the Package-- as new---- need-- to BE ----cleaned up

I still hang every prop on my mag balance,,,BUT that sucker has to REALLY be way out of whack to get me concerned and fussing now a days...

HEY I am a HACK sport flyer.... ...

You wanna win the WC or NATS...balance you prop to within .0000007 grams

You wanna fly this Sunday...

I believe ANY store bought 9X4 mounted on your OS 20 FP will work right our of the package...just fine

MNSHO

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Balance propellers.

Re: Balance propellers.

Yep, nice thing with a profile or any plane where the engine is mounted horizontal is the luxury, that with a slightly out of balanced prop you could simply rotate prop 180 putting the mass (or taking away) from the opposite side of crank. It's impossible to perfectly balance an engine, let alone a prop, it may be balanced at a given rpm, but at best its always a compromise.

I still have my cheesey plastic wheel prop balancer i got from Hobby Lobby in the eighties and would always check a new prop, lightly sand or spray clear on light side, making sure it was 'close'.

I still have my cheesey plastic wheel prop balancer i got from Hobby Lobby in the eighties and would always check a new prop, lightly sand or spray clear on light side, making sure it was 'close'.

Last edited by Mark Boesen on Thu May 18, 2017 9:54 am; edited 1 time in total

Re: Balance propellers.

Re: Balance propellers.

Oh, with the Coxes, I found that simply balancing the prop made a whole lot of difference in vibration levels. The old nylon Top Flite's and Tornado's were notoriously out of balance. Given the manufacturer has already provided a counterbalance weight on the crankshaft makes me think laws of diminishing returns on flipping the prop on a pancake mounted engine. Might work for a very minor imbalance problem.

Fox .35's are vibrating nightmares, perhaps would cure those?

I just sanded the back side of the heavy blade until balanced, which was sufficient at least for me on these Coxes.

Fox .35's are vibrating nightmares, perhaps would cure those?

I just sanded the back side of the heavy blade until balanced, which was sufficient at least for me on these Coxes.

GallopingGhostler- Top Poster

Posts : 5713

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Similar topics

Similar topics» Please help me to identify this COX engine

» Propellers, so how many do you have?

» Propellers?

» Propellers

» 5 x 3 propellers

» Propellers, so how many do you have?

» Propellers?

» Propellers

» 5 x 3 propellers

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules