Log in

Search

Latest topics

» My N-1R build logby roddie Yesterday at 9:29 pm

» Funny what you find when you go looking

by rsv1cox Yesterday at 3:21 pm

» Landing-gear tips

by 1975 control line guy Yesterday at 8:17 am

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 7:45 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» My latest doodle...

by TD ABUSER Mon Nov 18, 2024 11:30 am

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

» Free Flight Radio Assist

by rdw777 Sun Nov 17, 2024 6:03 pm

» Tribute Shoestring build

by amurphy6812 Sun Nov 17, 2024 5:43 pm

Cox Engine of The Month

A choke-tube with velocity-stack configured Bee

Page 1 of 1

A choke-tube with velocity-stack configured Bee

A choke-tube with velocity-stack configured Bee

I bench-ran a .049 reed-valve engine last weekend as part of a water-cooling test. I had set it up with a choke-tube and an experimental velocity-stack.. which created too many variables for my test. It didn't go well.. lots of gremlins came out of the woods... and stuck their fingers in my work..  (that's my story.. and I'm stickin' to it..)

(that's my story.. and I'm stickin' to it..)

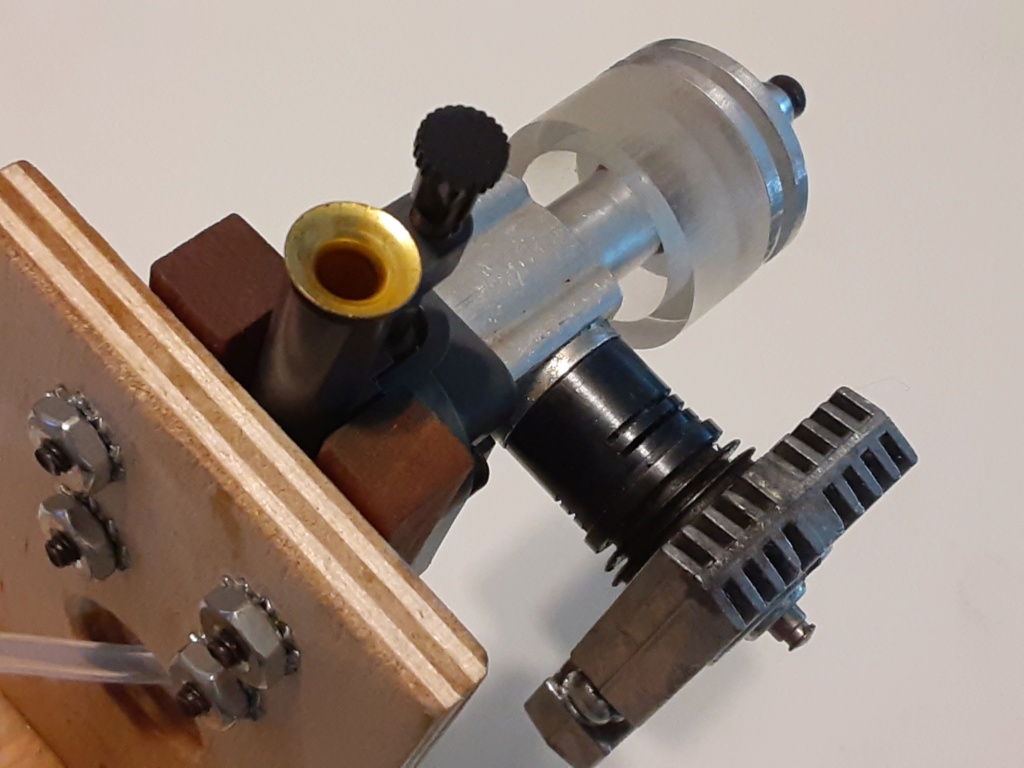

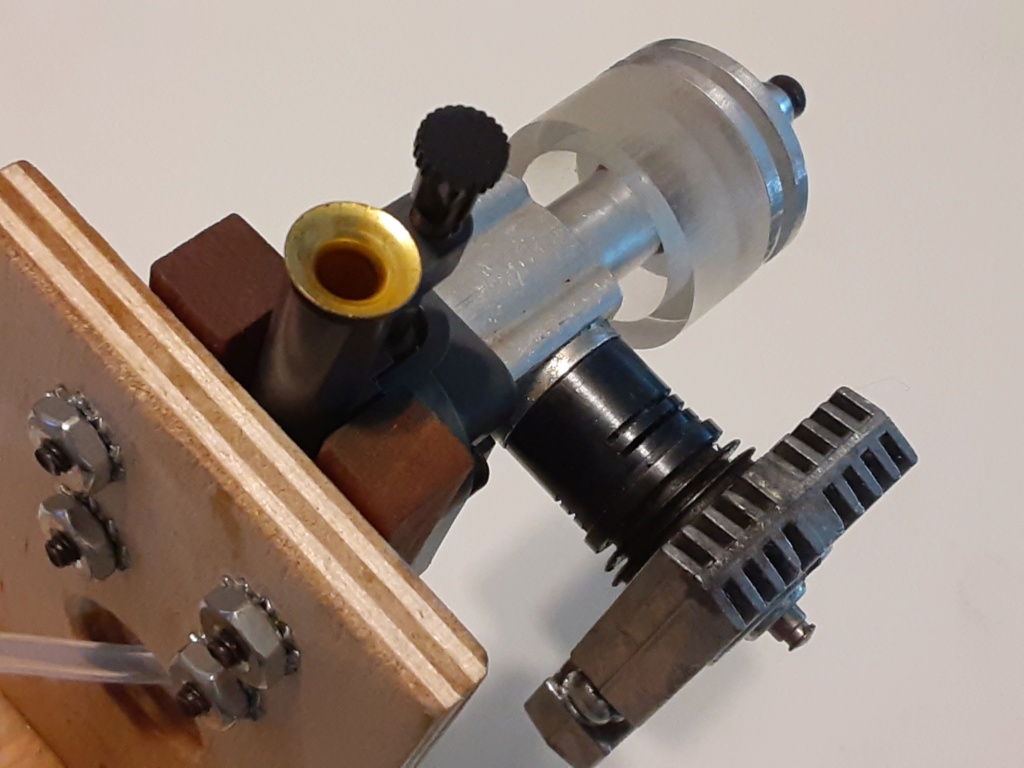

This afternoon.. I got the urge to reconfigure a different engine.. in a similar way.. but not water-cooled. The engine came in a "box-O-engines" that I sourced a few years ago. A Babe Bee with a single fill-tube on the backplate.

missing needle.... and a cam-style starter-spring.. without a hex drive-plate.

Very clean inside..

I donated a needle from my Bee needle stock... stuffed the 5cc bowl and mazac/zamac backplate in a little baggie..... and proceeded to put together an alternate "back-end" for the little mill.

and proceeded to put together an alternate "back-end" for the little mill.

I gave the back of the crankcase's gasket surface a little "massage".. over glass and 600 grit paper...

I had done a "needle-seal" using silicone tubing on the water-cooled engine's carb. and I wanted to do the same to this engine. I paid a bit more attention to the fitting of the tubing... to the needle.

I found a small flat-washer that fit perfectly around the needle-shaft and up against the spring-collar.

then I cut a length of tubing* to make a seal.

There's ample clearance for both; the tubing-seal.. and the flat-washer retainer.

With the back-end/carb. configured; I decided on a cylinder-orientation. The choke-tube (height) interferes with a parallel cylinder if using the Cox (Sandblaster) heatsink.. and the Cox heat-sink is replacing the water-cooling for this engine's testing. Therefore; I reoriented the cylinder position from 12:00 to 3:00; which will work for an application that is waiting.

Orienting the cylinder/crankcase 90 degrees from the NVA when using the horseshoe backplate/carb. leaves one of the four engine-mounts inaccessible from the front-side. This can be defeated by the use of #5 cap-screws and a ball-end driver.

I made some modifications to the bench-mount. When the engine "ran" for the water-cooling test; the tank was gyrating..

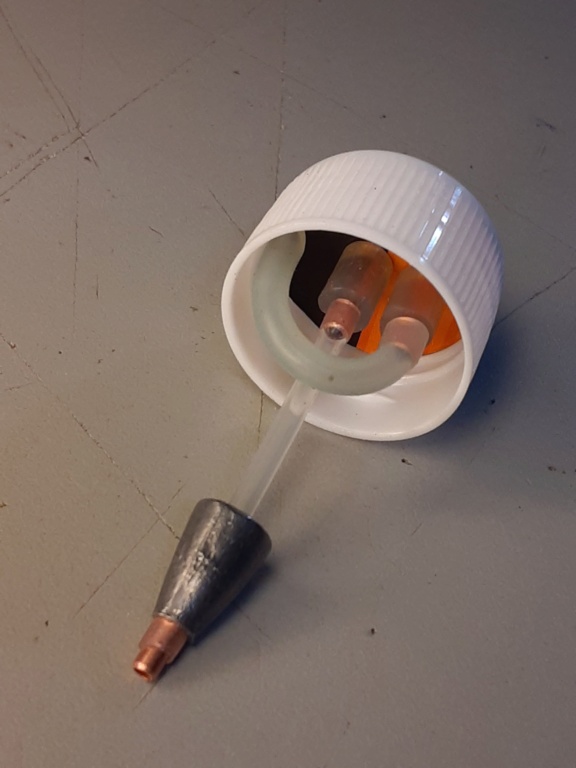

I'm actually "happy" that my little custom clunk-tank fed the engine.. until I pinched the line. I decided to make a mount to keep it still..

Oh.. almost forgot; the velocity stack is made from a brass compression-fitting with a heat-shrink sleeve to lock it in place.

If the weather permits tomorrow; I'll run er' up... and report.

This afternoon.. I got the urge to reconfigure a different engine.. in a similar way.. but not water-cooled. The engine came in a "box-O-engines" that I sourced a few years ago. A Babe Bee with a single fill-tube on the backplate.

missing needle.... and a cam-style starter-spring.. without a hex drive-plate.

Very clean inside..

I donated a needle from my Bee needle stock... stuffed the 5cc bowl and mazac/zamac backplate in a little baggie.....

I gave the back of the crankcase's gasket surface a little "massage".. over glass and 600 grit paper...

I had done a "needle-seal" using silicone tubing on the water-cooled engine's carb. and I wanted to do the same to this engine. I paid a bit more attention to the fitting of the tubing... to the needle.

I found a small flat-washer that fit perfectly around the needle-shaft and up against the spring-collar.

then I cut a length of tubing* to make a seal.

There's ample clearance for both; the tubing-seal.. and the flat-washer retainer.

With the back-end/carb. configured; I decided on a cylinder-orientation. The choke-tube (height) interferes with a parallel cylinder if using the Cox (Sandblaster) heatsink.. and the Cox heat-sink is replacing the water-cooling for this engine's testing. Therefore; I reoriented the cylinder position from 12:00 to 3:00; which will work for an application that is waiting.

Orienting the cylinder/crankcase 90 degrees from the NVA when using the horseshoe backplate/carb. leaves one of the four engine-mounts inaccessible from the front-side. This can be defeated by the use of #5 cap-screws and a ball-end driver.

I made some modifications to the bench-mount. When the engine "ran" for the water-cooling test; the tank was gyrating..

I'm actually "happy" that my little custom clunk-tank fed the engine.. until I pinched the line. I decided to make a mount to keep it still..

Oh.. almost forgot; the velocity stack is made from a brass compression-fitting with a heat-shrink sleeve to lock it in place.

If the weather permits tomorrow; I'll run er' up... and report.

Re: A choke-tube with velocity-stack configured Bee

Re: A choke-tube with velocity-stack configured Bee

Friend, I must highlight the quality of your work and presentation, it is to be applauded.

I follow your progress although sometimes I don't write, Roddie...my first friend from the USA!

I follow your progress although sometimes I don't write, Roddie...my first friend from the USA!

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: A choke-tube with velocity-stack configured Bee

Re: A choke-tube with velocity-stack configured Bee

MauricioB wrote:Friend, I must highlight the quality of your work and presentation, it is to be applauded.

I follow your progress although sometimes I don't write, Roddie...my first friend from the USA!

I Love You my friend! We share a common bond!!!

Re: A choke-tube with velocity-stack configured Bee

Re: A choke-tube with velocity-stack configured Bee

I can definitely learn a lot from watching your posts. Thanks Roddie

Greenman38633- Gold Member

- Posts : 151

Join date : 2024-02-05

Re: A choke-tube with velocity-stack configured Bee

Re: A choke-tube with velocity-stack configured Bee

I hope you get to run it calling for rain again through day/night today  Too much! ! anyway looks good , I like the tank and mount you have made .

Too much! ! anyway looks good , I like the tank and mount you have made .

getback- Top Poster

Posts : 10436

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: A choke-tube with velocity-stack configured Bee

Re: A choke-tube with velocity-stack configured Bee

I Like that too . How did you leak proof the tank And do you think a pill bottle would work ?

akjgardner- Diamond Member

Posts : 1600

Join date : 2014-12-28

Age : 65

Location : Greensberg Indiana

Re: A choke-tube with velocity-stack configured Bee

Re: A choke-tube with velocity-stack configured Bee

Roddie, love your experimenting, shows a creative mind at work. Today, seems many just like to go with the flow and not find there is more of the world out there to explore, and we can do it with both for fun and humor.

GallopingGhostler- Top Poster

Posts : 5721

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: A choke-tube with velocity-stack configured Bee

Re: A choke-tube with velocity-stack configured Bee

GallopingGhostler wrote:Roddie, love your experimenting, shows a creative mind at work. Today, seems many just like to go with the flow and not find there is more of the world out there to explore, and we can do it with both for fun and humor.

Yes, I bet roddie saves pen springs too. Mine just went dry. Nothing goes to waste. Multitude of uses.

rsv1cox- Top Poster

Posts : 11244

Join date : 2014-08-18

Location : West Virginia

Re: A choke-tube with velocity-stack configured Bee

Re: A choke-tube with velocity-stack configured Bee

Yes, I do that too, I think we are not alone in accumulating potential repair material for our engines and the planes/vehicles/boats that are powered by them. I find a certain amount of joy when I find a solution that works perfectly well and restores function.

GallopingGhostler- Top Poster

Posts : 5721

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: A choke-tube with velocity-stack configured Bee

Re: A choke-tube with velocity-stack configured Bee

GallopingGhostler wrote:Yes, I do that too, I think we are not alone in accumulating potential repair material for our engines and the planes/vehicles/boats that are powered by them. I find a certain amount of joy when I find a solution that works perfectly well and restores function.

So now there are 4 of us who use these springs haha..

Don't forget the lighter (encendedor de cigarrillos) stone springs which are perfect for the Cox Babe Bee .049/ Black Widow/ Queen Bee tank hose etc. etc.

Lighter (encendedor de cigarrillos) O-rings are also used for tanks, among other things!

And don't forget the springs and aerosol valves... I'm a "ciruja" haha

humor:

"ciruja" in Argentina: Person who makes a living by going through the garbage.

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: A choke-tube with velocity-stack configured Bee

Re: A choke-tube with velocity-stack configured Bee

Greenman38633 wrote:I can definitely learn a lot from watching your posts. Thanks Roddie

Thanks for your interest Mark. We don't see much use of the choke-tube.. so I thought it would be good to give it some attention.

Re: A choke-tube with velocity-stack configured Bee

Re: A choke-tube with velocity-stack configured Bee

akjgardner wrote:I Like that too . How did you leak proof the tank And do you think a pill bottle would work ?

Hi Joe, I sourced a package of .5oz. (15cc) clear plastic bottles w/caps from Amazon.. I guess it would depend on your type of pill bottle..

I used 3/32" alloy tubing for my fittings. I "melted" holes through the plastic bottle cap using a short piece of the tubing and a "pointed-tip" in my little pencil type soldering iron.

This forms smooth "burr-free" holes. The cardboard seal inside the cap must be removed and punches made to align with the holes in the cap. I actually made my own cap-seal using the "coated" cardboard found in refrigerated food packaging which is more resistant to "soak-through".

I soldered little steel flat-washers onto my tubes to prevent them pushing-through the cap.. and beveled the ends.

The "clunk" is a fishing worm-weight. This was actually my first time using the little tank and it worked pretty well considering it was bouncing around quite a bit.

Re: A choke-tube with velocity-stack configured Bee

Re: A choke-tube with velocity-stack configured Bee

rsv1cox wrote:GallopingGhostler wrote:Roddie, love your experimenting, shows a creative mind at work. Today, seems many just like to go with the flow and not find there is more of the world out there to explore, and we can do it with both for fun and humor.

Yes, I bet roddie saves pen springs too. Mine just went dry. Nothing goes to waste. Multitude of uses.

Absolutely!!! I get a LOT of enjoyment from tinkering, measuring, fitments/fit-ups.. It really helps to have supplies, stock and tools to work with... not to mention; an open/creative mindset.

Re: A choke-tube with velocity-stack configured Bee

Re: A choke-tube with velocity-stack configured Bee

Roddie, I audiotached your vids, and here are the peak values I recorded:

No 1 vid:

No.2 vid:

I did not measure significant difference.

( To put it in the context of our discussions regarding "ram air charging" I meant under this term a setup, where the propeller air is blasted directly into a scoop on the carb, whose axis is parallel with the propeller airflow..so those notes of mine on ram air charge do not apply to your bench runs where the carb air intake is perpendicular to the prop airflow.)

No 1 vid:

No.2 vid:

I did not measure significant difference.

( To put it in the context of our discussions regarding "ram air charging" I meant under this term a setup, where the propeller air is blasted directly into a scoop on the carb, whose axis is parallel with the propeller airflow..so those notes of mine on ram air charge do not apply to your bench runs where the carb air intake is perpendicular to the prop airflow.)

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: A choke-tube with velocity-stack configured Bee

Re: A choke-tube with velocity-stack configured Bee

balogh wrote:Roddie, I audiotached your vids, and here are the peak values I recorded:

No 1 vid:

No.2 vid:

I did not measure significant difference.

( To put it in the context of our discussions regarding "ram air charging" I meant under this term a setup, where the propeller air is blasted directly into a scoop on the carb, whose axis is parallel with the propeller airflow..so those notes of mine on ram air charge do not apply to your bench runs where the carb air intake is perpendicular to the prop airflow.)

Thanks for the audio-tach readings Andras! Yes.. I understand and agree my friend.

Similar topics

Similar topics» I will bench run a choke-tube (.049 reed-valve) accessory with custom velocity-stack and aero-prop, later on today for the holiday

» Choke Tube "stuff"...

» Choke tube?

» For Sale: ODD Stuff! Jetex Augmenter Tube and Glendale Hobby Supply Engine Choke/Cut Off

» For Sale 1960 OK Cub .024 Twin Stack

» Choke Tube "stuff"...

» Choke tube?

» For Sale: ODD Stuff! Jetex Augmenter Tube and Glendale Hobby Supply Engine Choke/Cut Off

» For Sale 1960 OK Cub .024 Twin Stack

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules