Log in

Search

Latest topics

» Free Flight Radio Assist by GallopingGhostler Today at 6:41 pm

» Brushless motors?

by GallopingGhostler Today at 6:35 pm

» Tribute Shoestring build

by 1/2A Nut Today at 2:24 pm

» Cox 020 PeeWee rebuild questions

by TD ABUSER Today at 2:17 pm

» Landing-gear tips

by 1975 control line guy Today at 9:28 am

» My current avatar photo

by GallopingGhostler Yesterday at 7:39 pm

» It's the X Wing that has a canard

by rdw777 Yesterday at 6:58 pm

» music vids.. some of your favorites

by Kim Thu Nov 14, 2024 3:28 pm

» New Model Build

by bsadonkill Thu Nov 14, 2024 1:19 pm

» Kofuku Maru Fishing Boat Model

by Levent Suberk Thu Nov 14, 2024 11:39 am

» TEE DEE Having issues

by GallopingGhostler Wed Nov 13, 2024 11:38 pm

» Pathé Modeling Videos

by Levent Suberk Wed Nov 13, 2024 2:10 pm

Cox Engine of The Month

a cheap sport muffler

Page 1 of 5

Page 1 of 5 • 1, 2, 3, 4, 5

a cheap sport muffler

a cheap sport muffler

NOTE: The materials list and methods have been updated since this thread was created. Please peruse the entire thread for the most up to date information/testing etc. Thanks, Roddie

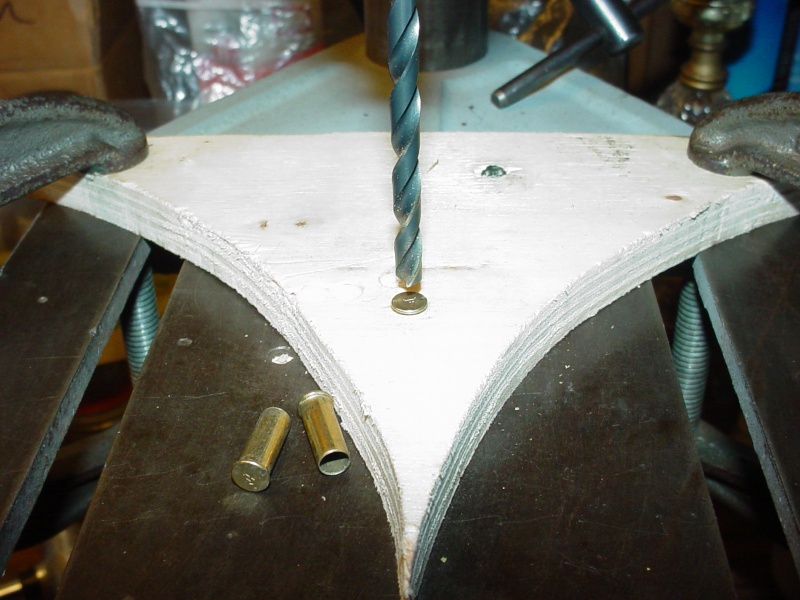

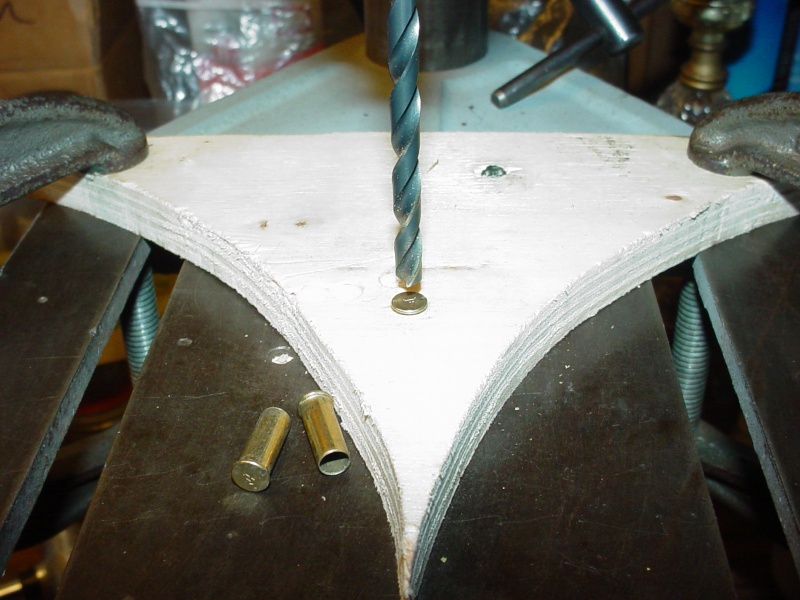

I thought of this several years ago for my .049 reedies, and tried different mat'ls. This is what I settled on. Matl's. needed are; Bicycle inner-tube discs (x2) cut to 2" dia. with 7/16" holes punched in center... stapled together around edges; except where pipes will exit. 1" dia. alum. tubing (.035" wall thickness) for inner-chamber; cut to 1/2"L. with hole(s) drilled for pipe(s) Pipes shown (x2) are common plumbing supply parts... but .22cal. shell casings would also work. (the "flare" on the tube is what is needed to keep it from falling out) note: you can experiment here with # of pipes (single/dual)... and dia. of pipe(s)

After stapling the rubber discs together; punch the 7/16" dia. hole in the center (I used a short pc. of K&S brass tubing-sharpened on one end, a hammer and a block of wood) The 1" dia. x 1/2"L. alum. "ring" inner-chamber with pipe-hole(s) drilled, is inserted through one hole in the rubber; observing your pipe-exit location(s). The pipe(s) can then be installed from the inside... out. This is your muffler!!!

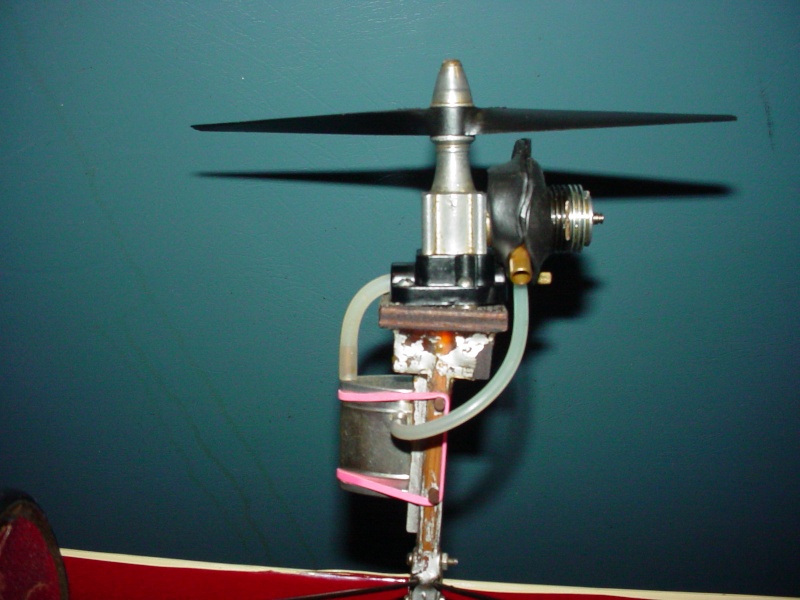

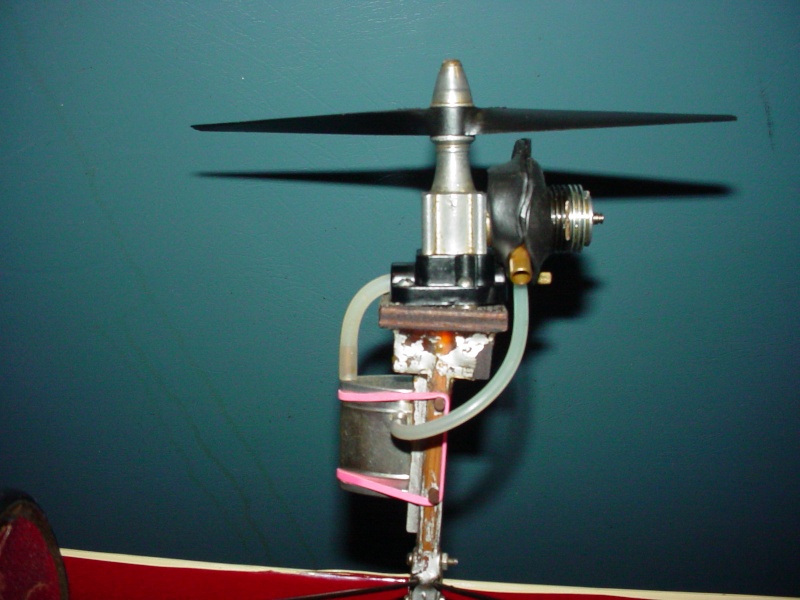

It was designed to "push-on"/"pull-off" without any engine disassembly or interference with the needle. The rubber isolates from vibration, and seals around the cylinders' exhaust ports like a "boot". It has proved to be very durable, and can be swapped quickly between engines.

You'll notice a significant decrease in the exhaust "note"; which is important with todays shrinking flying sites and noise restrictions.

There's no doubt that you can expand on this design; as we are all curious, innovative and resourceful, from having this hobby!

This pic is the muffler shown disassembled; that was in use on my "reed valve engine throttle" posts' vid... and weighs (as pictured) 8gr. (Single pipe 7gr.)

You "can" decrease the dia. of the rubber discs (which is where most of the weight is) but if the rubber "body" stretches too much after the "inner ring" is installed; it will affect the seal at the cyl. wall. Perhaps punching a smaller dia. (than 7/16") in the center of the discs, would correct this.

I thought of this several years ago for my .049 reedies, and tried different mat'ls. This is what I settled on. Matl's. needed are; Bicycle inner-tube discs (x2) cut to 2" dia. with 7/16" holes punched in center... stapled together around edges; except where pipes will exit. 1" dia. alum. tubing (.035" wall thickness) for inner-chamber; cut to 1/2"L. with hole(s) drilled for pipe(s) Pipes shown (x2) are common plumbing supply parts... but .22cal. shell casings would also work. (the "flare" on the tube is what is needed to keep it from falling out) note: you can experiment here with # of pipes (single/dual)... and dia. of pipe(s)

After stapling the rubber discs together; punch the 7/16" dia. hole in the center (I used a short pc. of K&S brass tubing-sharpened on one end, a hammer and a block of wood) The 1" dia. x 1/2"L. alum. "ring" inner-chamber with pipe-hole(s) drilled, is inserted through one hole in the rubber; observing your pipe-exit location(s). The pipe(s) can then be installed from the inside... out. This is your muffler!!!

It was designed to "push-on"/"pull-off" without any engine disassembly or interference with the needle. The rubber isolates from vibration, and seals around the cylinders' exhaust ports like a "boot". It has proved to be very durable, and can be swapped quickly between engines.

You'll notice a significant decrease in the exhaust "note"; which is important with todays shrinking flying sites and noise restrictions.

There's no doubt that you can expand on this design; as we are all curious, innovative and resourceful, from having this hobby!

This pic is the muffler shown disassembled; that was in use on my "reed valve engine throttle" posts' vid... and weighs (as pictured) 8gr. (Single pipe 7gr.)

You "can" decrease the dia. of the rubber discs (which is where most of the weight is) but if the rubber "body" stretches too much after the "inner ring" is installed; it will affect the seal at the cyl. wall. Perhaps punching a smaller dia. (than 7/16") in the center of the discs, would correct this.

Last edited by roddie on Sun Mar 17, 2024 10:34 am; edited 7 times in total (Reason for editing : add'l. comment for pic;)

Re: a cheap sport muffler

Re: a cheap sport muffler

Something I didn't mention about this muffler design. If you run a "sure-Start"/"Prod." engine set-up with an external tank or a TeeDee... you can "tap" a pres. feed for the tank. A sm. flared "lead-out" guide; as one of your "header-pipes" does the trick, along with a larger sz. (than intake) tubing back to the tank and capping the vent... (more advantageous to the TeeDee; as the reedies "suck" fuel by design.) I like to try different combinations for various results.

Running (x2) 1/4" pipes as I often do; doesn't affect performance at all... and you get the benefit of reduced SPL's and a "cleaner airplane".

Rog

Running (x2) 1/4" pipes as I often do; doesn't affect performance at all... and you get the benefit of reduced SPL's and a "cleaner airplane".

Rog

Re: a cheap sport muffler

Re: a cheap sport muffler

Having a little trouble visualizing how this goes together. Maybe a crude sketch of an X-ray view would make it clear. Are the desks stretched tight at the staples when the liner pipe is in place?

kevbo- Silver Member

- Posts : 91

Join date : 2013-03-05

Re: a cheap sport muffler

Re: a cheap sport muffler

WingingIt74 wrote:A pic of one installed would be good as well.

Here's the link to my post about the reed valve venturi throttle, which shows a close-up "pic" of the muffler and also a "vid" of the muffler in operation. (there are also pics in my gallery; of the muffler installed)

https://www.coxengineforum.com/t5486-049-reed-valve-venturi-throttle

To answer Kev's question; The 2 rubber discs with 7/16" dia. hole punched in the center; you simply "stretch open" after stapling them together. You install the inner-ring (with it's pipe hole(s) previously drilled)... "through" the 7/16" dia. hole, so it is "sandwiched between the rubber"... inside. Once this "inner-ring" is installed inside the rubber "body"; it forms a chamber, into which you install your pipe(s) from the "inside/out"... through either one of the 7/16" dia. holes. The completed muffler will be about 9/16" in height/thickness. When installed (pushed-on) over the glowhead/cylinder and resting on the crankcase; it "encases" the exhaust ports.

Hope this helps. If not; I will try to clarify further.

Thanks for your interest.

Roger

Re: a cheap sport muffler

Re: a cheap sport muffler

Okay, now I see how the muffler works. I wasn't getting it either. Pretty cool.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: a cheap sport muffler

Re: a cheap sport muffler

I too am getting it now. In the photo of the OP one of the rubber disks ha some mold marks that were confusing me.

kevbo- Silver Member

- Posts : 91

Join date : 2013-03-05

Re: a cheap sport muffler

Re: a cheap sport muffler

Using the dual 1/4" dia. "pipes" does not restrict exhaust flow very much (if at all)... You could even get creative by finding "bendy type" drinking-straws that fit the pipes' O.D. and CA glue them onto the pipe(s). Trim the ends of the straw to make a 90 deg. "bend"; just out of the muffler... and extend to wherever you want the exhaust to exit. Fasten the straw to the fuse (after cleaning fuse; of any oil), with sm. tabs of Velcro-hook & loop, and "run it right to the tail". It could even run down a landing gear strut... (outer for C/L flying)... something I haven't tried, but want to.

I haven't had any issues with the stapled rubber muffler "body" melting. I don't know what kind of rubber it is, but it is resistant to heat (in this app.) and unaffected by glow fuel. The "drinking straws" would be a test. All matl's here are negligible in weight. The muffler w/dual 1/4" brass pipes weighs 8gr. Single 1/4" brass pipe weighs 7gr. Most of the weight is in the rubber discs. You could "save half a gram here and there" by using alum. pipes with a flare, or decreasing "slightly"; the dia. of the rubber discs. Drinking-straw exhaust extensions; even if they ran the length of the fuse, would weigh practically nothing.

Imagine... how much cleaner your airplane would be after a flight!

I haven't had any issues with the stapled rubber muffler "body" melting. I don't know what kind of rubber it is, but it is resistant to heat (in this app.) and unaffected by glow fuel. The "drinking straws" would be a test. All matl's here are negligible in weight. The muffler w/dual 1/4" brass pipes weighs 8gr. Single 1/4" brass pipe weighs 7gr. Most of the weight is in the rubber discs. You could "save half a gram here and there" by using alum. pipes with a flare, or decreasing "slightly"; the dia. of the rubber discs. Drinking-straw exhaust extensions; even if they ran the length of the fuse, would weigh practically nothing.

Imagine... how much cleaner your airplane would be after a flight!

Re: a cheap sport muffler

Re: a cheap sport muffler

That is a neat muffler. Thanks for sharing.  There is nothing like home brewed ingenuity.

There is nothing like home brewed ingenuity.

Shawn

Shawn

sdjjadk- Platinum Member

- Posts : 640

Join date : 2012-04-07

Location : Southern Maryland

Re: a cheap sport muffler

Re: a cheap sport muffler

Thanks much Shawn... You know... "writing" about it's construction gave me even more ideas to try. As with "any" reedie; an exhaust prime is needed (at least when "cold starting" with a spring starter or "flipping" the prop).sdjjadk wrote:That is a neat muffler. Thanks for sharing. :)There is nothing like home brewed ingenuity.

Shawn

"Any" muffler will block the exhaust ports; preventing this. Cutting a sm. (1/4"L.) "slit" with a #11 blade, in the muffler's rubber body; somewhere "parallel" in between the engine's cyl. and the muffler's inner-chamber "ring"... would allow a priming needle/syringe to be inserted through the slit; to get a shot of fuel in there. A "slit" would close back up and "seal"; after the syringe is withdrawn.

Who knows... maybe a "series" of slits could eliminate the need for "pipe(s)" altogether... The slits might act as "valves"; opening up with the exhaust pulses... So many ways to experiment.

A 26" std. bicycle tire tube; yields enough mat'l. to make a "couple dozen" muffler bodies; when cut-open "lengthwise"... and then into 2" dia. discs... so; it's not expensive to make a bunch in different configurations. A 72" piece of 1" dia. alum. "thin-wall" tubing is avail. at any home center. Cutting 1/2"L. "rings" from it; yields enough of the "inner-chamber" parts; to make "several" dozen... Just make sure that the glow head fits inside the tubing with a "little clearance"... or it defeats the major advantage of being able to simply; "push" the muffler on... and "pull" it off; over the cylinder/glow head.

Thanks again; for your interest,

Roger

Re: a cheap sport muffler

Re: a cheap sport muffler

You can get a crude prime when filling by putting a finger over the tank overflow and applying a little pressure with the filling device (syringe, bulb, whatever you use). It is tricky to gauge how much prime you are giving, and many of the tanks don't seal real well, so it can be a bit messy. Seems like often the tanks seal well enough to keep the fuel in, but leak like a sieve under any pressure at all.

kevbo- Silver Member

- Posts : 91

Join date : 2013-03-05

Re: a cheap sport muffler

Re: a cheap sport muffler

Or you could choke the engine with a closed throttle position if you are using one of the r/c throttle setups like Roger made.

Shawn

Shawn

Last edited by sdjjadk on Tue Aug 27, 2013 10:58 am; edited 1 time in total

sdjjadk- Platinum Member

- Posts : 640

Join date : 2012-04-07

Location : Southern Maryland

Re: a cheap sport muffler

Re: a cheap sport muffler

Thanks Roger for the how too.

As with your throttle system, I too will try the muffler sometime.

Shawn

As with your throttle system, I too will try the muffler sometime.

Shawn

sdjjadk- Platinum Member

- Posts : 640

Join date : 2012-04-07

Location : Southern Maryland

Re: a cheap sport muffler

Re: a cheap sport muffler

Hey Kev... Yes... I've found this to be true! I made my own elec. starter years ago... using a 540 "can" motor held in a tube about 10"L. The motor shaft has a sm. "gear" pressed onto it. I affixed a 1"L. pc. of "automotive" type rubber fuel tubing (5/16" i.d.) over the gear (press-fit) which engages the Cox alum. spinner nicely. I added a sm. momentary push-switch, and about 6ft. of lamp cord (18-2) wiring with banana clips; for hook-up to my power panel.kevbo wrote:You can get a crude prime when filling by putting a finger over the tank overflow and applying a little pressure with the filling device (syringe, bulb, whatever you use). It is tricky to gauge how much prime you are giving, and many of the tanks don't seal real well, so it can be a bit messy. Seems like often the tanks seal well enough to keep the fuel in, but leak like a sieve under any pressure at all.

A few "quick bursts" with a rich needle setting; cold-starts my "Bee's" quickly without an exhaust prime. This method actually "prevents" flooding. Using the elec. starter "with" an exhaust prime can result in a broken crank-pin, if you're not careful.

Note; I ALWAYS... put a few drops of "3 in 1 oil" between the prop drive-plate/case, and hand-flip a few times to "work it in". This helps to prevent wear... along with "light" (not heavy-handed) pressure while engaging the prop with the starter.

I'll post a pic of the starter sometime soon; along with a "how-to" for anyone interested in making one.

Roger

Re: a cheap sport muffler

Re: a cheap sport muffler

Your Welcome Shawn!... and yes; you are correct about priming with a closed venturi needle.sdjjadk wrote:Thanks Roger for the how too.

As with your throttle system, I too will try the muffler sometime.

Shawn

Here's another way (same principal) to prime a "mufflered" Bee-style tank-back engine. Using a "spare" back-plate or "un-mounted" engine; take your standard "Popsicle-stick", and file/sand "one end" to fit into the "air inlet area" on the back-plate; matching the taper and the radius at the venturi opening. You may have to consider engine mount "offset"... although; I usually sand that angle into my firewalls if needed.

With engine mounted; it must be a "snug" fit between the firewall and backplate. "Wipe it clean"... slip it in... flip the prop a few times, then remove it. Paint the stick a fluorescent color, so you don't lose it. If you buy a Popsicle... you can make 2 of them...

Roger

Re: a cheap sport muffler

Re: a cheap sport muffler

Hi roger,

I have an old astro-flight 1/2A starter. It is exactly as you discribe your home brew one. Except it has an aluminum cup pressed onto the can motor. It came with a gum rubber insert but that did not survive, so it now has automotive heater hose, just like yours.

I have an old astro-flight 1/2A starter. It is exactly as you discribe your home brew one. Except it has an aluminum cup pressed onto the can motor. It came with a gum rubber insert but that did not survive, so it now has automotive heater hose, just like yours.

kevbo- Silver Member

- Posts : 91

Join date : 2013-03-05

Re: a cheap sport muffler

Re: a cheap sport muffler

That is cool Kev... as long as it works. Does the Astro-flite's cone/cup have a "V" groove for belt starting? Mine doesn't have that feature... but I've often thought about using a "Dumas" 1/2-A marine flywheel. (there would be a 2nd Dumas flywheel it the boat, it would be starting...) Then again; I wouldn't "side-load" a 540 motors' output shaft too much... That would surely wear it out quick.

Last edited by roddie on Tue Aug 27, 2013 6:15 pm; edited 1 time in total (Reason for editing : comprehension changes)

Re: a cheap sport muffler

Re: a cheap sport muffler

I thought of making (well trying to make) a 1/2a starter using an old plastic flashlight case and an old electric car motor along with the batteries and use the flash light switch to turn it on and off.kevbo wrote:Hi roger,

I have an old astro-flight 1/2A starter. It is exactly as you discribe your home brew one. Except it has an aluminum cup pressed onto the can motor. It came with a gum rubber insert but that did not survive, so it now has automotive heater hose, just like yours.

sdjjadk- Platinum Member

- Posts : 640

Join date : 2012-04-07

Location : Southern Maryland

Re: a cheap sport muffler

Re: a cheap sport muffler

I sent Bernie my muffler article for his emag today; along with some construction photos. For any of you attempting to make a muffler "now"... here's some info.

I mentioned using brass .22 cal. shell casings for a pipe. Not having any... and not having ever owned a gun; I researched their "size" specifications. They are all between .224"/.226" in dia. The "short" is .413" in length. The "long" is .613" in length, the "extra-long" is .750" in length. The "rim" dia. for all 3 is .278".

(EDIT-9/3) If you obtain several of these; you can drill-out the "primer-end" either: completely... or with graduating smaller holes, for varied degrees of exhaust restriction/performance tuning.

Drilling the hole in the chamber/ring for the pipe to fit through, can be done with a common 15/64" drill; which has a .234" dia. and would be adequate... unless your a "perfectionist"... in which case; a #1 drill (.228" dia.) would be a precise fit.

The pipe "length" is a matter of preference, although I stated in the article; for the pipe to be at least 1/2"L. (.500") but no longer than 3/4" (.750").

A local shooting range will "no doubt" have them... and probably "give" you a few.

I mentioned using brass .22 cal. shell casings for a pipe. Not having any... and not having ever owned a gun; I researched their "size" specifications. They are all between .224"/.226" in dia. The "short" is .413" in length. The "long" is .613" in length, the "extra-long" is .750" in length. The "rim" dia. for all 3 is .278".

(EDIT-9/3) If you obtain several of these; you can drill-out the "primer-end" either: completely... or with graduating smaller holes, for varied degrees of exhaust restriction/performance tuning.

Drilling the hole in the chamber/ring for the pipe to fit through, can be done with a common 15/64" drill; which has a .234" dia. and would be adequate... unless your a "perfectionist"... in which case; a #1 drill (.228" dia.) would be a precise fit.

The pipe "length" is a matter of preference, although I stated in the article; for the pipe to be at least 1/2"L. (.500") but no longer than 3/4" (.750").

A local shooting range will "no doubt" have them... and probably "give" you a few.

Re: a cheap sport muffler

Re: a cheap sport muffler

Here's a pressure set-up. I have not tried this yet, but it should work, "in theory". It uses one exhaust pipe (1/4" dia.) and one pressure tap made from a sm. brass lead-out guide (.078" o.d./.074" i.d.) connected to the tank with sm. silicone fuel tubing. If you were to use a smaller dia. exhaust pipe; you would create more pressure in the muffler-chamber. It would be a balancing-act with "your" particular engine set-up. By design; "choking-off" the exhaust completely, is unlikely; because of the way that the rubber muffler-body "seals" around the cylinder... I.E. you'd get exhaust "blow-by" before that would happen.

Re: a cheap sport muffler

Re: a cheap sport muffler

Roddie, did you ever look at different ways to assemble the rubber shroud?

I'm looking at it and thinking that turning it inside out would make it look a little cleaner (if it would still fit around the inner pipe. Also, maybe gluing the two rubber disks together with the patch cement for tire repairs instead of stapling. It would make installing it over any tubes or pipes harder - just some thoughts that popped into my head looking at your design.

I'm looking at it and thinking that turning it inside out would make it look a little cleaner (if it would still fit around the inner pipe. Also, maybe gluing the two rubber disks together with the patch cement for tire repairs instead of stapling. It would make installing it over any tubes or pipes harder - just some thoughts that popped into my head looking at your design.

VUgearhead- Gold Member

- Posts : 155

Join date : 2013-07-02

Age : 57

Location : Boynton Beach, FL

Re: a cheap sport muffler

Re: a cheap sport muffler

Excellent points... I took your "turning the rubber body inside-out" suggestion, and attempted it. It resulted in a smaller "triangular" shape... "neat looking"... but would cause problems with the inner-chamber "fit"; because of the rubber seam being on the inside.VUgearhead wrote:Roddie, did you ever look at different ways to assemble the rubber shroud?

I'm looking at it and thinking that turning it inside out would make it look a little cleaner (if it would still fit around the inner pipe. Also, maybe gluing the two rubber disks together with the patch cement for tire repairs instead of stapling. It would make installing it over any tubes or pipes harder - just some thoughts that popped into my head looking at your design.

The "joining-method" of the rubber; using your suggested "inner-tube cement" may work... I haven't tried it. What I "can" tell you; is that the staples hold up to extreme "stretching" (as witnessed by turning the rubber inside-out...) The cement may peel apart... and may not be impervious to the exhaust wastes/heat.

Having the rubber seam on the "outside" creates an environment for the inner-chamber to "self-center" itself, inside the "pocket" and hold it in position; once inserted.

You also don't want to compromise the "design-seal" that the finished muffler makes, around the engine cylinder. Attempting to "stretch" the rubber body beyond the way I designed it, will affect this seal.

Thanks for your interest though... There's obviously many different ways to design/re-design something; to make it better, neater, lighter, stronger etc.

Re: a cheap sport muffler

Re: a cheap sport muffler

I finally found some .22 cal. shell casings to use as exhaust-pipes for this muffler. The rim acts as the flare did on my other pipes made from plumbing supply compression fittings... (which are .250" dia. and wide-open) These shell casings are .228" dia. and the closed "primer-cap" on the rim end, can be drilled-out for varying degrees of back-pressure.

Most of you are familiar with the original Cox .049 muffler... not much adjustability there... Think about the size of the openings in your cylinder's exhaust ports... you probably wouldn't want to restrict those too much... if you didn't have to... in order to quiet your engine down a few notches.

My muffler design has a larger expansion chamber than the original Cox muffler.. and does not require engine disassembly. A pressure tap is an option. The exhaust note is "directional" as with any muffler... but with this design, it can be rotated 360 degrees.. and attaching a "drinking straw" of the appropriate diameter to the exhaust pipe... routes exhaust-wastes wherever you want them to go.

If utilizing a "pressure-to-tank" line... there will be a "back-pressure" differential.. depending on the muffler's main-pipe orifice size.

I hope to be able to produce a descent sport muffler that will have the "adjustability" for multiple applications.

Most of you are familiar with the original Cox .049 muffler... not much adjustability there... Think about the size of the openings in your cylinder's exhaust ports... you probably wouldn't want to restrict those too much... if you didn't have to... in order to quiet your engine down a few notches.

My muffler design has a larger expansion chamber than the original Cox muffler.. and does not require engine disassembly. A pressure tap is an option. The exhaust note is "directional" as with any muffler... but with this design, it can be rotated 360 degrees.. and attaching a "drinking straw" of the appropriate diameter to the exhaust pipe... routes exhaust-wastes wherever you want them to go.

If utilizing a "pressure-to-tank" line... there will be a "back-pressure" differential.. depending on the muffler's main-pipe orifice size.

I hope to be able to produce a descent sport muffler that will have the "adjustability" for multiple applications.

Re: a cheap sport muffler

Re: a cheap sport muffler

I have drilled out the .22 cal. shell casings which have an o.d. of .228" and an i.d. of .205" to 11 different sizes from .144" to .204" (approx. .005/.007" graduations) for varied degrees of exhaust flow. The shell casing serves as the "main muffler pipe". The aluminum (1" tube) inner-muffler chamber/ring is center-drilled to .228" to accept any of the shell-casing pipes, which are installed from the "inside-out".. of the chamber.. the shell casings' "rim" acts as a stop for the pipe. When the muffler is installed (merely "pushed-on" over the Cox .049's cylinder..) the main exhaust pipe is held captive... (same for the flared pressure-tap insert; except it receives fuel tubing on the outside wall of the chamber.. to hold it captive. This fuel tubing can either be plugged.. or plumbed to a tank-vent for muffler pressure.

Different configurations can be tested.. all having the benefit of reduced SPL's.. (which is the main objective to using a muffler)... but with this design; it gives you performance options. Maximum performance is achieved by running dual "wide-open" (.204" drilled) pipes... with the option of a pressure-line to a tank.

Anyone interested in more info... feel free to ask.

Roddie

Different configurations can be tested.. all having the benefit of reduced SPL's.. (which is the main objective to using a muffler)... but with this design; it gives you performance options. Maximum performance is achieved by running dual "wide-open" (.204" drilled) pipes... with the option of a pressure-line to a tank.

Anyone interested in more info... feel free to ask.

Roddie

Re: a cheap sport muffler

Re: a cheap sport muffler

I'll be doing some testing on one with different pipe configurations soon. First I'll fly it with a Tee Dee on my Streak. And after the CEF Speed Freakout, I'll use it on my mustang racer for tank pressure evaluation.

Regarding the above picture, you might find it's more stable and drains the tank better if you shim the rear end of it away from the fuse so that it's oriented tangent to the circle rather than yawing out with the plane.

Rusty

Regarding the above picture, you might find it's more stable and drains the tank better if you shim the rear end of it away from the fuse so that it's oriented tangent to the circle rather than yawing out with the plane.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Page 1 of 5 • 1, 2, 3, 4, 5

Similar topics

Similar topics» Super sport 049

» WTB .049 muffler or muffler parts

» Cox Sandblaster clean-up

» RC flying on the cheap........................

» Why are Tee Dee 010 so expensive?

» WTB .049 muffler or muffler parts

» Cox Sandblaster clean-up

» RC flying on the cheap........................

» Why are Tee Dee 010 so expensive?

Page 1 of 5

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules