Log in

Search

Latest topics

» My current avatar photoby roddie Today at 8:48 pm

» It's the X Wing that has a canard

by 1975 control line guy Today at 8:05 pm

» Cox 020 PeeWee rebuild questions

by balogh Today at 4:39 pm

» Free Flight Radio Assist

by TD ABUSER Today at 2:58 pm

» Pathé Modeling Videos

by Levent Suberk Today at 2:10 pm

» New Model Build

by rdw777 Today at 10:28 am

» My latest doodle...

by layback209 Today at 1:20 am

» Drones, pretty nifty...........

by rsv1cox Yesterday at 6:55 pm

» Project Cox .049 r/c & Citabrian Champion

by roddie Yesterday at 6:20 pm

» My N-1R build log

by roddie Yesterday at 3:27 pm

» Octura engines?

by UncleLumpy Yesterday at 8:16 am

» Tatone EM-7

by sosam117 Yesterday at 7:50 am

Cox Engine of The Month

Mc Coy 19- Need some start up help

Page 1 of 1

Mc Coy 19- Need some start up help

Mc Coy 19- Need some start up help

I bought a very nice Mc Coy 19 (new ?) from e bay but its been a long time since owned one of this size.

What type of fuel would be good for it and what should I do for break in? Any tips would help!

Thanks RK Flyer

What type of fuel would be good for it and what should I do for break in? Any tips would help!

Thanks RK Flyer

RK Flyer- Gold Member

- Posts : 274

Join date : 2013-07-16

Location : Somerset, Kentucky

Re: Mc Coy 19- Need some start up help

Re: Mc Coy 19- Need some start up help

The Mccoy is a neat little engine, unfortunately they can be short lived. This post is in regards to the Mccoy REDHEADS and not the rectangular Mccoy .19 series 21 Black heads. The first and most important fact about using one is the fuel. Use a minimum of 25% castor oil ONLY. A good hot plug is also in order. I'm not a Fox plug user (They will work however), I prefer Thunderbolt R/C longs or equivalents like Fireballs or K&B L1's. If you decide to use any other fuel, consider it a book end. I had brand new redhead Mccoy .19's wear out in one run. This was especially true with the .19's. The Testor's Mccoy series 21 engines used a ringed piston which was a Dyke's ring and these actually worked quite well. Many have switched the internals from the series .21 into the redheads for duration and longevity. Keep in mind, this engine was produced for several years and the quality from one run to a next was all over the place. I'm not suggesting your engine is a POS or it will wear out immediately, my experience goes far back with these and I've learned a great deat about these engines as to the how and why. A 8x6 prop is a good choice, a Top Flite Super M if you can find one is even better (Wide paddle blade). Realize the gaskets were inferior on those engines. Due to their age(40+ years old), they're more than likely dried out and no good. Breaking in a Mccoy is usually not a process. They usually wore out before they broke in. I don't mean to be sarcastic here. If new, run it rich on the ground a few times until it holds a decent needle setting and isn't shaking all over the place and go fly. These engines were under $5 at one point and pilots like my dad tossed them and bought another for the next weekend. The screws they used to retain the head bolts are dead soft and only one type of screwdriver properly fits them which most don't have. My suggestion is to replace them with 4-40 1/4allen socket heads. I personally remove all gaskets and reseal the engine with high temp rtv silicone. This includes the head gasket as well which takes about 30 minutes to dig it out and properly clean the groove in the cylinder head. I don't reinstall a head gasket, I substitute the gasket for the RTV and let it sit 20-30 min prior to reassembly. This not only seals the head properly, it raises the compression due to it lowering the cylinder head a few thousandth's.

There's a base gasket between the steel cylinder and the case, these are the most problematic and if leaking, the engine is going to leak down compression and the RTV resolves this issue . I lap the case on a piece of glass with 400 grit sandpaper and oil to completely level and flatten the casting to provide a good gasket seal. In addition, if you decide to remove and use the RTV as gasket, the 3 and there are only 3 screws that hold the head on, they will be too long by 1/8" and therefore will require the allen socket heads to be cut. The ideal head bolt length is 7/8".

(These next suggestions are based on my experimentation and if you have hands of stone please skip the next step) This can and will ruin a piston if you have no experience with small engines

It's imperative that the nylon bushing or if you have the first version it has a brass bushing in the connecting rod on the large end. This bushing takes up the end play of the crank . If the engine feels light on compression, this engine has a very unique characteristic to it. It has a domed piston. The pistons are very soft and are susceptible to wearing out which is due to the metalurgy of the piston itself, it's not iron, it's sintered iron which was powder metal filings compressed under heat. This piston can be placed in the sleeve and put on a anvil or solid flat surface. I use a 3/8 steel dowel and a very light ball peen hammer and I place the dowel directly on the highest part of the dome and tap. This expands the sidewalls of the piston . Do not strike the baffle on top of the piston as this will break it. This process sometimes requires me to do this with the piston out of the cylinder which can really expand the top which now requires the piston to be lapped into the sleeve. I've taken completely worn out Mccoy's and made them run better than new. I've done this process repeatedly. If required, the piston is inserted upside down in the sleeve. I use a piece of 3/16" wooden dowel through the conrod as a T handle and I use Dupont #7 or toothpaste as a lapping compound and twirl the piston up and down in the sleeve. I do this at the bottom of the skirt until I can just get the piston back into the bore. I then resinsert properly and check the fit up at the top of the sleeve. It should pinch at the top. If not take it out and give a few more hits. Once the lapping is done properly, there should be a extremely shiny band around the top of the piston which is even for about 3/32".

Now that you read this and probably think I'm completely out of my mind, I would personally run the engine as is. These engines are like kits to me and I enjoy making them tick once again. Don't run it too lean as they don't sustain well to that. I would run it rich and use the fuel I recommend which is Sig 25% Champion or something similar like S&W 28% and see how it does. Removing the needle and placing a short piece of fuel tubing properly cut to the correct length on the needle which will be squished up against the spraybar can resolve air leaks at the needle. Chellie provides gaskets for these engines. She's extremely knowledgeable about these engines. She's rebuilt hundreds of them and I'm sure you could e-mail here for a request of the step by step process on what she does to these engines. Her how to lap in a piston is detailed and exceptionally edited for anyone to understand. Here's a link to her gaskets. She's the only one providing gaskets for the Mccoy's in the past 30 years. The quality of these gaskets are excellent as well as the fits. http://www.ebay.com/itm/McCOY-19-RH-BH-Gasket-Kit-Nylon-Crank-Throw-Spacer-/131010858688?pt=US_Radio_Control_Control_Line&hash=item1e80db0ec0 If you need help, don't hesitate to ask. Ken

There's a base gasket between the steel cylinder and the case, these are the most problematic and if leaking, the engine is going to leak down compression and the RTV resolves this issue . I lap the case on a piece of glass with 400 grit sandpaper and oil to completely level and flatten the casting to provide a good gasket seal. In addition, if you decide to remove and use the RTV as gasket, the 3 and there are only 3 screws that hold the head on, they will be too long by 1/8" and therefore will require the allen socket heads to be cut. The ideal head bolt length is 7/8".

(These next suggestions are based on my experimentation and if you have hands of stone please skip the next step) This can and will ruin a piston if you have no experience with small engines

It's imperative that the nylon bushing or if you have the first version it has a brass bushing in the connecting rod on the large end. This bushing takes up the end play of the crank . If the engine feels light on compression, this engine has a very unique characteristic to it. It has a domed piston. The pistons are very soft and are susceptible to wearing out which is due to the metalurgy of the piston itself, it's not iron, it's sintered iron which was powder metal filings compressed under heat. This piston can be placed in the sleeve and put on a anvil or solid flat surface. I use a 3/8 steel dowel and a very light ball peen hammer and I place the dowel directly on the highest part of the dome and tap. This expands the sidewalls of the piston . Do not strike the baffle on top of the piston as this will break it. This process sometimes requires me to do this with the piston out of the cylinder which can really expand the top which now requires the piston to be lapped into the sleeve. I've taken completely worn out Mccoy's and made them run better than new. I've done this process repeatedly. If required, the piston is inserted upside down in the sleeve. I use a piece of 3/16" wooden dowel through the conrod as a T handle and I use Dupont #7 or toothpaste as a lapping compound and twirl the piston up and down in the sleeve. I do this at the bottom of the skirt until I can just get the piston back into the bore. I then resinsert properly and check the fit up at the top of the sleeve. It should pinch at the top. If not take it out and give a few more hits. Once the lapping is done properly, there should be a extremely shiny band around the top of the piston which is even for about 3/32".

Now that you read this and probably think I'm completely out of my mind, I would personally run the engine as is. These engines are like kits to me and I enjoy making them tick once again. Don't run it too lean as they don't sustain well to that. I would run it rich and use the fuel I recommend which is Sig 25% Champion or something similar like S&W 28% and see how it does. Removing the needle and placing a short piece of fuel tubing properly cut to the correct length on the needle which will be squished up against the spraybar can resolve air leaks at the needle. Chellie provides gaskets for these engines. She's extremely knowledgeable about these engines. She's rebuilt hundreds of them and I'm sure you could e-mail here for a request of the step by step process on what she does to these engines. Her how to lap in a piston is detailed and exceptionally edited for anyone to understand. Here's a link to her gaskets. She's the only one providing gaskets for the Mccoy's in the past 30 years. The quality of these gaskets are excellent as well as the fits. http://www.ebay.com/itm/McCOY-19-RH-BH-Gasket-Kit-Nylon-Crank-Throw-Spacer-/131010858688?pt=US_Radio_Control_Control_Line&hash=item1e80db0ec0 If you need help, don't hesitate to ask. Ken

Ken Cook- Top Poster

- Posts : 5634

Join date : 2012-03-27

Location : pennsylvania

Re: Mc Coy 19- Need some start up help

Re: Mc Coy 19- Need some start up help

Hi Ken, I have a few larger (than.049) engines, and one of them is a McCoy .35 Red-Head. Would the same/similar advice you gave for the .19 apply as well? My engine was purchased 2nd hand... but (other than elongated frt. beam-mount holes) showed no signs of having been run. I bench-ran it once, on about 1/4 oz. of Sig "25" using a rich 4-cycle needle setting. It was very easy starting and ran steadily before I pinched-off the fuel. That's the only time I ran it.Ken Cook wrote:The Mccoy is a neat little engine, unfortunately they can be short lived. This post is in regards to the Mccoy REDHEADS and not the rectangular Mccoy .19 series 21 Black heads. Ken

https://www.coxengineforum.com/t5570-my-mccoy-engines

Every few years, I go through my "in-storage" engines... and put a few drops of 3-in-one oil on moving parts. I keep them separately packed in qt. sz. ziplock freezer bags.

I.Y.O...would my .35 Red-Head be a good candidate for a gasket kit replacement "now"...and also having a spare kit on-hand?

Do you know what length; replacement "socket-head" type head-screws for the .35 would be?

"Could" my .35 engine share the "sintered-iron" piston style as in the .19?

There's photos in the link above, of my McCoys.

Having spent most of my modeling time around vintage c/l stunt people, they strive for engine longevity... through care, maintenance and proper tuning/fuel. It's been many years since I've been in contact with those people and sadly, some are gone. I've enjoyed reading about your particular experience/advice when helping CEF members with engine issues.

Thanks Ken,

Roger

Re: Mc Coy 19- Need some start up help

Re: Mc Coy 19- Need some start up help

Roger, the elongated bolt holes wasn't done by the first owner. This was done by Mccoy. That bolt hole pattern can be shared between some other wide case engines, K&B and also Fox .35's. Sometimes the .35's were prone to wearing out the case and side to side play is sometimes recognizable when a prop is on and you rock it back and forth. This was resolved in the later Lightning bolt case engines which has the lightning bolt in the casting on the case. I believe the heads also now had the plugs offset on the top of the cylinder.

All of what I detailed essentially is the same other than prop choice. I specifically use a 10x6 on them and I don't try and run these hard. I just enjoy them for what they are. Always make sure the nylon bushing is in the back of the conrod. I don't make a habit of taking these apart unless I plan on redoing them. I only dismantle when I feel it's necessary. The head bolt info is the same as the .19-.29-.35 all share the same size.

Just for general information, if an engine sits especially one that's been run on high castor, the wrist pin to conrod joint needs to be manually freed up. I personally put Risolone or trans fluid in the engine prior to storage.If the conrod is seized on the wrist pin of a Mccoy, it will quickly wear it out. These engines use brass end pads on the wrist pin and the wristpin holes can get really egged out on the piston. This is where the high castor takes some of that load to prevent all this hammering from poorly fit parts.

Don't try and use a muffler or it will possibly do damage to it. The seller on Ebay has gone over the top to provide us Mccoy users with what was non existent for years. So in my opinion, if you desire to use this engine, I would purchase the gaskets. You won't find them again and cutting your own is a major PITA. I didn't even bat an eye at the price. There's a lot of info provided by the seller in regards to what I wrote and more which will give a old Mccoy new lease on life. Ken

All of what I detailed essentially is the same other than prop choice. I specifically use a 10x6 on them and I don't try and run these hard. I just enjoy them for what they are. Always make sure the nylon bushing is in the back of the conrod. I don't make a habit of taking these apart unless I plan on redoing them. I only dismantle when I feel it's necessary. The head bolt info is the same as the .19-.29-.35 all share the same size.

Just for general information, if an engine sits especially one that's been run on high castor, the wrist pin to conrod joint needs to be manually freed up. I personally put Risolone or trans fluid in the engine prior to storage.If the conrod is seized on the wrist pin of a Mccoy, it will quickly wear it out. These engines use brass end pads on the wrist pin and the wristpin holes can get really egged out on the piston. This is where the high castor takes some of that load to prevent all this hammering from poorly fit parts.

Don't try and use a muffler or it will possibly do damage to it. The seller on Ebay has gone over the top to provide us Mccoy users with what was non existent for years. So in my opinion, if you desire to use this engine, I would purchase the gaskets. You won't find them again and cutting your own is a major PITA. I didn't even bat an eye at the price. There's a lot of info provided by the seller in regards to what I wrote and more which will give a old Mccoy new lease on life. Ken

Ken Cook- Top Poster

- Posts : 5634

Join date : 2012-03-27

Location : pennsylvania

Re: Mc Coy 19- Need some start up help

Re: Mc Coy 19- Need some start up help

Thanks much Ken. When the .35 Red-Head eventually gets a plane, it'll probably be one of 3 kits I have; Ringmaster, Warrior or Nobler. I'm not what you'd call a real experienced flyer... so I wouldn't be putting any undue stress on this motor through aggressive flight maneuvers... and I would always run it on the "rich" side, using fuel with a healthy percentage of castor. I generally have Sig "Champion-25" on hand, and run my Cox's on it. With the 10 x 6 prop you recommended, would this be a good combo for the engine/planes that I listed?

I plan on buying a couple gasket sets... while they're available, it's just a smart thing to do.

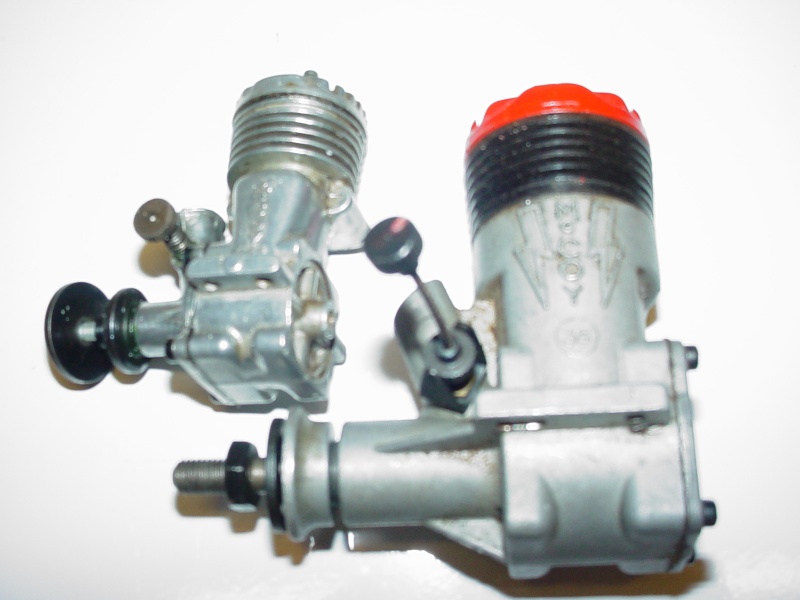

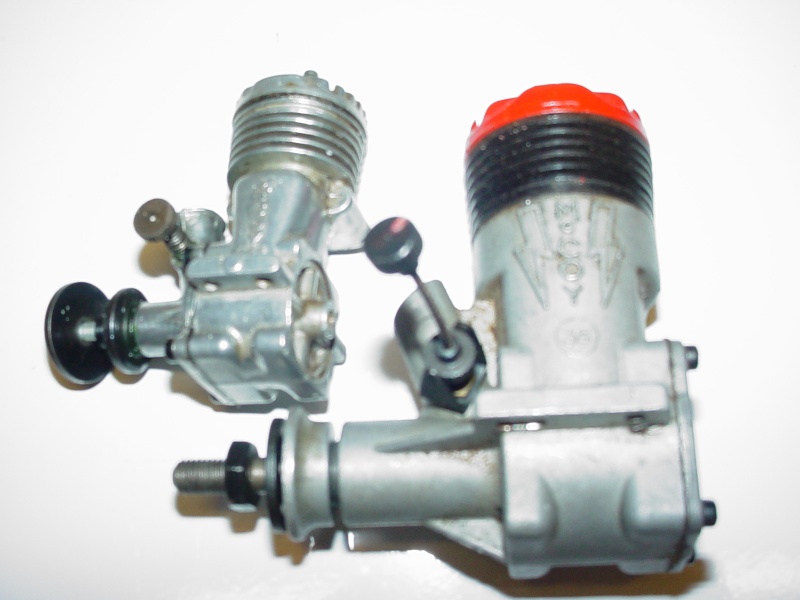

I have the "lightning bolt" case version with the offset plug. Here's pics. with an .098

I plan on buying a couple gasket sets... while they're available, it's just a smart thing to do.

I have the "lightning bolt" case version with the offset plug. Here's pics. with an .098

Re: Mc Coy 19- Need some start up help

Re: Mc Coy 19- Need some start up help

Just to be clear when talking Sig Champion 25 you mean 25% oil correct?

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Mc Coy 19- Need some start up help

Re: Mc Coy 19- Need some start up help

Ron, I'm referring to the "nitro" percentage. Would Sig's 50/50 castor/synthetic oil blend "out of the bottle" be a "no-no" for regular use in my McCoy?... or my other engines of similar construction/displacement for that matter? I'm asking because I also have a vintage Veco .35C (on the Warrior) and Fox .15, .29 and .35 stunt engines of that same era. I would never think of running any of them "screaming-lean"... but should I be adding castor to the Sig Champion fuels for their regular/continued use? None of these engines have ever/will ever use mufflers.Cribbs74 wrote:Just to be clear when talking Sig Champion 25 you mean 25% oil correct?

I've only "bench-ran" (a short run) my McCoy .35 "one time"... using "straight" Sig Champion 25, running "plenty rich" on the needle. It started instantly and ran very well that one time... probably less than a minute with a 10" prop. before I pinched-off the fuel line.

I've never tried adding castor to my fuels... and have always used straight "out of the bottle" Sig Champion "25" and "35" (nitro%) in my Cox reedies... so that's the fuel I generally have "on-hand"...

Re: Mc Coy 19- Need some start up help

Re: Mc Coy 19- Need some start up help

I suppose I shouldn't of been so vague with my description. The Mccoy does like a bit of nitro. They run well on 10%. The "25 %" is the oil content. I run many of my iron piston engines on 50/50 but not a Mccoy. This same fuel can be used for all your other engines. Ken

Last edited by Ken Cook on Mon Oct 07, 2013 2:54 pm; edited 1 time in total

Ken Cook- Top Poster

- Posts : 5634

Join date : 2012-03-27

Location : pennsylvania

Re: Mc Coy 19- Need some start up help

Re: Mc Coy 19- Need some start up help

Roddie,

I am a Fox user and Fox's of that era used a higher castor however, I do use Powermaster 10/22 without issue. 10%nitro and 22% oil which is 50/50 castor/synth.

I think Ken was suggesting the Sig Champion 25 Castor based fuel. 25% Nitro would kill that McCoy very quickly.

Here is a link:

http://www.sigmfg.com/IndexText/SIGCF100.html

I am a Fox user and Fox's of that era used a higher castor however, I do use Powermaster 10/22 without issue. 10%nitro and 22% oil which is 50/50 castor/synth.

I think Ken was suggesting the Sig Champion 25 Castor based fuel. 25% Nitro would kill that McCoy very quickly.

Here is a link:

http://www.sigmfg.com/IndexText/SIGCF100.html

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Mc Coy 19- Need some start up help

Re: Mc Coy 19- Need some start up help

Lol Ken beat me to it!

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Mc Coy 19- Need some start up help

Re: Mc Coy 19- Need some start up help

Thanks very much guys... from both me and my engines! I need to purchase a gallon of the Sig "full-castor" fuel.

As far as glow-fuel "shelf-life" is concerned, how long is "too long" to have it in storage? I have 3 qts. of Sig Champion 25 and 35 (% nitro that I use for the Cox engines) One qt. is un-opened... but old... the other 2 are even older... I'm talking better than 15 years... yet when I occasionally run one of my reedies on the fuel, it runs great.

I should add that I keep the fuel tightly capped always... even when I fill a fuel bulb, I tightly re-cap the bottle immediately. Maybe this has helped. I keep it stored in a cool dark location as well.

Is it the "nitro" element that doesn't last... or does the castor degrade? or both? I imagine the methanol and synthetic oil elements would last longer? I am surprised that my old fuel still works... but what the heck... I might as well use it, if it does! Now that I'm back in touch with model people... I plan on being more active with the hobby again, after a LONG hiatus.

You guys fly so much... your fuel never has a chance to get old!

As far as glow-fuel "shelf-life" is concerned, how long is "too long" to have it in storage? I have 3 qts. of Sig Champion 25 and 35 (% nitro that I use for the Cox engines) One qt. is un-opened... but old... the other 2 are even older... I'm talking better than 15 years... yet when I occasionally run one of my reedies on the fuel, it runs great.

I should add that I keep the fuel tightly capped always... even when I fill a fuel bulb, I tightly re-cap the bottle immediately. Maybe this has helped. I keep it stored in a cool dark location as well.

Is it the "nitro" element that doesn't last... or does the castor degrade? or both? I imagine the methanol and synthetic oil elements would last longer? I am surprised that my old fuel still works... but what the heck... I might as well use it, if it does! Now that I'm back in touch with model people... I plan on being more active with the hobby again, after a LONG hiatus.

You guys fly so much... your fuel never has a chance to get old!

Re: Mc Coy 19- Need some start up help

Re: Mc Coy 19- Need some start up help

Actually Roddie in my experience fuel lasts quite a while. A couple years ago I ran some fuel out of an opened late 60's fuel can. It worked just fine. I have also run 15yr old Sig without issue.

I think it's just a hit and miss thing. For bench runs I would use old fuel all day long. In the air where it counts I would only use fresh as possible.

Ron

I think it's just a hit and miss thing. For bench runs I would use old fuel all day long. In the air where it counts I would only use fresh as possible.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Similar topics

Similar topics» Does Old Fuel Work? Because my NEW .49 with spring start won't start.

» wanted Cox pull start cord or pull start repair kit

» Pee Wee rc won't start

» Jim's sure start did

» How do you start this?

» wanted Cox pull start cord or pull start repair kit

» Pee Wee rc won't start

» Jim's sure start did

» How do you start this?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules