Log in

Search

Latest topics

» My latest doodle...by batjac Today at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Today at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Today at 9:22 pm

» Roger Harris revisited

by rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Mylar/Stainless steel reeds with circlip-type reed retainer

Page 1 of 2

Page 1 of 2 • 1, 2

Mylar/Stainless steel reeds with circlip-type reed retainer

Mylar/Stainless steel reeds with circlip-type reed retainer

I have a few old COX reedies designed originally for the star-shape beryllium reeds.

Once I replace the old star reed with a mylar or stainless steel reed, I feel these are a bit stuck under the circlip, being obviously thicker than the beryllium (the groove for the circlip is too close to the reed seat bottom and thus will not allow an unobstructed float of the thicker mylar or stainless steel reed).

As a consequence, the suck-and-blow test shows it takes a larger depression in the crankcase to open the mylar and stainless steel reed valve than it takes for the beryllium, and the charge of the engine will be less. I derive this will have a negative impact on the engine output...

Any advice on how to enable the mylar/stainless steel reeds to float better under the circlip retainer, and experience on possible output deterioration with the myler/stainless/circlip combo, from any one of you will be appreciated.

Once I replace the old star reed with a mylar or stainless steel reed, I feel these are a bit stuck under the circlip, being obviously thicker than the beryllium (the groove for the circlip is too close to the reed seat bottom and thus will not allow an unobstructed float of the thicker mylar or stainless steel reed).

As a consequence, the suck-and-blow test shows it takes a larger depression in the crankcase to open the mylar and stainless steel reed valve than it takes for the beryllium, and the charge of the engine will be less. I derive this will have a negative impact on the engine output...

Any advice on how to enable the mylar/stainless steel reeds to float better under the circlip retainer, and experience on possible output deterioration with the myler/stainless/circlip combo, from any one of you will be appreciated.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

One quick thing to check is the circlip itself and make sure it's not flipped over. It snaps into the retainer one way and the center tang will hold the reed in place if the clip is upside down.

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

I don't use the SS ones but have noticed ,and this had come up before that they are cut a little long and tend to bow when installed, simply lightly sand the rounded edges till fit is correct to let it float as intended with the clip installed with the protruding of the clip out so as not to press on the reed . Eric  Andrew said that right, Thanks

Andrew said that right, Thanks

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Older OEM circlips were thinner wire diameter than the replacements available today. If you replaced with a thicker dia circclip I have seen this happen where the Reed is stuck. Find a thinner circlip and it should be fine.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Thanks

The center part is not flush and it elevates from the reed so it is OK. I think the mylar is too thick and overlaps the groove so the clip holds it down too strongly

The center part is not flush and it elevates from the reed so it is OK. I think the mylar is too thick and overlaps the groove so the clip holds it down too strongly

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Thanks Jason I think this is stock clip but will compare with another

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Thanks for bringing that up Jason , I have seen this in some engines I have bought /cleaned , but have now bought any new circlips for lack of need . Eric

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Another thing you can do is face the clip, it takes a little time, trial and error but I've done it just make sure its even.

(Bandit)

(Bandit)

TDbandit- Platinum Member

- Posts : 897

Join date : 2014-12-01

Age : 53

Location : Riverdale Georgia

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

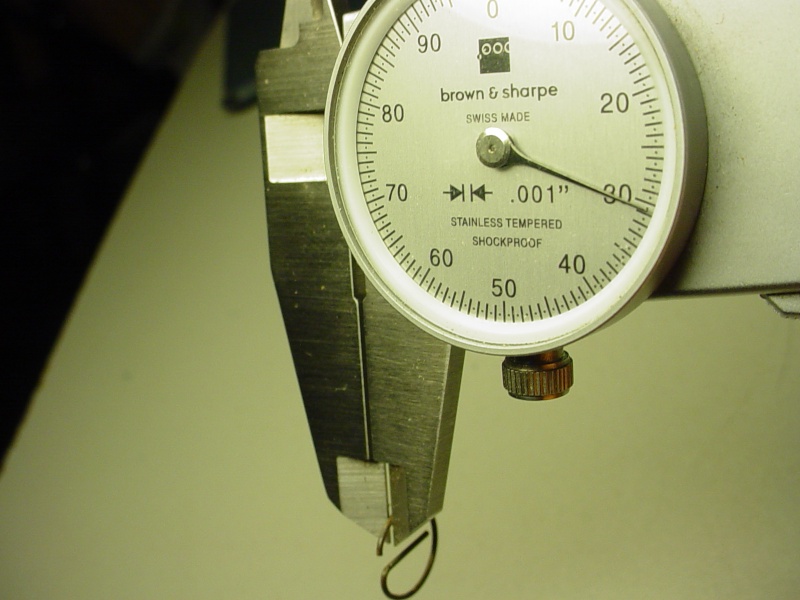

I have heard that the steel reeds can wear the anodizing off the seat. I can't speak from experience though. I do have some steel reeds.. and they're only .001" thicker than the original copper-star type. My Mylar reeds measure .005" in thickness. My steel reeds measure .002"... and the old beryllium/copper type measure .001". You're really going to see a difference with the Mylar type in this application.

Something to try.. (I plan on trying this..) is to thin-out the backside of a circlip, like Bandit mentioned. To do this evenly would be very important... so I got to thinking of a way to attempt it. If you have an oil-stone.. that would probably work best. A 3/8" diameter hardwood dowel will fit inside the circumference of the circlip. If you cut a piece about an inch long and slot one end "on-center" for the clip's "tang" to fit into.. you can then chuck it into a VSR hand drill.. and spin the clip on the stone with some cutting-oil using low speed for a few seconds at a time.. while stopping to check the fit until you achieve the right clearance for the reed you plan to use. If you have a set of vernier/calipers.. you can measure for the amount of material you are removing. It will only need to be a few thousandths of an inch.. (approximately .1mm or less) depending on the reed-thickness/clip-wire diameter.

A standard hacksaw-blade works well for cutting the shallow slot. I seem to have misplaced my oil-stone though..

Something to try.. (I plan on trying this..) is to thin-out the backside of a circlip, like Bandit mentioned. To do this evenly would be very important... so I got to thinking of a way to attempt it. If you have an oil-stone.. that would probably work best. A 3/8" diameter hardwood dowel will fit inside the circumference of the circlip. If you cut a piece about an inch long and slot one end "on-center" for the clip's "tang" to fit into.. you can then chuck it into a VSR hand drill.. and spin the clip on the stone with some cutting-oil using low speed for a few seconds at a time.. while stopping to check the fit until you achieve the right clearance for the reed you plan to use. If you have a set of vernier/calipers.. you can measure for the amount of material you are removing. It will only need to be a few thousandths of an inch.. (approximately .1mm or less) depending on the reed-thickness/clip-wire diameter.

A standard hacksaw-blade works well for cutting the shallow slot. I seem to have misplaced my oil-stone though..

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Thanks Roddie A good idea. As a simplistic man I would have just rubbed the clip on a flattened fine grit sandpaper

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Me too, in fact I did just that the other day. I have several grits spray-glued to my table top. But Roddie is an inventive man of precision. And if we took the small amount of time to make his simple special tools, we might be able to perform many tasks quicker and better.balogh wrote:Thanks Roddie A good idea. As a simplistic man I would have just rubbed the clip on a flattened fine grit sandpaper

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

RknRusty wrote:Me too, in fact I did just that the other day. I have several grits spray-glued to my table top. But Roddie is an inventive man of precision. And if we took the small amount of time to make his simple special tools, we might be able to perform many tasks quicker and better.balogh wrote:Thanks Roddie A good idea. As a simplistic man I would have just rubbed the clip on a flattened fine grit sandpaper

Rusty

Thanks Rusty/Andy.. Rubbing by hand on fine-grit sandpaper would work fine too. I've often wondered whether a reed "itself" could be thinned by placing it in-between two blocks faced with fine paper.. and twisting the blocks. Maybe even try applying some rouge and use two small flat steel blocks without any paper applied?

Of course.. Mylar probably won't take well to sanding.. and being the "thicker" material that it is; might float during operation if thinned too much. I don't know. I imagine that there's an optimal "flex-factor" between the different reed materials.. or there wouldn't be the different thicknesses. Too rigid.. and it won't flex enough to open/operate.. and to flexible, it will begin to float at less than optimal engine rpm.

Here are examples of the differing wire sizes between my .049 circlips.. just to prove that it will make a difference in which clip is used for a particular reed thickness.

The thinner wire would be your best choice with a thicker reed.

This .033" diameter wire (below) would likely be your best option for the vintage thin copper reed.

I would imagine that Cox originally designed the reed-retention system around the standard .031" wire size back in the early days. Whether they specified a +/- .001" max tolerance in the wire-size from the vendor, is something that we can only wonder about.

I realize that not everyone has a vernier/caliper to measure with.. but they are great for things like this.

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

That is a very nice caliper. Brown and Sharpe are my favorite tools

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

I brought this up a few years back.

In the end as long as the reed can rotate freely 180 degrees in the reed holder then I guess it doesn't matter how you do it.

As for sanding the reed itself, I would be worried that the edges of the reed would become "fuzzy" I've never tried it so it may work.

Ron

In the end as long as the reed can rotate freely 180 degrees in the reed holder then I guess it doesn't matter how you do it.

As for sanding the reed itself, I would be worried that the edges of the reed would become "fuzzy" I've never tried it so it may work.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

One more thing... if you happen to try using a different/used circlip/reed combo.. make sure they've been cleaned with solvent. I use a solvent-soaked Q-tip (cotton swab) to clean my reeds (and seating area). A small flat piece of rubber makes a good base to lay the reed for cleaning.. and helps to keep it from sliding around while swabbing it. This can also help to avoid bending/creasing a fragile copper reed. That type can be ruined with discouraging ease. Lifting any reed from a flat surface can be challenging. I usually try pressing my index finger against the center of a reed to pick it up. It will usually stick for a second or two.. long enough to drop it onto the palm of your other hand where you can carefully lift under an edge with tweezers.

Andreas, I hope you don't mind me having mentioned these tips here. I thought that were relative to the topic.. and although some people may know these things already.. some may not.

Were you able to achieve a good fit/seal?

Andreas, I hope you don't mind me having mentioned these tips here. I thought that were relative to the topic.. and although some people may know these things already.. some may not.

Were you able to achieve a good fit/seal?

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Thanks Roddie any advice is appreciated. Sometimes the solution to a problem hides in tiny details one would not even think of.

The clip and the reed both are immaculately clean so I will resort to thinning the clip.

Looking at the flanged cap type retainers one would wonder how the reed that freely travels a long way between the reed seat and the retainer cap can efficiently seal as for a significant time while it flies back towards the seat when the piston moves down and develops pressure in the crankcase the reed is open and some charge will inevitably be pushed our of the crankcase? I would think the old reed retainer design where reed travel is limited more by the clip should be a more efficient design That is why I try to combine the mylar with the circlip.

What is your opinion?

The clip and the reed both are immaculately clean so I will resort to thinning the clip.

Looking at the flanged cap type retainers one would wonder how the reed that freely travels a long way between the reed seat and the retainer cap can efficiently seal as for a significant time while it flies back towards the seat when the piston moves down and develops pressure in the crankcase the reed is open and some charge will inevitably be pushed our of the crankcase? I would think the old reed retainer design where reed travel is limited more by the clip should be a more efficient design That is why I try to combine the mylar with the circlip.

What is your opinion?

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

balogh wrote:Thanks Roddie any advice is appreciated. Sometimes the solution to a problem hides in tiny details one would not even think of.

The clip and the reed both are immaculately clean so I will resort to thinning the clip.

Looking at the flanged cap type retainers one would wonder how the reed that freely travels a long way between the reed seat and the retainer cap can efficiently seal as for a significant time while it flies back towards the seat when the piston moves down and develops pressure in the crankcase the reed is open and some charge will inevitably be pushed our of the crankcase? I would think the old reed retainer design where reed travel is limited more by the clip should be a more efficient design That is why I try to combine the mylar with the circlip.

What is your opinion?

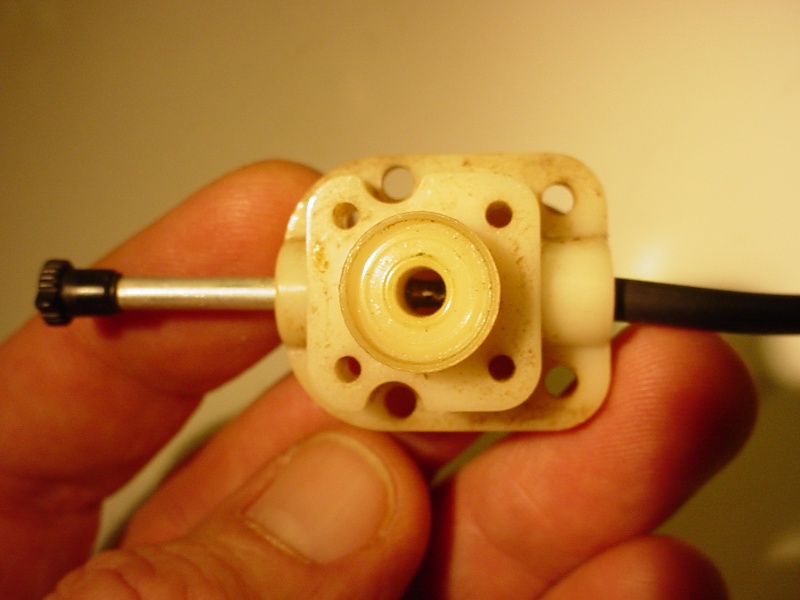

That's a really good question.. and one that I've pondered myself. There's quite a science to reed-induction vs. rotary-valve. Ron Cribbs prefers the reed to rotate freely under a circlip. I tend to agree with his way of thinking. The "cap-style" plastic flanged-retainer I believe is designed around the later .005" thick Mylar "oblong" reed.. I'm curious as to the "design-gap" in this style retainer. The reed is not held by a clip at it's perimeter.. but allowed to "float" within a gap.

The original Cox "star-shaped" beryllium/copper reeds have 4 symmetrical legs extending out from the center which are retained by the circlip. Did this act as a "suspension-system" when the reed lifts off it's seat on the intake stroke? The seat-area is smaller and symmetrical; as compared to the "two sided" oblong reed. The fuel-charge enters through 4 equally-radiussed points.. compared to the oblong's two blunt-straight sides. Both work.. but I've heard that the thin star-shaped/copper-beryllium reed will start to "float" at higher rpm's.

I have some Cox circlip-style horseshoe backplates. The early postage-stamp plastic backplates I think used a higher-quality plastic (Delrin?) than the later horseshoe type.. and as a result; the plastic would fail/crack in the circlip seat area. I have some horseshoe backplates with this condition. I also think that they came with oblong Mylar reeds.. unlike the postage-stamp type. So.. was the circlip-gap increased in the horseshoe backplate; to accommodate the thicker reed?

At some point.. a star-shaped Mylar reed was introduced. I have one.. and it's .005" in thickness. I believe it's from an early white-plastic "circlip-style" horseshoe backplate with an aluminum needle.

Here's that backplate..

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Thanks. The gap in the flanged retainer is just too large and probably is not designed so to acommodate the thicker reed. Maybe it is safer to mount the reed without damaging it than with the circlip...

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

So just to verify the Circlip direction, it sits in the groove, and the bent tang in center faces "up" where it's not holding the reed down, correct?

Dane Martin- Silver Member

- Posts : 76

Join date : 2016-02-11

Age : 42

Location : Las Vegas, NV

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Correct! If not sure if it is in good just give the reed seat the blow/suck test to see if it seals appropriately.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Ok, just making sure i haven't lost my mind! I tried two different reeds on my 020 and both failed the suck / blow test. However, they're used and probably just no good. I've already ordered kits from cox so I'll be good

Dane Martin- Silver Member

- Posts : 76

Join date : 2016-02-11

Age : 42

Location : Las Vegas, NV

is the circlip in correctly?

is the circlip in correctly?

Dane Martin wrote:Ok, just making sure i haven't lost my mind! I tried two different reeds on my 020 and both failed the suck / blow test. However, they're used and probably just no good. I've already ordered kits from cox so I'll be good

Just checking, but is the circlip in correctly? There should be a space between the clip straight piece and the reed. Also make sure there is no debris, dust, old dried fuel, etc. on the reed causing a non-flat surface. Sometimes after you have taken all the precautions there is a tiny piece of dirt on the bottom of the reed.

happydad

happydad- Rest In Peace

- Posts : 1592

Join date : 2012-05-28

Age : 79

Location : Escondido, CA

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Try flipping the reed over and test again.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

You know I'm just going to tell you guys all the same BS, I've been running these forever, i cleaned it good, blah no blah.... HAHA!!

Ok, I'll try cleaning it again, I'll scrub everything with a tooth brush, and then put it back in Cake's (the wife) tooth brush holder. I like her, i like nitro.. Maybe a good combo!

Ah! As I'm rambling, i pulled it apart and see an indentation in the reed. That's gotta be bad, right?

Ok, I'll try cleaning it again, I'll scrub everything with a tooth brush, and then put it back in Cake's (the wife) tooth brush holder. I like her, i like nitro.. Maybe a good combo!

Ah! As I'm rambling, i pulled it apart and see an indentation in the reed. That's gotta be bad, right?

Dane Martin- Silver Member

- Posts : 76

Join date : 2016-02-11

Age : 42

Location : Las Vegas, NV

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

Re: Mylar/Stainless steel reeds with circlip-type reed retainer

RIGHT , WAIT ON YOUR KITS AND ALL WILL BEE GOOD .getbackDane Martin wrote:You know I'm just going to tell you guys all the same BS, I've been running these forever, i cleaned it good, blah no blah.... HAHA!!

Ok, I'll try cleaning it again, I'll scrub everything with a tooth brush, and then put it back in Cake's (the wife) tooth brush holder. I like her, i like nitro.. Maybe a good combo!

Ah! As I'm rambling, i pulled it apart and see an indentation in the reed. That's gotta be bad, right?

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Mylar reeds

» star mylar reeds

» Mylar reed valver failure

» Help! Need Reed valve retainer spring for Cox 010 engine

» WTB Horseshoe backplates with wire reed retainer (not plastic cage)

» star mylar reeds

» Mylar reed valver failure

» Help! Need Reed valve retainer spring for Cox 010 engine

» WTB Horseshoe backplates with wire reed retainer (not plastic cage)

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules