Log in

Search

Latest topics

» Free Flight Radio Assist by Levent Suberk Yesterday at 11:26 pm

» Brushless motors?

by GallopingGhostler Yesterday at 6:35 pm

» Tribute Shoestring build

by 1/2A Nut Yesterday at 2:24 pm

» Cox 020 PeeWee rebuild questions

by TD ABUSER Yesterday at 2:17 pm

» Landing-gear tips

by 1975 control line guy Yesterday at 9:28 am

» My current avatar photo

by GallopingGhostler Fri Nov 15, 2024 7:39 pm

» It's the X Wing that has a canard

by rdw777 Fri Nov 15, 2024 6:58 pm

» music vids.. some of your favorites

by Kim Thu Nov 14, 2024 3:28 pm

» New Model Build

by bsadonkill Thu Nov 14, 2024 1:19 pm

» Kofuku Maru Fishing Boat Model

by Levent Suberk Thu Nov 14, 2024 11:39 am

» TEE DEE Having issues

by GallopingGhostler Wed Nov 13, 2024 11:38 pm

» Pathé Modeling Videos

by Levent Suberk Wed Nov 13, 2024 2:10 pm

Cox Engine of The Month

a cheap sport muffler

Page 4 of 5

Page 4 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Re: a cheap sport muffler

Re: a cheap sport muffler

There's a knack to drilling-out the primer-end of the shell-casing. I haven't made a lot of these. It seems that the jaws of a small locking-plier set work best for gripping the casing for drilling-out the primer-end. I used a drill-press, a backing-block and light oil applied inside the casing. I found that the oil is necessary for getting the job done.

again.. to completely drill-out a .22 cal. ammo casing requires a #5 (.205" dia.) drill. A 13/64" (.2031" dia.) is the next closest fractional-size drill for achieving "full-flow" through the casing (pipe).

again.. to completely drill-out a .22 cal. ammo casing requires a #5 (.205" dia.) drill. A 13/64" (.2031" dia.) is the next closest fractional-size drill for achieving "full-flow" through the casing (pipe).

Re: a cheap sport muffler

Re: a cheap sport muffler

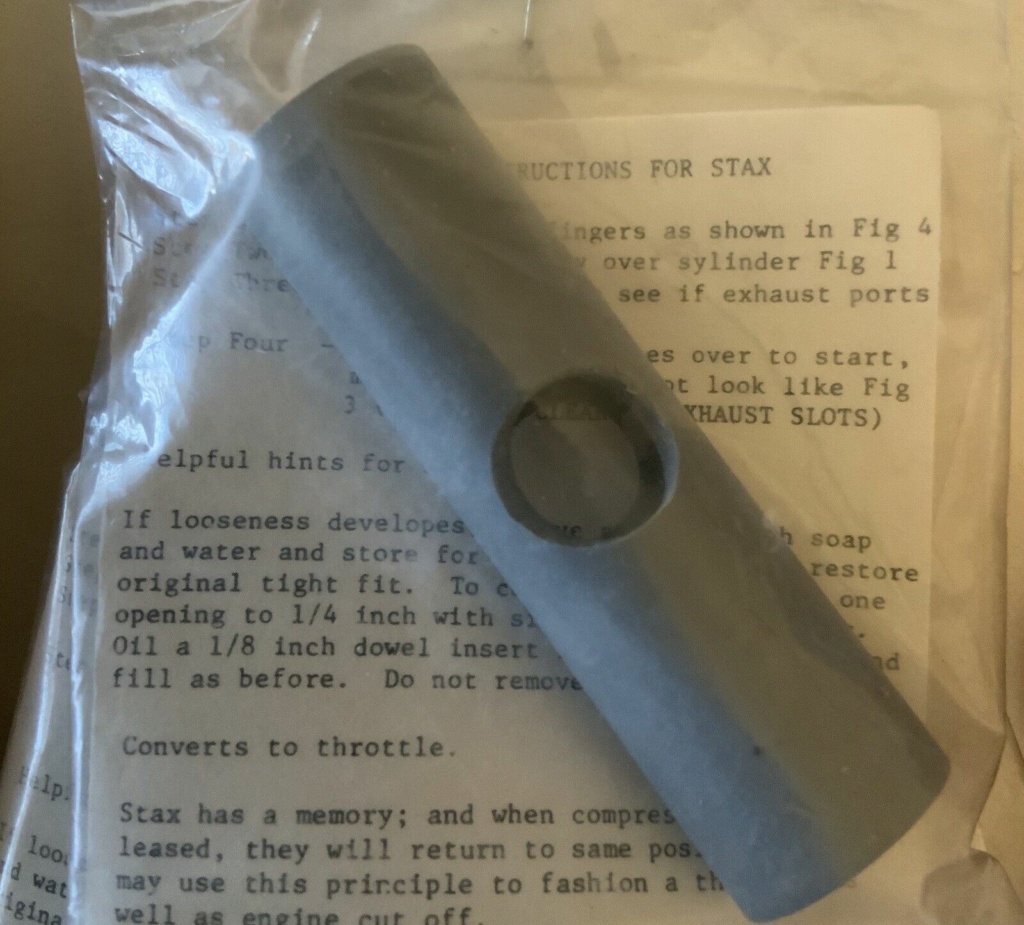

I have quite a few of those rubber tube mufflers. Bob Davis from Davis Diesel offered them at one time.

Ken Cook- Top Poster

- Posts : 5634

Join date : 2012-03-27

Location : pennsylvania

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

steel-wool pipe-packing

steel-wool pipe-packing

Just a little messin' around.. before the year ends. XXXX steel-wool packing for the pipe(s)... that won't "blow-out" under pressure. I'm hoping to "soften" the shrill tone of the exhaust-note.. while also being able to re-direct the engine's exhaust-oil mist/spray.

parts breakdown;

assembled pipe;

Shown installed in housing.. along with an assembled muffler;

I have X3 coarser grades of steel-wool that I can also try. The super-fine (XXXX) might load-up with exhaust-oil causing a restriction of flow.. but we'll just have to test it to find out.

parts breakdown;

assembled pipe;

Shown installed in housing.. along with an assembled muffler;

I have X3 coarser grades of steel-wool that I can also try. The super-fine (XXXX) might load-up with exhaust-oil causing a restriction of flow.. but we'll just have to test it to find out.

Re: a cheap sport muffler

Re: a cheap sport muffler

Great solution, Roddie. I think you can spare the safety spin if you slightly mushroom the steel wool packing at its end inside the muffler so that the flue gases cannot spit it out from the cartridge shell? Or stick a short pin - longer than the shell internal diameter - into the same packing end radially to lock it inside?

balogh- Top Poster

Posts : 4957

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: a cheap sport muffler

Re: a cheap sport muffler

balogh wrote:Great solution, Roddie. I think you can spare the safety spin if you slightly mushroom the steel wool packing at its end inside the muffler so that the flue gases cannot spit it out from the cartridge shell? Or stick a short pin - longer than the shell internal diameter - into the same packing end radially to lock it inside?

Hi Andras, Yea.. the safety-pin is a bit ungainly but it's not going to loosen/fall-out from vibration. I don't want to risk having something come loose "inside" the housing that could find its way into an exhaust-port. The silicone tubing has a .187" ID which fits TIGHT over the .228" shell-casing's OD.. so it's not going to loosen/fall-off either.

More testing is needed overall.. but I like it when I think-up new things to try, without deviating too much from my original design. It might provide an option for a different application.

The "tubing" for instance when installed on a pipe; prevents the pipe from sliding backward. A short "slice" stretched-over an installed-pipe from the "outside".. will make installation of the muffler easier.. because there's nothing on the inside of the chamber.. to get hung-up.

Just to recap; my muffler slides-on (like a rubber-boot) over the glowhead and cylinder.. without the need for engine disassembly. An exhaust-prime can be done, the engine started and tuned prior to installing the muffler.. which I feel is a major advantage and there is absolutely no metal-to-metal contact between the muffler and the engine when installed correctly. An incorrect installation is unlikely.. due to the design.

A marine application could benefit from a longer length of tubing routed astern; to a pipe running through a model boat's transom.. which would greatly decrease the amount of exhaust-oil getting into the bilge.. PLUS; make for a scale-acting exhaust.

An "oil-sump" is another design-option that was discussed and tested recently.. which collects some of the oil into a wadding-media within a vented sump.

The "silencing" ability of this design is limited by the rubber (body) component. It's not going to suppress SPL's as much as a conventional (alum. canister) model-engine muffler will.

The silicone rubber is highly resistant to heat (up to 450F).. which makes it an attractive option. I've sourced three different thickness sheets to test. Thinnest is .031" followed by .045" and thickest .078".

The .031" sheet tore at the punched-hole, when attempting to insert the inner-chamber component. I will revisit that stock though.. and try something different.

The .078" sheet was too thick for my paper-stapling method when doubled-up. It is also heavier than the design requires.

The .045" sheet is the preferred thickness.. and has been fab'd into a few units. I sent one to my friend Robert down in WV.. for testing.

The .045" silicone sheet has similar workability.. when compared to the original butyl sheet material that I've sourced from bicycle-tire inner-tubes in my original design from 30 years ago. This makes sense.. because that butyl sheet is also .045" avg. thickness.

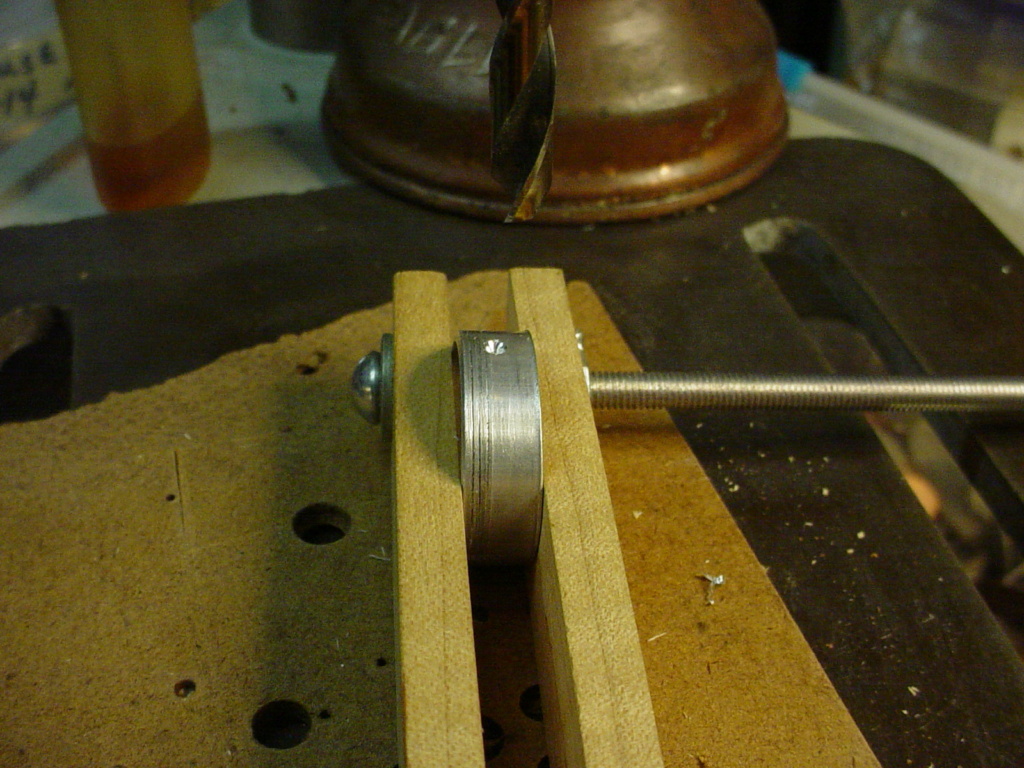

The inner-part (1" dia. aluminum ring from thin-wall tubing) has been a tougher component for me to fab. thus far. Both the cutting to length.. and drilling pipe-holes.

I had a friend cut some pieces (rings) to length.. using a lathe. The tubing was too thin (wall).. which proved to be problematic for the lathe's "jaws" gripping tight-enough so as not to spin-out.. vs. distortion of the tube from the over-tightening of the jaws.

I use a plumbing-type "pipe-cutter" to cut my rings to length now. The length needs to be at least the distance between the base of the engine's cylinder.. and a bit above the top of the cylinder's exhaust-port. This assures the sealing of the exhaust-ports by the muffler-assembly.. once installed.

A pipe-hole needs to be drilled in the ring afterward. The pipe (brass casing) OD is .228" avg. and I've found that a standard-size 15/64" diameter (.2344"/5.95mm) drill works best as the finish-size for pipe-installation.. especially if pipes are swapped-out frequently; as can be the case with varied-orifice pipes. The .006" difference is just enough to make a pipe easier to install.. which needs to be done after the ring is installed into the outer rubber body. tighter tolerances proved harder to work with.

Drilling the 15/64" pipe-holes is best done in stages.. (at least three) with smaller drills. It's easier to accurately center-drill the side of a small aluminum ring.. starting with a smaller drill and finishing with the finish-size one. I used a fixture that I originally made for hard-soldering tin-plate panels for fuel-tanks.

Drilling-out the "primer-end" of the header-pipe (spent .22 LR ammo. casing) has it's own set of challenges. The largest drill possible is a #5 (.205") which totally opens the casing. I've been using a small curved-jaw locking-plier set to keep the casing from "slipping" radially.. and a drop or two of cutting-oil inside the casing to help the drill.

Ooo.. 57 min. til the New Year!

Re: a cheap sport muffler

Re: a cheap sport muffler

I love it Roddie that lots of consideraton goes into a basically 3 component item for its full functionality! Congrats again and Happy New Year to you too!.

balogh- Top Poster

Posts : 4957

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: a cheap sport muffler

Re: a cheap sport muffler

balogh wrote:I love it Roddie that lots of consideraton goes into a basically 3 component item for its full functionality! Congrats again and Happy New Year to you too!.

Thanks Andras. Most people wouldn't fuss around with these things as much as I do, but I enjoy it... and it does add a new dimension to the functionality of our Cox engines.

Re: a cheap sport muffler

Re: a cheap sport muffler

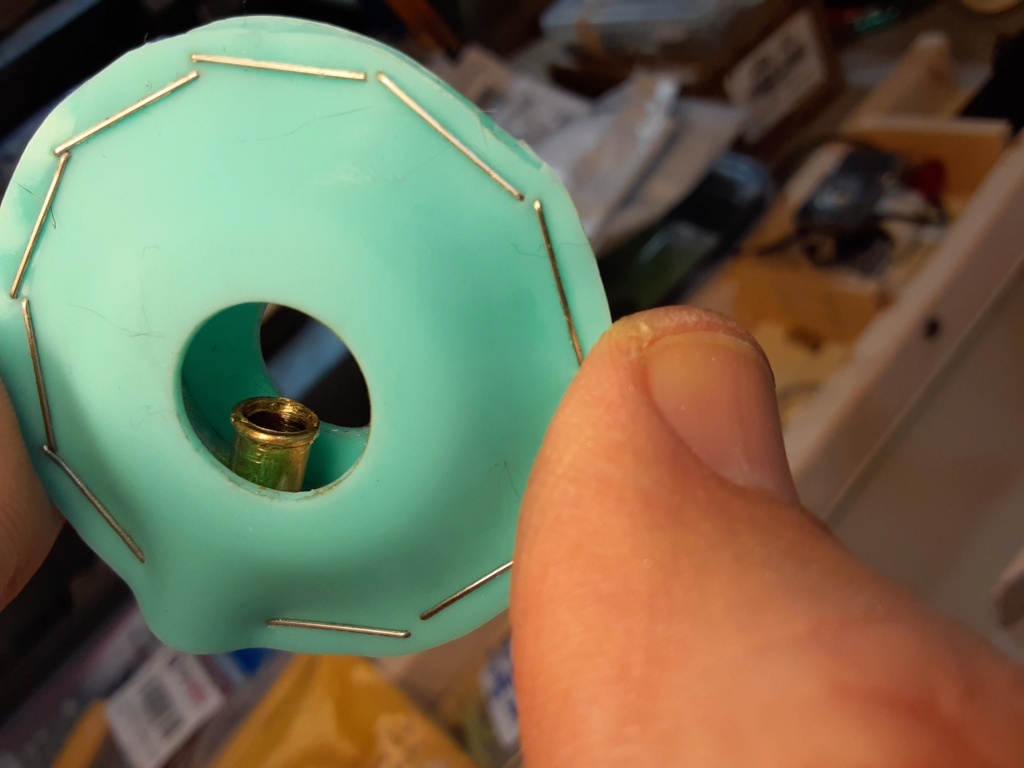

Hi again.. and thanks for your interest. I'm finding that the silicone (I'm using .045" sheet) tear's easily if cut in an area of tension. Attempting to install the inner aluminum ring is best done by starting with a ring that's had its outer edges smoothed.

Petroleum jelly aids in the insertion of the ring...

A bit of twisting.. will slip the ring between the silicone discs..

... then the ring can be manipulated into position.

A "pipe" can now be inserted..

Petroleum jelly aids in the insertion of the ring...

A bit of twisting.. will slip the ring between the silicone discs..

... then the ring can be manipulated into position.

A "pipe" can now be inserted..

Re: a cheap sport muffler

Re: a cheap sport muffler

I was thinking

what stops us from getting mufflers printed?

what stops us from getting mufflers printed?

robot797- Platinum Member

- Posts : 787

Join date : 2013-07-28

Age : 34

Re: a cheap sport muffler

Re: a cheap sport muffler

I am not well versed in 3D printing, but the material, that should be on the one hand printable, should be heat resistant on the other. The hot flue gases restricted by any muffler from immediate mixing with fresh air will heat the muffler body to high temperature..

balogh- Top Poster

Posts : 4957

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: a cheap sport muffler

Re: a cheap sport muffler

I ment metal 3d printed

It's getting cheap lately

It's getting cheap lately

robot797- Platinum Member

- Posts : 787

Join date : 2013-07-28

Age : 34

more fabrication/tooling

more fabrication/tooling

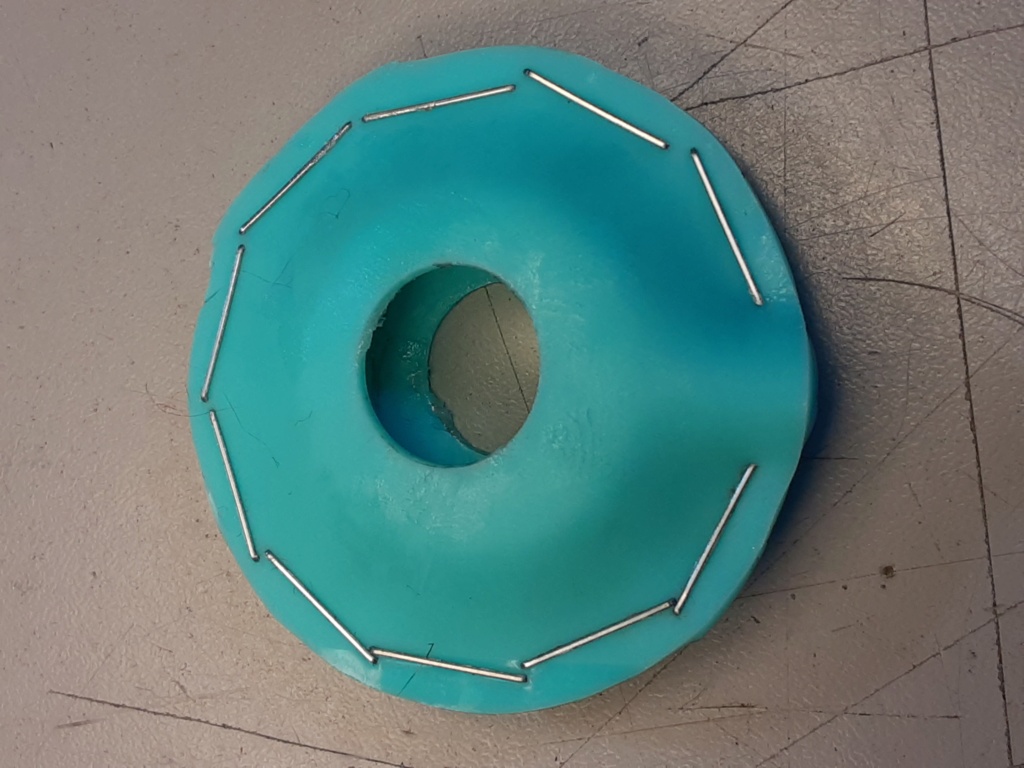

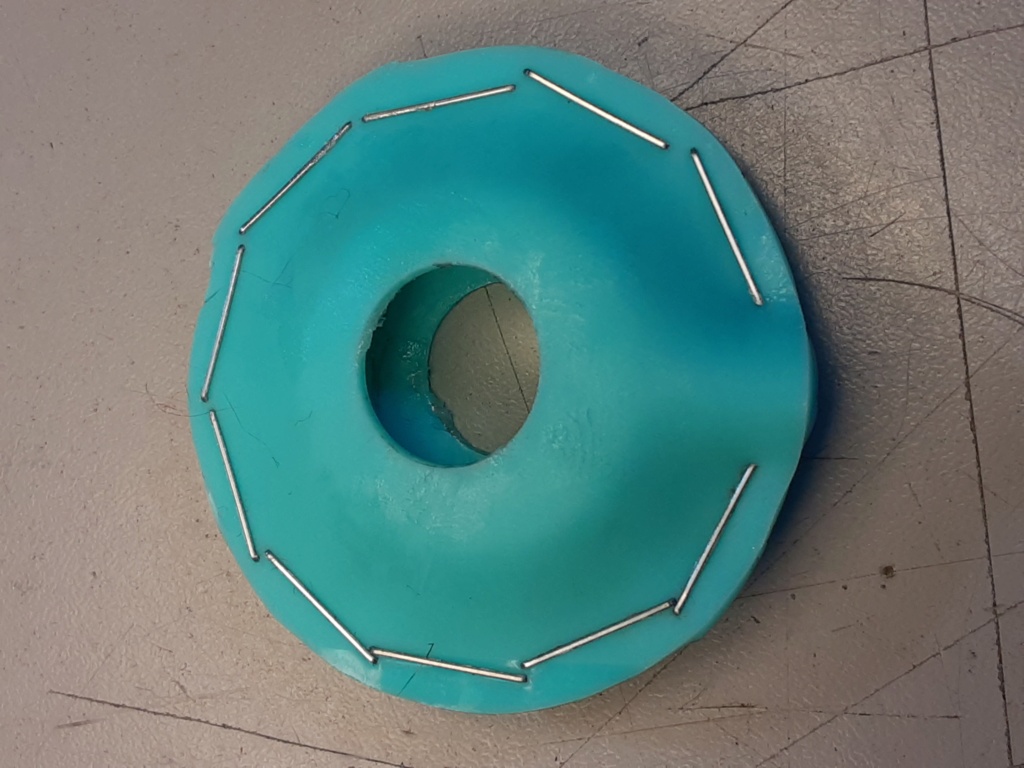

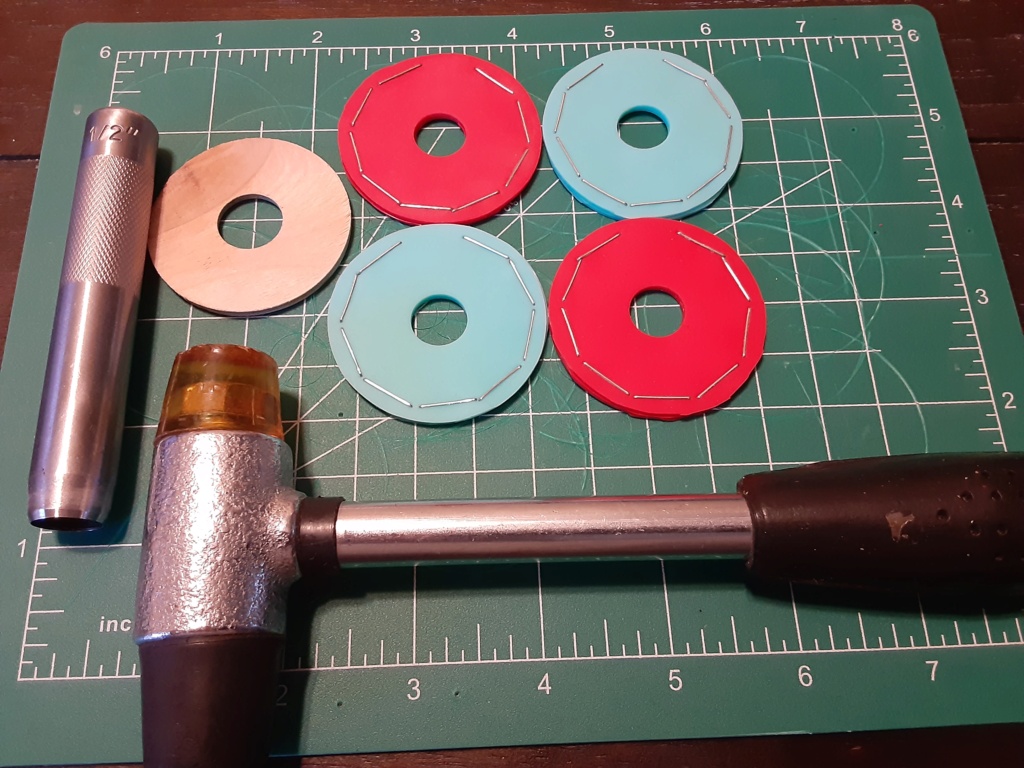

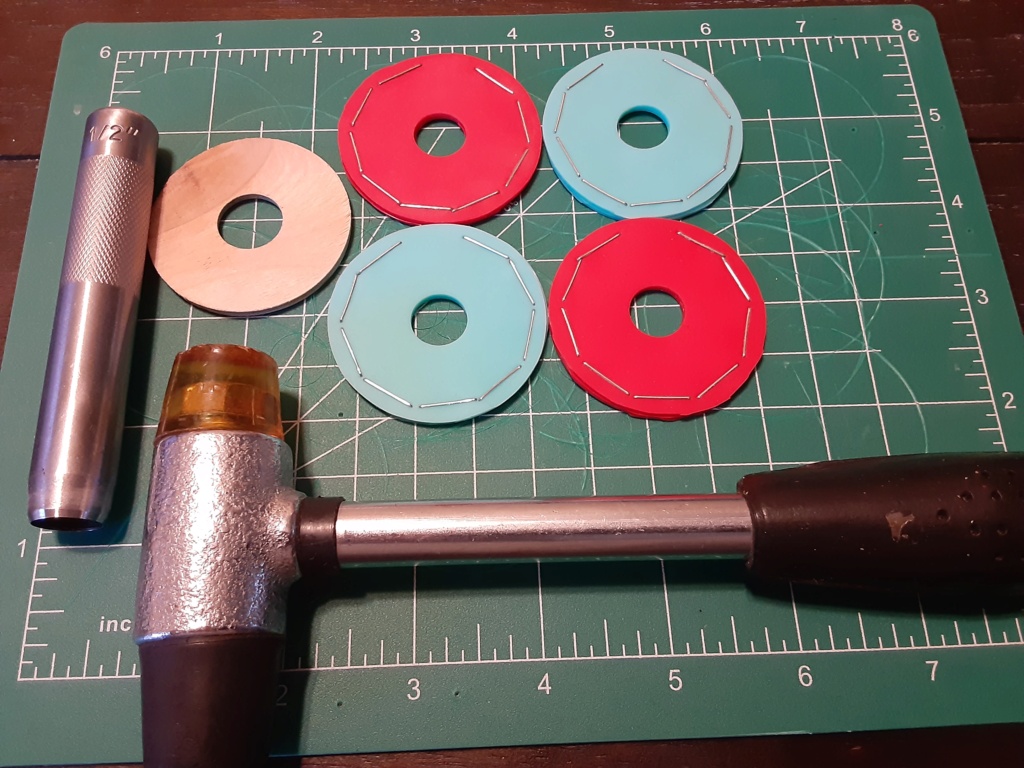

This muffler design seems to keep tugging at me. It's something that I'd like to make available.. if people wanted it. Besides.... I'll need to recoup what I've spent in research and development.

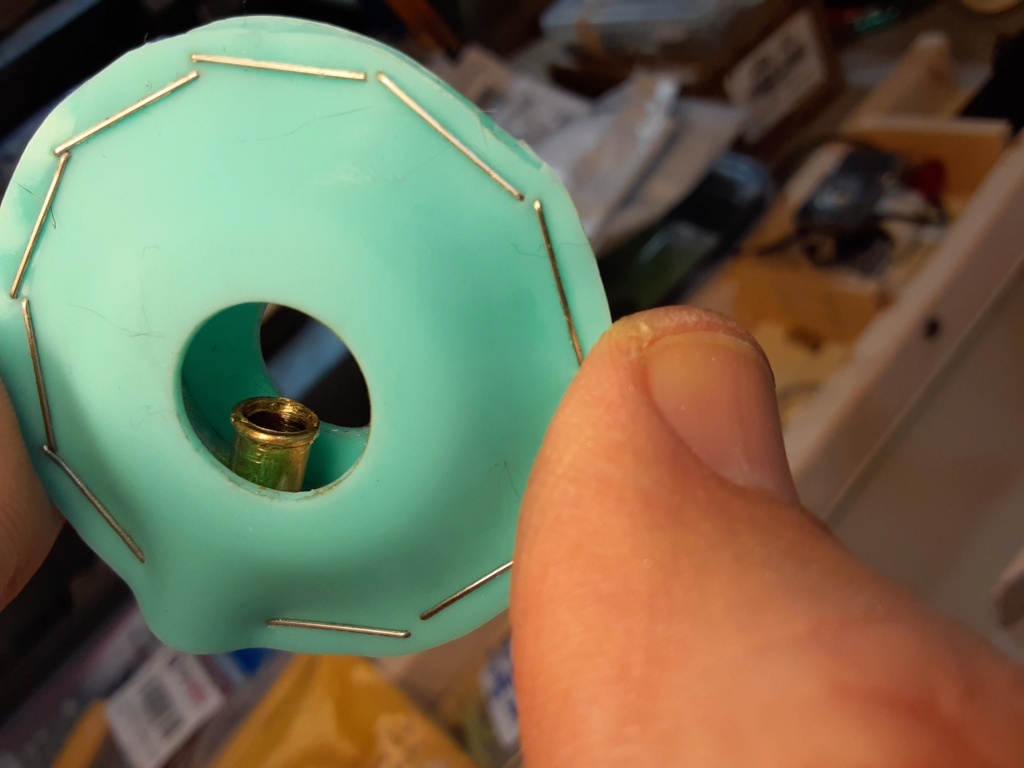

I'm pretty much ready to send-out (parcel post) some units for Beta testing. The unit fits over/around Cox .049/.051 REED VALVE engine's cylinders. This radial design may block the Medallion/Tee Dee's air-intake/carburetor. That's my disclaimer..

So.... I've been having this problem.. center-punching (accurately..) the rubber component. See below; I carefully "cut" the pair of rubber discs to mirror each other.. staple them together with my custom radial depth shoe/fixture.. and finish-off by botching the center-punch.

So I used a 2" hole-saw to cut a guide from some 3mm birch ply. and a rotary-rasp to enlarge the "centered" center-hole.. to the size/OD of my 1/2" leather-punch. On center now.

I'm pretty much ready to send-out (parcel post) some units for Beta testing. The unit fits over/around Cox .049/.051 REED VALVE engine's cylinders. This radial design may block the Medallion/Tee Dee's air-intake/carburetor. That's my disclaimer..

So.... I've been having this problem.. center-punching (accurately..) the rubber component. See below; I carefully "cut" the pair of rubber discs to mirror each other.. staple them together with my custom radial depth shoe/fixture.. and finish-off by botching the center-punch.

So I used a 2" hole-saw to cut a guide from some 3mm birch ply. and a rotary-rasp to enlarge the "centered" center-hole.. to the size/OD of my 1/2" leather-punch. On center now.

Ridgid-cut rings.. and crocus cloth

Ridgid-cut rings.. and crocus cloth

Last edited by roddie on Sun Mar 17, 2024 10:39 am; edited 1 time in total

FRV application?

FRV application?

I'm sizing components to fit Cox FRV (.049/.051) engine's cylinder's; where there's minimal clearance in-between the engine's venturi. This version will likely require cylinder R & R for installation.

an easier method..

an easier method..

I mentioned the need to "smooth" the sharp outer-edges/corners on the aluminum ring before attempting to force it through the opening in the silicone "pod". I used my rotary-rasp with a short piece of garden hose wrapped-around it.. and then wrapped double-sided foam-tape around the garden hose.

The "foam tape" was key in making this work. After sizing it to the ring's inner circumference; i peeled off the backing paper to expose the adhesive. I then applied talcum powder to "unstick" the surface. A ring could now be easily twisted-onto my custom arbor with the foam expanding to hold it in place.

Single wraps of each was enough to hold a ring in place enough to spin in my VSR cordless drill. A small piece of emery-cloth in my free hand to quickly round-off the sharp-corner from the cut ring.

The "foam tape" was key in making this work. After sizing it to the ring's inner circumference; i peeled off the backing paper to expose the adhesive. I then applied talcum powder to "unstick" the surface. A ring could now be easily twisted-onto my custom arbor with the foam expanding to hold it in place.

Single wraps of each was enough to hold a ring in place enough to spin in my VSR cordless drill. A small piece of emery-cloth in my free hand to quickly round-off the sharp-corner from the cut ring.

Re: a cheap sport muffler

Re: a cheap sport muffler

Very thoroughly thought of details of production, Roddie, I admire your devotion to details..

balogh- Top Poster

Posts : 4957

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: a cheap sport muffler

Re: a cheap sport muffler

I'm neither that familiar with 3D printing, either. You're right, András, it would have to be a temperature resistant plastic. I don't know if silicon rubber can be 3D printed.balogh wrote:I am not well versed in 3D printing, but the material, that should be on the one hand printable, should be heat resistant on the other. The hot flue gases restricted by any muffler from immediate mixing with fresh air will heat the muffler body to high temperature..

Cox went with a silicone rubber cover style muffler over an aluminum exhaust throttle ring with the new R/C Bee around 1977 - 1978. I found it to effectively muffle, and after many flights, inside portions of the silicone rubber ring develops surface cracks and scorching by direct contact of the hot Castor laden exhaust gases, but still maintained its integrity. (Advantage to the silicone cover was it could be easily removed where noise was not a problem, and engine would have a touch more power.)

But I heard that Cox got threatened with a lawsuit for silicon muffler copyright violation with a small engine manufacturer for I think lawn equipment or motorscooters. Based on info someone presented a while back, it seemed to be a far stretch of imagination as the designs were completely different, but Cox relented and withdrew the R/C Bee (which incindently was an excellent throttlable R/C engine especially with its extended capacity tank), and came out with the Dragonfly with standard all metal exhaust throttle ring muffler several years later.

GallopingGhostler- Top Poster

Posts : 5713

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: a cheap sport muffler

Re: a cheap sport muffler

I had been thinking of that silicone muffler when Roddie started this thread. Think I still have one. I bet Roddie could get some great ideas if he got a little lathe. I was thinking of another Cox ringed muffler that had a thin spring steel washer on top to hold it on. The silicone washer could maybe be enough to hold it on. It would need a whole new design though.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: a cheap sport muffler

Re: a cheap sport muffler

or get it printed in china (in metal)

I might want to do that one day

I might want to do that one day

robot797- Platinum Member

- Posts : 787

Join date : 2013-07-28

Age : 34

Re: a cheap sport muffler

Re: a cheap sport muffler

robot797 wrote:or get it printed in china (in metal)

I might want to do that one day

I've been working up-to a design that's "cheap" Peter. Would I like to produce/sell it?........... I've thought about it. I wouldn't want to promote my design.. before it was tested.. and found to be an acceptable upgrade for specific applications.

There's little to no market for a product like I've been working on here. I'm 64 years old.. and I'd LOVE to see the next best thing in modeling. What will it be?

Last edited by roddie on Tue Mar 19, 2024 11:56 pm; edited 1 time in total

Page 4 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Similar topics

Similar topics» Super sport 049

» WTB .049 muffler or muffler parts

» Cox Sandblaster clean-up

» RC flying on the cheap........................

» Why are Tee Dee 010 so expensive?

» WTB .049 muffler or muffler parts

» Cox Sandblaster clean-up

» RC flying on the cheap........................

» Why are Tee Dee 010 so expensive?

Page 4 of 5

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules