Log in

Search

Latest topics

» Purchased the last of any bult engines from Ken Enyaby sosam117 Today at 11:32 am

» Chocolate chip cookie dough.........

by rsv1cox Today at 10:20 am

» Tee Dee .020 combat model

by rsv1cox Today at 10:07 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

Cox Engine of The Month

Back to the Yak - Yak-9 Build, Part II

Page 4 of 9

Page 4 of 9 •  1, 2, 3, 4, 5, 6, 7, 8, 9

1, 2, 3, 4, 5, 6, 7, 8, 9

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Good Rusty! How about some pictures? If you have time....

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

I tack funky wings into the misshapen hole with CA and kicker. After it is secure. straight, etc. I come back with thickened epoxy. Whole lot less stress of "OMG IT IS MOVING ON ME!!" and the like.

I ordered some cotton flocking from Aircraft Spruce. The stuff is wonderful for thickening epoxy, but not as light as other options.

Phil

I ordered some cotton flocking from Aircraft Spruce. The stuff is wonderful for thickening epoxy, but not as light as other options.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

How about that Minwax/filling/sanding question, anyone got ideas on that?

Thanks.

Rusty

Thanks.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

RknRusty wrote:How about that Minwax/filling/sanding question, anyone got ideas on that?

Thanks.

Rusty

Done it. Prefer clear dope, but the weather allowing me to work outside is another story, so I'll continue to use minwax polycryllic on bashers.

I have used polycryllic straight, I have not tried using cornstarch in it yet. I have sanded, and I have used denatured alcohol to strip the excess (different planes) and find that stripping with denatured alcohol and a scrub pad is easier, and results in an excellent surface. I have also found that a several apply-dry-strip cycles yield better results than putting a couple coats on and taking it down once. The work inside vs work outside might be affecting this too.

The polcryllic is clearly NOT fuel proof. It must be coated with a fuel proof product. I have not tested for exhaust.

I use "Testors Wood and Metal Cement" to fuel proof screw holes by filling and re-drilling the hole. I would expect fuel penetration to cause coating failure, so I take some steps to protect the obvious areas.

I find polycryllic to build a heavier coating than dope + cornstarch. I need to try polcryllic + cornstarch.

You will want to finish sand prior to the first coat of any product you use. You can sand additionally between coats even if stripping the polycryllic, just let it dry first.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Thanks, Phil, I'll give it a try. I'll spackle any dings that look deep enough and sand all smooth and start with the Polycrillic treatment. After that, a coat of primer, sanded, and then Rustoleum. It's going to be rainy and cold this weekend, so maybe next week.

I'll take some pictures after I finish working on it tonight. It should start looking like a plane.

Rusty

I'll take some pictures after I finish working on it tonight. It should start looking like a plane.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

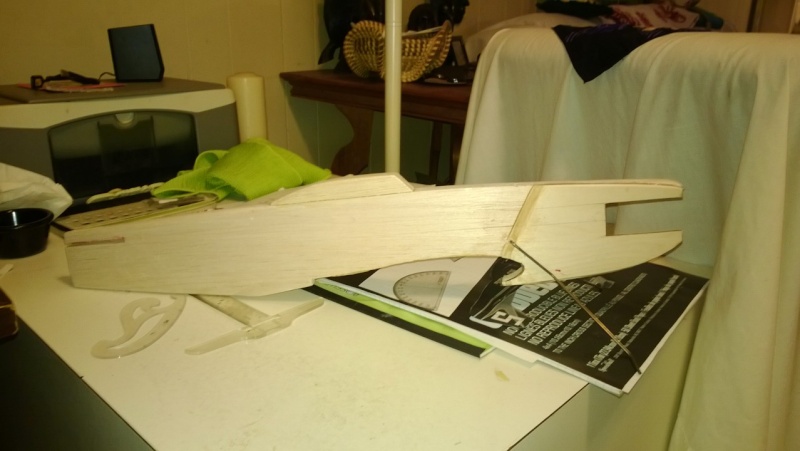

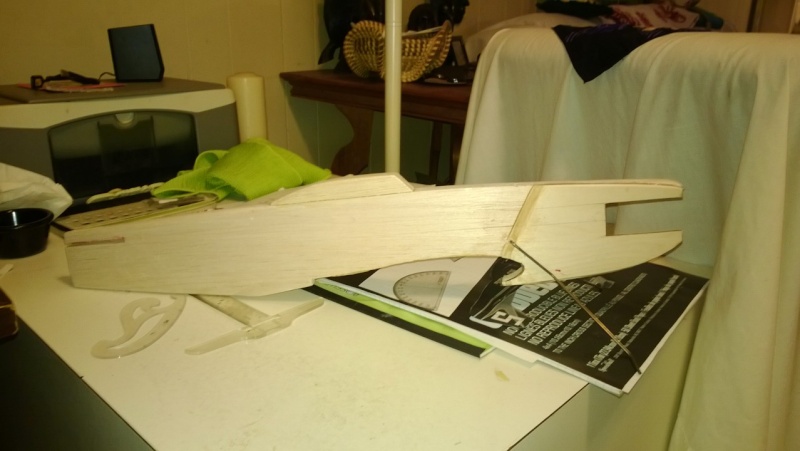

It's amazing how much work goes into something that looks as simple as this.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

It'll be worth it buddy... having that wing sit where you want it to.

edit: I read back a few comments that I missed.. Where do you find Minwax Polycrylic? I'm looking for a sealer for my speed model... Is this applied with a brush, then sanded smooth? I plan on a Rust-o-leum gloss-white base color.

Is that grey sandable-primer over the Polycrylic in the photo of the ply-doublers Rusty?

edit: I read back a few comments that I missed.. Where do you find Minwax Polycrylic? I'm looking for a sealer for my speed model... Is this applied with a brush, then sanded smooth? I plan on a Rust-o-leum gloss-white base color.

Is that grey sandable-primer over the Polycrylic in the photo of the ply-doublers Rusty?

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

I can see where all the time went. It will pay off. Looks great Rusty.

Ron

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

I got a small can of Polycrillic at Lowes. You brush it on and strip it down as Phil said above, and redo it until it looks ready for paint. I'm going to spackle and sand before the first coat, but that doesn't mean it's the right way. Never having used it, I'm guessing. It's water based, so after the first coat, I'm going to paint it and clamp it flat and let it dry to prevent warping. After that I think it'll be safe from warping from moisture. Then I'll spray Rustoleum primer(unless someone says I don't need it), sand it down until it's almost gone, then spray my white on. The plane is going to be mostly white with red, silver and black trim. Maybe silver Monokote flames on the white wings. The same sort of flames as the Refried Bean in my avatar. It's about time to cover the wings now. The flaps are already primed and sanded with no Polycrillic, and they are ready for white paint too.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

No that's where I beveled the doubler at an angle down to a sharp edge. It's raw wood in the picture. Ken suggested I do that, as it makes that edge less of a stress riser.roddie wrote:...Is that grey sandable-primer over the Polycrylic in the photo of the ply-doublers Rusty?

Rusty

EDIT: Oops, misunderstood the question. Just a funny picture, all raw wood.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

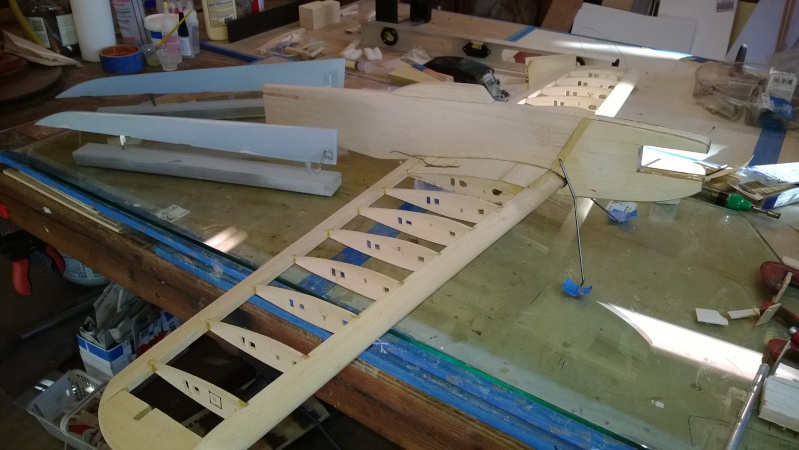

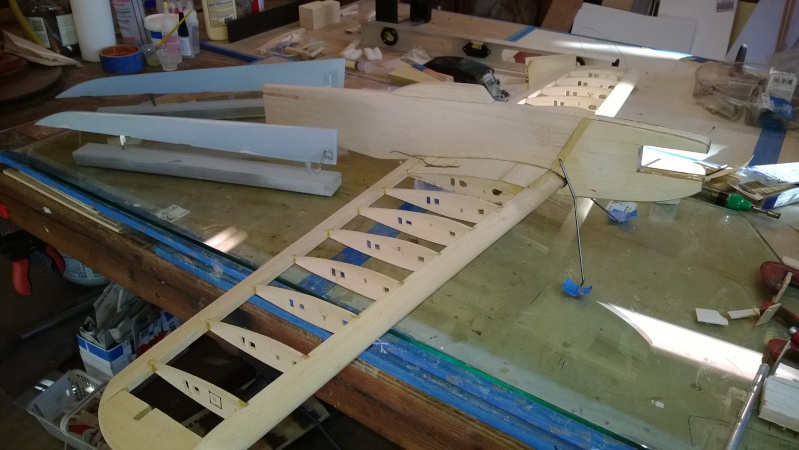

Nothing left but the details. This is the best engine bearer I've ever made. It fits perfectly with no wiggle room for the Fox .35 and dead straight on the centerline. The fuse is two 1/4" sheets of medium balsa laminated with 60 minute epoxy, and the doublers are birch ply. The bearers are rock hard maple sticks from a Shoestring kit.

I have to think about what to do next. I think I'll shape and sand the fuse, then go ahead and finish it and paint it, minus the detail markings. I hope that keeps it from changing shape. I've been keeping it pinned under weights to prevent bowing and it seems to be stable. Hopefully the water based Polycryllic won't warp it. I'll apply it very thin, and on one side at a time so I can clamp it down flat while it dries. After the first coat it will hopefully be humidity proof. Whenever I have good painting weather, I'll go ahead and paint the flaps white so they'll be ready to attach. The wing is holding straight nicely so I can Monokote it any time now.

Starting to look like a plane.

I have to think about what to do next. I think I'll shape and sand the fuse, then go ahead and finish it and paint it, minus the detail markings. I hope that keeps it from changing shape. I've been keeping it pinned under weights to prevent bowing and it seems to be stable. Hopefully the water based Polycryllic won't warp it. I'll apply it very thin, and on one side at a time so I can clamp it down flat while it dries. After the first coat it will hopefully be humidity proof. Whenever I have good painting weather, I'll go ahead and paint the flaps white so they'll be ready to attach. The wing is holding straight nicely so I can Monokote it any time now.

Starting to look like a plane.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

The argument I have for painting both sides together is that the expansion should even out and keep it straight.

You could block it up and paint it in thirds on both sides if you feel you need to clamp it.

Phil

You could block it up and paint it in thirds on both sides if you feel you need to clamp it.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

It looks great Rusty, I didn't realize that the wing sat so low in the fuse. I say hit the whole thing with the Poly. I doubt it will penetrate enough to twist the fuse.

Either way will work though.

Ron

Either way will work though.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

I'll take that as advice. I was looking at everything I can do to make it quick and easy, so I think before I put the sealer on, I'll go ahead and mount the air scoop, tail fin and cheek block(not part of the kit). I'll make the exhaust pipes out of some 1/8" aluminum tub glued into a balsa block. I didn't get much sanding and shaping done today. Wife came home from work early.pkrankow wrote:The argument I have for painting both sides together is that the expansion should even out and keep it straight....

Phil

The air scoop on the underside is shaped nothing like the one on a real Yak, but shaped more to support the underside of the wing. I think I'll shape it realistically and make a less clunky support out of a basswood strip to help secure the wing. I'm also going to add a small scoop on the forward top fuselage. I hope my decals aren't discolored. I hope I can find some small Cyrillic letters for writing on the side... something in Russian like "Hitler is a Pussy." I need to know about what scale size this plane is so I can choose the right decals. Anyone got a guess?

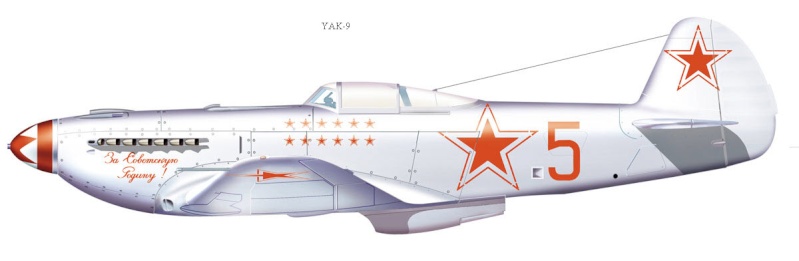

Here's what I think it will look like:

The stab and rudder will be painted separately before assembly. I may or may not ink the panel lines and rivets. If I do, what kind of marker should I use?

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

If it won't be getting a final layer of clear, "sharpie oil based paint pens" are out, they dissolve very rapidly in glow fuel.

Phil

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

I'll spray Lustrekote on it, but that might cause the sharpie ink to run too. Since the lines and rivets don't have to be black, maybe a sharp #3 pencil would work. It might look more realistic too.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Rusty, when you see the panel lines and graphics on stunt ships, they're almost always done in india ink. Typically these are done with Rapidograph pens. Just for the record, india ink will run and bleed if yoru not careful when doping over them. Top Flite makes a panel line pen if your interested. I would assume the same thing, light dry coats at first and then make them wet after they dried. The Top Flite panel line pen is inexpensive. I can't comment on how well it works, I can only bet that it would require the same paint techniques as the other available items. Ken

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Ken, I found the Top Flite panel pen on my LHS website. It says to clear coat it, so I'm thinking Lustrekote will be safe if I'm careful. Lustrekote is a TF product. Thanks for the tip. One of the SH guys suggested the Rapidograph pens and they have them at Staples, for an arm and a couple of toes. Thanks, I'll be heading for the HS for that TF pen.

I got it mostly shaped and sanded today. There are a couple of minor dents in the balsa to spackle and then I'll Minwax it. I had a chance to buy some clear Aerogloss hot fuelproof dope at the HS the other day. I left it there, partly because I couldn't remember if it was butyrate or nitrate, and also because I couldn't really afford it. No other builders go to that shop, so it'll still be there if i decide to get it for the Skyray. Meanwhile I'll just Minwax the Yak. We'll have a couple of warm days over the weekend. I think it will be over 70 and clear tomorrow, so good for applying the sealer. Depends on the family duties at this time of year though. I want to get it sealed soon, all but the inboard doubler where a cheek will go.

Rusty

I got it mostly shaped and sanded today. There are a couple of minor dents in the balsa to spackle and then I'll Minwax it. I had a chance to buy some clear Aerogloss hot fuelproof dope at the HS the other day. I left it there, partly because I couldn't remember if it was butyrate or nitrate, and also because I couldn't really afford it. No other builders go to that shop, so it'll still be there if i decide to get it for the Skyray. Meanwhile I'll just Minwax the Yak. We'll have a couple of warm days over the weekend. I think it will be over 70 and clear tomorrow, so good for applying the sealer. Depends on the family duties at this time of year though. I want to get it sealed soon, all but the inboard doubler where a cheek will go.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Maaaaan, finally get a day with some shop time and it's rain rain raining, all day long. I know some of you have worse, sorry about that. But it's time to paint the polycryllic on the wood and it's 100% humidity in the shop and I can all but hear the balsa soaking it up. I'll turn the heater on full blast even though it's 70 degrees to try and fight back.

So no painting, and I read a good article on Aeromaniacs last night about how great PC is, and am looking forward to starting my first next-level finish. I wish I hadn't already primered my flaps so I could PC them. But they're already slotted for the hinges and I'm not doing that again. Too much like work.

So, I'll shape up the cheek for the inboard side. I haven't decided whether to gouge the meat out of a 1/2" block or just use a 1/4" sheet... strictly a cosmetic choice. I can glue the fin on it and spackle some minor dents, that should be fine with the heater blowing. Crap' it sounds torrential out there. And I can get the Monokote going and cover the wing. It's almost all kit wood, hard as a rock and amazingly straight. I could probably beat someone to death with the dang thing if I had to. If I get really ambitious I can make the exhaust pipe block for the cheek too. I'm sounding really ambitious now, but y'all know how I like to dream big.

In the news, the ISS and crew are having some precarious problems. Of course NASA minimizes it, but it sounds to me like they're just a glitch away from boarding the Soyuz pods. I'll be glad when they get a spare SpaceX Dragon up there. The station cooling system is down to zero redundancy and spacesuits are failing. One suit nearly drowned an Italian astronaut in July, another started filling with water this week for a so-called unrelated reason, and yesterday a spacewalker started freezing and had to come in early. Luckily they were far enough ahead of schedule to get the day's job done.

Okay, my coffee was really strong this morning. See y'all in the funny pages.

Rusty

So no painting, and I read a good article on Aeromaniacs last night about how great PC is, and am looking forward to starting my first next-level finish. I wish I hadn't already primered my flaps so I could PC them. But they're already slotted for the hinges and I'm not doing that again. Too much like work.

So, I'll shape up the cheek for the inboard side. I haven't decided whether to gouge the meat out of a 1/2" block or just use a 1/4" sheet... strictly a cosmetic choice. I can glue the fin on it and spackle some minor dents, that should be fine with the heater blowing. Crap' it sounds torrential out there. And I can get the Monokote going and cover the wing. It's almost all kit wood, hard as a rock and amazingly straight. I could probably beat someone to death with the dang thing if I had to. If I get really ambitious I can make the exhaust pipe block for the cheek too. I'm sounding really ambitious now, but y'all know how I like to dream big.

In the news, the ISS and crew are having some precarious problems. Of course NASA minimizes it, but it sounds to me like they're just a glitch away from boarding the Soyuz pods. I'll be glad when they get a spare SpaceX Dragon up there. The station cooling system is down to zero redundancy and spacesuits are failing. One suit nearly drowned an Italian astronaut in July, another started filling with water this week for a so-called unrelated reason, and yesterday a spacewalker started freezing and had to come in early. Luckily they were far enough ahead of schedule to get the day's job done.

Okay, my coffee was really strong this morning. See y'all in the funny pages.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Rusty, I don't know if it would make any difference humidity wise or if your wife would allow it but you can paint that polycrylic in the house fume free.

Jim

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Nice weather and a lull in holiday festivities coincided today. Humidity in the low 50s and temp in the shop in the mid 60s. I sanded the minor spackling and cut silkspan to fit the fuselage sides. While the Polycrilic was warming in front of the heater, I made a rotating mount with a dowel and a PVC tube to hold the nose of the fuse so I could spin it over while I worked.

I cleaned the fuse with a rag and acetone and sprayed the silkspan lightly with water. Then brushed a coat of Poly on one side of the fuse. I laid the silk on it and fiddled with it pressing it out with my thumb, having to lift and pull a few times. You have to be pretty quick because a thin coat of poly sets quickly. I did pretty well though, learning where to make cuts to get it to form around curves like the canopy. I left the doublers raw since I am going to put a cheek on one and haven't decided how to fuelproof the engine side. I might buy a bottle of aeroglosss clear or maybe the old thinned epoxy method. I can't put the cheek on before I find where to drill the engine holes. After I had the silkspan as wrinkle free as possible, I painted another coat of poly on it and secured the wrap-around edges. Then I squeeged it off to a minimal coat. Before I started the other side, I had second thoughts. Thinking it's going to be sanded anyway, I brushed on an ultra thin coat over it to make sure all of the silkspan's weave was filled.

Flip and repeat for the other side, and it looks great. Can't see any paper except for a couple of tiny wrinkles, but they are barely visible. Next time I'll have the hang of it. Now I'm all practiced up for when I build the Skyray. After I did the first side, I noticed the warp toards the outboard side had grown. But after I applied the second side it mostly straightened out. I think it's about where it always was. But after it was all tack free, I weighted it to help either hold it in place or hopefully de-warp it further. Up until now, I would never have noticed it during a build.

It should be rock hard after 24 hours and I can sand or alcohol strip as recommended by Phil. Nothing to do but wait now, so I got the Streaks down and went over to the church with my son to fly. Got one run of cox engine flight time, but the needle was stuck to the fuel tube seal and refused to cooperate. We were only using 15% nitro and after flooding it due to needle problems, we gave up flipping and flew BFSII with the Norvel. I got a good flight in, then my son flew. I told him to do a loop. He did, and the pullout went awry and it sporked really really hard. A terrible sound. Liberated the nose from the LE. That was my best flyer. It'll take some thinking. Maybe I'll just cut the wing out and make a new one. Time will tell.

Rusty

I cleaned the fuse with a rag and acetone and sprayed the silkspan lightly with water. Then brushed a coat of Poly on one side of the fuse. I laid the silk on it and fiddled with it pressing it out with my thumb, having to lift and pull a few times. You have to be pretty quick because a thin coat of poly sets quickly. I did pretty well though, learning where to make cuts to get it to form around curves like the canopy. I left the doublers raw since I am going to put a cheek on one and haven't decided how to fuelproof the engine side. I might buy a bottle of aeroglosss clear or maybe the old thinned epoxy method. I can't put the cheek on before I find where to drill the engine holes. After I had the silkspan as wrinkle free as possible, I painted another coat of poly on it and secured the wrap-around edges. Then I squeeged it off to a minimal coat. Before I started the other side, I had second thoughts. Thinking it's going to be sanded anyway, I brushed on an ultra thin coat over it to make sure all of the silkspan's weave was filled.

Flip and repeat for the other side, and it looks great. Can't see any paper except for a couple of tiny wrinkles, but they are barely visible. Next time I'll have the hang of it. Now I'm all practiced up for when I build the Skyray. After I did the first side, I noticed the warp toards the outboard side had grown. But after I applied the second side it mostly straightened out. I think it's about where it always was. But after it was all tack free, I weighted it to help either hold it in place or hopefully de-warp it further. Up until now, I would never have noticed it during a build.

It should be rock hard after 24 hours and I can sand or alcohol strip as recommended by Phil. Nothing to do but wait now, so I got the Streaks down and went over to the church with my son to fly. Got one run of cox engine flight time, but the needle was stuck to the fuel tube seal and refused to cooperate. We were only using 15% nitro and after flooding it due to needle problems, we gave up flipping and flew BFSII with the Norvel. I got a good flight in, then my son flew. I told him to do a loop. He did, and the pullout went awry and it sporked really really hard. A terrible sound. Liberated the nose from the LE. That was my best flyer. It'll take some thinking. Maybe I'll just cut the wing out and make a new one. Time will tell.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Rusty, I never used or even tried Polycrilic as an attachment coat. I actually should restate that as I've used it on wood but I lay 1/2oz glass cloth over the entire fuse side and brush the Polycrilic over it. 2 coats and I go to primer. This is the only time I use primer. I sand it all off using the weave of the cloth as a reference to know how much is required. I would highly suggest trying thinned white glue for silkspan attachment as I can tell you with 100% certainty it isn't going to lift at the seams and it's never coming off of the wood. A throw away sponge brush works great and the cost of white Elmer's is very inexpensive with no smell. You can silkspan wings the same way. One thing that works well is precutting the sheets. I spray them with water using a spray bottle and just prior to laying it down, I just lay the piece on a dry towel to soak up any excess water. This allows the silkspan to shrink evenly and it also promotes adhesion without having the silkspan rob the moisture from the work. I have the adhesive thinned white glue already on the model. Just lay the piece on a squeegee the solution through the weave. This will wrinkle but all of it will tighten up and what doesn't come out will sand off. Any warps is easily taken out using a heat gun . All you need to do is to not sand through the silkspan. 240-320 to start just to knock down the highs generally works well. Thinned white glue and I mean milk like consistency has very little weight. It gives you good working time and pieces can be repositioned easily and you don't have the dope smell to deal with. This allows me to cover inside and the stinky stuff is applied on a nice day when the weather permits.

The main thing about using white glue is to not allow it to go out into a open bay as the white glue is a terrific primer and this area will flash and shine more than the unglued silkspan. This isn't a issue with solid areas or planked areas. In regards to your doubler, I would seal it up with Ploycrilic and sand smooth and use Rustoleum right over the Poly. Most oil migration takes place through penetrations like landing gear holes and motor mount holes. Sealing those areas are important. Another problematic spot is the end grain of the fuse encapsulated between the doublers. Making sure the engine isn't too tight of fit between motor mount blocks prevents the paint from rubbing off exposing those areas as well. I personally see no need for you to epoxy the doubler as that will just add even further weight. WHile I'm not a advocate of Rustoleum, I know many that use it with good success including yourself. It rapidly deterioated for me and it only took me once to forego using it. And I did let it cure. I haven't used it for a stunter using mild fuels though. Ken

The main thing about using white glue is to not allow it to go out into a open bay as the white glue is a terrific primer and this area will flash and shine more than the unglued silkspan. This isn't a issue with solid areas or planked areas. In regards to your doubler, I would seal it up with Ploycrilic and sand smooth and use Rustoleum right over the Poly. Most oil migration takes place through penetrations like landing gear holes and motor mount holes. Sealing those areas are important. Another problematic spot is the end grain of the fuse encapsulated between the doublers. Making sure the engine isn't too tight of fit between motor mount blocks prevents the paint from rubbing off exposing those areas as well. I personally see no need for you to epoxy the doubler as that will just add even further weight. WHile I'm not a advocate of Rustoleum, I know many that use it with good success including yourself. It rapidly deterioated for me and it only took me once to forego using it. And I did let it cure. I haven't used it for a stunter using mild fuels though. Ken

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Thanks for the tips, Ken. I'll add them to my page of finishing methods. And do you think there's any reason to spray primer on top of the sanded Polycrilic before adding color?

I have another question. I read (guess where ) that flat paint has better adhesion and lighter weight for the first rounds of color coating. Will the top coat of clear Lustrekote make it look just as glassy as if I had used glossy paint underneath? Mine will be white if that matters. Or maybe at least the last coat before the clear should be glossy.

) that flat paint has better adhesion and lighter weight for the first rounds of color coating. Will the top coat of clear Lustrekote make it look just as glassy as if I had used glossy paint underneath? Mine will be white if that matters. Or maybe at least the last coat before the clear should be glossy.

I checked it today and the poly is rock hard and looks really nice prior to sanding. I unfortunately forgot to weigh it before I had it tack glued onto my painting jig. I would like to know how much weight I added. I test sanded a couple of spots that were a little bumpy where the silkspan overlapped around the canopy. It smooths out pretty quickly.I'm interested to see how well it all smooths out. Tomorrow we have a gathering of about 20 guys at Watt's house to fly and eat and fly from 10 until dark, so I won't get any work done.

Rusty

I have another question. I read (guess where

I checked it today and the poly is rock hard and looks really nice prior to sanding. I unfortunately forgot to weigh it before I had it tack glued onto my painting jig. I would like to know how much weight I added. I test sanded a couple of spots that were a little bumpy where the silkspan overlapped around the canopy. It smooths out pretty quickly.I'm interested to see how well it all smooths out. Tomorrow we have a gathering of about 20 guys at Watt's house to fly and eat and fly from 10 until dark, so I won't get any work done.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

Seems to me if you are going to blow off a day of building then flying is a good reason!

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Back to the Yak - Yak-9 Build, Part II

Re: Back to the Yak - Yak-9 Build, Part II

yea... I ditto what Ron said. (fly'em if you got'em)... I was also curious about the weight of "gloss" vs. using a flat finish.. only to be top-coated by several thin coats of clear (Lustre-Kote). Maybe with a distinct color it would matter... (for depth?) but.. I am also using "white" as a main color on my present model.. and I feel that you can get a nice looking super lightweight finish when using white. Primer coats get sanded off almost completely anyway.

Page 4 of 9 •  1, 2, 3, 4, 5, 6, 7, 8, 9

1, 2, 3, 4, 5, 6, 7, 8, 9

Similar topics

Similar topics» Yak-9 Build, part one

» Part ID: Back Plate Extension?

» building a Guillows kit P 40

» Shoestring flights - I brought it home! Now, can I do it again?

» Guillows Cessna 150 build circa 1970 (Build Log)

» Part ID: Back Plate Extension?

» building a Guillows kit P 40

» Shoestring flights - I brought it home! Now, can I do it again?

» Guillows Cessna 150 build circa 1970 (Build Log)

Page 4 of 9

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules