Log in

Search

Latest topics

» My N-1R build logby roddie Today at 3:51 pm

» Funny what you find when you go looking

by GallopingGhostler Today at 3:49 pm

» My latest doodle...

by TD ABUSER Today at 11:30 am

» Duende V model from RC Model magazine 1983.

by MauricioB Today at 10:56 am

» Landing-gear tips

by 1975 control line guy Today at 10:07 am

» Brushless motors?

by rsv1cox Yesterday at 6:40 pm

» Free Flight Radio Assist

by rdw777 Yesterday at 6:03 pm

» Tribute Shoestring build

by amurphy6812 Yesterday at 5:43 pm

» Cox 020 PeeWee rebuild questions

by LooseSpinner99 Yesterday at 5:17 pm

» My current avatar photo

by GallopingGhostler Fri Nov 15, 2024 7:39 pm

» It's the X Wing that has a canard

by rdw777 Fri Nov 15, 2024 6:58 pm

» music vids.. some of your favorites

by Kim Thu Nov 14, 2024 3:28 pm

Cox Engine of The Month

The Metal Backplates

Page 1 of 1

The Metal Backplates

The Metal Backplates

I have been through a few comments on this site re the metal backplates and their finish.

I am still confused and I have quite a few that I would like to clean up and restore.

At first I thought these were a brass or bronze finish but this ended in disaster (only tried on broken plates!). (Fill and level with solder, smooth, electrolytic flash copper coating followed by brass or bronze)

Firstly, what is the base metal of the plate?

It looks like Mazak (Pot metal).

Secondly, having seen some of the earlier plates in pristine condition (shiny silvery) - they look to be Zinc plated. This has been quoted by Mark, recently, as being Zinc Dichromate but as far as I can see - that would produce a yellow brassy finish.

Thirdly, the yellowish finish - that could be zinc dichromate but it could also be zinc plating followed by a dip in "yellow chromate". This makes the zinc plate last longer.

Does anyone know the definitive process?

I am still confused and I have quite a few that I would like to clean up and restore.

At first I thought these were a brass or bronze finish but this ended in disaster (only tried on broken plates!). (Fill and level with solder, smooth, electrolytic flash copper coating followed by brass or bronze)

Firstly, what is the base metal of the plate?

It looks like Mazak (Pot metal).

Secondly, having seen some of the earlier plates in pristine condition (shiny silvery) - they look to be Zinc plated. This has been quoted by Mark, recently, as being Zinc Dichromate but as far as I can see - that would produce a yellow brassy finish.

Thirdly, the yellowish finish - that could be zinc dichromate but it could also be zinc plating followed by a dip in "yellow chromate". This makes the zinc plate last longer.

Does anyone know the definitive process?

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: The Metal Backplates

Re: The Metal Backplates

I know the process changed over the years. Very early versions do not have the coating, later versions do. I would not be surprised if the coating was changed over time as the process costs changed.

I know most of my back plates are a "harder" metal, is not iron or brass, and have a "yellow" or "brown" coating which chips relatively easily. I would assume it is a zinc or aluminum alloy that is well suited to die casting.

Phil

interesting read

http://en.wikipedia.org/wiki/Mazak_%28alloy%29

more interesting read

http://en.wikipedia.org/wiki/Chromate_conversion_coating

Phil

I know most of my back plates are a "harder" metal, is not iron or brass, and have a "yellow" or "brown" coating which chips relatively easily. I would assume it is a zinc or aluminum alloy that is well suited to die casting.

Phil

interesting read

http://en.wikipedia.org/wiki/Mazak_%28alloy%29

more interesting read

http://en.wikipedia.org/wiki/Chromate_conversion_coating

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: The Metal Backplates

Re: The Metal Backplates

Hi Ian,

I don’t know about definitive, but here’s what I know/think I know: The first (’56) backplates were a ‘clear’ dichromate soon followed by the ‘yellow’ dichromate, if this was the result of different companies doing the plating during this time I’m not sure.

I had just emailed Mud about this as I’d seen a 'yellow' RR-1 with vent tubes and the later ventless bakeplate (c.1957) in 'clear' but, once they went to the ‘brass’ plating in ’58 there was no other plating.

I don’t know about definitive, but here’s what I know/think I know: The first (’56) backplates were a ‘clear’ dichromate soon followed by the ‘yellow’ dichromate, if this was the result of different companies doing the plating during this time I’m not sure.

I had just emailed Mud about this as I’d seen a 'yellow' RR-1 with vent tubes and the later ventless bakeplate (c.1957) in 'clear' but, once they went to the ‘brass’ plating in ’58 there was no other plating.

Last edited by Mark Boesen on Mon Feb 11, 2013 11:20 am; edited 1 time in total

Re: The Metal Backplates

Re: The Metal Backplates

WingingIt74 wrote:The coating kinda reminds me of the old Rochester carburetors.

http://www.caswellplating.com.au/store/store.php/products/yellow-chromate-concentrate---cadmium-look

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: The Metal Backplates

Re: The Metal Backplates

Mark Boesen wrote:yep, thats where i get my dye for anodizing.

Now is the RR1 crankcase adonised and then dyed yellow or is that dipped in yellow chromate?

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: The Metal Backplates

Re: The Metal Backplates

yep, the crankcase anodized and then dyed yellow.

Last edited by Mark Boesen on Tue Aug 13, 2013 2:49 pm; edited 1 time in total

Mudhen- Gold Member

- Posts : 489

Join date : 2011-09-19

Re: The Metal Backplates

Re: The Metal Backplates

What years were the back plates made that didn't say "made in USA?" Mine is a darker kind of brownish color. I would assume that it's prior to the brass plating and has aged itself to that color.

Motra- Gold Member

- Posts : 111

Join date : 2010-08-20

Location : SLC, UT

Re: The Metal Backplates

Re: The Metal Backplates

'58-'59 to '63-'64, a little Brasso metal polish would clean it up nice, looks like it might of came from a pt-19.

Re: The Metal Backplates

Re: The Metal Backplates

As usual, I will arm myself with chemicals and give all permutations a go. I have quite a few busted backplates to work on!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: The Metal Backplates

Re: The Metal Backplates

fine steel wool gets the backplates looking new again, i have 2 that look brand new.

looperdude- Silver Member

- Posts : 83

Join date : 2013-07-30

Age : 26

Location : High Point. NC

Re: The Metal Backplates

Re: The Metal Backplates

i'd be careful on the early backplates, the coating is not very thick and the steel wool would likely remove some, BRASSO metal polish and a soft toothbrush works.

Re: The Metal Backplates

Re: The Metal Backplates

After a great deal of research and testing, I can say that the backplates are zinc plated. It is extremely thin - only microns - and is applied after the alloy has been treated with Zincate.

The finished plating is then treat with a passivate to protect the Zinc.

A silver finish with clear passivate and the yellow (which darkens (eventually) to a brassy finish) with yellow passivate.

After treating with zincate the backplates can be plated with nickel or brass - this does not give an original finish. It only comes with time.

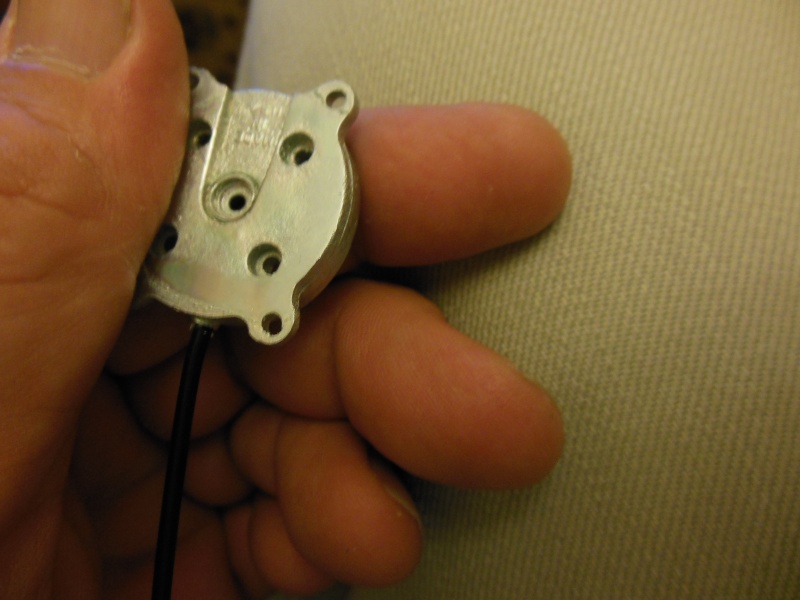

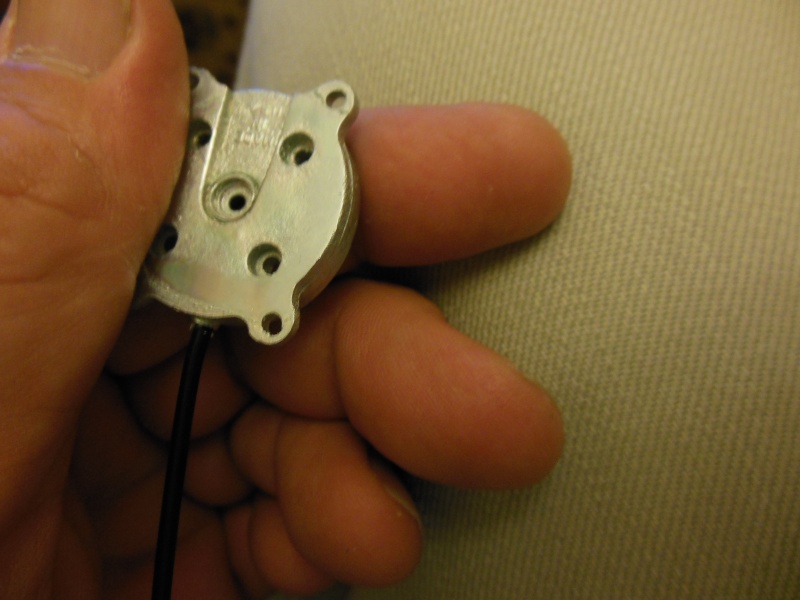

This is one that was quite badly pitted and corroded. Here it is after plating and passivating.

I would not recommend anything too abrasive (including steel wool) to clean a backplate. When the finish has been penetrated the zinc will corrode badly. Not immediately but over time.

I would not delve further than brasso!

The finished plating is then treat with a passivate to protect the Zinc.

A silver finish with clear passivate and the yellow (which darkens (eventually) to a brassy finish) with yellow passivate.

After treating with zincate the backplates can be plated with nickel or brass - this does not give an original finish. It only comes with time.

This is one that was quite badly pitted and corroded. Here it is after plating and passivating.

I would not recommend anything too abrasive (including steel wool) to clean a backplate. When the finish has been penetrated the zinc will corrode badly. Not immediately but over time.

I would not delve further than brasso!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: The Metal Backplates

Re: The Metal Backplates

well then that just sucks, wish i would have known that before putting steel wool on 'em.

looperdude- Silver Member

- Posts : 83

Join date : 2013-07-30

Age : 26

Location : High Point. NC

Re: The Metal Backplates

Re: The Metal Backplates

If you are gonna run them they still have YEARS of life in them even without the coating.

Phil

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: The Metal Backplates

Re: The Metal Backplates

yeah i guess thats all that matters.

looperdude- Silver Member

- Posts : 83

Join date : 2013-07-30

Age : 26

Location : High Point. NC

Re: The Metal Backplates

Re: The Metal Backplates

There's an old saying... "Paint & Chrome... Don't get ya' Home"

[

Agreed!

But where does it end?

[

Agreed!

But where does it end?

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: The Metal Backplates

Re: The Metal Backplates

gotta love those "Brits"... check this out... I just LOVE this!!!!

Turn up your speakers!

Turn up your speakers!

Last edited by roddie on Mon Aug 26, 2013 9:30 pm; edited 1 time in total (Reason for editing : comment "turn up your speakers!")

Re: The Metal Backplates

Re: The Metal Backplates

thats one cool rig

bullit132- Gold Member

- Posts : 197

Join date : 2013-04-11

Age : 63

Location : charleston,sc

Similar topics

Similar topics» Metal back plate

» wtb - metal postage stamp backplates

» Maybe a "Thing"--Maybe Not...Thick Washers for Metal Backplates

» Aluminium backplates

» WTB: one or two metal backplates witout vents/fuel nipples for .049

» wtb - metal postage stamp backplates

» Maybe a "Thing"--Maybe Not...Thick Washers for Metal Backplates

» Aluminium backplates

» WTB: one or two metal backplates witout vents/fuel nipples for .049

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules