Log in

Search

Latest topics

» Tee Dee .020 combat modelby Ken Cook Today at 5:09 am

» Roger Harris revisited

by TD ABUSER Today at 2:30 am

» My latest doodle...

by batjac Yesterday at 10:05 pm

» Retail price mark-up.. how much is enough?

by gkamysz Yesterday at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Yesterday at 9:22 pm

» My N-1R build log

by GallopingGhostler Yesterday at 3:04 pm

» Chocolate chip cookie dough.........

by roddie Yesterday at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 11:32 am

» Free Flight Radio Assist

by rdw777 Yesterday at 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Interchageable TD RC and BigMig RC options

Page 1 of 1

Interchageable TD RC and BigMig RC options

Interchageable TD RC and BigMig RC options

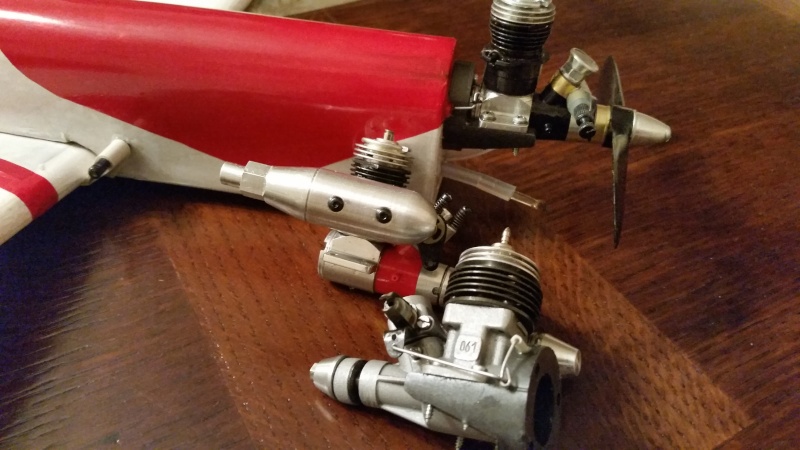

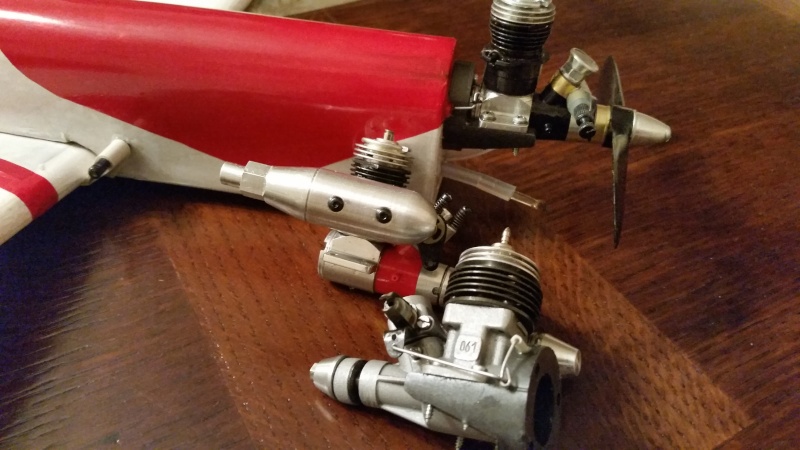

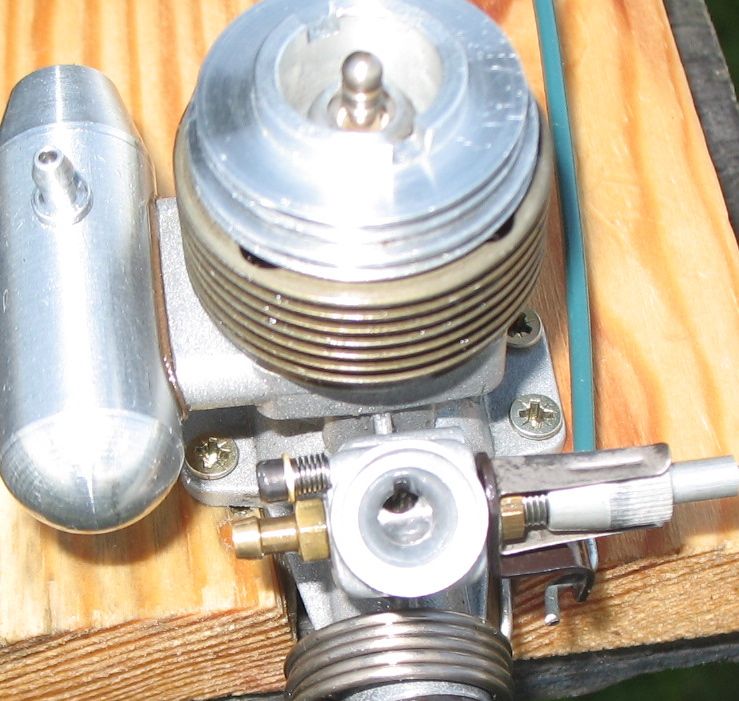

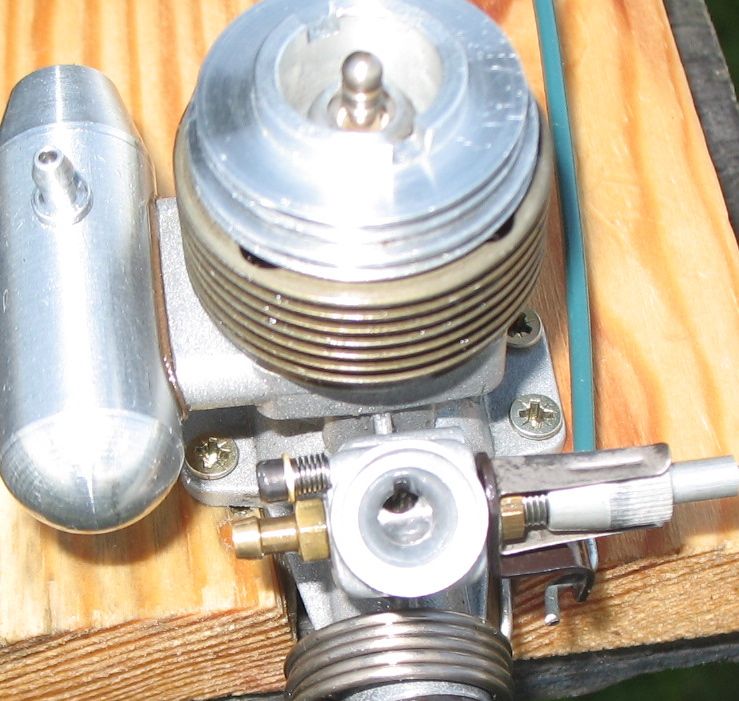

A couple weeks ago when I completed my Skorch R/C project (courtesy 1/2A Nut) I thought of giving a try to a wider range of R/C engines in my stable, including an exhaust throttled TD 049, a TD 50 RC, and YES, a NV Big Mig 061 RC as well. (The latter improved since my bitter early experience, with a new set of Revlite cylinder/piston combo that does have a good compression!!!! Just for you to know that even an adamant COX worshipper like me will not give up trying to revive a NV just for the fun of fiddling on model engines, no matter what brand or make).

So here I am with a set of 3 options of which 2 have their throttle arms on the right side of the engine, and the NV on the left.

In order to accommodate the NV with the same pushrod outlet from the firewall, I added an extra linkage, by drilling a hole on the top of a Dave Brown engine mount, pushing through a torsional lever then linking it to the carb arm with another intermediate linkage rod..all bent with a plyer from a thin pushrod.

I have tried already the TD 050R/C but given its non-SPI cylinder and muffler the engine speed with the 5x4 Thimble D. prop of Bernie was only around 19k or so, unloaded (I have not tached it in the air with my smartphone tach app as I was alone and had to handle the control sticks on the transmitter). The Skorch was a brute to fly...so fast.

I was in the field today with the Skorch and flew it with the TD 049 exhasut throttle setup. It was even faster, even though it also has a non-SPI cylinder, but un-muffled. I guess the engine speed unloaded must have been around 20-21k. ( I will replace the non-SPI with a new SPI cylinder once I got it from the ebayer).

First thing after the heavy winds subside here hopefully tomorrow will be for me to replace the TD 049 with the NV BigMig061 setup...I ran already some 4 oz fuel through it on a stand (with the cylinder pre-heated before starting up so as to reduce the pinch/prevent excessive wear in the cold, unrun engine).

I will continue this thread with my experience shared with you on the NV..I promise to stay objective and unbiased.

So here I am with a set of 3 options of which 2 have their throttle arms on the right side of the engine, and the NV on the left.

In order to accommodate the NV with the same pushrod outlet from the firewall, I added an extra linkage, by drilling a hole on the top of a Dave Brown engine mount, pushing through a torsional lever then linking it to the carb arm with another intermediate linkage rod..all bent with a plyer from a thin pushrod.

I have tried already the TD 050R/C but given its non-SPI cylinder and muffler the engine speed with the 5x4 Thimble D. prop of Bernie was only around 19k or so, unloaded (I have not tached it in the air with my smartphone tach app as I was alone and had to handle the control sticks on the transmitter). The Skorch was a brute to fly...so fast.

I was in the field today with the Skorch and flew it with the TD 049 exhasut throttle setup. It was even faster, even though it also has a non-SPI cylinder, but un-muffled. I guess the engine speed unloaded must have been around 20-21k. ( I will replace the non-SPI with a new SPI cylinder once I got it from the ebayer).

First thing after the heavy winds subside here hopefully tomorrow will be for me to replace the TD 049 with the NV BigMig061 setup...I ran already some 4 oz fuel through it on a stand (with the cylinder pre-heated before starting up so as to reduce the pinch/prevent excessive wear in the cold, unrun engine).

I will continue this thread with my experience shared with you on the NV..I promise to stay objective and unbiased.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Interchageable TD RC and BigMig RC options

Re: Interchageable TD RC and BigMig RC options

The carb on the Norvel engine can easily be rotated 180°. Just make sure that it doesn't hit the crank, there is a little relief on one side, just mimic that on the other side of the carburetor stem.

Is that the regular glow plug on the Norvel?

Just use what you have on the Cox engines instead, and you are in for a treat.

I also remove the intake screen and the throttle stop screw, it can interfere with full throttle setting and it is better to use the radio end points instead.

Is that the regular glow plug on the Norvel?

Just use what you have on the Cox engines instead, and you are in for a treat.

I also remove the intake screen and the throttle stop screw, it can interfere with full throttle setting and it is better to use the radio end points instead.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Interchageable TD RC and BigMig RC options

Re: Interchageable TD RC and BigMig RC options

That plug is probably more responsible for your compression or lack of .

Ken Cook- Top Poster

- Posts : 5638

Join date : 2012-03-27

Location : pennsylvania

Re: Interchageable TD RC and BigMig RC options

Re: Interchageable TD RC and BigMig RC options

balogh wrote:.............(The latter improved since my bitter early experience, with a new set of Revlite cylinder/piston combo that does have a good compression!!!! Just for you to know that even an adamant COX worshipper like me will not give up trying to revive a NV just for the fun of fiddling on model engines, no matter what brand or make).

...................I will continue this thread with my experience shared with you on the NV..I promise to stay objective and unbiased.

Good for you --- I'm glad you've sourced a decent P/C combo. Nothing is more frustrating than trying to get good performance from an ill fitted engine. Hopefully your experience with the new combo will be much more satisfying.

Re: Interchageable TD RC and BigMig RC options

Re: Interchageable TD RC and BigMig RC options

Thanks to all...I tried to rotate the carb on the NV but then it hits on mine the silencer. The glow-plug mod comes right from NV, the adapter is their standard part. To tell the truth I have never had a good outcome with these glow plug adapters, the one from COX Int'l I tried to use on COX lead to overheating no matter how many shims I had under the head. I am not sure how the NV will perform with that, I just simply find it handy because standard plugs are widely available in my part of the world, while COX glow heads and NV plugs are not so much.

Anyways, I will find it out tomorrow, wheather permitting. Just as I write this we have a thunderstorm, downpour and spring-time temperature in a season when in my childhood Santa really had the sledge and reindeers as best option to ship stuff to kids...I just saw him on a hovercraft wading through stormwater, commanding on the bridge half-naked and in sunglasses. All this after a very shiny but windy day.

Anyways, I will find it out tomorrow, wheather permitting. Just as I write this we have a thunderstorm, downpour and spring-time temperature in a season when in my childhood Santa really had the sledge and reindeers as best option to ship stuff to kids...I just saw him on a hovercraft wading through stormwater, commanding on the bridge half-naked and in sunglasses. All this after a very shiny but windy day.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Interchageable TD RC and BigMig RC options

Re: Interchageable TD RC and BigMig RC options

Now I'm jealous. It was pretty cold this morning. Low to mid 30's but the wind was up a bit. Last Sunday when I managed to go flying the thermometer claimed 46 deg. It was the coldest day I experienced in the past 2 months even when the temps were in the upper 20's. I mean frigid cold. It was soooo cold no one would hold a plane to launch it due to the prop blast. It became a engine test stand day. Ken

Ken Cook- Top Poster

- Posts : 5638

Join date : 2012-03-27

Location : pennsylvania

Re: Interchageable TD RC and BigMig RC options

Re: Interchageable TD RC and BigMig RC options

balogh wrote:Thanks to all...I tried to rotate the carb on the NV but then it hits on mine the silencer. The glow-plug mod comes right from NV, the adapter is their standard part. To tell the truth I have never had a good outcome with these glow plug adapters, the one from COX Int'l I tried to use on COX lead to overheating no matter how many shims I had under the head. I am not sure how the NV will perform with that, I just simply find it handy because standard plugs are widely available in my part of the world, while COX glow heads and NV plugs are not so much.

As you can see from my picture there is no problem with rotating the carb. If the throttle-arm hits the muffler you simply undo it and shift its position on the barrel.

The Cox and Norvel heads are interchangeable, so you can simply but a Cox head on the Norvel engine too.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Interchageable TD RC and BigMig RC options

Re: Interchageable TD RC and BigMig RC options

Take a vid (If) you can con mama to go out with you perhaps a box of chocolates will make it happen or take her out for lunch.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Interchageable TD RC and BigMig RC options

Re: Interchageable TD RC and BigMig RC options

Hey Kris a QB is up for grabs if you need a diesel backup.

http://www.ebay.com/itm/COX-QUEEN-BEE-074-RC-/141510265322?pt=Radio_Control_Parts_Accessories&hash=item20f2ab49ea#ht_28wt_1155

http://www.ebay.com/itm/COX-QUEEN-BEE-074-RC-/141510265322?pt=Radio_Control_Parts_Accessories&hash=item20f2ab49ea#ht_28wt_1155

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Interchageable TD RC and BigMig RC options

Re: Interchageable TD RC and BigMig RC options

Thanks, I already have 2 more NIB waiting/begging for a conversion.

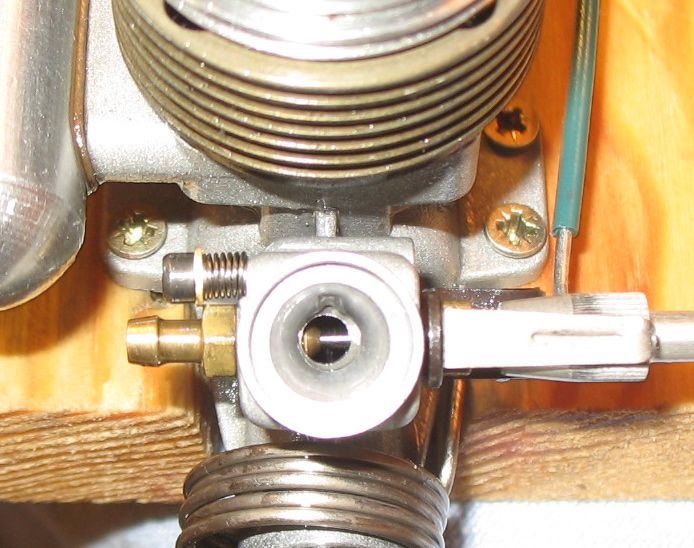

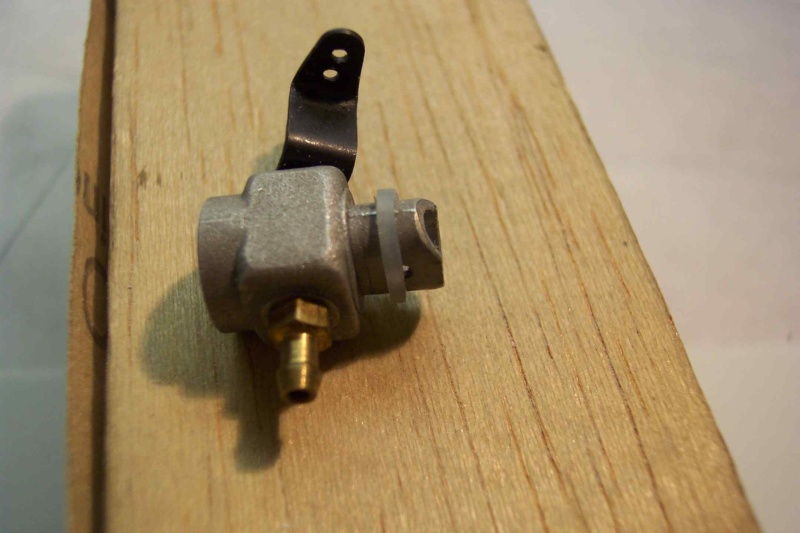

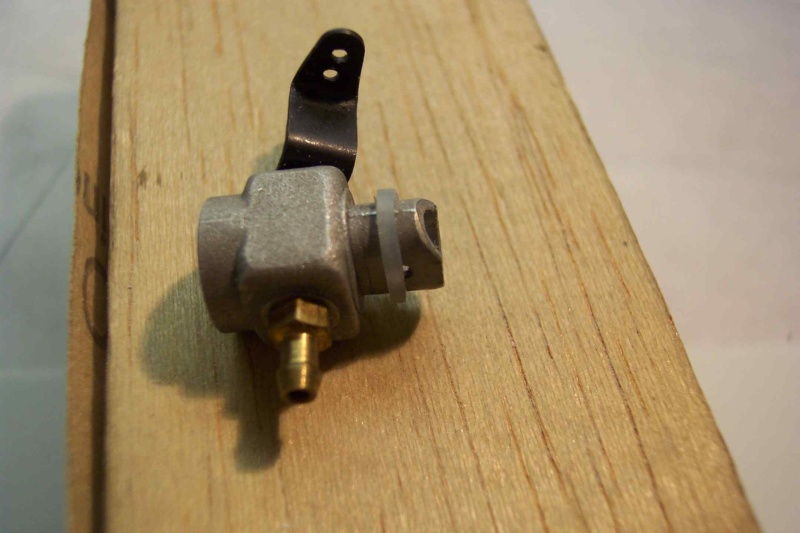

Back to the Norvel, the reason for taking the intake screen of is to be able to check the barrel position. The throttle barrel is not guided by a screw (as is the most common solution on larger engines) instead it is threaded onto the opposing fuel inlet. This means that they get a built in fuel metering as the barrel and needle moves in at lower throttle settings. It does however also mean that they are a bit sensitive to the assembly of the throttle arm and throttle stop (that stop the throttle lever rather than the barrel). So by removing the screen one can check the throttle movement, and by removing the throttle stop one can set it up for a correct operation by using the servo end points.

The throttle barrel position can also be changed by multiples of 180°, so one needs to check the factory assembly. They might not have put it in an optimum position (i.e. unrestricted intake bore at full throttle), but this is easily remedied by undoing the lever and putting it in a position such that full throttle is unrestricted.

Here is a picture from a Norvel .074 that illustrates what to look for;

Back to the Norvel, the reason for taking the intake screen of is to be able to check the barrel position. The throttle barrel is not guided by a screw (as is the most common solution on larger engines) instead it is threaded onto the opposing fuel inlet. This means that they get a built in fuel metering as the barrel and needle moves in at lower throttle settings. It does however also mean that they are a bit sensitive to the assembly of the throttle arm and throttle stop (that stop the throttle lever rather than the barrel). So by removing the screen one can check the throttle movement, and by removing the throttle stop one can set it up for a correct operation by using the servo end points.

The throttle barrel position can also be changed by multiples of 180°, so one needs to check the factory assembly. They might not have put it in an optimum position (i.e. unrestricted intake bore at full throttle), but this is easily remedied by undoing the lever and putting it in a position such that full throttle is unrestricted.

Here is a picture from a Norvel .074 that illustrates what to look for;

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Interchageable TD RC and BigMig RC options

Re: Interchageable TD RC and BigMig RC options

Thanks for the advice Kris. In a closer look at the throttle barrel of my 061 I was wondering how airtight it is around its periometer where it intersects with the carb housing. I could not see any sealing ring or similar, meaning, that even when the barrel is fully closed some air may ingress at the housing intersection.

I read about airtightness issues with NV-s, was it not about this barrel area? Where the carb sits in the cranckase there is a rubber O-ring which seems OK.

I read about airtightness issues with NV-s, was it not about this barrel area? Where the carb sits in the cranckase there is a rubber O-ring which seems OK.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Interchageable TD RC and BigMig RC options

Re: Interchageable TD RC and BigMig RC options

I have only had problems with the stem of the carb. Even though there is a rubber seal there, it is not enough since there is no (or very little) pressure against the seal. It is enough though to put some silicon or permatex there when it is assembled.

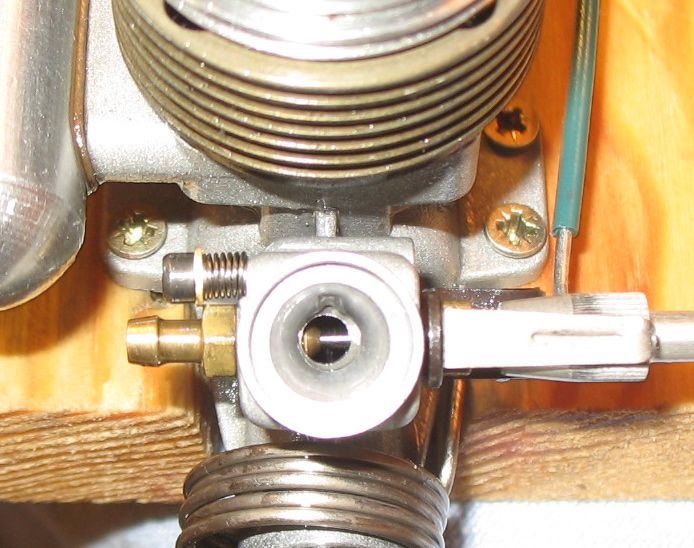

Leaks around the barrel are less of an issue I think. Most airbleed carbs have a similar construction. A small leak around the throttle barrel may well affect the actual airbleed setting, but not do much else. The Norvel carbs have a fixed airbleed hole (older ones) or a notch in the carburator body for extra compensation at the low end. Small leaks will affect the fuel ratio around idle but not do so much at full throttle. In order to test for a leak one can put silicon grease around the throttle barrel and see if that changes the running.

I don't think that the grease will stay on there for very long though, so it is only a short term test.

The low-end compensation on the Norvel .074 can be seen in the picture above, and is perhaps more obvious here when the throttle is set closer to idle;

Leaks around the barrel are less of an issue I think. Most airbleed carbs have a similar construction. A small leak around the throttle barrel may well affect the actual airbleed setting, but not do much else. The Norvel carbs have a fixed airbleed hole (older ones) or a notch in the carburator body for extra compensation at the low end. Small leaks will affect the fuel ratio around idle but not do so much at full throttle. In order to test for a leak one can put silicon grease around the throttle barrel and see if that changes the running.

I don't think that the grease will stay on there for very long though, so it is only a short term test.

The low-end compensation on the Norvel .074 can be seen in the picture above, and is perhaps more obvious here when the throttle is set closer to idle;

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Interchageable TD RC and BigMig RC options

Re: Interchageable TD RC and BigMig RC options

Andrew --

I posted the following over in RCU in the NORVEL FAQ. This FAQ and one on COX engines are stickied at the top of the Half A forum.

****************************************

NORVEL R/C and C/L engines originally shipped with the carb or venturi bodies glued to the crankcase. Once removed, they had to be reattached using some type of adhesive. Although the carb bodies are now retained with a screw in the more recent variations, they still ship with a sealer to block air leaks. This seal can be broken during a crash, extended usage or whenever the carb is removed. On some engines I've seen, the carb body/crankcase fit is rather loose and can be a source for air leaks. The O-rings provided by NORVEL are fairly small and some are of a rather hard composition rubber. Due to size or hardness, they may not provide the air-tight seal needed at the carb/crankcase juncture resulting in difficult needling or inconsistent runs. Attempts to tighten the retaining screw will have no effect on this fit and may only result in stripping the threads or breaking the screw.

One remedy is to cut donuts from a length of large silicon fuel tubing using a sharp Xacto or razor blade, being careful to keep the cuts as symmetrical as possible. The thickness of the donuts is strictly trial and error and you may want to cut several at one time. Remove the existing O-ring and pull your new silicon O-ring over the carb or venturi base. Be sure it is not twisted or rolled and that it is oriented ID/OD as it was cut from the tubing. The silicon ring should be just thick enough so that it bulges slightly when the retaining screw is in place. If it doesn't bulge, then it will not seal well enough. If the silicon ring is too thick, it may pop out of the groove formed by the carb body and crankcase opening, again allowing air in. The silicon tubing is resilient and will seal even though the carb body may have some movement.

A short piece of tubing inserted between the needle and needle valve nut will block possible leaks there. The tubing should either slip over the nut or fit tightly against it and cover about one third of the smooth tapered portion of the needle. If it extends too far over the needle, it will interfere with the needle spring.

Lastly, if the wire needle extension is not needed for a cowled engine, cutting it off and filing flush with the knurled portion will reduce suspended weight on the carb barrel. The wire extension will also tend to vibrate at certain engine RPMs increasing the barrel/carb body wear. File a notch in the knurled end to visually help with needle settings.

I posted the following over in RCU in the NORVEL FAQ. This FAQ and one on COX engines are stickied at the top of the Half A forum.

****************************************

NORVEL R/C and C/L engines originally shipped with the carb or venturi bodies glued to the crankcase. Once removed, they had to be reattached using some type of adhesive. Although the carb bodies are now retained with a screw in the more recent variations, they still ship with a sealer to block air leaks. This seal can be broken during a crash, extended usage or whenever the carb is removed. On some engines I've seen, the carb body/crankcase fit is rather loose and can be a source for air leaks. The O-rings provided by NORVEL are fairly small and some are of a rather hard composition rubber. Due to size or hardness, they may not provide the air-tight seal needed at the carb/crankcase juncture resulting in difficult needling or inconsistent runs. Attempts to tighten the retaining screw will have no effect on this fit and may only result in stripping the threads or breaking the screw.

One remedy is to cut donuts from a length of large silicon fuel tubing using a sharp Xacto or razor blade, being careful to keep the cuts as symmetrical as possible. The thickness of the donuts is strictly trial and error and you may want to cut several at one time. Remove the existing O-ring and pull your new silicon O-ring over the carb or venturi base. Be sure it is not twisted or rolled and that it is oriented ID/OD as it was cut from the tubing. The silicon ring should be just thick enough so that it bulges slightly when the retaining screw is in place. If it doesn't bulge, then it will not seal well enough. If the silicon ring is too thick, it may pop out of the groove formed by the carb body and crankcase opening, again allowing air in. The silicon tubing is resilient and will seal even though the carb body may have some movement.

A short piece of tubing inserted between the needle and needle valve nut will block possible leaks there. The tubing should either slip over the nut or fit tightly against it and cover about one third of the smooth tapered portion of the needle. If it extends too far over the needle, it will interfere with the needle spring.

Lastly, if the wire needle extension is not needed for a cowled engine, cutting it off and filing flush with the knurled portion will reduce suspended weight on the carb barrel. The wire extension will also tend to vibrate at certain engine RPMs increasing the barrel/carb body wear. File a notch in the knurled end to visually help with needle settings.

Re: Interchageable TD RC and BigMig RC options

Re: Interchageable TD RC and BigMig RC options

Thanks Andrew,

it was really exhaustive. Will check the black O-ring on my carb body stem for brittleness and replace it as advised if found imadequate.

I am wondering if such tips find their way back to the manufacturer? NV has a customer review collection attached to each engine

http://www.nvengines.com/index.php?page=shop.product_details&flypage=flypage.tpl&product_id=24&category_id=1&option=com_virtuemart&Itemid=65 as well as a Support page on their website. I cannot find discussions of these remedy iissues there meaning NV continues the production with these smaller or bigger pitfalls.

Also recommended by NV on their site is the cold break-inhttp://www.nvengines.com/index.php?option=com_content&view=category&layout=blog&id=45&Itemid=18 that logically leads to excesive engine wear and loss of compression.

Given the popularity of these engines I think it would make sense for an experienced NV user like one of you here on CEF to advise NV on a best effort basis aboit what NV may be doing better?

it was really exhaustive. Will check the black O-ring on my carb body stem for brittleness and replace it as advised if found imadequate.

I am wondering if such tips find their way back to the manufacturer? NV has a customer review collection attached to each engine

http://www.nvengines.com/index.php?page=shop.product_details&flypage=flypage.tpl&product_id=24&category_id=1&option=com_virtuemart&Itemid=65 as well as a Support page on their website. I cannot find discussions of these remedy iissues there meaning NV continues the production with these smaller or bigger pitfalls.

Also recommended by NV on their site is the cold break-inhttp://www.nvengines.com/index.php?option=com_content&view=category&layout=blog&id=45&Itemid=18 that logically leads to excesive engine wear and loss of compression.

Given the popularity of these engines I think it would make sense for an experienced NV user like one of you here on CEF to advise NV on a best effort basis aboit what NV may be doing better?

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Similar topics

Similar topics» NV BigMig 049 and 061 life expectancy

» Base coat options

» Sportsman .15 glow plug options

» One of many Line reel options worth considering

» Base coat options

» Sportsman .15 glow plug options

» One of many Line reel options worth considering

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules