Log in

Search

Latest topics

» Free Flight Radio Assist by GallopingGhostler Today at 12:54 pm

» My N-1R build log

by akjgardner Today at 12:39 pm

» Purchased the last of any bult engines from Ken Enya

by getback Today at 12:05 pm

» Funny what you find when you go looking

by rsv1cox Yesterday at 3:21 pm

» Landing-gear tips

by 1975 control line guy Yesterday at 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» My latest doodle...

by TD ABUSER Mon Nov 18, 2024 11:30 am

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

» Tribute Shoestring build

by amurphy6812 Sun Nov 17, 2024 5:43 pm

Cox Engine of The Month

Reed Valve Design Ideas Poll

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

RE: Reed valve design polls

RE: Reed valve design polls

Regarding designs of the actual reed valve itself, Cox flirted with a Beryllium Copper rectangle reed.

I have one from a bag of about 50 that was in R&D.

The guy was more than really difficult dealing with so I got the one only.

I hate to use it because of it's oddity, although it would been fun to compare with the stainless steel version in use.

I read later that there maybe possible environmental issues working with Beryllium alloys, and I concluded that may why Cox didn't use them, Maybe cost too?

I scored a bunch of Cox stuff from a Texas seller on eBay so, I got a number of the mylar star shaped reeds that will do me a while.

I have one from a bag of about 50 that was in R&D.

The guy was more than really difficult dealing with so I got the one only.

I hate to use it because of it's oddity, although it would been fun to compare with the stainless steel version in use.

I read later that there maybe possible environmental issues working with Beryllium alloys, and I concluded that may why Cox didn't use them, Maybe cost too?

I scored a bunch of Cox stuff from a Texas seller on eBay so, I got a number of the mylar star shaped reeds that will do me a while.

66 Malibu- Gold Member

- Posts : 477

Join date : 2012-02-28

Location : Georgia

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

66 Malibu wrote:

I scored a bunch of Cox stuff from a Texas seller on eBay so, I got a number of the mylar star shaped reeds that will do me a while.

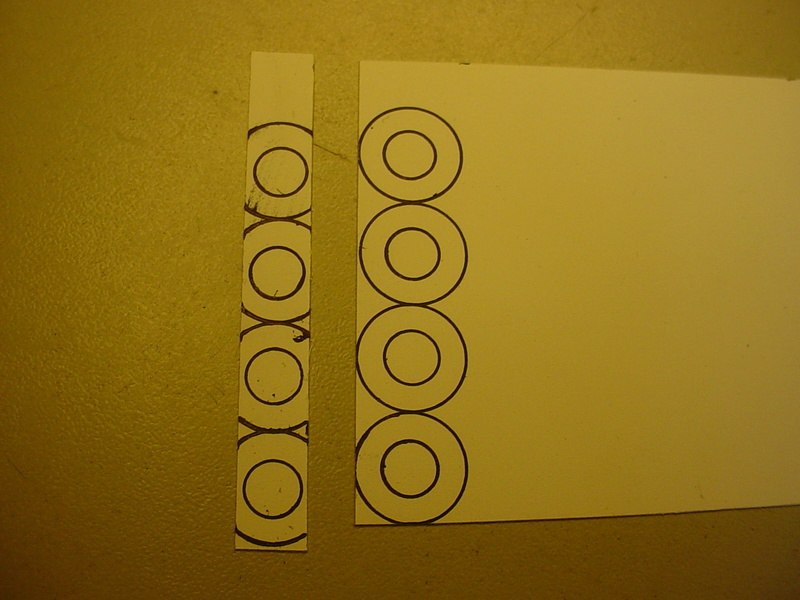

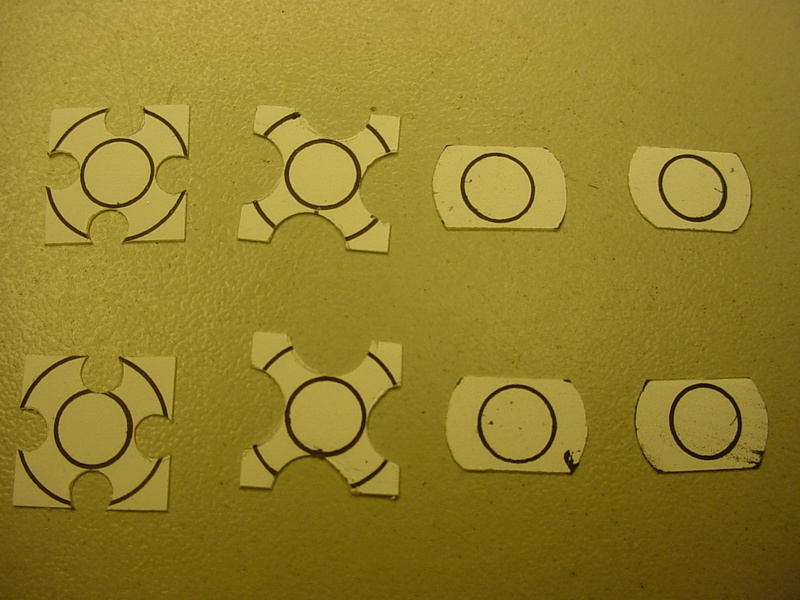

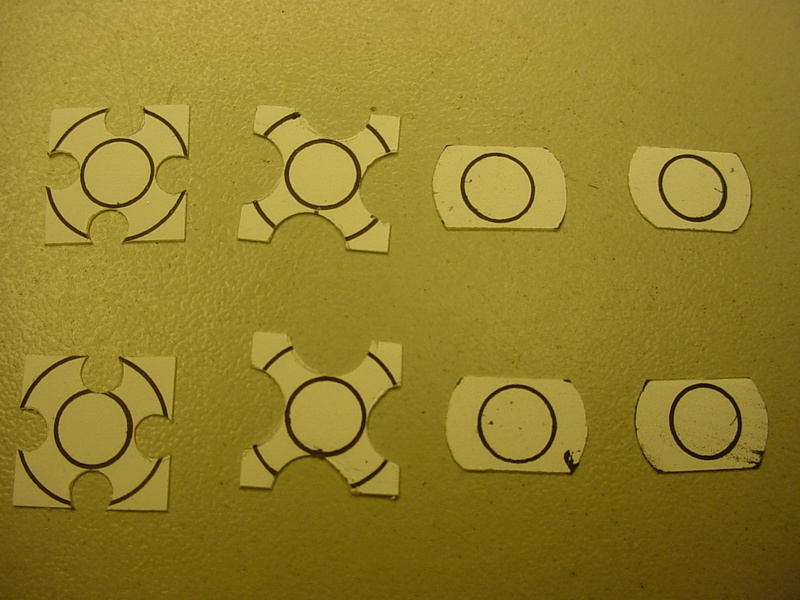

I did some more messing around today with redneck reed design..

Then I nibbled-out the four radius-cuts using a paper hole-punch..

This leaves just the "legs" to trim.. which is easier than trying to cut-out the entire circle cleanly with scissors..

It needs to be test-run.. but the "blow/suck" method reveals that it seals.

Then there's what I'll call my "hybrid"..

I'll be working on a method to more accurately index the cuts.. because symmetry is likely a key to whether the reed will function correctly.

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

Nice work Roddie!

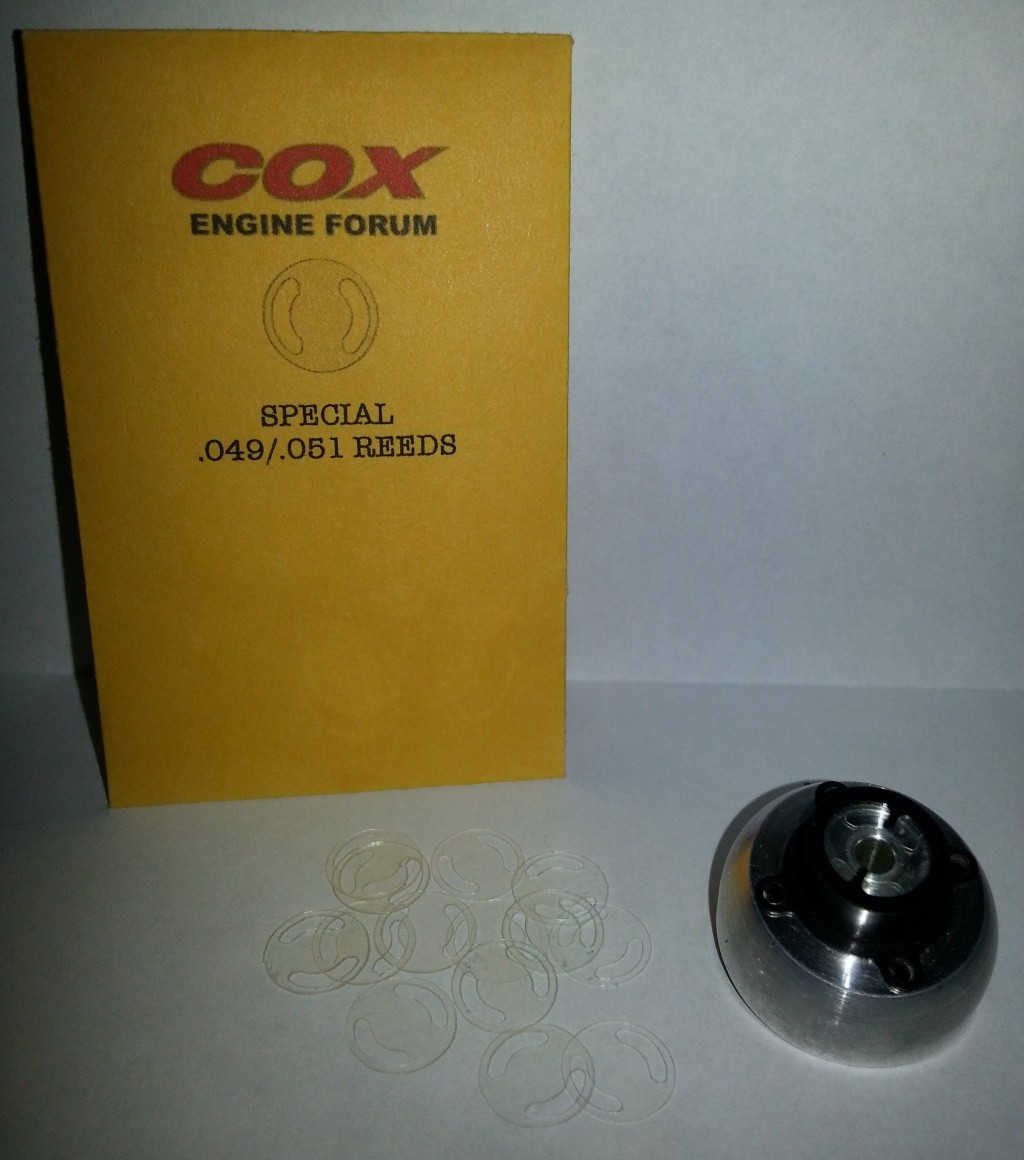

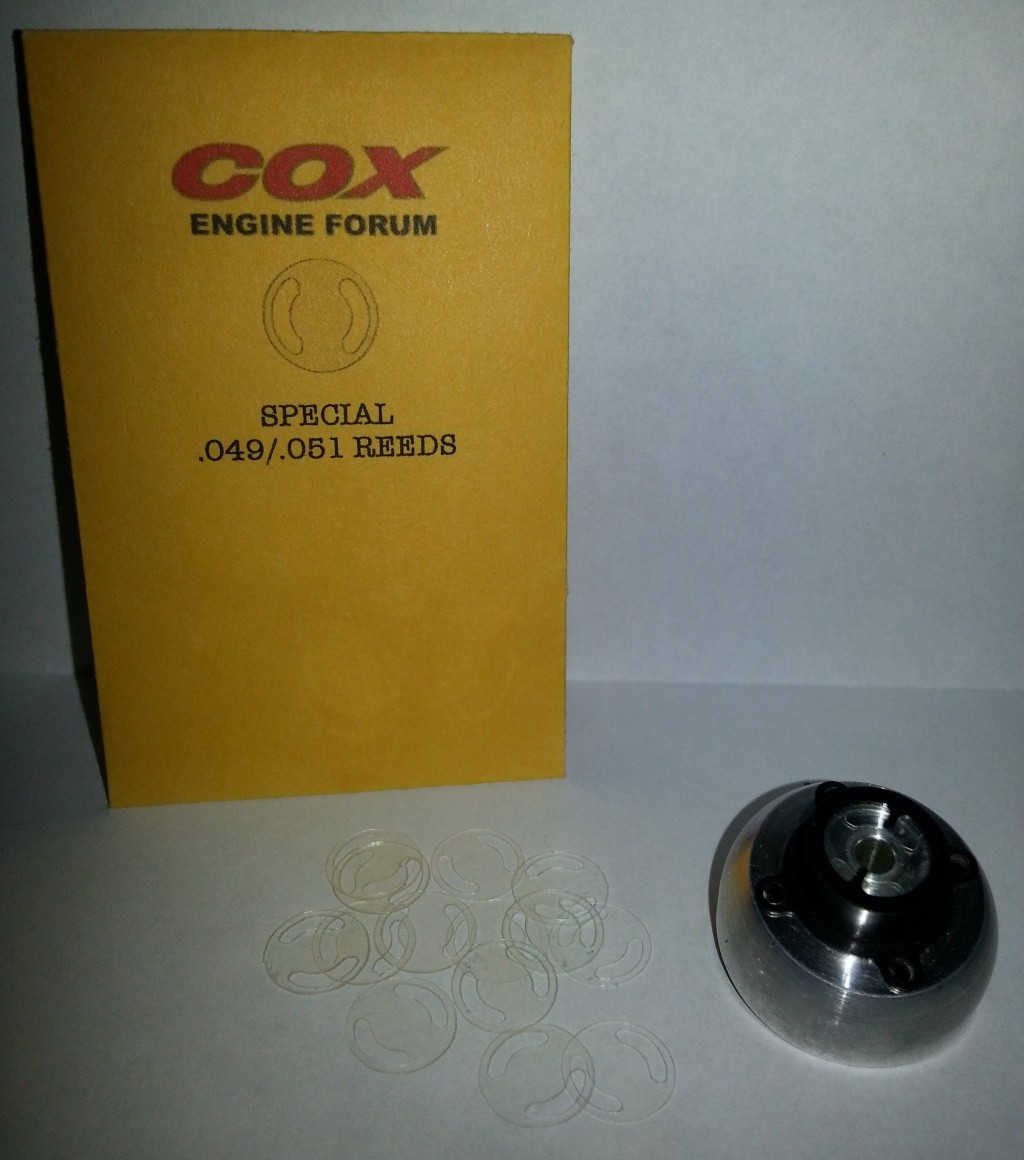

I've played around with various reed designs over the years. I like the Mylar star reeds the best.

One reed design I think could be a winner is this:

These were designed off a reed I hand cut out of a floppy disk one day. Jason made the first machine-cut ones off the design. I need to get a new cutting mat for my die-cut machine, then I can get back to cutting them out. I know a few of you guys on here are probably waiting for them. They need to be ran through a lot of tests to see if they really improve anything first. I know I sent some to a few members on here...have never heard anything back about performance though.

I've played around with various reed designs over the years. I like the Mylar star reeds the best.

One reed design I think could be a winner is this:

These were designed off a reed I hand cut out of a floppy disk one day. Jason made the first machine-cut ones off the design. I need to get a new cutting mat for my die-cut machine, then I can get back to cutting them out. I know a few of you guys on here are probably waiting for them. They need to be ran through a lot of tests to see if they really improve anything first. I know I sent some to a few members on here...have never heard anything back about performance though.

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

Roddie I like the star shape but to me the "hybrid" leaves too small transfer area i.e. only 2 small bites through which the mixture is drawn into the crankcase...of course your bench test will tell us if I am wrong

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

RE: Reed valve design ideas

RE: Reed valve design ideas

Roddie,

Great creativity and engineering to make a complicated shape easy for even me to do !!!!

Thanks, Steve

Great creativity and engineering to make a complicated shape easy for even me to do !!!!

Thanks, Steve

66 Malibu- Gold Member

- Posts : 477

Join date : 2012-02-28

Location : Georgia

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

My gaskets finally came from Cox Int. today. Now I can resume testing.

I've been thinking of getting some of those Cox Forum reeds to try.

I've been thinking of getting some of those Cox Forum reeds to try.

SkyStreak- Bronze Member

- Posts : 31

Join date : 2018-02-26

Location : Mo

Re: Reed Valve Design Ideas Poll

Re: Reed Valve Design Ideas Poll

by balogh on Mon Mar 26, 2018 2:27 pm

Roddie I like the star shape but to me the "hybrid" leaves too small transfer area i.e. only 2 small bites through which the mixture is drawn into the crankcase...of course your bench test will tell us if I am wrong

You're probably correct Andras.. but we'll see. I'm hoping to possibly improve fuel-economy without sacrificing performance. Who knows how much (if any) unburnt fuel passes through the exhaust ports. It certainly happens with a rich needle-setting.

by 66 Malibu on Mon Mar 26, 2018 5:40 pm

Roddie,

Great creativity and engineering to make a complicated shape easy for even me to do !!!!

Thanks, Steve

I actually enjoy messing around with these kinds of things Steve. I'll probably end up in the funny-farm from it one day though..

A circle-template is a must-have tool. I use it for lots of things. It definitely came in handy for this application. I used the 7/16" and 7/32" to mark the reed's outer-diameter and seat-area respectively. This helps to provide a ball-park reference when punching the radii for the star-shape.

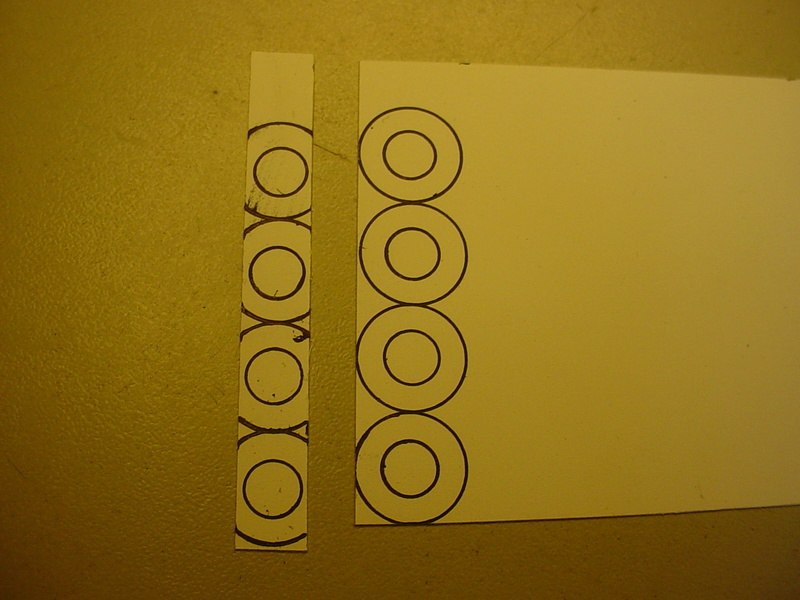

The oblong/oval-shape reed is easy to make.. once you get the hang of it. The "straight-sides" are approximately .270" apart. If you cut a strip of material to that width.. and a couple of inches long; you've then established the cross-section for cutting as many reeds as will fit on the strip.. side-by-side. I use a small steel-rule and razor-knife. The 7/16" circle-template is used to mark the radii by placing it over the strip and sighting-it on-center. Mark the radii with a fine-point pen. Using a "nibbling-action" with good sharp scissors; cut the radii "on".. or just inside the ink-mark.

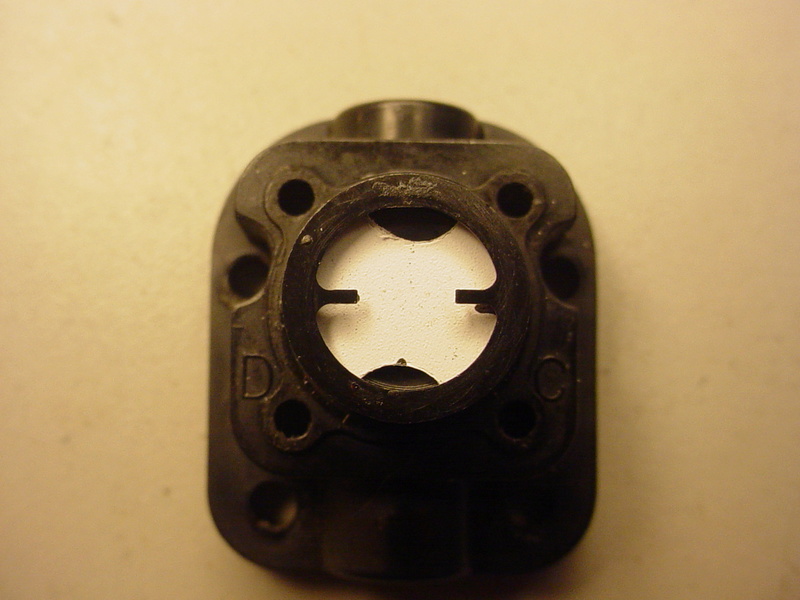

You'll know where to cut after making a couple. If the overall radius is too "large".. the reed will warp in the housing.. and won't seat properly. Too "small".. will allow side-movement of the reed which would probably cause "floating" and loss of power. In extreme cases.. a reed that is much too small could slip past the retainer.. and get sucked into the crankcase.

I made a couple more reeds this morning.. marking the seat-area..

Note a new experimental cross-flow reed-type having x4 radii of .125" accomplished using my 1/8" hole-punch.

Again; this material is a semi-rigid type of plastic-sheet which is "gloss-smooth" on one side and has a "matte-finish" on the other side. The thickness is .008". The smooth/reflective side faces the valve-seat.. and the matte-side I use to make my ink-marks.

Roddie I like the star shape but to me the "hybrid" leaves too small transfer area i.e. only 2 small bites through which the mixture is drawn into the crankcase...of course your bench test will tell us if I am wrong

You're probably correct Andras.. but we'll see. I'm hoping to possibly improve fuel-economy without sacrificing performance. Who knows how much (if any) unburnt fuel passes through the exhaust ports. It certainly happens with a rich needle-setting.

by 66 Malibu on Mon Mar 26, 2018 5:40 pm

Roddie,

Great creativity and engineering to make a complicated shape easy for even me to do !!!!

Thanks, Steve

I actually enjoy messing around with these kinds of things Steve. I'll probably end up in the funny-farm from it one day though..

A circle-template is a must-have tool. I use it for lots of things. It definitely came in handy for this application. I used the 7/16" and 7/32" to mark the reed's outer-diameter and seat-area respectively. This helps to provide a ball-park reference when punching the radii for the star-shape.

The oblong/oval-shape reed is easy to make.. once you get the hang of it. The "straight-sides" are approximately .270" apart. If you cut a strip of material to that width.. and a couple of inches long; you've then established the cross-section for cutting as many reeds as will fit on the strip.. side-by-side. I use a small steel-rule and razor-knife. The 7/16" circle-template is used to mark the radii by placing it over the strip and sighting-it on-center. Mark the radii with a fine-point pen. Using a "nibbling-action" with good sharp scissors; cut the radii "on".. or just inside the ink-mark.

You'll know where to cut after making a couple. If the overall radius is too "large".. the reed will warp in the housing.. and won't seat properly. Too "small".. will allow side-movement of the reed which would probably cause "floating" and loss of power. In extreme cases.. a reed that is much too small could slip past the retainer.. and get sucked into the crankcase.

I made a couple more reeds this morning.. marking the seat-area..

Note a new experimental cross-flow reed-type having x4 radii of .125" accomplished using my 1/8" hole-punch.

Again; this material is a semi-rigid type of plastic-sheet which is "gloss-smooth" on one side and has a "matte-finish" on the other side. The thickness is .008". The smooth/reflective side faces the valve-seat.. and the matte-side I use to make my ink-marks.

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» What's the Best Reed for Cox Reed Valve Engines.

» New Cox Reed Design

» Reed Speed--Best Model Poll

» Reed Function and Design

» Reed Valve

» New Cox Reed Design

» Reed Speed--Best Model Poll

» Reed Function and Design

» Reed Valve

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules