Log in

Search

Latest topics

» Tee Dee .020 combat modelby Ken Cook Today at 3:23 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Free Flight Radio Assist

by rdw777 Yesterday at 4:51 pm

» Purchased the last of any bult engines from Ken Enya

by getback Yesterday at 12:05 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

Cox Engine of The Month

COX engine throttles

Page 1 of 6

Page 1 of 6 • 1, 2, 3, 4, 5, 6

COX engine throttles

COX engine throttles

I think I will start this off with the COX TeeDee 010 since we already inadvertantly started the conversation over on the for sale off site auctions post.

I`m currently working on some throttles for the 010`s and 020`s

COX did make throttle sleeves for the 020`s and even sold peewee`s equipped from the factory with them and there used to be throttle sleeved 010 piston and cylinder sets available but supplies didn`t last long. I had purchased one of those to replace the first 2 throttled 010`s I had worked up,and although a nice set, I was un-impressed with the throttling performance of running a throttle sleeve by itself.

Throttling a 010 can be a complex challenge if you are a real stickler for a nice linear proportional throttle response with this little engine but success has been claimed and a measure achieved depending on the standards set by the individual.

I have found the use of an exhaust throttle working in unison with an intake throttle seems to be a pretty sweet combo.

I have had exhaust throttles that work pretty well but are difficult to replicate; I believe the engines themselves may be a complex variable such as exhaust port locations in comparrison to crankshaft orrientation ; for example the best running 010`s I have seem to be the engines that have the exhaust ports lined up with the crankshaft whereas the engines that have the exhaust ports lined up in oposition to the crankshaft run well but less so.

I`m currently working on some throttles for the 010`s and 020`s

COX did make throttle sleeves for the 020`s and even sold peewee`s equipped from the factory with them and there used to be throttle sleeved 010 piston and cylinder sets available but supplies didn`t last long. I had purchased one of those to replace the first 2 throttled 010`s I had worked up,and although a nice set, I was un-impressed with the throttling performance of running a throttle sleeve by itself.

Throttling a 010 can be a complex challenge if you are a real stickler for a nice linear proportional throttle response with this little engine but success has been claimed and a measure achieved depending on the standards set by the individual.

I have found the use of an exhaust throttle working in unison with an intake throttle seems to be a pretty sweet combo.

I have had exhaust throttles that work pretty well but are difficult to replicate; I believe the engines themselves may be a complex variable such as exhaust port locations in comparrison to crankshaft orrientation ; for example the best running 010`s I have seem to be the engines that have the exhaust ports lined up with the crankshaft whereas the engines that have the exhaust ports lined up in oposition to the crankshaft run well but less so.

Jaspur_x- Banned

- Posts : 710

Join date : 2011-04-22

Age : 52

Location : Shanksville,Pa, yes that flight 93 place

Re: COX engine throttles

Re: COX engine throttles

If the exhaust ports are line up opposed to the crank, then the bypass ports are front and back. I wonder if the oscillating piston rod stirs more turbulence into the charge entering the front bypass than it does to the other the other. That could possibly cause a less even distribution in the combustion chamber that doesn't happen if the bypasses are on either side of the rotating assembly.Jaspur_x wrote:...I have had exhaust throttles that work pretty well but are difficult to replicate; I believe the engines themselves may be a complex variable such as exhaust port locations in comparrison to crankshaft orrientation ; for example the best running 010`s I have seem to be the engines that have the exhaust ports lined up with the crankshaft whereas the engines that have the exhaust ports lined up in oposition to the crankshaft run well but less so.

Thinking about this reminded me(unrelated to the above comments), I used to think the crescent counterbalance was an oil slinger.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

RknRusty

RknRusty

That is one possible conclusion among several other possible varriables.

I by some twist of fate got a 1 in a million COX TeeDee 010, the needle valve body was not functional /defective;and would not allow flow at all until 1/4 turn before the needle fell out,where the needle is so loose it can be wiggled to allow more or less airflow.

I by some twist of fate got a 1 in a million COX TeeDee 010, the needle valve body was not functional /defective;and would not allow flow at all until 1/4 turn before the needle fell out,where the needle is so loose it can be wiggled to allow more or less airflow.

Jaspur_x- Banned

- Posts : 710

Join date : 2011-04-22

Age : 52

Location : Shanksville,Pa, yes that flight 93 place

Re: COX engine throttles

Re: COX engine throttles

That is strange. Maybe there is some swarf left over from machining or drilling at the factory. Even so, that's a long way to turn it, maybe they stuck the wrong needle into it. I've never seen a TD .010 in real life, so I don't really know what the NV looks like.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

well........

well........

It is nearly identical to a COX TeeDee 051,049 or 020 but much much smaller, I need a microscope or a very large magnifying glass to see into the needle valve`s hole, that needle valve body is a great conversation piece, 1 of the most rare COX parts lol

Jaspur_x- Banned

- Posts : 710

Join date : 2011-04-22

Age : 52

Location : Shanksville,Pa, yes that flight 93 place

Re: COX engine throttles

Re: COX engine throttles

Hey, Jaspur, did you ever find a use for those Fine thread NVs in the red backplates? I'm looking for ideas on how to maybe make some remote NVs for my Norvels, wondering if you came up with any ideas I could use.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

I Sure did RknRusty

I Sure did RknRusty

I sure do have a plan for them,never got that proect rolling yet, do you need 1 of them?

I`m sure its possible to use one of the cox pieces to make a remote nv,I will have to look up an engine that uses a remote nva to see how it would transfer to go onto a norvel,I still have a few norvels but I prefer my COX and havn`t messed with the norvels in a long time.

Should simply be remove a lot of the excess plastic to make it more the size of a cox teedee nvb, and install it somewhere in the fuel line of the norvel and depending on the model you are putting the engine into you could mount the remote nva in all sorts of configurations;or simply mount it to the engine like the big boy engines with remote nva`s

I`m sure its possible to use one of the cox pieces to make a remote nv,I will have to look up an engine that uses a remote nva to see how it would transfer to go onto a norvel,I still have a few norvels but I prefer my COX and havn`t messed with the norvels in a long time.

Should simply be remove a lot of the excess plastic to make it more the size of a cox teedee nvb, and install it somewhere in the fuel line of the norvel and depending on the model you are putting the engine into you could mount the remote nva in all sorts of configurations;or simply mount it to the engine like the big boy engines with remote nva`s

Jaspur_x- Banned

- Posts : 710

Join date : 2011-04-22

Age : 52

Location : Shanksville,Pa, yes that flight 93 place

Re: COX engine throttles

Re: COX engine throttles

Nah, put 'em to good use. JPvelo gave me two valves and a needle. I can get more from Texastimers.com if I need to.Jaspur_x wrote:I sure do have a plan for them,never got that proect rolling yet, do you need 1 of them?...

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

ok

ok

I`m thinking of a project that rhymes with a custom peewee020 throttled of course, now what part could I add to a peewee020 that needs a fine threaded nva???

Jaspur_x- Banned

- Posts : 710

Join date : 2011-04-22

Age : 52

Location : Shanksville,Pa, yes that flight 93 place

Re: COX engine throttles

Re: COX engine throttles

I have always wondered how much the cylinder position in relation to the crank has an effect on running, mine is not perfectly square with the crank... but runs like a dream,

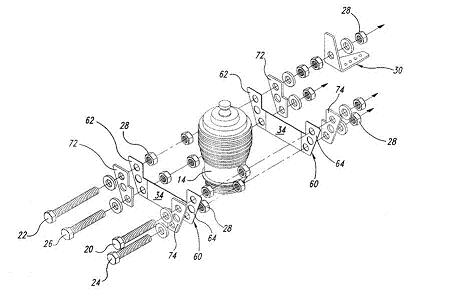

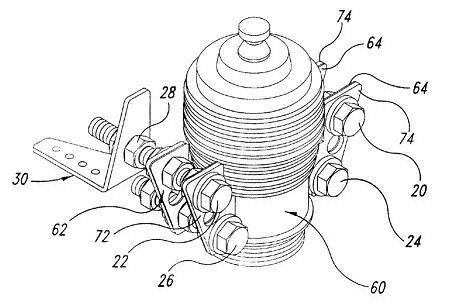

Here pictured is my most recent attempt at a throttle, finished it up today, will test it in the next few days.. still have to make a control horn, and tweak the fit a bit more... getting much better at cutting the halves out, the fit is very good, will see how it works, as one can see in the pic im missing the shoulder pieces... will fab those up soon. Also as one can see i flipped the needle valve over, but a little more grinding in key areas and it should fit properly Im running the 020 prop slightly cut down, runs great!

Im running the 020 prop slightly cut down, runs great!

Roger's original patent... http://www.google.com/patents?id=P5IQAAAAEBAJ&pg=PA6&source=gbs_selected_pages&cad=3#v=onepage&q&f=false

Here pictured is my most recent attempt at a throttle, finished it up today, will test it in the next few days.. still have to make a control horn, and tweak the fit a bit more... getting much better at cutting the halves out, the fit is very good, will see how it works, as one can see in the pic im missing the shoulder pieces... will fab those up soon. Also as one can see i flipped the needle valve over, but a little more grinding in key areas and it should fit properly

Im running the 020 prop slightly cut down, runs great!

Im running the 020 prop slightly cut down, runs great!

Roger's original patent... http://www.google.com/patents?id=P5IQAAAAEBAJ&pg=PA6&source=gbs_selected_pages&cad=3#v=onepage&q&f=false

Last edited by mx862 on Sun Jan 20, 2013 9:13 pm; edited 1 time in total

mx862- Gold Member

- Posts : 105

Join date : 2012-12-17

Location : Whistler BC

your pics

your pics

I can`t get working out your pics figurd out ,I told yo I`m behind on tech. Anyway, from what I can see in your pics it looks like you are onto something, this is the first time I got a good look at the microflite pet design. If you keep at it you`ll get it figurd I`d bet.

I`m not sure where you can scource the brass sheet you`ll need,maybe check lowes, home inprovement type places, blacksmith shops, heating/plumbing shops,welding/fab shops maybe a decent old school hardware store , or your local hobby shop.

I`m not sure where you can scource the brass sheet you`ll need,maybe check lowes, home inprovement type places, blacksmith shops, heating/plumbing shops,welding/fab shops maybe a decent old school hardware store , or your local hobby shop.

Jaspur_x- Banned

- Posts : 710

Join date : 2011-04-22

Age : 52

Location : Shanksville,Pa, yes that flight 93 place

Re: COX engine throttles

Re: COX engine throttles

Hobby Lobby the craft store has the brass sheet. Tinplate steel salvaged from metal cans (I save olive oil and Coleman fuel cans for this) should also be suitable, if somewhat on the thick side. Stovepipe is another option, but even thicker than the cans.

The design is fairly simple and could be made in paper or card, unrolled, then traced onto the metal.

Neat idea, I might have to make one as an experiment.

Phil

The design is fairly simple and could be made in paper or card, unrolled, then traced onto the metal.

Neat idea, I might have to make one as an experiment.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: COX engine throttles

Re: COX engine throttles

I went ahead and re-uploaded the pics using a different hosting site.

I get K&S sheets at my local hobby shop, but they dont have a good selection, this stuff here looks to be the right thickness, i have to redo one side tomorrow, the bends were not very good, so as can be seen in the pics the slots are the same size as the exhaust port bridge, id like to have them smaller, making a new half it should be tighter.

What i do is... i copied the pic of the side piece's from the pdf. then opened it in paint, and saved it as a jpeg, then used the the page setup option when printing to minimize it, after getting it close, i cut the paper pattern and check to see if its a tight fit between, the top cooling fin and the lip on the cylinder, this can take a few attempts, i tried 25%,26%27% and settled on 28%, then print a bunch of copies at that size... sorry Jaspur a bit complicated

Cut them into sections and use a glue stick or white glue to attach to brass, let dry.

then i use a tiny center punch, to very carefully punch in the middle of where the holes are going to be, be very careful, it has to be perfect, otherwise the holes on the two halves wont align properly.

I take it to my drill press and drill out the holes, 2mm on this version, but should be 1.5mm, i did not have any M1.5 bolts, so used the M2's, the bottom nuts all had to be ground down to half their size, otherwise they hit the cylinder.

Cutting and bending can be a pain in the @ss, for the top part i will score with a #11 blade, the rest cut by a very good old pair of scissors, then the paper and glue can be removed under hot water, to get perfect sharp bends, score the area before bending... once done i use jeweler files and a dremel to get the final shape

That is how i make mine... but im sure there are other methods depending on the tools one has.

I will go ahead and upload the pic for the side plates... make it easier on the technologically challenged

I get K&S sheets at my local hobby shop, but they dont have a good selection, this stuff here looks to be the right thickness, i have to redo one side tomorrow, the bends were not very good, so as can be seen in the pics the slots are the same size as the exhaust port bridge, id like to have them smaller, making a new half it should be tighter.

What i do is... i copied the pic of the side piece's from the pdf. then opened it in paint, and saved it as a jpeg, then used the the page setup option when printing to minimize it, after getting it close, i cut the paper pattern and check to see if its a tight fit between, the top cooling fin and the lip on the cylinder, this can take a few attempts, i tried 25%,26%27% and settled on 28%, then print a bunch of copies at that size... sorry Jaspur a bit complicated

Cut them into sections and use a glue stick or white glue to attach to brass, let dry.

then i use a tiny center punch, to very carefully punch in the middle of where the holes are going to be, be very careful, it has to be perfect, otherwise the holes on the two halves wont align properly.

I take it to my drill press and drill out the holes, 2mm on this version, but should be 1.5mm, i did not have any M1.5 bolts, so used the M2's, the bottom nuts all had to be ground down to half their size, otherwise they hit the cylinder.

Cutting and bending can be a pain in the @ss, for the top part i will score with a #11 blade, the rest cut by a very good old pair of scissors, then the paper and glue can be removed under hot water, to get perfect sharp bends, score the area before bending... once done i use jeweler files and a dremel to get the final shape

That is how i make mine... but im sure there are other methods depending on the tools one has.

I will go ahead and upload the pic for the side plates... make it easier on the technologically challenged

Last edited by mx862 on Sun Jan 20, 2013 9:20 pm; edited 3 times in total

mx862- Gold Member

- Posts : 105

Join date : 2012-12-17

Location : Whistler BC

Re: COX engine throttles

Re: COX engine throttles

This is the unaltered scan from the pdf...[img] [/img]

[/img]

[/img]

[/img]

mx862- Gold Member

- Posts : 105

Join date : 2012-12-17

Location : Whistler BC

Re: COX engine throttles

Re: COX engine throttles

Very nice work, MX.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: COX engine throttles

Re: COX engine throttles

Thanks,, this is only a rough version, want to aquire some brass M1.5 bolts, washers, and nuts, to make this thing properly, but for now it will serve its purpose as a prototype.

Pictured is a new side piece and shoulder pieces ready to be carefully cut out

Some advice if trying this...

Make sure you center punch the holes dead center or very close to it, use a lupe if need be, this has caused me alot of headache, so i really take my time. I use a 3mm steel rod (old rc heli mainshaft) sharpened to a point on a dremel, i find i have to resharpen it constantly as the steel is soft, otherwise it looses its precision.

Make sure the drill bit is clean before going to the next hole, pieces of brass stuck in the channel of the bit, will make larger holes.

Score the bend lines, then curve the piece over (i use an Xacto aluminum handle as it appears to be the same diameter as the cylinder) use what you have, then using flat jawed pliers bend the sides at the score lines, if done properly this makes an almost perfect piece with very little tweaking to do afterwards.

And when working with the paper templates... make sure you dont have sweaty hands as it smudges (common sense goes a long way)

Just trying to help those attempting this and avoid all the little hiccups.

Roger was a good guy with a good product, but the way the product was introduced, he basically shot himself in the foot and lost alot of customers, i remember the MF thread on rcu, that was something... i got him on the phone once back in 2008, normally it was a woman answering the phone... his wife i think???

The poor guy passed away last year RIP, and only a handful of these ever made in into peoples hands.

Pictured is a new side piece and shoulder pieces ready to be carefully cut out

Some advice if trying this...

Make sure you center punch the holes dead center or very close to it, use a lupe if need be, this has caused me alot of headache, so i really take my time. I use a 3mm steel rod (old rc heli mainshaft) sharpened to a point on a dremel, i find i have to resharpen it constantly as the steel is soft, otherwise it looses its precision.

Make sure the drill bit is clean before going to the next hole, pieces of brass stuck in the channel of the bit, will make larger holes.

Score the bend lines, then curve the piece over (i use an Xacto aluminum handle as it appears to be the same diameter as the cylinder) use what you have, then using flat jawed pliers bend the sides at the score lines, if done properly this makes an almost perfect piece with very little tweaking to do afterwards.

And when working with the paper templates... make sure you dont have sweaty hands as it smudges (common sense goes a long way)

Just trying to help those attempting this and avoid all the little hiccups.

Roger was a good guy with a good product, but the way the product was introduced, he basically shot himself in the foot and lost alot of customers, i remember the MF thread on rcu, that was something... i got him on the phone once back in 2008, normally it was a woman answering the phone... his wife i think???

The poor guy passed away last year RIP, and only a handful of these ever made in into peoples hands.

mx862- Gold Member

- Posts : 105

Join date : 2012-12-17

Location : Whistler BC

Re: COX engine throttles

Re: COX engine throttles

mx862 wrote:

Roger was a good guy with a good product, but the way the product was introduced, he basically shot himself in the foot and lost alot of customers, i remember the MF thread on rcu, that was something.........

That was the most contentious thread I have ever read, before or since. His refusal or inability to answer any straight forward question ended up with him being labeled a charlatan or snake oil salesman. The qualities of his product, good or bad, ended up being buried in his interaction with the RCU members. Yes, he definitely shot himself in the foot.

Re: COX engine throttles

Re: COX engine throttles

A few years ago we sold him a quantity of 049 engines as he was planning to develop a throttle for them. After not hearing anything for a year, we had our own developped.

He seemed like a real nice guy on the phone and he had some good ideas.

He seemed like a real nice guy on the phone and he had some good ideas.

Re: COX engine throttles

Re: COX engine throttles

Tested the throttle today with mixed results, the engine was very touchy and finicky with it , runs fine without it, slight rmp change was noticed but not what i would call a working throttle, it was very quiet though...

was studying the patent and the handful of pics that exist of the MF throttle yesterday and noticed something that i haven't before, the two halves are made of very thin brass, twice as thin as what i used if not more, with shoulder pieces being much thicker to support the thin halves, the gap between the 2 halves appear to be quite a bit smaller than the exhaust bridge, smaller than the gap on mine.

There are 2 different versions of the throttle in the patent document, the latter being the production version, exhaust gaps vary, with the smallest on the production version.

I will order up various sheets of brass and the proper micro brass hardware.. i think this just might work, My first version of the throttle was a much simplified design, with only 2 bolts holding the halves together, that version had zero rpm change... so overall im pleased with the progress.

I have other ideas for throttle design, but will explore this one thoroughly, as believe it or not its the simplest, i dont have a lathe anymore so machining one is out.

Will keep at it

was studying the patent and the handful of pics that exist of the MF throttle yesterday and noticed something that i haven't before, the two halves are made of very thin brass, twice as thin as what i used if not more, with shoulder pieces being much thicker to support the thin halves, the gap between the 2 halves appear to be quite a bit smaller than the exhaust bridge, smaller than the gap on mine.

There are 2 different versions of the throttle in the patent document, the latter being the production version, exhaust gaps vary, with the smallest on the production version.

I will order up various sheets of brass and the proper micro brass hardware.. i think this just might work, My first version of the throttle was a much simplified design, with only 2 bolts holding the halves together, that version had zero rpm change... so overall im pleased with the progress.

I have other ideas for throttle design, but will explore this one thoroughly, as believe it or not its the simplest, i dont have a lathe anymore so machining one is out.

Will keep at it

mx862- Gold Member

- Posts : 105

Join date : 2012-12-17

Location : Whistler BC

Re: COX engine throttles

Re: COX engine throttles

If you were closer I would spot you some tarnished brass shim stock. I have extra from making a few pop pop boat motors. I got some 001, and 003 inches, maybe a couple other sizes.

You know, PM me an address, I can cut a couple pieces off the rolls and put two stamps on an envelope, and we hope it gets there without wrinkles.

Phil

You know, PM me an address, I can cut a couple pieces off the rolls and put two stamps on an envelope, and we hope it gets there without wrinkles.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: COX engine throttles

Re: COX engine throttles

Thanks For the offer Phil, i really appreciate it, but i think i will check out the local model rail road shops, i think they carry brass sheets in various thickness, probably have the hardware too, im going to be leaving for a week on work related business, but when im back i will continue with the project.

I got a plane halfway built and i need a throttled 010.

Will keep updating..

Anyone else working on a 010 throttle please post your ideas.

BTW if anyone still wants to visit the old site... use the wayback machine http://archive.org/web/web.php

One good pic of the engine and throttle, the other good pic in in an rcu thread in a post by AndyW where he got the engine from Roger... which i cannot seem to find...

Arthur.

I got a plane halfway built and i need a throttled 010.

Will keep updating..

Anyone else working on a 010 throttle please post your ideas.

BTW if anyone still wants to visit the old site... use the wayback machine http://archive.org/web/web.php

One good pic of the engine and throttle, the other good pic in in an rcu thread in a post by AndyW where he got the engine from Roger... which i cannot seem to find...

Arthur.

mx862- Gold Member

- Posts : 105

Join date : 2012-12-17

Location : Whistler BC

Re: COX engine throttles

Re: COX engine throttles

The trip to the model train shop payed off, now i have everything i need.

When i return from my trip, i will build a proper one.

When i return from my trip, i will build a proper one.

mx862- Gold Member

- Posts : 105

Join date : 2012-12-17

Location : Whistler BC

Re: COX engine throttles

Re: COX engine throttles

arthur

here is a better copy of the pic in my profile.

i have just dug out the second version, and will attempt to fit it up tomorrow....

unfortunately the only 010 i have is currently mounted in my tether car... see thread in models section.

but it need to come out for a good clean before the car is finished anyway.

cheers

a

here is a better copy of the pic in my profile.

i have just dug out the second version, and will attempt to fit it up tomorrow....

unfortunately the only 010 i have is currently mounted in my tether car... see thread in models section.

but it need to come out for a good clean before the car is finished anyway.

cheers

a

ado1974- Silver Member

- Posts : 94

Join date : 2012-12-15

Location : melbourne australia

Re: COX engine throttles

Re: COX engine throttles

pkrankow wrote:If you were closer I would spot you some tarnished brass shim stock. I have extra from making a few pop pop boat motors. I got some 001, and 003 inches, maybe a couple other sizes.

You know, PM me an address, I can cut a couple pieces off the rolls and put two stamps on an envelope, and we hope it gets there without wrinkles.

Phil

Hey phil

Funny how people share interests made a pop pop boat for my little girl couple of months go used tin cans etc turned out ok not a scale model more a fun one for

Lttleun she loves it next time round will do a proper one got some advice from bill Canada (on utube ) he's the man who can in pop pops or put puts however u pronounce very nice bloke very helpful

Dizzyman2011- Gold Member

- Posts : 391

Join date : 2012-11-21

Age : 43

Location : Newbury Berkshire uk

Page 1 of 6 • 1, 2, 3, 4, 5, 6

Similar topics

Similar topics» A little help plz

» "ACE" Style throttles now available

» Cox Surestart throttles

» Throttles for Cox Tee Dee .049 / .020 / .010 engines --- videos

» *Cox Engine of The Month* Submit your pictures! -December 2015- *ENGINE GIVEAWAY*

» "ACE" Style throttles now available

» Cox Surestart throttles

» Throttles for Cox Tee Dee .049 / .020 / .010 engines --- videos

» *Cox Engine of The Month* Submit your pictures! -December 2015- *ENGINE GIVEAWAY*

Page 1 of 6

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules