Log in

Search

Latest topics

» It's the X Wing that has a canardby 1975 control line guy Today at 12:12 am

» My current avatar photo

by GallopingGhostler Yesterday at 7:02 pm

» Cox 020 PeeWee rebuild questions

by LooseSpinner99 Yesterday at 4:38 pm

» music vids.. some of your favorites

by Kim Yesterday at 3:28 pm

» New Model Build

by bsadonkill Yesterday at 1:19 pm

» Kofuku Maru Fishing Boat Model

by Levent Suberk Yesterday at 11:39 am

» Free Flight Radio Assist

by rdw777 Yesterday at 11:24 am

» TEE DEE Having issues

by GallopingGhostler Wed Nov 13, 2024 11:38 pm

» Pathé Modeling Videos

by Levent Suberk Wed Nov 13, 2024 2:10 pm

» My latest doodle...

by layback209 Wed Nov 13, 2024 1:20 am

» Drones, pretty nifty...........

by rsv1cox Tue Nov 12, 2024 6:55 pm

» Project Cox .049 r/c & Citabrian Champion

by roddie Tue Nov 12, 2024 6:20 pm

Cox Engine of The Month

Engine rebuild - giving it the needle

Page 1 of 1

Engine rebuild - giving it the needle

Engine rebuild - giving it the needle

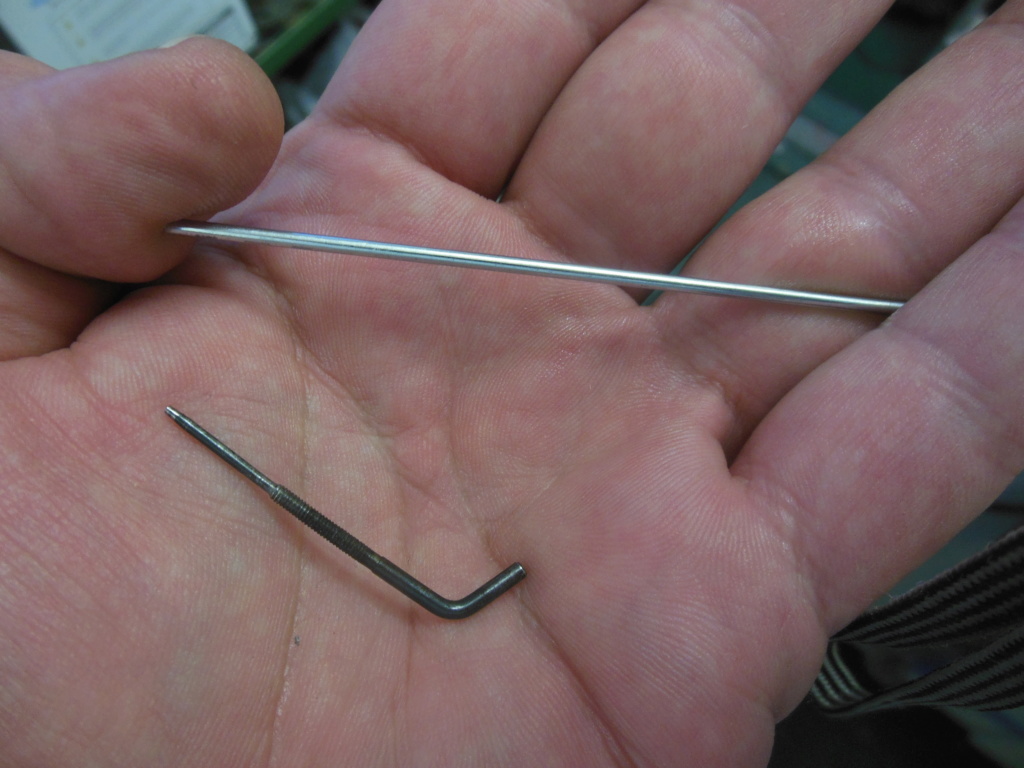

Perhaps the most common event in the demise of an engine is the needle valve assembly. I recently got a box of Zom parts but probably enough bits to build three engines. All with missing needles and broken assemblies.

You have to start somewhere and with this I will show the needle. I have mentioned before that set up for this, trial and test fitting is about an hour. With the first one under your belt every other one is around four minutes.

How is it done? Easy peasy!

Take a suitable piece of metal - compare it to the original and knock off all the bits that don't match.

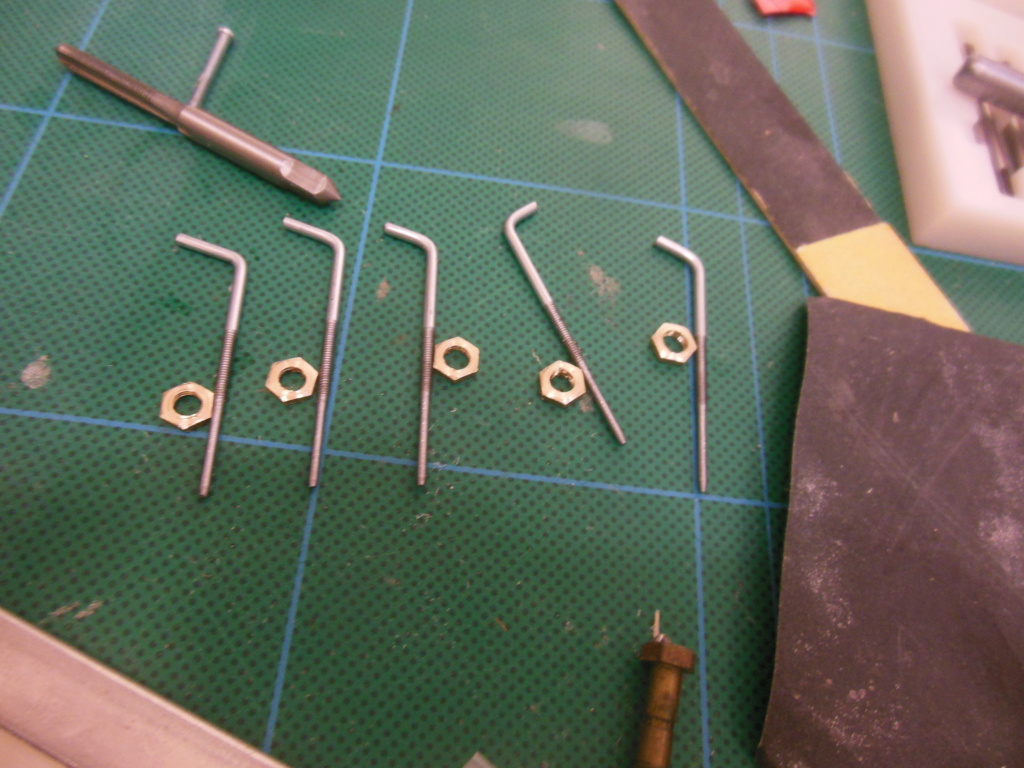

Really - this one starts with 2mm stainless steel rod. (Don't use piano wire for this unless you want to ruin a die)

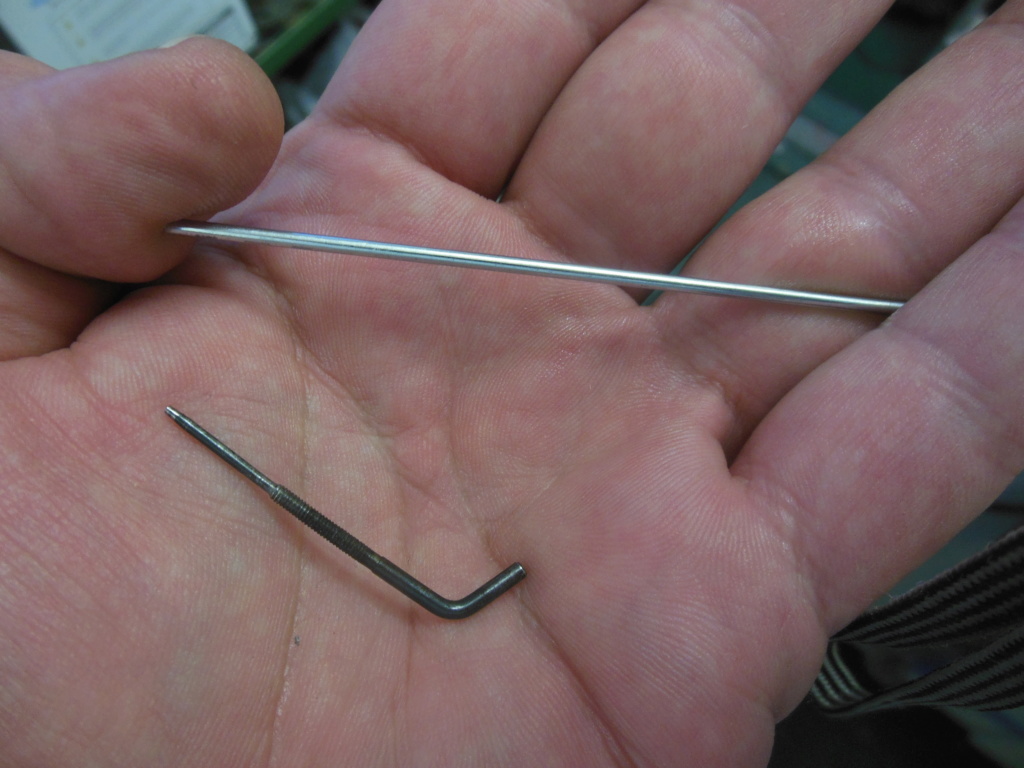

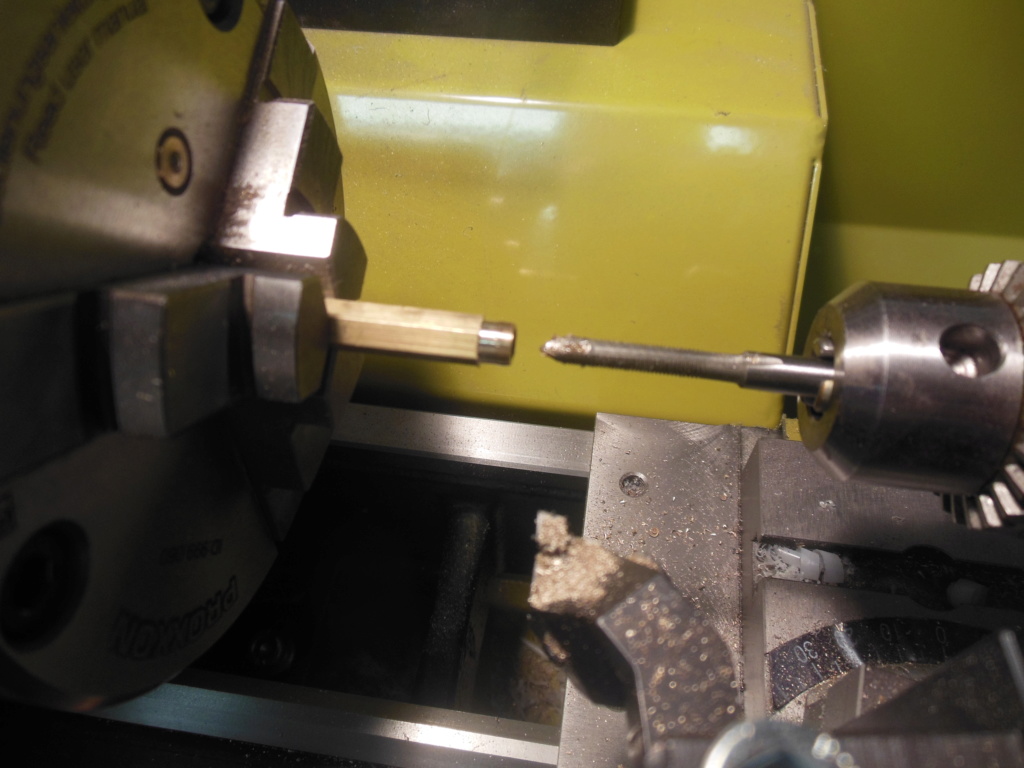

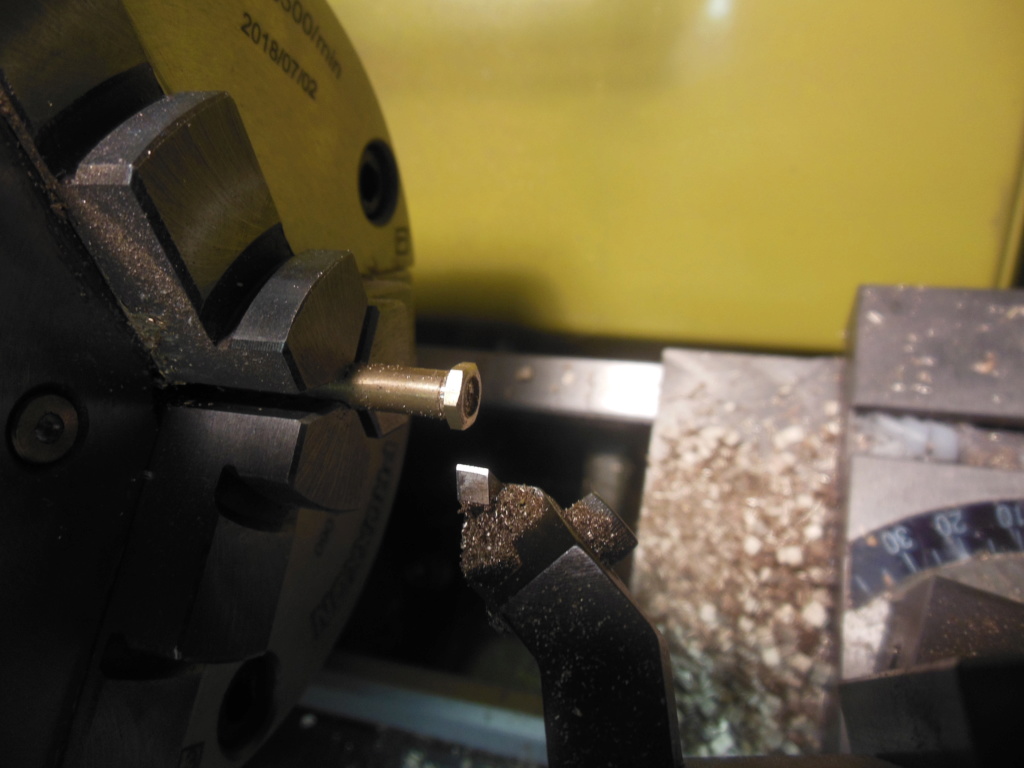

The pointy end on this is reduced to 1.26mm. The best way I know is to grind it to size.

This one uses a well worn M2 die. The thread is larger than M2 but not the next size up.

Bend the end and repeat

Install

and test

This Zom does 10,250 on a Taipan 8x6 propeller. At the end of the video I show the towel I use to wipe up the exhaust residue. That is the right colour for safe running. Could be a tad darker but never, ever sooty black.

You have to start somewhere and with this I will show the needle. I have mentioned before that set up for this, trial and test fitting is about an hour. With the first one under your belt every other one is around four minutes.

How is it done? Easy peasy!

Take a suitable piece of metal - compare it to the original and knock off all the bits that don't match.

Really - this one starts with 2mm stainless steel rod. (Don't use piano wire for this unless you want to ruin a die)

The pointy end on this is reduced to 1.26mm. The best way I know is to grind it to size.

This one uses a well worn M2 die. The thread is larger than M2 but not the next size up.

Bend the end and repeat

Install

and test

This Zom does 10,250 on a Taipan 8x6 propeller. At the end of the video I show the towel I use to wipe up the exhaust residue. That is the right colour for safe running. Could be a tad darker but never, ever sooty black.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

Good work Ian.

Levent Suberk- Diamond Member

- Posts : 2263

Join date : 2017-12-24

Location : Türkiye

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

Aside from a missing needle, one of the engines was missing the locking nut and so ....

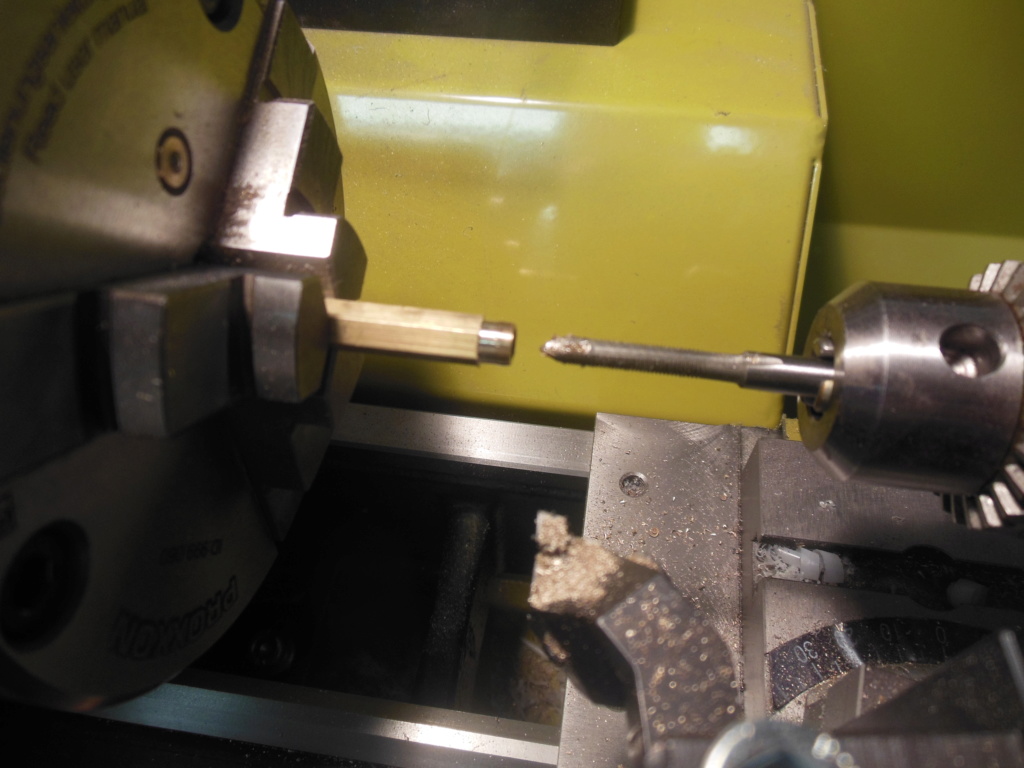

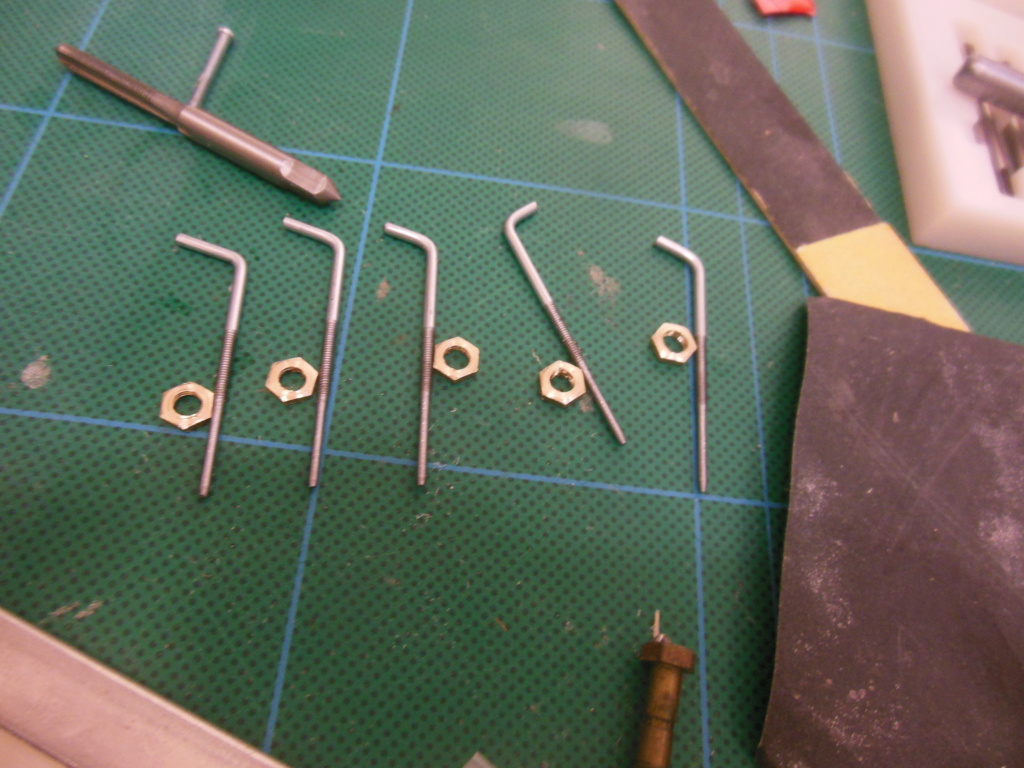

Then another engine had no assembly at all - so started making the nuts. Although these are M4 nuts - the are not standard metric but metric fine. These are not easy to buy along with being half nuts. Standard M4 metric has a 0.7mm thread - these are 0.5mm

Once set up, it is easy to make a few

Followed by the more complicated - not difficult but fiddly - needing four different size holes drilling centrally, M2 internal thread, M4 fine external thread and a cross drilling.

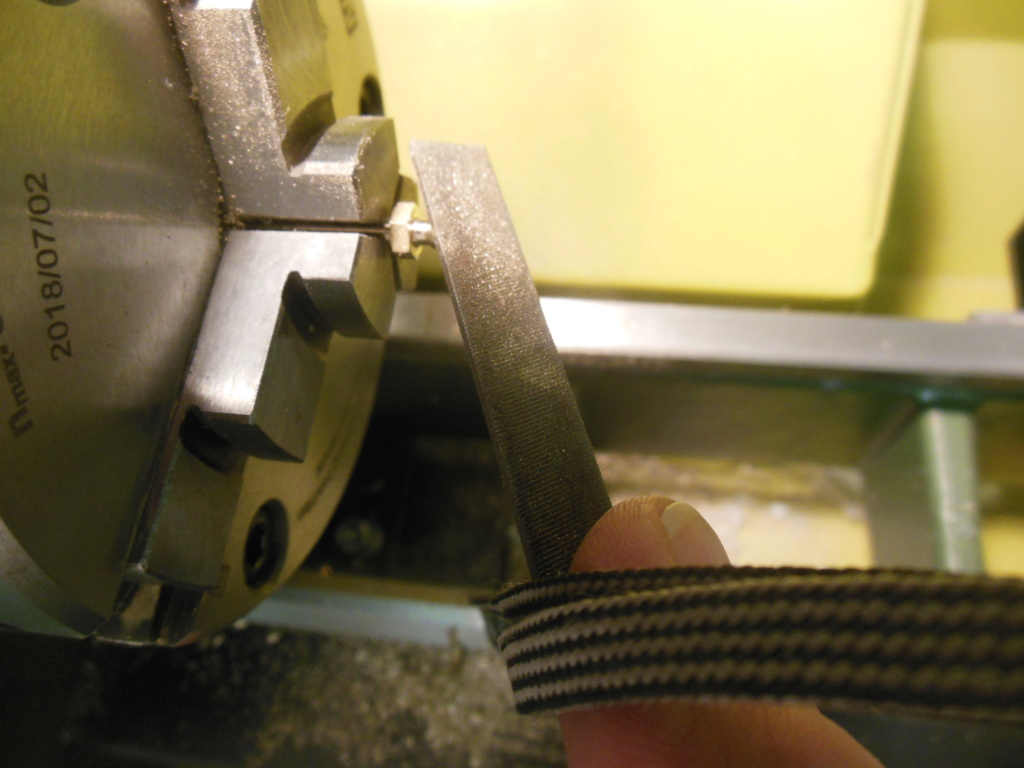

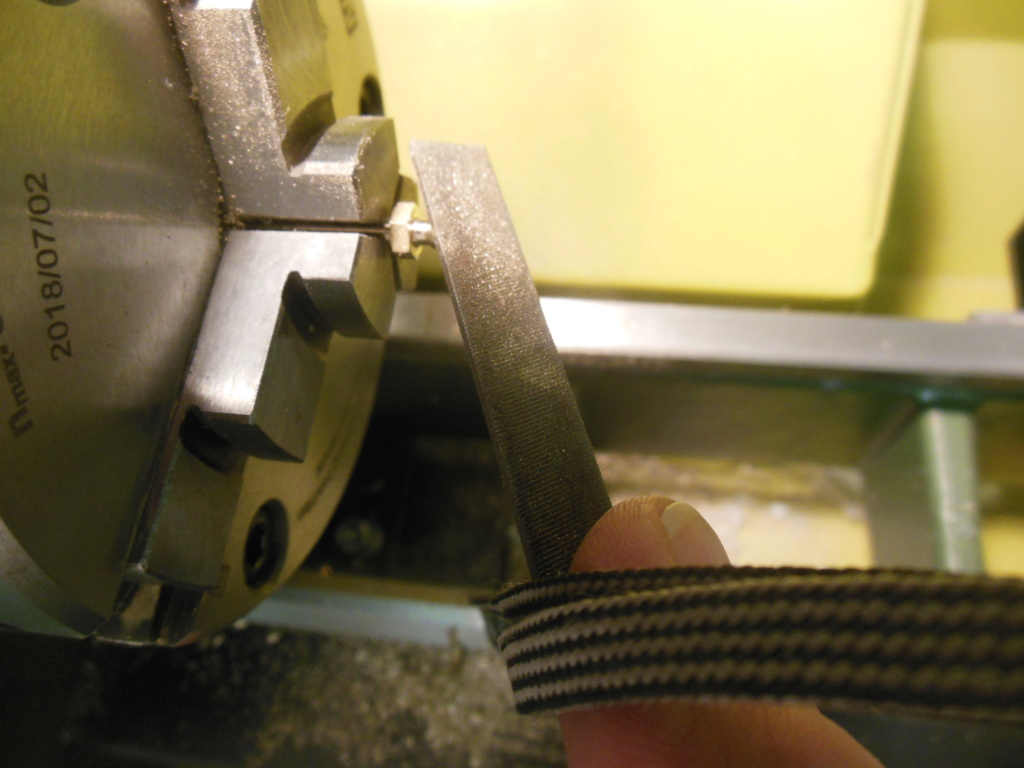

This is then reversed in the lathe to shape the fuel pipe connection. Here is where I regret my delay in converting this lathe to CNC.

I have everything I need for this but time!

Still, I rough cut the shape and then use a series of files and shape by eye.

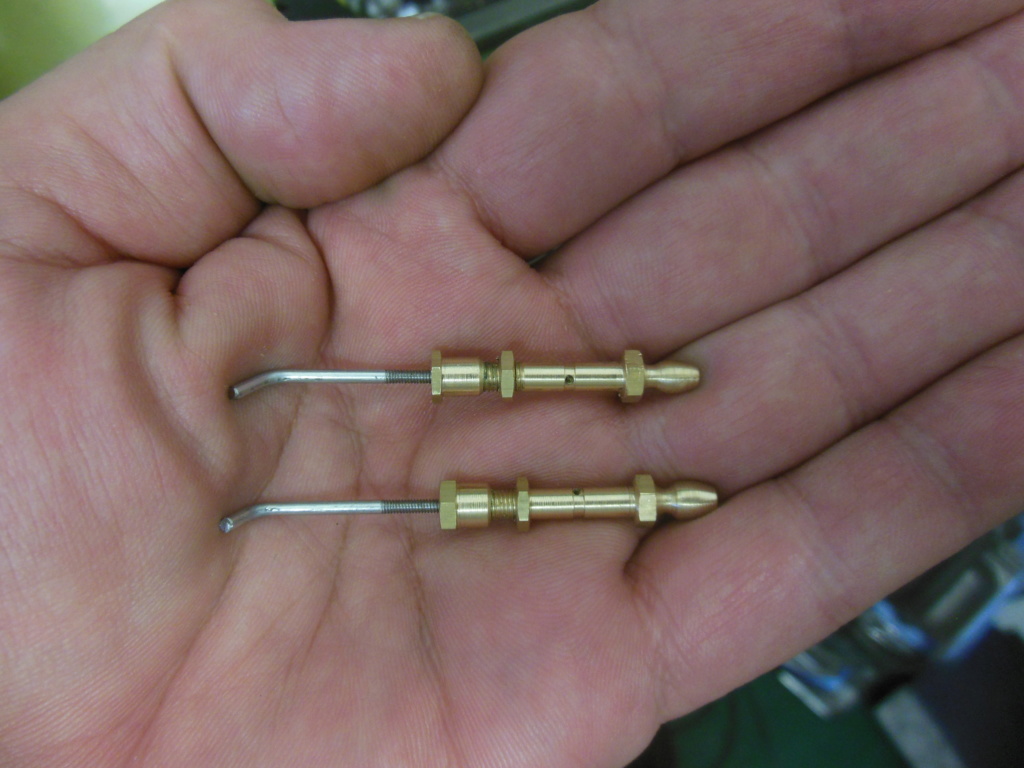

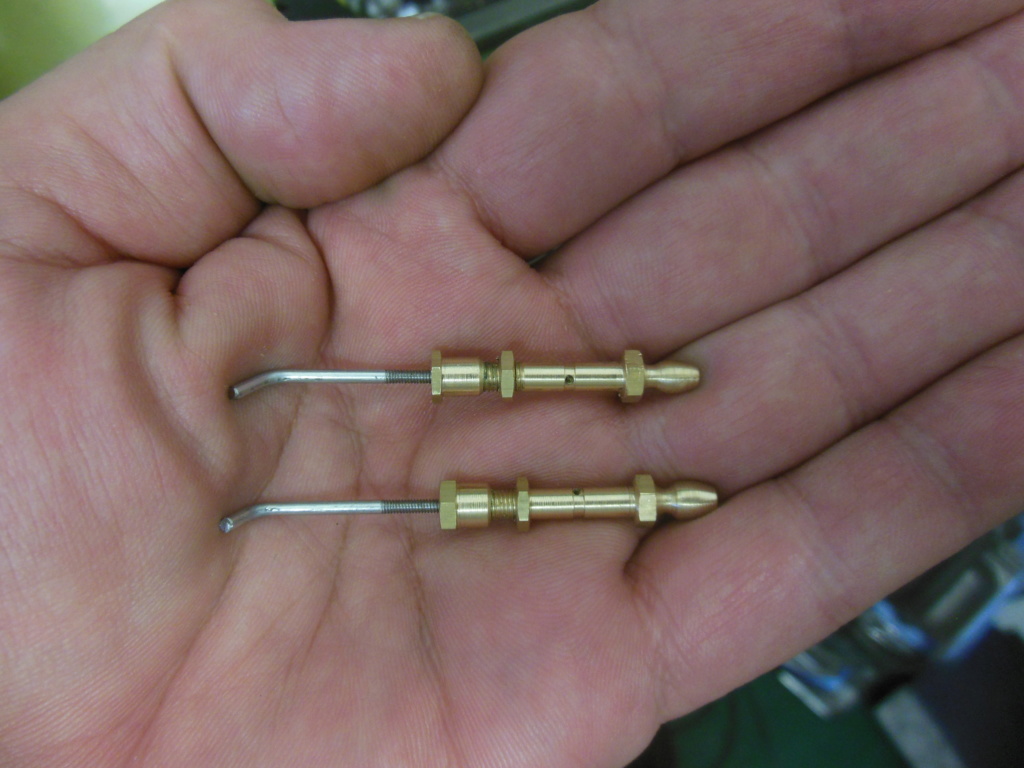

Here are a couple finished.

Then another engine had no assembly at all - so started making the nuts. Although these are M4 nuts - the are not standard metric but metric fine. These are not easy to buy along with being half nuts. Standard M4 metric has a 0.7mm thread - these are 0.5mm

Once set up, it is easy to make a few

Followed by the more complicated - not difficult but fiddly - needing four different size holes drilling centrally, M2 internal thread, M4 fine external thread and a cross drilling.

This is then reversed in the lathe to shape the fuel pipe connection. Here is where I regret my delay in converting this lathe to CNC.

I have everything I need for this but time!

Still, I rough cut the shape and then use a series of files and shape by eye.

Here are a couple finished.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

Ian, Great work, you show off!! Most Cox Engine folks don't have access to a machine shop tools. So how do we do this kind of work with a drill press, vise grips and a hammer??? Just Kidding.

Mark

Mark

Mark

Mark

Mark Diedrichs- Gold Member

- Posts : 434

Join date : 2017-11-11

Age : 72

Location : fairfield ohio

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

This is the NVA with the needle and locking screw fitted to a ZOM G5 glow 2.49. This engine was totally siezed (gummed up). Freed with a little heat and then doused with methanol.

Here is the first start from cold with a 8x3 prop. It managed 16,000 revs but a subsequent run with a 8x6 only managed 8,500. Not good, I would expect 10,500. Needs a bit more investigation.

This one, second run (needle set) with all new NVA did 10,800 on a 8x6 prop.

Both engines now need a good clean up.

Here is the first start from cold with a 8x3 prop. It managed 16,000 revs but a subsequent run with a 8x6 only managed 8,500. Not good, I would expect 10,500. Needs a bit more investigation.

This one, second run (needle set) with all new NVA did 10,800 on a 8x6 prop.

Both engines now need a good clean up.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

Mark Diedrichs wrote:Ian, Great work, you show off!! Most Cox Engine folks don't have access to a machine shop tools. So how do we do this kind of work with a drill press, vise grips and a hammer??? Just Kidding.

Mark

This reminds me of a pre Monty Python sketch

I am a Yorkshire man!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

Ian, the Monty P. vid was as you are, BRILLIANT!!!!! What's Next Bro???? Mark

Ian, the Monty P. vid was as you are, BRILLIANT!!!!! What's Next Bro???? Mark

Mark Diedrichs- Gold Member

- Posts : 434

Join date : 2017-11-11

Age : 72

Location : fairfield ohio

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

Almost exactly the same project I am doing right now. I am doing a dozen, with 7 done as remote needles. M2 x 0.4 pitch. I just plunged the points in two steps, as a grinder would not fit on the Hardinge or Taig. Then the motor burned out in the Hardinge. $$$$ I think some if the non remote needles will be 8-32. Not sure if I will bother with the lock nut. I am using M2 pushrods, they have roll formed threads and are soft steel. I like your Dremel drill press.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

The hardest part is to get a fine enough thread pitch for an accurate needle tuning, I feel. So a smaller thread size will have better thread pitch, without having go into too specialised threads. The smallest needle I have made was with an M1.2 thread (for an RC carb on the VA .020 engine), this gives a thread pitch of 0.25mm which is about 100 threads/inch, so quite good in terms of fine pitch. I made mine from brass which is easier to work with on these small length scales.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

Mark,

Next steps are to clean up the engines, rework the drive plates and drive nuts and then salvage bearings and parts from the "beyond repair". This started as six seemingly basket cases for 80 Euros - I will end up with four good runners one of which will be pristine.

The runners

Beyond repair

Aspeed,

These NVAs are copies of the original ZOM NVAs which ZOM copied the style from Super Tigre. MVVS NVAs are the same. They all have lock nuts and they definitely need them. The needle loosens easily as the engine warms up and, if they fall out, they are difficult to find in grass. I haven't seen any this style that don't have a lock nut.

Not sure about 8-32 - that is in M4 territory. Closer might be 2-56 or 2-64.

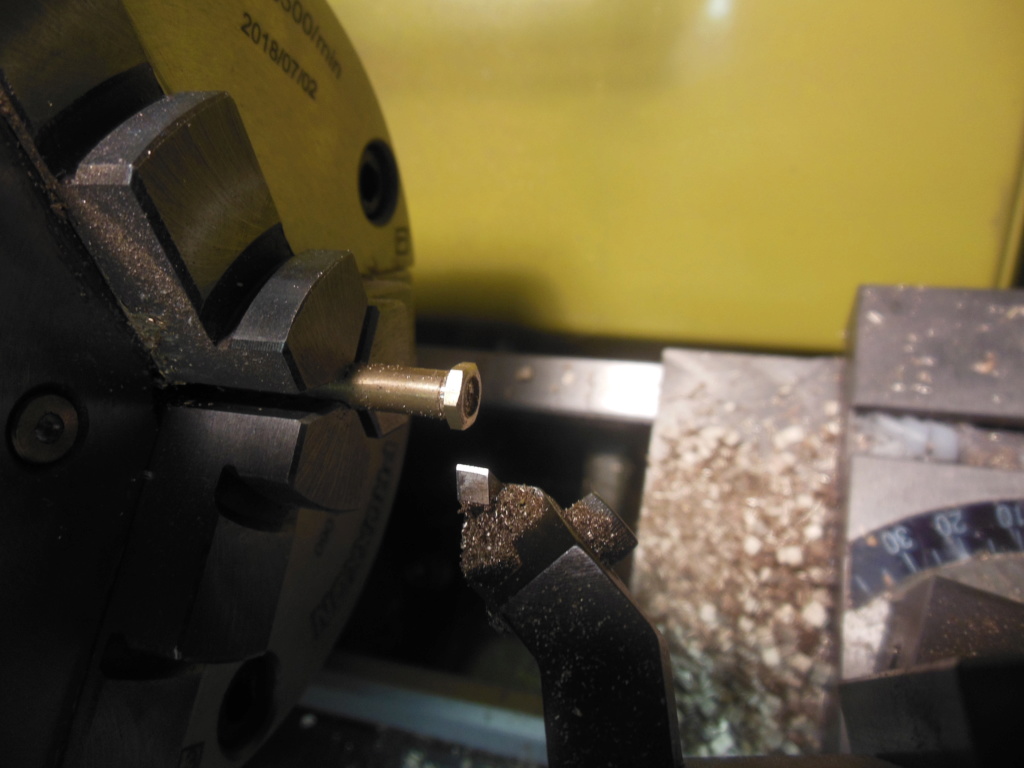

When the motor started to act up on my Myford Speed 10 (Imperial) (not the lathe in the pictures above - that is a Proxxon (metric)), a direct replacement motor was expensive. I found it easier to replace it with a more modern three phase motor diven from a speed controller (single phase) and not much more expensive.

This made the lathe a lot more flexible and I don't have to change the belts for speed as often. It also has a "jog" function that helps me when tapping and die cutting.

This is still my favourite lathe.

This is the Proxxon used above

Kris,

The M2 fine thread has a 0.25mm pitch. It is confusing here because most coarse sets here have the M2 fine but M3 and above is coarse.

I use a small set of fine - M2.5 and below. M2.5 - 0.35 pitch, M2.2 to M2.0 - 0.25 pitch and M1.8 to M1.0 - 0.20 pitch.

The M1.2 you are quoting is coarse pitch so you could drop to a finer pitch.

I like the VA engines but only have 049s. That looks like a superb example of an 020.

I also make NVAs from brass. These are work in progress for combat planes.(not mine)

Next steps are to clean up the engines, rework the drive plates and drive nuts and then salvage bearings and parts from the "beyond repair". This started as six seemingly basket cases for 80 Euros - I will end up with four good runners one of which will be pristine.

The runners

Beyond repair

Aspeed,

These NVAs are copies of the original ZOM NVAs which ZOM copied the style from Super Tigre. MVVS NVAs are the same. They all have lock nuts and they definitely need them. The needle loosens easily as the engine warms up and, if they fall out, they are difficult to find in grass. I haven't seen any this style that don't have a lock nut.

Not sure about 8-32 - that is in M4 territory. Closer might be 2-56 or 2-64.

When the motor started to act up on my Myford Speed 10 (Imperial) (not the lathe in the pictures above - that is a Proxxon (metric)), a direct replacement motor was expensive. I found it easier to replace it with a more modern three phase motor diven from a speed controller (single phase) and not much more expensive.

This made the lathe a lot more flexible and I don't have to change the belts for speed as often. It also has a "jog" function that helps me when tapping and die cutting.

This is still my favourite lathe.

This is the Proxxon used above

Kris,

The M2 fine thread has a 0.25mm pitch. It is confusing here because most coarse sets here have the M2 fine but M3 and above is coarse.

I use a small set of fine - M2.5 and below. M2.5 - 0.35 pitch, M2.2 to M2.0 - 0.25 pitch and M1.8 to M1.0 - 0.20 pitch.

The M1.2 you are quoting is coarse pitch so you could drop to a finer pitch.

I like the VA engines but only have 049s. That looks like a superb example of an 020.

I also make NVAs from brass. These are work in progress for combat planes.(not mine)

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

The Myford looks to be in good shape. I had a Myford 7 for a short time that needed some love, but had to liquidate it because of a move. Thought I would show a pic of one of the first batch of needle valves I made. This one is on a "combatish" plane. The OD of the spray bar is #6-32, and the needle was from #2-56 threaded rod. Turned out to be stainless so I could not solder a big washer on the end, so I used a couple nuts.

Used fuel tubing instead of a lock nut similar to the ones you are making for the combat guys. The #2-56 adjustment works well on a suction tank. Not sure about bladders. I shortened the spray bar a fair bit since that pic was taken. Less damage from crashes. I am waiting for a motor for the lathe. 1 1/2 HP single phase 240V. Here we normally use 120V. The Hardinge originally had a 2 or 3 speed motor 600V 3 phase, with forward and reverse, but I changed it out to use at home. Just one speed, forward and reverse. The old motor that burned out was used and lasted 30 years, so I can't complain, but I will. I guess the high speeds put a load on the tired old motor. I tried a Phase shifter and transformer on the lathe (and mill) but it did not work well. The motors overheated when used all day and stalled when cold. That was in the days before VFD.

Used fuel tubing instead of a lock nut similar to the ones you are making for the combat guys. The #2-56 adjustment works well on a suction tank. Not sure about bladders. I shortened the spray bar a fair bit since that pic was taken. Less damage from crashes. I am waiting for a motor for the lathe. 1 1/2 HP single phase 240V. Here we normally use 120V. The Hardinge originally had a 2 or 3 speed motor 600V 3 phase, with forward and reverse, but I changed it out to use at home. Just one speed, forward and reverse. The old motor that burned out was used and lasted 30 years, so I can't complain, but I will. I guess the high speeds put a load on the tired old motor. I tried a Phase shifter and transformer on the lathe (and mill) but it did not work well. The motors overheated when used all day and stalled when cold. That was in the days before VFD.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

It is possible to solder brass to stainless steel using silver solder and a special flux.

There are also special pastes that make it easier.

There are also special pastes that make it easier.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

Ian-I am not sure if you are aware of them-but Tracy Tools in Devon have more metric taps and dies in all sorts of obscure pitches than most people could poke a blunt stick at...just check out page 1 of their metric listings... https://www.tracytools.com/taps-and-dies/metric-taps-dies

....and they're right in your backyard....so to speak...

ChrisM

'ffkiwi'

PS FWIW the VA 020 as shown above turned out to be one big disappointment and not a patch on their 049s....mine fell well short of a TD 020 performance-wise, on glow-though it may prove better on diesel (in which form I've never gotten around to running it.)......likewise the Fora 020s were equally disappointing....and about that time the Russians lost interest in producing micro glow and diesels for an apparently very critical and numerically small market...

....and they're right in your backyard....so to speak...

ChrisM

'ffkiwi'

PS FWIW the VA 020 as shown above turned out to be one big disappointment and not a patch on their 049s....mine fell well short of a TD 020 performance-wise, on glow-though it may prove better on diesel (in which form I've never gotten around to running it.)......likewise the Fora 020s were equally disappointing....and about that time the Russians lost interest in producing micro glow and diesels for an apparently very critical and numerically small market...

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

I often use Tracy tools. Before they moved to Devon they were based 5 minutes walk from my house in London.

One of the few places in the UK where you can get bottom taps, UNC and UNF. Most places here can supply Metric but Tracy can supply BA, ME, BSW, BSF........... even left hand taps.

Unfortunately, they don’t do the oddball Cox taps and dies. I have to turn those threads on the lathe.

One of the few places in the UK where you can get bottom taps, UNC and UNF. Most places here can supply Metric but Tracy can supply BA, ME, BSW, BSF........... even left hand taps.

Unfortunately, they don’t do the oddball Cox taps and dies. I have to turn those threads on the lathe.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

ian1954 wrote:I often use Tracy tools. Before they moved to Devon they were based 5 minutes walk from my house in London.

One of the few places in the UK where you can get bottom taps, UNC and UNF. Most places here can supply Metric but Tracy can supply BA, ME, BSW, BSF........... even left hand taps.

Unfortunately, they don’t do the oddball Cox taps and dies. I have to turn those threads on the lathe.

Even at the other end of the earth-they are my 'go to' source for most taps and dies....along with 'modelfixings.co.uk'....both firms have mail order service that others struggle to come close to-but many should try and emulate....!

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

ffkiwi wrote:

PS FWIW the VA 020 as shown above turned out to be one big disappointment and not a patch on their 049s....mine fell well short of a TD 020 performance-wise, on glow-though it may prove better on diesel (in which form I've never gotten around to running it.).....

Not sure what you are referring to there. These are great engines, and the VA .020 shown above is beating my Cox TD .020 engines with ease, even in the form shown with a full RC carb and a muffler. Here are some tach numbers on 10% nitro:

Cox 4.5x2 prop: 19700rpm

Cox 4x2.5 prop: 21400rpm

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

I could not get better than 16,500 on 25% nitro on my example on a Cox grey 4.5x2-as I noted earlier, I have not run it as a diesel yet-despite it coming with the optional factory diesel head. 16,500 is Cox Pee Wee territory-and way down on my typical TD 020s which run from 19,500 to 20,500 on the same prop and fuel-considering I have about a dozen TD 020s-those figures are solid-and represent bog standard unmodified TD 020 performance-there has been no shimming, polishing or anything else done; likewise the VA is exactly as received from Dave Banks-no optimisation or modding has been done. I'm sure my figures can be improved upon with work-but as received I was disappointed with it, considering its pedigree and design specs....

Yours does not appear to have the factory head.....

ChrisM

'ffkiwi'

Yours does not appear to have the factory head.....

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

Ahh yes, the factory head might not be "great", I vaguely remember a discussion on RCU (some +10years ago) where AndyW was machining Cox .010 and .020 heads into inserts to use instead of the stock head. I wanted to save the stock head and don't remember if I ever tried it, or simply made a new head and clamp in order to take a turbo plug straight away.

Otherwise the build quality is right up there with the VA .049 MkII, in my experience.

Otherwise the build quality is right up there with the VA .049 MkII, in my experience.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

Agreed-the build quality is great...the design is modern.....which is probably why I was so disappointed with it after running it. Not all the VA engines got it right-the Mills .25cc being another case in point. One day I must revisit the 020.....and give some serious thought to the head issues... I have nearly all the various VA engines-other than the Micro 0.4cc.....and most are excellent-a few were not.

ChrisM

'ffkiwi'

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

Surfer_kris wrote:The head clamp and insert is very easy to make in lathe, once you have the proper thread die. It is a little tight with a Turbo plug in these small engines, and it doesn't leave much options for the squish band and bowl shape, but here is what I made for mine, and it seems to work just fine:

All good-what IS the thread?-something along the lines of M12x1 at a guess...or possibly M12x .75? -looking at the as yet unused diesel head insert-which is a push-pull type with a brass contra and about a 2mm squish band...

As you say-a bit tight-but with a turbo you get a lot of options...

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

The thread is 12x0.75 mm, I've written a few posts on the topic in the VA .020 thread here: https://www.coxengineforum.com/t10946-russian-va-020-engines

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

Surfer_kris wrote:The thread is 12x0.75 mm, I've written a few posts on the topic in the VA .020 thread here: https://www.coxengineforum.com/t10946-russian-va-020-engines

Don't know how I managed to miss that forum thread-though most of it dates to a time before I joined the Cox forum. I should also note that my VA 020 was purchased around 2000 or 2001 from Dave Banks-the UK agent (apparently you had to be a Dave to get the agency-I mean really?..well yes Dave Banks UK, Dave Acton US, Dave Palmer Canada, Dave Owen Australia....!)-all my self purchased new VA engines came from either Dave Banks or Dave Owen [I've obtained one or two second hand in later years]-and looking at your posts in the other thread I have a feeling mine may be a very early model-or from the first production tranche (if there was more than one-which is by no means impossible-I know for absolute certainty there were at least three different variants of the VA Bambi-I've seem them...!] -the anodised head clamp for a start seems to hint at either a later run-or a model produced specially for the US market. In light of the comments on the other thread-I've given mine a good oiling and loosening up (its at least 15 years -possibly more-since it was last run)-and I would describe mine as being anything but undercompressed-in fact in glow form it feels more like a diesel! I also note that it came just with the spare diesel head, no spare venturi -and definitely no spare head shims-which from the sound of things is an oversight I may well come to regret...or it may simply be that if it is as I suspect an early model-they simply weren't provided with the early ones...

And-giving some critical thought to it-it is unlikely that Dave Banks would have had many in stock-perhaps only 5 or 10 examples? For a start-the 020 class does not have any significant following in the UK-there are no competition classes for it-and what designs are built are generally sport and well catered for by a Pee Wee...unlike the US with 020 Replica, PAAload and Clipper cargo FF classes-plus the SMALL RC fraternity-and NZ where 020 Replica was-for a time-the most popular vintage FF competition class all thru the 80s and well into the 90s. I may be reading more into it than is warranted-but I imagine that Dave Banks might well have responded to a suggestion by VA that " Hey I've got this neat little 020 glow that the FFers will love-especially with the Cox TD 020 going out of production-you want to take a few with your other motors?" with something along the lines of "Well there's not much call for that sort of thing at home-they love your little diesels but an 020 glow....?....tell you what I'll take half a dozen ..if they sell- well then I'll place a bigger follow up order..."

So I'm speculating here that mine is a very early one-perhaps even a pre production job-before some of the minor issues were ironed out....

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

I purchased mine when it was announced on the forum here. I bought 2 of them and I just recently ran mine in stock form. While I'm not impressed with the rpm numbers using the Cox Pee Wee standard prop, I will say it starts easy and runs consistently. In addition, while the rpm's are not high, for what I'm going to be flying, it will be too much. A Midwest Sniffer with even a anemic engine goes out of sight in just a few seconds. Not only do I not want to lose the plane, I certainly don't want to try and find a replacement. At the time of purchase, 80 of the VA .020's were available on Ebay.

Ken Cook- Top Poster

- Posts : 5634

Join date : 2012-03-27

Location : pennsylvania

Re: Engine rebuild - giving it the needle

Re: Engine rebuild - giving it the needle

80 examples for sale on Ebay sounds very much like the bulk of a production run....which might well have been 100 engines in a batch [this being a typical number for an AH production run-which as already mentioned earlier in the VA 020 thread, VA had a hand in making components for]-so I am speculating that either these 'recent ones' were either the remnant of an earlier run which had failed to sell elsewhere-or alternatively produced to order, again not an unknown situation-and a system used by MP Jet in the Czech Republic-who according to David Owen, did not manufacture engines routinely, but only to firm order from their agents.

ChrisM

'ffkiwi'

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Similar topics

Similar topics» Engine rebuild help please

» Tee Dee Engine rebuild

» Another C.T. engine rebuild completed -- this time a Cox Tee Dee .049

» Giving away my Cox collection

» Giving it another shot

» Tee Dee Engine rebuild

» Another C.T. engine rebuild completed -- this time a Cox Tee Dee .049

» Giving away my Cox collection

» Giving it another shot

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules