Log in

Search

Latest topics

» My latest doodle...by batjac Yesterday at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Yesterday at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Yesterday at 9:22 pm

» Roger Harris revisited

by rsv1cox Yesterday at 3:38 pm

» My N-1R build log

by GallopingGhostler Yesterday at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Yesterday at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 11:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Mylar/Stainless steel reeds with circlip-type reed retainer

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

10-4! I'll get the pics up when I'm assembling it. Make sure the Circlip direction is correct. Thanks guys

Dane Martin- Silver Member

- Posts : 76

Join date : 2016-02-11

Age : 42

Location : Las Vegas, NV

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

balogh wrote:

Looking at the flanged cap type retainers one would wonder how the reed that freely travels a long way between the reed seat and the retainer cap can efficiently seal as for a significant time while it flies back towards the seat when the piston moves down and develops pressure in the crankcase the reed is open and some charge will inevitably be pushed our of the crankcase? I would think the old reed retainer design where reed travel is limited more by the clip should be a more efficient design That is why I try to combine the mylar with the circlip.

Check out Paul G's article on Mouse engines:

http://www.nclra.org/TechTopics/GibeaultMousePrimer.pdf?NCLRA=804dbc1703828132cecd5dae78076991

On page 3 he describes the performance differences of various reed types and materials and the way I read it, actually the plastic retainer with mylar reed is the best performing combination.

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Thanks Kari a good read.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Here is my controversy-stirring experience with the Killer Bee and stock horseshoe backplates:

The Venom clone I built last week (see below) originally included the red Killer Bee backplate having a reed retainer cap (the red one on the 2nd picture). The critter did not want to turn the 5x4 COX prop quicker that say, 16,5-17k rpm no matter what I did.

So I almost gave up and retired this otherwise perfect TeeDeeReedie.

Then as a last resort I swapped the KB backplate with a white horseshoe stock backplate, having a berillium star reed.

The engine revved 19,5k i.e. 3k faster than with the red KB backplate!!!

I have always suspected the KB reed retainer cap (and all Surestart caps) allows to long travel for the reed, which will not be able close the venturi during the full pre-compression cycle in the cranckase, and part of the fuel/air charge escapes thru the venturi. (Just look at the distance between the seated reed and the black retaining stick on the cup of the KB plate, and compare it to the white horseshoe details)

So I am done with my theories, many of you will certainly have opposite experience..I will appreciate your comments.

The Venom clone I built last week (see below) originally included the red Killer Bee backplate having a reed retainer cap (the red one on the 2nd picture). The critter did not want to turn the 5x4 COX prop quicker that say, 16,5-17k rpm no matter what I did.

So I almost gave up and retired this otherwise perfect TeeDeeReedie.

Then as a last resort I swapped the KB backplate with a white horseshoe stock backplate, having a berillium star reed.

The engine revved 19,5k i.e. 3k faster than with the red KB backplate!!!

I have always suspected the KB reed retainer cap (and all Surestart caps) allows to long travel for the reed, which will not be able close the venturi during the full pre-compression cycle in the cranckase, and part of the fuel/air charge escapes thru the venturi. (Just look at the distance between the seated reed and the black retaining stick on the cup of the KB plate, and compare it to the white horseshoe details)

So I am done with my theories, many of you will certainly have opposite experience..I will appreciate your comments.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Hi Andras, This subject always fascinates me. Paul G. states that the copper reed tends to "float" above 16K.. and he sees the best performance from the thicker mylar-style reed; star-shaped for the circlip-style holder and oval-shaped for the cap-style holder.

I see an exhaust-shield installed in your assembled engine photo. Did you use it with the KB Back-plate? If not; that extra thickness could be sealing the case better. If by chance your screws are bottoming in the case.. they won't tighten enough to seal correctly without it. You might try measuring how much thread-length your screws have when installed through the backplate.. vs. the useable threads in the case. The case threads were known for not being tapped deep enough. Some people re-tap the 2-56 threads deeper. If you don't have a tap; alternately shortening the screws slightly, would fix that problem.

As for the reed.. I would guess that its operating-gap is directly related to it's ability to flex away from the seat while being retained at it's outer edges (without being pinched by the circlip) It's generally known "not" to install the circlip backwards; which would restrict the center of the reed from flexing. Regarding the cap-style retainer designed around the .005" (.15mm) reed; when assembled, would provide a very small gap.. (possibly .0005") so as not to pinch the reed. I don't believe that a "good" reed comes anywhere close to contacting the "cross-tang" on a properly-installed circlip.. or the two "prongs" on the cap-style retainer during operation. Those prongs may be there to prevent the reed from being sucked into the crankcase if the edge-retention fails? Maybe the same prevention with the cross-tang on the circlip?

I wouldn't give up on the KB backplate. I believe it has issues with a suction-only fuel delivery. Mine wouldn't run past an exhaust-prime until I increased the size of the fuel line. I was running the Tee Dee ported cylinder like you are. You would probably see rpm#'s close to or over 20K if you tried a pressure-bladder.. but it would be hard to tune for consistency, without a fine-thread NV. Your engine is obviously capable of that.. so I'd surmise it's lack of performance with the KB backplate to be flow-related.. if all other factors were the same.. ie: using the same glow-head/number of head-gaskets etc.. and as I mentioned; the integrity of the backplate/case sealing.

I apologize if I've mentioned this before.. but what I did to improve my suction feed, was to use larger fuel line compressed into a short sleeve of alloy tubing to seal tightly on the smaller fuel-barb on the backplate.

I hope you'll experiment further.. and report. We all want to get the best reliable performance out of our engines!

I see an exhaust-shield installed in your assembled engine photo. Did you use it with the KB Back-plate? If not; that extra thickness could be sealing the case better. If by chance your screws are bottoming in the case.. they won't tighten enough to seal correctly without it. You might try measuring how much thread-length your screws have when installed through the backplate.. vs. the useable threads in the case. The case threads were known for not being tapped deep enough. Some people re-tap the 2-56 threads deeper. If you don't have a tap; alternately shortening the screws slightly, would fix that problem.

As for the reed.. I would guess that its operating-gap is directly related to it's ability to flex away from the seat while being retained at it's outer edges (without being pinched by the circlip) It's generally known "not" to install the circlip backwards; which would restrict the center of the reed from flexing. Regarding the cap-style retainer designed around the .005" (.15mm) reed; when assembled, would provide a very small gap.. (possibly .0005") so as not to pinch the reed. I don't believe that a "good" reed comes anywhere close to contacting the "cross-tang" on a properly-installed circlip.. or the two "prongs" on the cap-style retainer during operation. Those prongs may be there to prevent the reed from being sucked into the crankcase if the edge-retention fails? Maybe the same prevention with the cross-tang on the circlip?

I wouldn't give up on the KB backplate. I believe it has issues with a suction-only fuel delivery. Mine wouldn't run past an exhaust-prime until I increased the size of the fuel line. I was running the Tee Dee ported cylinder like you are. You would probably see rpm#'s close to or over 20K if you tried a pressure-bladder.. but it would be hard to tune for consistency, without a fine-thread NV. Your engine is obviously capable of that.. so I'd surmise it's lack of performance with the KB backplate to be flow-related.. if all other factors were the same.. ie: using the same glow-head/number of head-gaskets etc.. and as I mentioned; the integrity of the backplate/case sealing.

I apologize if I've mentioned this before.. but what I did to improve my suction feed, was to use larger fuel line compressed into a short sleeve of alloy tubing to seal tightly on the smaller fuel-barb on the backplate.

I hope you'll experiment further.. and report. We all want to get the best reliable performance out of our engines!

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

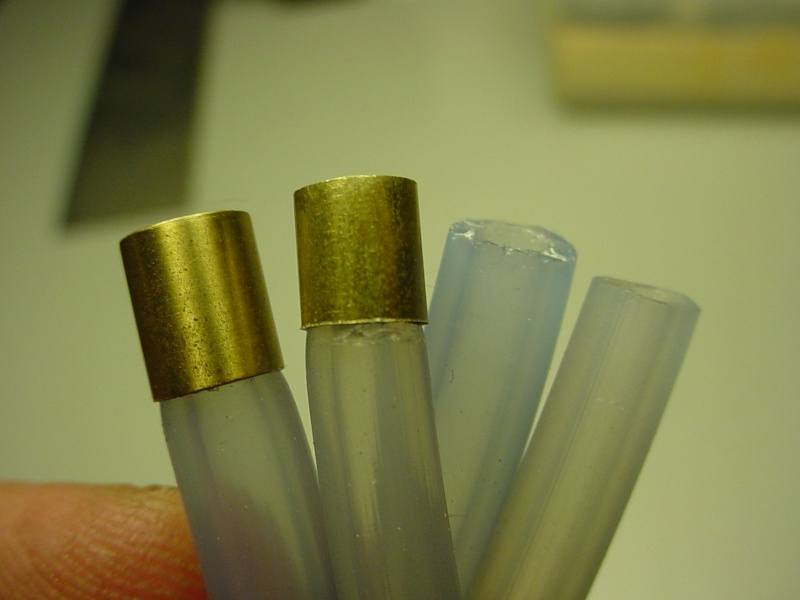

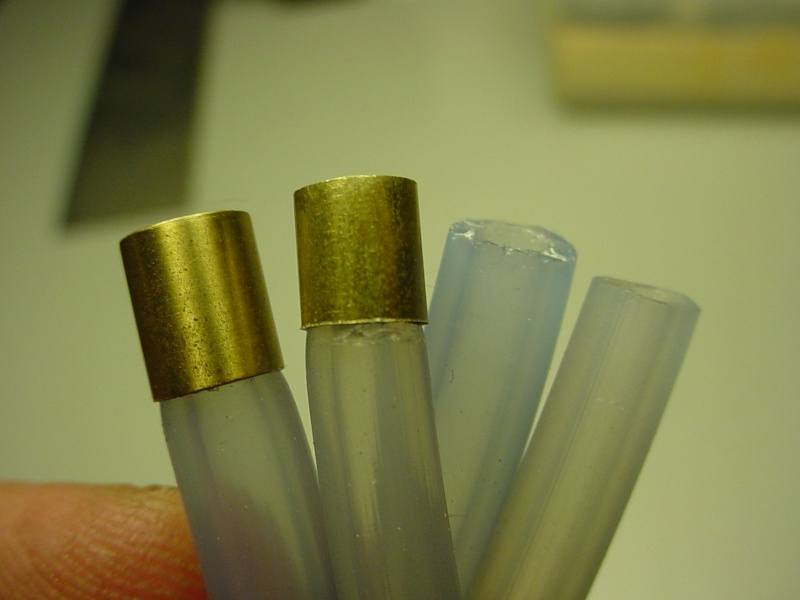

I always assumed the white reed was the Teflon. Davis Diesel made some of these. I never had good success with that reed. I found it to leak upon install prior to running and sometimes two stick together without notice. The clear reed is one I always referred to as the Mylar. If my terminology is incorrect, the clear always worked the best for me. Unfortunately, the Mylar gets distorted very easily getting sucked into the hole. While it's fresh though it always ended up being the most reliable and best performer.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

I have had good experience with the Mylar , I got some of the Teflon at http://coxengines.ca/cox-.049-reed-valve-teflon-6.html These are POS they need to bee discontinued there like a piece of paper when you bend them in the least (very flimsy) and I can see where they would suck into the venture , they want hold there shape! got them because for resale they were less $$ . never tried the crystal or the steel , I am looking at finding some phasic film (like on a binder ) to make some ?? may even fine colors  Eric

Eric

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» Mylar reeds

» star mylar reeds

» Mylar reed valver failure

» Help! Need Reed valve retainer spring for Cox 010 engine

» WTB Horseshoe backplates with wire reed retainer (not plastic cage)

» star mylar reeds

» Mylar reed valver failure

» Help! Need Reed valve retainer spring for Cox 010 engine

» WTB Horseshoe backplates with wire reed retainer (not plastic cage)

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules