Log in

Search

Latest topics

» Purchased the last of any bult engines from Ken Enyaby getback Today at 7:24 am

» My N-1R build log

by rsv1cox Today at 7:05 am

» Funny what you find when you go looking

by rsv1cox Yesterday at 3:21 pm

» Landing-gear tips

by 1975 control line guy Yesterday at 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» My latest doodle...

by TD ABUSER Mon Nov 18, 2024 11:30 am

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

» Free Flight Radio Assist

by rdw777 Sun Nov 17, 2024 6:03 pm

» Tribute Shoestring build

by amurphy6812 Sun Nov 17, 2024 5:43 pm

Cox Engine of The Month

Black Widow generating shavings in non-standard application

Page 1 of 1

Black Widow generating shavings in non-standard application

Black Widow generating shavings in non-standard application

Greetings fellows,

I recently received a couple of older 049s from a friend who used to do CL flying. I didn't have plans for them as my RC hobbies tend to stay on the ground and they prefer throttles. But I thought I might try to enter the Black Widow into our "outlaw class" pinewood derby this year. I had the engine running quite well after a clean-up and started to work on the chassis.

After an early test run, I found my glow element pounded to death and aluminum shavings in the engine. I believe the connecting rod was moving out and contacting the flange of the fuel tank, the area that surrounds the reed valve. I put some arrows on that area in the second image below. That is where the aluminum came from. I attributed it to my flywheel coming loose and causing harsh vibration. I cleaned it up and put it all back together with better fixing method for the flywheel.

A few more test runs (successful except for starting in direction opposite of what I wanted!) and I thought I was in good shape. But at the next re-start, I had no glow, and opening up the motor showed more shavings.The flywheel stayed on this time, so that sent me in other directions looking for problems. Listed below the photos is what I know about the engine that my current thinking says could be relevant:

Are there any common problems you guys know about or things that you can see in my application that would cause the rod to move along the crank pin enough to contact other parts?

I have a few more engine parts, including a different crank/case/piston/cylinder assembly that I might be able to press into service if you think it could be the cylinder-to-crank alignment, although for some reason the muffler I bought does not fit tightly on this case/cylinder combination. I need the muffler to keep castor oil off my drive flange and drive wheels!

Thanks for any help!

Matt

I recently received a couple of older 049s from a friend who used to do CL flying. I didn't have plans for them as my RC hobbies tend to stay on the ground and they prefer throttles. But I thought I might try to enter the Black Widow into our "outlaw class" pinewood derby this year. I had the engine running quite well after a clean-up and started to work on the chassis.

After an early test run, I found my glow element pounded to death and aluminum shavings in the engine. I believe the connecting rod was moving out and contacting the flange of the fuel tank, the area that surrounds the reed valve. I put some arrows on that area in the second image below. That is where the aluminum came from. I attributed it to my flywheel coming loose and causing harsh vibration. I cleaned it up and put it all back together with better fixing method for the flywheel.

A few more test runs (successful except for starting in direction opposite of what I wanted!) and I thought I was in good shape. But at the next re-start, I had no glow, and opening up the motor showed more shavings.The flywheel stayed on this time, so that sent me in other directions looking for problems. Listed below the photos is what I know about the engine that my current thinking says could be relevant:

- It was crashed. The cylinder had torn out of the crankcase. The threads show the damage, but enough remained to re-fit the parts. Maybe alignment is now off causing the rod to travel on the crank pin?

- No idea what previous use was like. Clearance at the piston end/ball and socket was 0.010" which I reduced to 0.003" (with a homemade tool after the first instance of shavings). The crank end had perceptible play, but I thought not excessive. Everything else seemed in proper shape.

- Maybe I am overspeeding it? I don't have a tach or a prop to use one with.

- I am side loading it with a rubber band on a long lever arm. This is how the friction drive is achieved. I assumed for a few sub 2 second pinewood derby runs, this should be ok. Not sure how this would lead to what I am seeing, but maybe.

- My drive flange (the rubber band pulls the drive snout on the crankshaft against this flange) has a slight wobble. Maybe this vibration is messing with it at high rpms?

Are there any common problems you guys know about or things that you can see in my application that would cause the rod to move along the crank pin enough to contact other parts?

I have a few more engine parts, including a different crank/case/piston/cylinder assembly that I might be able to press into service if you think it could be the cylinder-to-crank alignment, although for some reason the muffler I bought does not fit tightly on this case/cylinder combination. I need the muffler to keep castor oil off my drive flange and drive wheels!

Thanks for any help!

Matt

mmischni- Moderate Poster

- Posts : 15

Join date : 2017-05-16

Age : 46

Location : Madison, WI

Black Widow shavings

Black Widow shavings

Hi Matt,

Absolutely you have found one definite wearing spot on top of the tank reed area. The easy fix is to file a small clearance groove there and be done with it...

OR the more difficult fix is to carefully turn down the piston skirt .010" on a lathe (without damaging the piston).

The second area of "making metal" is when the crank pin grinds away at the front face of the tank. Most often it's just in one certain area & not

along the entire periphery. Again, further relieving of metal in the offending rub zone (by file or dremel) can help there...buy WHY you ask?

Well certainly one thing that causes the con rod to slide off the crank pin is when the steel crank pin has worn tapered.

We're only talking of wear in the 10 /thousandths of an inch (.0001"), so you'll never notice this unless you carefully measure it with a micrometer.

New cranks (with parallel ground crank pins) help prevent this kind of rubbing a lot.

As you've found out, aluminum particles & platinum glow elements hate each other. So your mission is to find all the rub spots & eliminate them one by one.

Sometimes a good replacement crank can eliminate several problems at once. Many think that with the crankshaft being pulled forward with the propellor

thrust load, that this crankpin rubbing can't occur with the engine running. Evidently it CAN!! With this in mind therefore, if you have excessive end play

in your c/case to drive plate area, those nice thin steel washers sold by Cox International can take up a lot of that slop & also end the rubbing.

You also note that your muffler is not tight. Probably not as serious a problem, but I don't like that in my motors either. It turns out that a head shim for

.15 sized engines (available in several thicknesses) fits very well in that area with some exterior trimming. They can perhaps tighten up that joint. Shims

can be cut from an aluminum foil pie plate with your trusty #11 exacto knife if need be.

Good luck with your troubleshooting Matt, let us know how you make out.

Cheers,

Paul (aka Mr. Mouse)

Absolutely you have found one definite wearing spot on top of the tank reed area. The easy fix is to file a small clearance groove there and be done with it...

OR the more difficult fix is to carefully turn down the piston skirt .010" on a lathe (without damaging the piston).

The second area of "making metal" is when the crank pin grinds away at the front face of the tank. Most often it's just in one certain area & not

along the entire periphery. Again, further relieving of metal in the offending rub zone (by file or dremel) can help there...buy WHY you ask?

Well certainly one thing that causes the con rod to slide off the crank pin is when the steel crank pin has worn tapered.

We're only talking of wear in the 10 /thousandths of an inch (.0001"), so you'll never notice this unless you carefully measure it with a micrometer.

New cranks (with parallel ground crank pins) help prevent this kind of rubbing a lot.

As you've found out, aluminum particles & platinum glow elements hate each other. So your mission is to find all the rub spots & eliminate them one by one.

Sometimes a good replacement crank can eliminate several problems at once. Many think that with the crankshaft being pulled forward with the propellor

thrust load, that this crankpin rubbing can't occur with the engine running. Evidently it CAN!! With this in mind therefore, if you have excessive end play

in your c/case to drive plate area, those nice thin steel washers sold by Cox International can take up a lot of that slop & also end the rubbing.

You also note that your muffler is not tight. Probably not as serious a problem, but I don't like that in my motors either. It turns out that a head shim for

.15 sized engines (available in several thicknesses) fits very well in that area with some exterior trimming. They can perhaps tighten up that joint. Shims

can be cut from an aluminum foil pie plate with your trusty #11 exacto knife if need be.

Good luck with your troubleshooting Matt, let us know how you make out.

Cheers,

Paul (aka Mr. Mouse)

Last edited by Paulgibeault on Tue May 16, 2017 1:48 pm; edited 1 time in total (Reason for editing : info added)

Paulgibeault- Gold Member

- Posts : 259

Join date : 2011-09-24

Location : Leduc, Alberta Canada

Re: Black Widow generating shavings in non-standard application

Re: Black Widow generating shavings in non-standard application

Hi Paul,

Thanks for the response. So it sounds like this is a problem that is not unheard of. I pushed on the crank and thought I recalled that the end play was insufficient to cause rubbing here from the crank pin, although I can't say for certain that things don't move differently while propelled by methanol!

Tell me more about relieving the piston skirt, as I don't follow how that would affect this problem. Do you mean shorten the piston by 0.010"? Or reduce its diameter by 0.010" at the bottom? If we think it is the connecting rod doing the deed, I don't see how this changes things.

Filing I am happy to do, if relieving the tank end a little is an OK solution. How far out will the connecting rod come off the pin? If I take all that tank material off, will it just walk itself right off the pin? Maybe I don't actually have that much material to remove, I don't remember how far before I get into the reed valve.

Thanks again!!

Matt

Thanks for the response. So it sounds like this is a problem that is not unheard of. I pushed on the crank and thought I recalled that the end play was insufficient to cause rubbing here from the crank pin, although I can't say for certain that things don't move differently while propelled by methanol!

Tell me more about relieving the piston skirt, as I don't follow how that would affect this problem. Do you mean shorten the piston by 0.010"? Or reduce its diameter by 0.010" at the bottom? If we think it is the connecting rod doing the deed, I don't see how this changes things.

Filing I am happy to do, if relieving the tank end a little is an OK solution. How far out will the connecting rod come off the pin? If I take all that tank material off, will it just walk itself right off the pin? Maybe I don't actually have that much material to remove, I don't remember how far before I get into the reed valve.

Thanks again!!

Matt

mmischni- Moderate Poster

- Posts : 15

Join date : 2017-05-16

Age : 46

Location : Madison, WI

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Black Widow generating shavings in non-standard application

Re: Black Widow generating shavings in non-standard application

Thanks Surfer_kris,

That photo I think helps me understand. Apparently the piston can contact the top of that area surrounding the reed valve? I don't think I have evidence of that. I don't have the confidence to try to hold the piston for machining anyhow, so that is out for me. I also don't have lots of time left to wait for parts any longer. Hopefully my last order of glow heads arrives next week! I have a glow plug adapter head, and lots of old glow plugs, but the motor doesn't seem to enjoy them. It ran yesterday with a standard glow plug, but not strong enough for me to even "dump the clutch" without stalling. I put my last cox glow head on and it ran much stronger, burning rubber the whole way down my little strip of track. Too bad I killed it!

I'll try to relieve the area that is being contacted and hope the connecting rod doesn't try to slip off the end of the crank pin. Maybe with the angles involved that isn't even possible. Hopefully I have enough plugs/glow heads to find out.

Thanks for the assistance so far!

Matt

That photo I think helps me understand. Apparently the piston can contact the top of that area surrounding the reed valve? I don't think I have evidence of that. I don't have the confidence to try to hold the piston for machining anyhow, so that is out for me. I also don't have lots of time left to wait for parts any longer. Hopefully my last order of glow heads arrives next week! I have a glow plug adapter head, and lots of old glow plugs, but the motor doesn't seem to enjoy them. It ran yesterday with a standard glow plug, but not strong enough for me to even "dump the clutch" without stalling. I put my last cox glow head on and it ran much stronger, burning rubber the whole way down my little strip of track. Too bad I killed it!

I'll try to relieve the area that is being contacted and hope the connecting rod doesn't try to slip off the end of the crank pin. Maybe with the angles involved that isn't even possible. Hopefully I have enough plugs/glow heads to find out.

Thanks for the assistance so far!

Matt

mmischni- Moderate Poster

- Posts : 15

Join date : 2017-05-16

Age : 46

Location : Madison, WI

Re: Black Widow generating shavings in non-standard application

Re: Black Widow generating shavings in non-standard application

Well between the last bit of "machining" and this most recent bout, there is a good bit of material removed from the reed valve surround. Not quite all the way around, but close. Taking it apart again reminded me how little clearance there is to deal with. I fear just removing some metal for clearance will (if I don't take too much and lose my reed retainer groove) just let the rod move out farther and end with more dead glow heads.

I have one other crankcase and crank of unknown vitality that I can try, and hope for the best. No time to wait for parts any longer, and really this was supposed to be a project done with "parts I already have!" So I don't really want to keep throwing money at this. Hopefully it will hold together for a few runs. This thing is acting a lot like the top fuel cars it is to be modeled after. I think I have had the motor apart after every run!

Thanks for the tips on shimming the muffler. Interestingly, for my other silver crankcase, the gap is more like 0.025". I will perhaps have to try out some gasket paper material of more substantial thickness than a pie plate. Not sure what kind of motor this crankcase was from. The black cylinder that was on it also did not have flats for the COX tool, so maybe some kind of aftermarket or knockoff? This might end up being a really neat-looking gravity-powered car after all.

Thanks again,

Matt

I have one other crankcase and crank of unknown vitality that I can try, and hope for the best. No time to wait for parts any longer, and really this was supposed to be a project done with "parts I already have!" So I don't really want to keep throwing money at this. Hopefully it will hold together for a few runs. This thing is acting a lot like the top fuel cars it is to be modeled after. I think I have had the motor apart after every run!

Thanks for the tips on shimming the muffler. Interestingly, for my other silver crankcase, the gap is more like 0.025". I will perhaps have to try out some gasket paper material of more substantial thickness than a pie plate. Not sure what kind of motor this crankcase was from. The black cylinder that was on it also did not have flats for the COX tool, so maybe some kind of aftermarket or knockoff? This might end up being a really neat-looking gravity-powered car after all.

Thanks again,

Matt

mmischni- Moderate Poster

- Posts : 15

Join date : 2017-05-16

Age : 46

Location : Madison, WI

Re: Black Widow generating shavings in non-standard application

Re: Black Widow generating shavings in non-standard application

An extra gasket or two on the tank might give enough clearance, without having to rework the tank.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Black Widow generating shavings in non-standard application

Re: Black Widow generating shavings in non-standard application

Hi Matt:

Perhaps it wasn't clear. That small groove on top of the tank is caused by the piston skirt hitting on it. It gets worse as the ball-socket joint loosens.

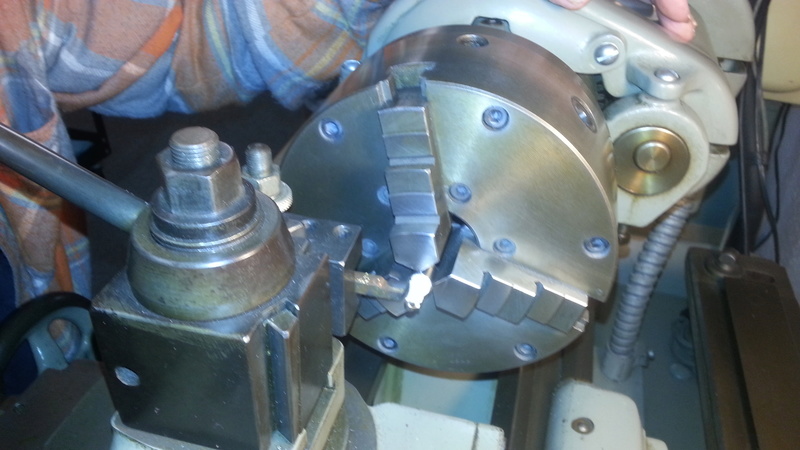

IF SPI is not a problem, cutting the bottom of the piston skirt .010" can provide the needed clearance. I hope this photo attaches OK. I am talking about shortening the piston height, not changing its diameter.

If running a muffler, this added SPI is probably not a good thing (now that I think of it).

However, filing a clearance groove on top of the tank where it's gouged, is a good idea and has no adverse effects. (as shown by surfer Kris, but he's gone to the extreme which is OK as long as there's enough metal to hold in the reed retainer).

The chaffing on the front of the tank is an entirely different problem, solved in other ways ranging from trying more (or thicker) c/case gaskets,

adding a drive shaft spacer washer up front to keep the crank end play to a minimum, or crankshaft replacement because of a tapered crankpin.

This is all ASSUMING your lower con rod hole is NOT worn or distorted. If it is, then nothing will help in this case. The design of the cox engine can

allow the con rod to walk aft until it grinds the tank back to death. Other than the tapering of the crankpin, I'm not sure what other factors are

responsible for this unwanted movement. HINT** mark one side of the conrod and try installing it the opposite way. In some cases the engine runs

better & chaffs less. It's worth a try & costs nothing...

I hope this has made it a bit clearer. Good luck!

Cheers, Paul

Perhaps it wasn't clear. That small groove on top of the tank is caused by the piston skirt hitting on it. It gets worse as the ball-socket joint loosens.

IF SPI is not a problem, cutting the bottom of the piston skirt .010" can provide the needed clearance. I hope this photo attaches OK. I am talking about shortening the piston height, not changing its diameter.

If running a muffler, this added SPI is probably not a good thing (now that I think of it).

However, filing a clearance groove on top of the tank where it's gouged, is a good idea and has no adverse effects. (as shown by surfer Kris, but he's gone to the extreme which is OK as long as there's enough metal to hold in the reed retainer).

The chaffing on the front of the tank is an entirely different problem, solved in other ways ranging from trying more (or thicker) c/case gaskets,

adding a drive shaft spacer washer up front to keep the crank end play to a minimum, or crankshaft replacement because of a tapered crankpin.

This is all ASSUMING your lower con rod hole is NOT worn or distorted. If it is, then nothing will help in this case. The design of the cox engine can

allow the con rod to walk aft until it grinds the tank back to death. Other than the tapering of the crankpin, I'm not sure what other factors are

responsible for this unwanted movement. HINT** mark one side of the conrod and try installing it the opposite way. In some cases the engine runs

better & chaffs less. It's worth a try & costs nothing...

I hope this has made it a bit clearer. Good luck!

Cheers, Paul

mmischni wrote:Hi Paul,

Thanks for the response. So it sounds like this is a problem that is not unheard of. I pushed on the crank and thought I recalled that the end play was insufficient to cause rubbing here from the crank pin, although I can't say for certain that things don't move differently while propelled by methanol!

Tell me more about relieving the piston skirt, as I don't follow how that would affect this problem. Do you mean shorten the piston by 0.010"? Or reduce its diameter by 0.010" at the bottom? If we think it is the connecting rod doing the deed, I don't see how this changes things.

Filing I am happy to do, if relieving the tank end a little is an OK solution. How far out will the connecting rod come off the pin? If I take all that tank material off, will it just walk itself right off the pin? Maybe I don't actually have that much material to remove, I don't remember how far before I get into the reed valve.

Thanks again!!

Matt

Paulgibeault- Gold Member

- Posts : 259

Join date : 2011-09-24

Location : Leduc, Alberta Canada

Re: Black Widow generating shavings in non-standard application

Re: Black Widow generating shavings in non-standard application

I've seen this happen when the nose of the crankcase and the driveplate wear down from being used as a "pusher" engine. This can also happen from the use of electric starters. The driveplate wears thinner and the nose of the crankcase wears back allowing excessive forward/backward crankshaft play, allowing the crankpin to make contact with the tank. Using a brass driveplate and thrust washers can help limit the wear.

Re: Black Widow generating shavings in non-standard application

Re: Black Widow generating shavings in non-standard application

Hi fellows,

thanks for the tips on this. I don't have contact between the piston and the reed valve area, just between the crank pin (or connecting rod) and the reed valve area. On closer inspection, the wrecked motor did indeed have some deformation where the cylinder snugs to the crankcase (left side of image). It would tend to lean the cylinder toward the crank, not away, so opposite of what I would expect to cause the issue I am seeing, but maybe.

I switched to my other crank case and crank, relieved the front of the reed valve area as much as I felt comfortable with, made a spacer for the muffler, and put it all together. Alas no not enough glow heads to risk on a scientific study, or even a test in final config! Trial by fire tomorrow. If it makes one powered run down the track, I will be happy

Also, Paul, I came across some tips on sealing these motors up written by you! So I tried to follow some of those, hoping for more consistent running. Nice tips!

Thanks again,

Matt

thanks for the tips on this. I don't have contact between the piston and the reed valve area, just between the crank pin (or connecting rod) and the reed valve area. On closer inspection, the wrecked motor did indeed have some deformation where the cylinder snugs to the crankcase (left side of image). It would tend to lean the cylinder toward the crank, not away, so opposite of what I would expect to cause the issue I am seeing, but maybe.

I switched to my other crank case and crank, relieved the front of the reed valve area as much as I felt comfortable with, made a spacer for the muffler, and put it all together. Alas no not enough glow heads to risk on a scientific study, or even a test in final config! Trial by fire tomorrow. If it makes one powered run down the track, I will be happy

Also, Paul, I came across some tips on sealing these motors up written by you! So I tried to follow some of those, hoping for more consistent running. Nice tips!

Thanks again,

Matt

mmischni- Moderate Poster

- Posts : 15

Join date : 2017-05-16

Age : 46

Location : Madison, WI

Re: Black Widow generating shavings in non-standard application

Re: Black Widow generating shavings in non-standard application

can you post some pictures of the drivetrain. They look real cool. Ken

Ken Cook- Top Poster

- Posts : 5635

Join date : 2012-03-27

Location : pennsylvania

Re: Black Widow generating shavings in non-standard application

Re: Black Widow generating shavings in non-standard application

Hi Ken,

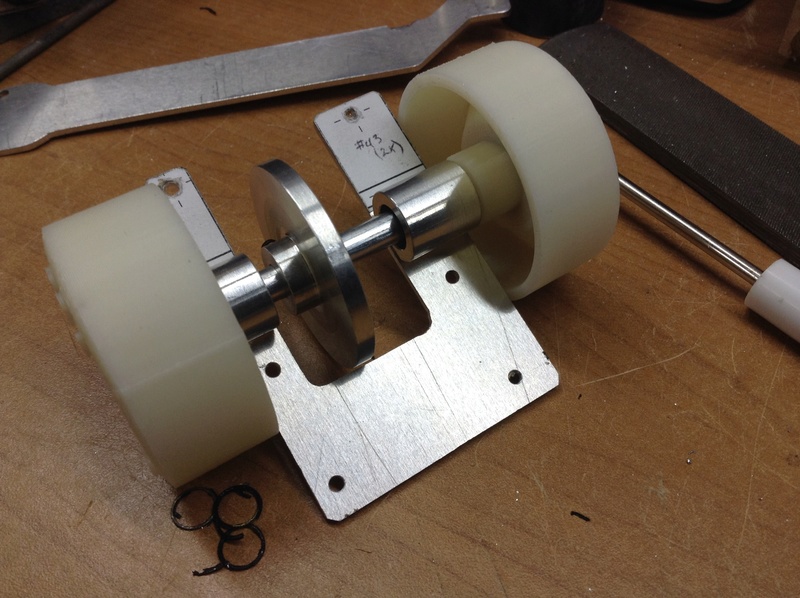

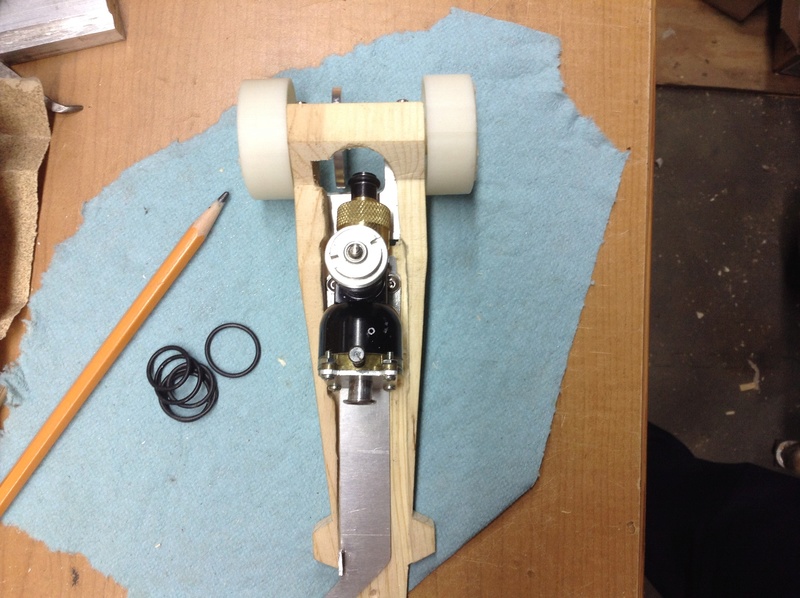

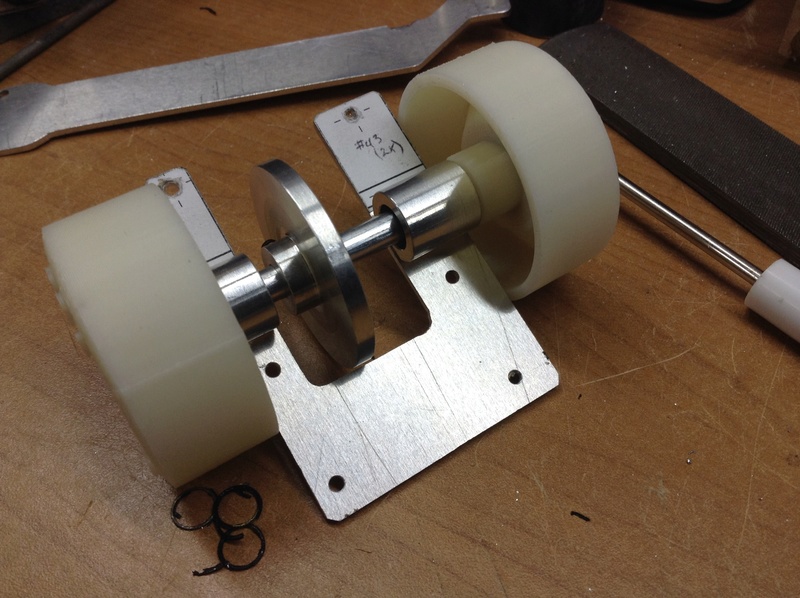

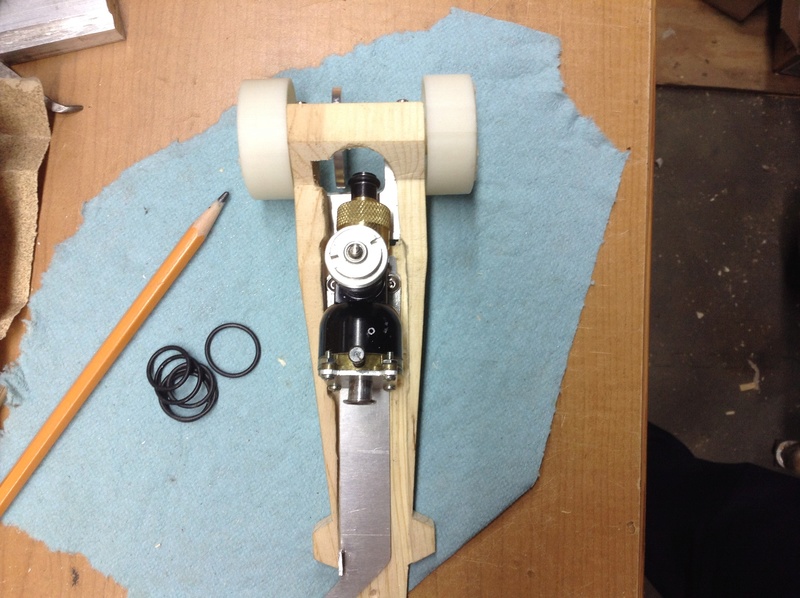

Here are some pics that should help show how it was accomplished. A couple of axle housings fastened to a plate. I have small bearings in each housing. Aluminum axle, aluminum drive plate. The engine has a brass flywheel with a cut-down prop-mounting nut on it. I also made a second threaded "lock nut" that fits inside the prop nut to try to lock it all down. Ultimately I still needed loctite! An o-ring provides the drive friction/compliance. The start pin on the derby track holds the front wings apart, which pivots the entire engine, holding the drive o-ring off the drive plate. I start the motor and load it up on the track. When the gate drops, a rubber band snaps the drive o-ring into contact with the drive plate and "dumps the clutch."

I got it running with no shrapnel produced. I had some drive train dialing-in issues that wasted my first two runs. I tried to decrease my drive ratio a bit since I was starting on a down hill, but I think I went to far. I still took first (dragster) and second (pickup truck) in the outlaw class this year. The dragster only beat the truck by a few thousandths of a second on its best recorded run (where the engine stalled part way down the track). A good typical pinewood derby car is in the neighborhood of 3 seconds. Many of the traditional cars were 3.2-3.5 seconds this race day. Races are typically won by a few 0.001 seconds. The truck and dragster got times of just over 2 seconds, and on an un-offical final run after the races, I got the dragster dialed in and ran a 1.6xx second run. It looked awesome. Left the line like a real top fuel.

Thanks again all for your help. My original problem could have been the crank shaft pin being tapered, or it could have been overspeeding things on a test run. Might also have been too much thrust and vibration caused by the alignment of my drive system. I don't know that I will know for sure. No shavings in the motor this time though, and it ran 4 runs, starting quickly each time and running as expected. If I get hold of a good video of it, I can try to share that too.

Thanks again!

Matt

Here are some pics that should help show how it was accomplished. A couple of axle housings fastened to a plate. I have small bearings in each housing. Aluminum axle, aluminum drive plate. The engine has a brass flywheel with a cut-down prop-mounting nut on it. I also made a second threaded "lock nut" that fits inside the prop nut to try to lock it all down. Ultimately I still needed loctite! An o-ring provides the drive friction/compliance. The start pin on the derby track holds the front wings apart, which pivots the entire engine, holding the drive o-ring off the drive plate. I start the motor and load it up on the track. When the gate drops, a rubber band snaps the drive o-ring into contact with the drive plate and "dumps the clutch."

I got it running with no shrapnel produced. I had some drive train dialing-in issues that wasted my first two runs. I tried to decrease my drive ratio a bit since I was starting on a down hill, but I think I went to far. I still took first (dragster) and second (pickup truck) in the outlaw class this year. The dragster only beat the truck by a few thousandths of a second on its best recorded run (where the engine stalled part way down the track). A good typical pinewood derby car is in the neighborhood of 3 seconds. Many of the traditional cars were 3.2-3.5 seconds this race day. Races are typically won by a few 0.001 seconds. The truck and dragster got times of just over 2 seconds, and on an un-offical final run after the races, I got the dragster dialed in and ran a 1.6xx second run. It looked awesome. Left the line like a real top fuel.

Thanks again all for your help. My original problem could have been the crank shaft pin being tapered, or it could have been overspeeding things on a test run. Might also have been too much thrust and vibration caused by the alignment of my drive system. I don't know that I will know for sure. No shavings in the motor this time though, and it ran 4 runs, starting quickly each time and running as expected. If I get hold of a good video of it, I can try to share that too.

Thanks again!

Matt

mmischni- Moderate Poster

- Posts : 15

Join date : 2017-05-16

Age : 46

Location : Madison, WI

Re: Black Widow generating shavings in non-standard application

Re: Black Widow generating shavings in non-standard application

Fabulous stuff there Matt, never seen anything like it. A video would be GREAT if you can do it. Cheers, Paul

Paulgibeault- Gold Member

- Posts : 259

Join date : 2011-09-24

Location : Leduc, Alberta Canada

COX 049 powered pinewood derby car

COX 049 powered pinewood derby car

Hello again,

I have posted the shortest videos and more build pictures at photobucket. I see photobucket is even worse these days with intrusive ads and failure to even work with Firefox, so sorry for that. I still have an account there and don't use such things much, so it will have to do. Hope you can get it to load. Enjoy, and thanks again for the assistance. It was a fun project and I got some minor glory out of it!

Matt

https://smg.photobucket.com/user/mmischni/library/Pinewood%20Derby

I have posted the shortest videos and more build pictures at photobucket. I see photobucket is even worse these days with intrusive ads and failure to even work with Firefox, so sorry for that. I still have an account there and don't use such things much, so it will have to do. Hope you can get it to load. Enjoy, and thanks again for the assistance. It was a fun project and I got some minor glory out of it!

Matt

https://smg.photobucket.com/user/mmischni/library/Pinewood%20Derby

mmischni- Moderate Poster

- Posts : 15

Join date : 2017-05-16

Age : 46

Location : Madison, WI

Re: Black Widow generating shavings in non-standard application

Re: Black Widow generating shavings in non-standard application

Agree with you about Photobucket. It is simply horrible to use these days. I'm abandoning that site.

706jim- Gold Member

- Posts : 472

Join date : 2013-11-29

Re: Black Widow generating shavings in non-standard application

Re: Black Widow generating shavings in non-standard application

Cool stuff Matt!! after reading the pages it sounds to me like you have alot of play in the crankcase /crank fit .. Which will surely give you some very bad runs and the wobble at the pin end can cause some contact with the tank/reed assy. If you want it to keep running (i would replace the CC assy. and crank to get rid of the movement ) I hope you atleast get the runs you need to compete !!

getback- Top Poster

Posts : 10437

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Black Widow generating shavings in non-standard application

Re: Black Widow generating shavings in non-standard application

I see part of the Genius of that rubber tension system is the engine plate has elongated holes... This (in my mind) would allow the engine to move in or out in the drive plate of the axle giving different effective gear ratios

I tend to think the drive plate needs knurling but intuitively know that will eat the O ring drive on the engine---- so I wonder if a quick smear of some sort of sticky snot like we put on slot car tiers would add a bit of anti slip to the arrangement.... but then I suppose a hole shot wheel stand is a bad thing....grin

I tend to think the drive plate needs knurling but intuitively know that will eat the O ring drive on the engine---- so I wonder if a quick smear of some sort of sticky snot like we put on slot car tiers would add a bit of anti slip to the arrangement.... but then I suppose a hole shot wheel stand is a bad thing....grin

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Black Widow generating shavings in non-standard application

Re: Black Widow generating shavings in non-standard application

Correct, I was unsure of what a good drive ratio would be. I gleaned from the interwebs that cox cars appeared to be about 4:1. Best I could do with the parts/constraints I had was 3.3:1 so I figured with starting on a downhill, that might be OK. I tried altering the ratio for higher top speed (i always forget, is that increasing or decreasing the ratio?), but it tended to stall the engine. That led me to think that a softer clutch engagement might be in order. Cleaning that drive plate and o-ring with denatured alcohol right before the race made for an awfully sticky setup, so not sure any additive is necessary. I actually thought my limitation would be traction between wheels and the track, but since I was stalling the engine, that may not be the case.

If I run it next year, I may try for softer rubber band tension to let it "slip the clutch" a bit until the wheel speed comes up some more. Then maybe I get higher speeds without a stall. And maybe new o-rings after each race! So many variables, so few races to dial it in!

getback, I did end up swapping the crankcase as the original was tweaked when the plane it came from crashed. I hadn't observed that before. Not sure if the crankcase fixed the problem,a s I changed too many variables, but it is possible! I did get successful runs. I hope to compile a few more and better videos and maybe get it on youtube for better viewing. Got to figure out how to convert .MTS files to something I can edit first...

Matt

If I run it next year, I may try for softer rubber band tension to let it "slip the clutch" a bit until the wheel speed comes up some more. Then maybe I get higher speeds without a stall. And maybe new o-rings after each race! So many variables, so few races to dial it in!

getback, I did end up swapping the crankcase as the original was tweaked when the plane it came from crashed. I hadn't observed that before. Not sure if the crankcase fixed the problem,a s I changed too many variables, but it is possible! I did get successful runs. I hope to compile a few more and better videos and maybe get it on youtube for better viewing. Got to figure out how to convert .MTS files to something I can edit first...

Matt

mmischni- Moderate Poster

- Posts : 15

Join date : 2017-05-16

Age : 46

Location : Madison, WI

Re: Black Widow generating shavings in non-standard application

Re: Black Widow generating shavings in non-standard application

Matt

Are the chassis metal pieces/parts sold already cut and bent? Or are they home made from a common template and bend profile?

I still have a few younger grand children and when they visited last year, I got some Pine wood derby car kits and made a track for them to build and play on

adding top fuel racing on a drag strip would be a cool project for next years visit (too little time this year)

I would like to see more photos of the entire system mostly how the nose trip system is keyed

and notes about the cars, rear ends, sources of your own and the other competitors in your OutLaw group

Hint for next race...Humm don't know the rules...

But if legal, I would make the drive sticky like you did, but put a very thin smear of castor on the Tires and let them initially burn out as gravity moves them down the track and as they self clean then more and more traction

Are the chassis metal pieces/parts sold already cut and bent? Or are they home made from a common template and bend profile?

I still have a few younger grand children and when they visited last year, I got some Pine wood derby car kits and made a track for them to build and play on

adding top fuel racing on a drag strip would be a cool project for next years visit (too little time this year)

I would like to see more photos of the entire system mostly how the nose trip system is keyed

and notes about the cars, rear ends, sources of your own and the other competitors in your OutLaw group

Hint for next race...Humm don't know the rules...

But if legal, I would make the drive sticky like you did, but put a very thin smear of castor on the Tires and let them initially burn out as gravity moves them down the track and as they self clean then more and more traction

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Black Widow generating shavings in non-standard application

Re: Black Widow generating shavings in non-standard application

Hi Fred,

Most everything was custom made for this. Since this car was much more involved than the Jeep, I actually drew this one up in CAD to make sure I could get it all in and aligned. I also did some drive ratio calcs to make sure I could fit the size drive parts I needed. For most parts I just printed out line drawings to scale, taped them on the material, and cut, drilled, and filed to the lines. I have other pictures, maybe I should put them on another thread. I have already posted most of the pics I have that show how the mech works. The rear end was all custom made, designed around RC bearings I already had. The friction drive I conceived of since it is more forgiving of alignment than gears (and easier to make!) and I thought I could make use of "tunability" of being able to easily alter drive ratio as you observed. As the thought process progressed, I was also able to use that to my advantage for the clutch/launch control mechanism as well.

Watch out for different track styles. I knew we were using an aluminum Best Track and made use of that track's features. This car will not run on a wooden track with a solid center section. My drive flange extends almost to the "road" between the rear wheels. Dimensions of Best Track are online, but check on what you will be racing on. Also, as you noted, find out the rules. I have seen Outlaw classes that still require 5oz weight limit, which I would not meet. Mine also violates the common requirement that no part of the car extend past the start pin (which my front wing most certainly does). Our Outlaw rules were pretty basic. "Fits on the track, doesn't damage the track, doesn't interfere with other cars."

Limiting traction is an interesting idea to soften the hook-up. I actually was worried about all the castor I would be leaving on the track unintentionally! I wiped it all down after the race since the track was borrowed from a local scout pack. Castor on the wheels also sounds hard to "tune" if it doesn't work as expected. But I am pretty sure you would still run faster than a gravity-powered entry even with a full film of oil between the tires and the track!

Matt

Most everything was custom made for this. Since this car was much more involved than the Jeep, I actually drew this one up in CAD to make sure I could get it all in and aligned. I also did some drive ratio calcs to make sure I could fit the size drive parts I needed. For most parts I just printed out line drawings to scale, taped them on the material, and cut, drilled, and filed to the lines. I have other pictures, maybe I should put them on another thread. I have already posted most of the pics I have that show how the mech works. The rear end was all custom made, designed around RC bearings I already had. The friction drive I conceived of since it is more forgiving of alignment than gears (and easier to make!) and I thought I could make use of "tunability" of being able to easily alter drive ratio as you observed. As the thought process progressed, I was also able to use that to my advantage for the clutch/launch control mechanism as well.

Watch out for different track styles. I knew we were using an aluminum Best Track and made use of that track's features. This car will not run on a wooden track with a solid center section. My drive flange extends almost to the "road" between the rear wheels. Dimensions of Best Track are online, but check on what you will be racing on. Also, as you noted, find out the rules. I have seen Outlaw classes that still require 5oz weight limit, which I would not meet. Mine also violates the common requirement that no part of the car extend past the start pin (which my front wing most certainly does). Our Outlaw rules were pretty basic. "Fits on the track, doesn't damage the track, doesn't interfere with other cars."

Limiting traction is an interesting idea to soften the hook-up. I actually was worried about all the castor I would be leaving on the track unintentionally! I wiped it all down after the race since the track was borrowed from a local scout pack. Castor on the wheels also sounds hard to "tune" if it doesn't work as expected. But I am pretty sure you would still run faster than a gravity-powered entry even with a full film of oil between the tires and the track!

Matt

mmischni- Moderate Poster

- Posts : 15

Join date : 2017-05-16

Age : 46

Location : Madison, WI

Re: Black Widow generating shavings in non-standard application

Re: Black Widow generating shavings in non-standard application

Finally got around to putting together some of the videos from the races. Enjoy!

https://youtu.be/j1ZbApqToRw

Matt

https://youtu.be/j1ZbApqToRw

Matt

mmischni- Moderate Poster

- Posts : 15

Join date : 2017-05-16

Age : 46

Location : Madison, WI

Similar topics

Similar topics» estes black widow ?

» Black Widow "touch up"?

» '73 Black Widow

» A REALLY Big Black Widow !!!

» black window questions

» Black Widow "touch up"?

» '73 Black Widow

» A REALLY Big Black Widow !!!

» black window questions

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules