Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

Cox Engine of The Month

Exact Threads of screw in glow plug igniters

Page 1 of 2

Page 1 of 2 • 1, 2

Exact Threads of screw in glow plug igniters

Exact Threads of screw in glow plug igniters

I am fighting to keep glow plugs alive and need more. I have 5-6 burnt out ones. I would like to drill out and tap the burnt out ones to accept the igniters.

I have done it a couple years back while in another country and place and shop. I forgot is it 1/4 " threads any special pitch on the threads?

Thanks

Ice

I have done it a couple years back while in another country and place and shop. I forgot is it 1/4 " threads any special pitch on the threads?

Thanks

Ice

Iceberg- Gold Member

- Posts : 382

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

Iceberg wrote:I am fighting to keep glow plugs alive and need more. I have 5-6 burnt out ones. I would like to drill out and tap the burnt out ones to accept the igniters.

I have done it a couple years back while in another country and place and shop. I forgot is it 1/4 " threads any special pitch on the threads?

Thanks

Ice

Looking at Wikipedia and google the 1/4”x 32 tpi seems to be the thread of choice.

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

Many thanks appreciate that information!

Ice

Ice

Iceberg- Gold Member

- Posts : 382

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

The Turbo plug info is not totally correct. The thread is 8mm x .75 as stated. I am not sure where the 9mm comes from. I drill 3/16" diameter hole through and the tap drill size is 7.25mm, with a 60 degree taper at the bottom. If you don't mind the trouble of getting that tapered bottom, the performance will be worth it. Especially on motors less than a .21. I went to my local machine tool store and the 8mm x 0.75 tap was in stock at the time. A 1/4 -32" would have been a special order and more $. It is the same as the carb body for a TD .049 though if that would ever be needed.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

aspeed wrote:The Turbo plug info is not totally correct. The thread is 8mm x .75 as stated. I am not sure where the 9mm comes from. I drill 3/16" diameter hole through and the tap drill size is 7.25mm, with a 60 degree taper at the bottom. If you don't mind the trouble of getting that tapered bottom, the performance will be worth it. Especially on motors less than a .21. I went to my local machine tool store and the 8mm x 0.75 tap was in stock at the time. A 1/4 -32" would have been a special order and more $. It is the same as the carb body for a TD .049 though if that would ever be needed.

Rather than trying to get an odd sized drill ground to a special non standard base angle-simply use a centre-ing drill-these have the correct 60 degree taper-to cut the base taper-then it is simply a case of using your tap drill=presumably with the usual 118 degree base angle to enlarge the hole to tapping size-without disturbing the 60 degree cone you cut earlier. By picking the right size of centre-ing drill, your tap drill will have very little metal to remove for the cylindrical part of the hole...

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

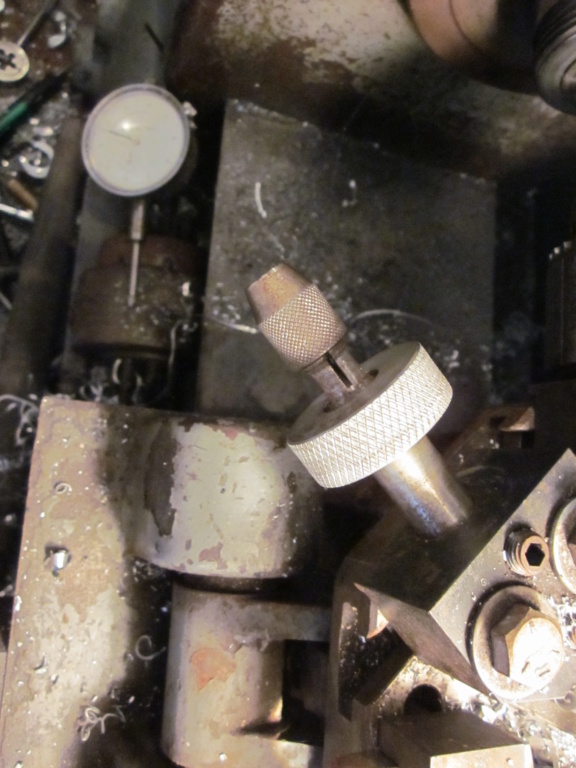

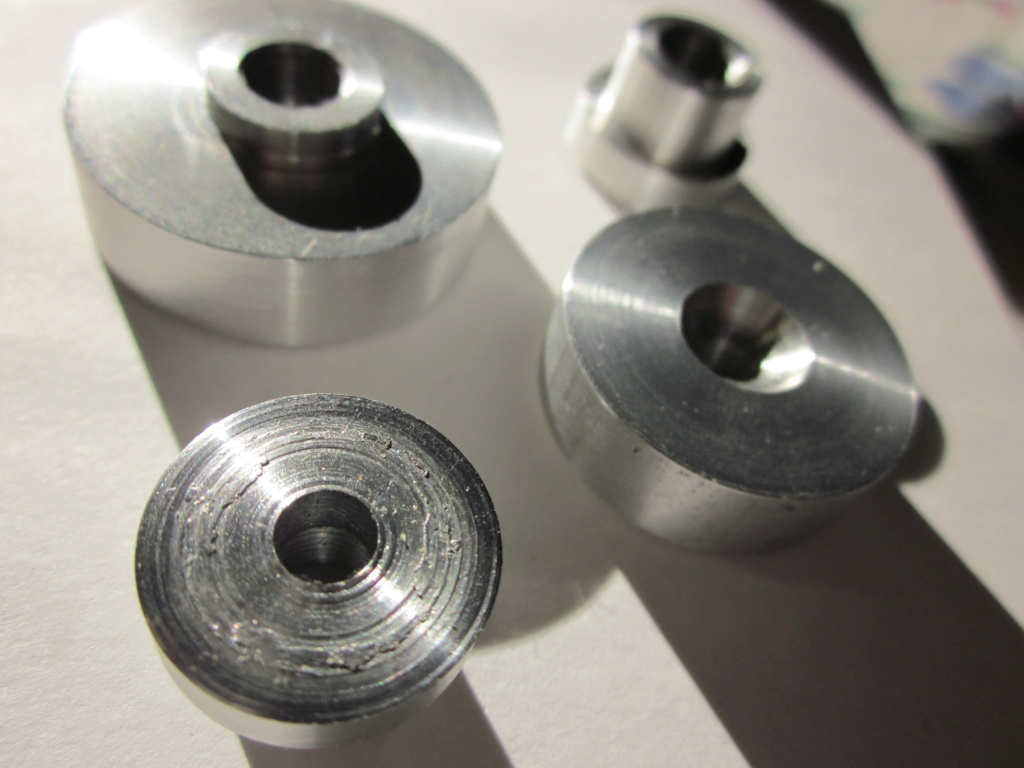

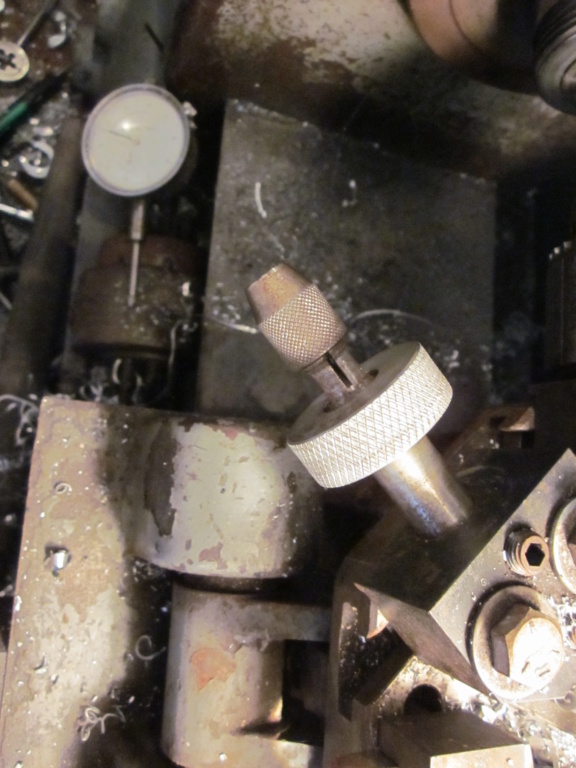

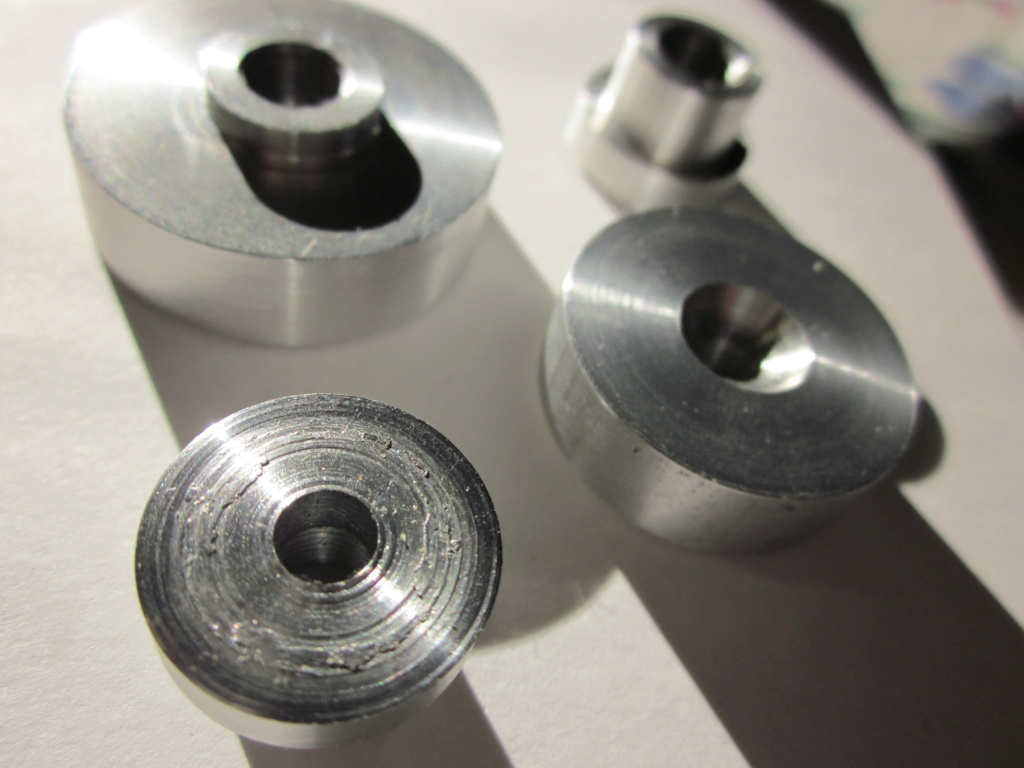

Yes, I used a centre drill for the angle and the diameter. My lathe allows the offset of the centre drill to cut the diameter to size with the centre drill after the 3/16" hole is in. I use the tap holder to centre the tap, and it is loose. The shallow knurl gives a grip, but when it seems tight you can let go like a clutch. I took some pics when I made a few head blanks a few years ago. Did 14 in different outer diameters. The pic is on the second operation, but you get the idea

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

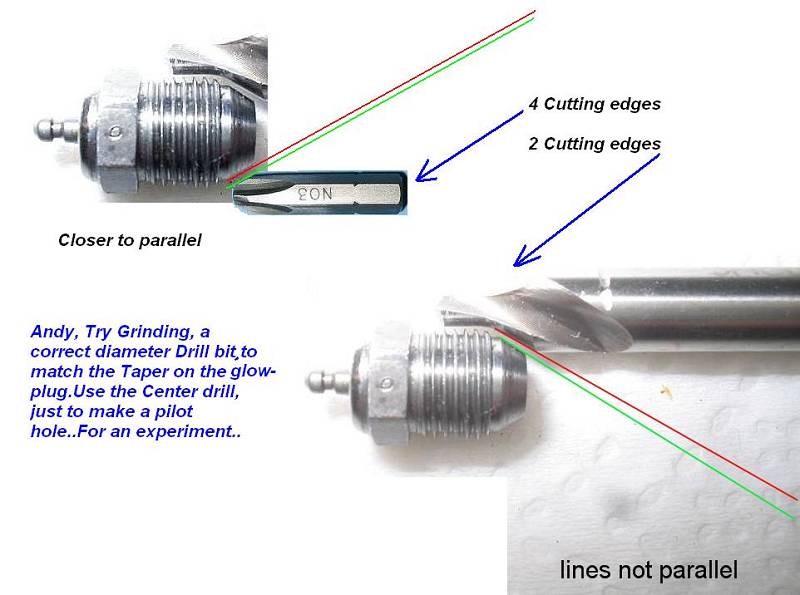

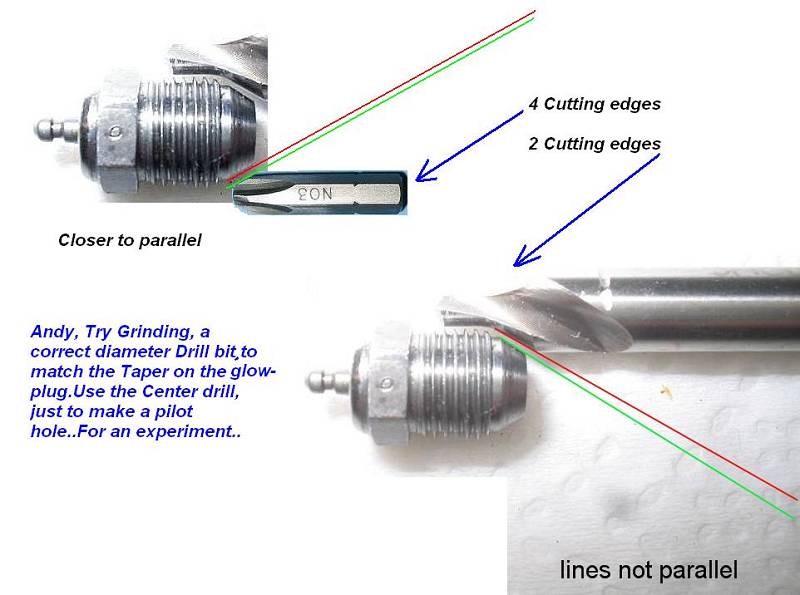

We have had this discussion many times before I believe, and I don't think that the center-drill has the correct angle for the conical part. Below is a picture from the RCU discussion at the time (mainly by AndyW and Japanman), the consensus was that a Philips screw driver bit does have the correct angle. Having the correct angle at the conical part gives a good seal even when it is just finger tight, and this prevents the head from deforming when the Turbo plug is tightened.

Below are the tools that I use to make heads for Turbo plugs, there is also a separate "thread" on this forum: https://www.coxengineforum.com/t10495-turbo-plug-heads

Below are the tools that I use to make heads for Turbo plugs, there is also a separate "thread" on this forum: https://www.coxengineforum.com/t10495-turbo-plug-heads

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

I utterly disagree-IF the turbo plug has a 60 degree angle-then a centre drill which IS ground to a 60 degree included angle MUST make a suitable and matching taper-and centre drills are produced to a long standing and tight standardised international specification. Note that there are centre drills which do not have a conical angle on them-but a radius curvature [I use these on venturis to improve the entry bellmouth]-but these are not standardised centre drills

Don't take this the wrong way-but I'd trust the specifications before your diagrams...

ChrisM

'ffkiwi'

Don't take this the wrong way-but I'd trust the specifications before your diagrams...

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

The diagram is not mine, it comes from the discussions of "Japanman" and "AndyW" some 10years ago.

Do you have any specification for the conical part of the Turbo plug?

I have never seen any official, only remarks on how Rossi plugs are a little different from OS plugs etc.

The Philips bit should have a tip angle of 2x26.5°=53°, so a little bit lower than a center drill. I have checked heads by using a felt-pen and the angle seems to be correct in the machined heads (using the philips bit).

Do you have any specification for the conical part of the Turbo plug?

I have never seen any official, only remarks on how Rossi plugs are a little different from OS plugs etc.

The Philips bit should have a tip angle of 2x26.5°=53°, so a little bit lower than a center drill. I have checked heads by using a felt-pen and the angle seems to be correct in the machined heads (using the philips bit).

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

Of course the discrepancy is readily explained if the angle on the turbo plugs is not in fact the 60 degrees it has been stated to be...the point I was trying to make earlier is that centre drills are very accurately manufactured-they have to be since one of their major common uses is drilling female conical recesses for lathe centres to fit....and these are virtually exclusively made to be 60 degrees included angle-as an industry standard...whether fixed, revolving or half centre

equally-if there is a bit of misallignment in the lathe tailstock, or the drill chuck-resulting in the drill not being truly axial relative to the headstock-then you would get a misaligned conical depression in the button-and hence a misfitting turboplug-even if everything else was done correctly.....this is the reason we have test bars made- to check lathe alignment.

Two of the best 'added value ' tools you can get for your lathe (in the context of model engine work!) are a tailstock tap and die holder...which pretty much guarantee....unless you're utterly hamfisted.....that any threads cut-male or female-are both truly axial...and straight...whether they be male on a crankshaft or spraybar, or female in a glowplug adaptor

I still have great skepticism that an interchangeable Philips head screwdriver bit is manufactured to a greater level of precision than a centre drill....

ChrisM

'ffkiwi'

equally-if there is a bit of misallignment in the lathe tailstock, or the drill chuck-resulting in the drill not being truly axial relative to the headstock-then you would get a misaligned conical depression in the button-and hence a misfitting turboplug-even if everything else was done correctly.....this is the reason we have test bars made- to check lathe alignment.

Two of the best 'added value ' tools you can get for your lathe (in the context of model engine work!) are a tailstock tap and die holder...which pretty much guarantee....unless you're utterly hamfisted.....that any threads cut-male or female-are both truly axial...and straight...whether they be male on a crankshaft or spraybar, or female in a glowplug adaptor

I still have great skepticism that an interchangeable Philips head screwdriver bit is manufactured to a greater level of precision than a centre drill....

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

I'm not questioning the accuracy of center drills or the inaccuracy of Philips bits. I simply haven't seen any official numbers for the design of the Turbo plug, so to me the design itself is the uncertain part.

I simply followed the recommendation at the time, using a Philips bit, it work and that's what I have been using since then. I have center drills to test with, I'll see if I can tell a difference. Perhaps making a dummy head or two is sufficient.

I simply followed the recommendation at the time, using a Philips bit, it work and that's what I have been using since then. I have center drills to test with, I'll see if I can tell a difference. Perhaps making a dummy head or two is sufficient.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

These topics come up quite often repeatedly, and in different forums. Like "how do you clean/free up a seized motor", "is castor oil really needed?"... I just measured a Merlin turbo plug and it is 60 degrees right on, as far as my little loupe scale can tell. I have found that after a few uses, the seat will wear a bit and the plug protrudes a bit into the chamber. I try to leave a bit of land at the chamber and where the taper ends, so it is a bit stronger there, not a sharp point. At least there will be .010" to wear away over the years. If a phillips bit works, great, it seems a bit crude, but is not really much worse than a centre drill. They have no side clearance like a drill does. I could not find a centre drill with the correct minor diameter of 7.25mm, so used one that is .250" or 6.35mm and offset it. Whatever works. I hope we have not overcomplicated this for the OP. It is really not that hard to do if you have a lathe. Just a couple tries to see how deep to go. In either case, with the 1/4-32" or metric thread, make sure there is still a way to get the head wrench on. I counterbored the old 1/4" style to get the plug wrench in, and still use the Cox wrench. There was not much room. FFKiwi, I have never seen those radiused centre drills. Sounds like the ticket for venturis. I have some oddball ones that are labelled Slocomb. They have a flat and a different angle. A radius would be nicer. Like the old Rossi .15 venturis used to have.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

aspeed wrote: FFKiwi, I have never seen those radiused centre drills. Sounds like the ticket for venturis. I have some oddball ones that are labelled Slocomb. They have a flat and a different angle. A radius would be nicer. Like the old Rossi .15 venturis used to have.

Aspeed-I picked up those radiused centre drills from a major tool supplier here in NZ some time ago-and for the very reason you latch onto-making nice venturis. I had no idea such items were made-and was chasing normal 60 degree centre drills at the time-but realised the usefulness of the other kind very quickly....

https://tradetools.co.nz/pages/search-results-page?q=centre+drills [see the photos-the radius ones start about 4 rows down....and there is quite a variety......you might also note a bit further down, the 'bell type' profile centre drills which might also be useful...

Given the NZ market is tiny compared to yours-I imagine you could find them somewhere locally....and if not- well you could always buy them from us....;-)

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

Could someone post a link to the centering drill that keeps being mentioned?

The Confused Mark

The Confused Mark

batjac- Diamond Member

Posts : 2374

Join date : 2013-05-22

Age : 61

Location : Broken Arrow, OK, USA

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

batjac wrote:Could someone post a link to the centering drill that keeps being mentioned?

The Confused Mark

what exactly do you think the link in the post immediately above your post is???

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

The 8mm one looks good with the 1/8" point. Maybe the shipping is cheaper from NZ than the Canadian postal service. I have had some nasty surprises with them. Malaysian tools are probably the same as we get here.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

aspeed wrote:The 8mm one looks good with the 1/8" point. Maybe the shipping is cheaper from NZ than the Canadian postal service. I have had some nasty surprises with them. Malaysian tools are probably the same as we get here.

Hard to say re postal times-especially in these trying times! I do know from Ebay purchasing that stuff mailed from Canada takes an inordinate amount of time to arrive down here....what its like in the reverse direction I have no idea....

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

Just wondering after the many informative comments.

I am able to locate in the isolated town I'm in lockdown in at the moment only a tap 1/4" x 28 not the exact 32 per inch as is the pitch of the threads for the plugs. Hoping to get a few of these milled heads off the line ASAP.

Might this 4 turns less per inch prevent the plug from working? The threads are 7/32 of an inch long so the turn might be about one turn less and slightly steeper pitch on the thread. Might work? I'm thinking might be?

Thanks

Ice

I am able to locate in the isolated town I'm in lockdown in at the moment only a tap 1/4" x 28 not the exact 32 per inch as is the pitch of the threads for the plugs. Hoping to get a few of these milled heads off the line ASAP.

Might this 4 turns less per inch prevent the plug from working? The threads are 7/32 of an inch long so the turn might be about one turn less and slightly steeper pitch on the thread. Might work? I'm thinking might be?

Thanks

Ice

Iceberg- Gold Member

- Posts : 382

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

Forget it-its a different thread entirely-you cannot go and screw a 1/4-32 thread item into a 1/4-28 threaded hole [well you can-but only at the cost of stripping the thread and ruining both items!]

Threads are not things to be cavalier with-there are very few threads that are interchangeable-and where there are it is generally as a result of poor tolerances rather than design-unfortunately model engines use a very wide range of thread types-BA and BSF in earlier British engines, metric in later British ones, metric in continental, Japanese and Chinese ones, UNC and UNF in US made ones-plus various non standard metric and imperial threads on larger screwed components -such as screw in backplates and glowheads. 1/4-28 is a UNF thread, 1/4-32 is a UNEF thread-totally different thread series....and the 1/4-32 thread used on glowplugs and model engine spark plugs is a fairly rare one-seemingly used only by model engines (and perhaps in gunsmithing)-so such tooling is a bit scarce to find-but 1/4-32 taps and dies CAN be found if you look hard

And things can be a little complicated-apart from thread diameter and pitch-the number of threads per inch-there is also thread ANGLE to consider-all the major thread series are different: UNC, UNF and metric threads have a 60 degree thread angle, BSW-British Standard Whitworth and BSF 'British Standard Fine' are both 55 degrees, BA 'British Association' threads are 47.5 degrees-so even though 1/4-20 UNC and 1/4 BSW bolts both have 20 threads per inch-they are not necessarily compatible...a 1/4 BSF bolt will screw into a 1/4UNC nut....but be very tight the opposite way round...because a 55 degree male thread will fit into a 60 degree female thread nut...but reverse the two-and it is a different story. Same will 7/32-32 and 12-32 threads you find on some early OS 15 engines.

So there are all sorts of pitfalls awaiting you unless you know what the threads you are dealing with are-and you have the correct tools to deal with those threads-so unless you can access or buy a 1/4-32 tap, then you can forget about tapping out Cox heads for a glowplug.....unless of course you can find a metric M8x .75 tap and fit a turbo plug...

And just to rub the point home....there is also a 1/4-32 thread in the ME series...this is the 'Model Engineer' series....with a 55 degree 'Whitworth form' thread profile....so this won't work either...you want the right 1/4-32 tap...a 1/4-32 UNEF one!

Hope this gives you a bit more insight. As someone with a very large number of engines-and a bit of model engineering under my belt-I have to utilise an ever increasing range of taps and dies for model engine use-and I STILL get caught out by the occasional one that I need but don't have...

ChrisM

'ffkiwi'

Threads are not things to be cavalier with-there are very few threads that are interchangeable-and where there are it is generally as a result of poor tolerances rather than design-unfortunately model engines use a very wide range of thread types-BA and BSF in earlier British engines, metric in later British ones, metric in continental, Japanese and Chinese ones, UNC and UNF in US made ones-plus various non standard metric and imperial threads on larger screwed components -such as screw in backplates and glowheads. 1/4-28 is a UNF thread, 1/4-32 is a UNEF thread-totally different thread series....and the 1/4-32 thread used on glowplugs and model engine spark plugs is a fairly rare one-seemingly used only by model engines (and perhaps in gunsmithing)-so such tooling is a bit scarce to find-but 1/4-32 taps and dies CAN be found if you look hard

And things can be a little complicated-apart from thread diameter and pitch-the number of threads per inch-there is also thread ANGLE to consider-all the major thread series are different: UNC, UNF and metric threads have a 60 degree thread angle, BSW-British Standard Whitworth and BSF 'British Standard Fine' are both 55 degrees, BA 'British Association' threads are 47.5 degrees-so even though 1/4-20 UNC and 1/4 BSW bolts both have 20 threads per inch-they are not necessarily compatible...a 1/4 BSF bolt will screw into a 1/4UNC nut....but be very tight the opposite way round...because a 55 degree male thread will fit into a 60 degree female thread nut...but reverse the two-and it is a different story. Same will 7/32-32 and 12-32 threads you find on some early OS 15 engines.

So there are all sorts of pitfalls awaiting you unless you know what the threads you are dealing with are-and you have the correct tools to deal with those threads-so unless you can access or buy a 1/4-32 tap, then you can forget about tapping out Cox heads for a glowplug.....unless of course you can find a metric M8x .75 tap and fit a turbo plug...

And just to rub the point home....there is also a 1/4-32 thread in the ME series...this is the 'Model Engineer' series....with a 55 degree 'Whitworth form' thread profile....so this won't work either...you want the right 1/4-32 tap...a 1/4-32 UNEF one!

Hope this gives you a bit more insight. As someone with a very large number of engines-and a bit of model engineering under my belt-I have to utilise an ever increasing range of taps and dies for model engine use-and I STILL get caught out by the occasional one that I need but don't have...

ChrisM

'ffkiwi'

ffkiwi- Gold Member

- Posts : 398

Join date : 2018-07-10

Location : Wellington, NZ

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

Hi Chris

Thanks for the info. Do you know if a 6/32 would work. I know 6mm is called 1/4" however likely a fractional difference.

Thanks

Darren

Thanks for the info. Do you know if a 6/32 would work. I know 6mm is called 1/4" however likely a fractional difference.

Thanks

Darren

Iceberg- Gold Member

- Posts : 382

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

6-32 is much smaller. It is #6 which is about .130" diameter. A 6mm thread is normally 1mm pitch, and no, it will not work. Maybe the best thing is just to get an adaptor head from Kamteknik that uses the turbo plugs. I would imagine they are available where you live. You would need to mail order a 1/4-32" tap anyway, and it will lose a lot of performance, so you may as well get the Kamteknik. They look pretty good to me.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

Hi aspeed

Trying to find all options.

Still looking for the 1/4-32 UNEF tap difficult little turkey to locate here.

Thanks a lot

Ice

Trying to find all options.

Still looking for the 1/4-32 UNEF tap difficult little turkey to locate here.

Thanks a lot

Ice

Iceberg- Gold Member

- Posts : 382

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

If you are burning out a lot of plugs, add another head shim to give less compression. It gets expensive after a while. A 1/4 32 tap is hard to find anywhere. I have a couple but they are rarely stocked. Holly carbs use that size for the jets.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

or 12 buck Galbreath Nelson heads and 5 buck Nelson plugs....still for sale

I know some purists are stuck on TURBO....but cost of tooling must be considered IMO

I know some purists are stuck on TURBO....but cost of tooling must be considered IMO

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Exact Threads of screw in glow plug igniters

Re: Exact Threads of screw in glow plug igniters

Iceberg wrote:Hi aspeed

Trying to find all options.

Still looking for the 1/4-32 UNEF tap difficult little turkey to locate here.

Thanks a lot

Ice

You don't really want to use the regular glow plugs, as there is a great power loss in .049 engine if you do. Hence the long discussion about Turbo plugs.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Page 1 of 2 • 1, 2

Similar topics

Similar topics» The .049 glow plug ?

» Cox Tee Dee high-compression glow head question

» .049 glow plug ?

» Glow Head Threads and Never-Seize

» .049 glow plug

» Cox Tee Dee high-compression glow head question

» .049 glow plug ?

» Glow Head Threads and Never-Seize

» .049 glow plug

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules