Log in

Search

Latest topics

» Tee Dee .020 combat modelby TD ABUSER Today at 12:38 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Free Flight Radio Assist

by rdw777 Yesterday at 4:51 pm

» Purchased the last of any bult engines from Ken Enya

by getback Yesterday at 12:05 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

Cox Engine of The Month

Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Page 27 of 30

Page 27 of 30 •  1 ... 15 ... 26, 27, 28, 29, 30

1 ... 15 ... 26, 27, 28, 29, 30

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Two can play at that

Gliders are doing over 500mph now (no motor). Also, they are measuring the speed after a U-turn, lol.

Honestly, I was showing the very high G turns in the video I posted, not so much the speed.

Gliders are doing over 500mph now (no motor). Also, they are measuring the speed after a U-turn, lol.

Honestly, I was showing the very high G turns in the video I posted, not so much the speed.

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

On a 049 motor, does someone know the conrod length? I googled it without any luck. tia!

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Surfer_kris wrote:That's nothing

Take a 12x24" prop and spin it up to around 27000rpm, that's good for about 280Mph:

Maybe half that RPM. Ralk Okon went about that fast with 8kRPM and a 12.5x44.5" 5 blade prop. http://www.speedcroco.de/4550-yge160evo-5-blatt.html

gkamysz- Gold Member

- Posts : 414

Join date : 2018-02-22

Location : Chicagoland

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

--Oz-- wrote:On a 049 motor, does someone know the conrod length? I googled it without any luck. tia!

What do you need the conrod length for? Or do you mean the distance from the big-end to the top of the piston?

If you want to calculate the difference in timing when you move the cylinder, it is the stroke that is important and it should be 0.386" (AFAIK).

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Surfer_kris wrote:--Oz-- wrote:On a 049 motor, does someone know the conrod length? I googled it without any luck. tia!

What do you need the conrod length for? Or do you mean the distance from the big-end to the top of the piston?

If you want to calculate the difference in timing when you move the cylinder, it is the stroke that is important and it should be 0.386" (AFAIK).

Rod length is required to calculate port timing from crank angle and height.

gkamysz- Gold Member

- Posts : 414

Join date : 2018-02-22

Location : Chicagoland

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

gkamysz wrote:Rod length is required to calculate port timing from crank angle and height.

Yep, thats exactly what I want it for!

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

At the position of the crank were the exhaust opens/closes the length of the rod is not that important. The distance from the crank pin to the crank center is the most important parameter.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Surfer_kris wrote:At the position of the crank were the exhaust opens/closes the length of the rod is not that important. The distance from the crank pin to the crank center is the most important parameter.

Sorry, but the error is too large to omit.

gkamysz- Gold Member

- Posts : 414

Join date : 2018-02-22

Location : Chicagoland

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

gkamysz wrote:Surfer_kris wrote:That's nothing

Take a 12x24" prop and spin it up to around 27000rpm, that's good for about 280Mph:

Maybe half that RPM. Ralk Okon went about that fast with 8kRPM and a 12.5x44.5" 5 blade prop. http://www.speedcroco.de/4550-yge160evo-5-blatt.html

Yes, the numbers don't seem to add up...

I was quoting the numbers provided by the pilot, but I guess those might be doppler "inflated".

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

gkamysz wrote:Surfer_kris wrote:At the position of the crank were the exhaust opens/closes the length of the rod is not that important. The distance from the crank pin to the crank center is the most important parameter.

Sorry, but the error is too large to omit.

I will have to check it in detail for a cox engine then. For large exhaust durations and small changes of the cylinder height I have found it to be negligible in the past. The big end of the conrod will then mainly move up and down, the sideways motion can be neglected.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

http://sceptreflight.com/Model%20Engine%20Tests/Cox%20Tee%20Dee%20049.html

Per link TD .049:

Bore: .01406"

Stroke: .386"

Swept Volume: .499 cu in. / .8177cc

Stroke / Bore Ratio: .951:1

Valve Timing: 50° ABDC to 45° ATDC

Dyno:

.145hp / 108w at 21k (30% nitro)

Torque 8.1 oz. in. at 14k nearly maintains to 20k

Per link TD .049:

Bore: .01406"

Stroke: .386"

Swept Volume: .499 cu in. / .8177cc

Stroke / Bore Ratio: .951:1

Valve Timing: 50° ABDC to 45° ATDC

Dyno:

.145hp / 108w at 21k (30% nitro)

Torque 8.1 oz. in. at 14k nearly maintains to 20k

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

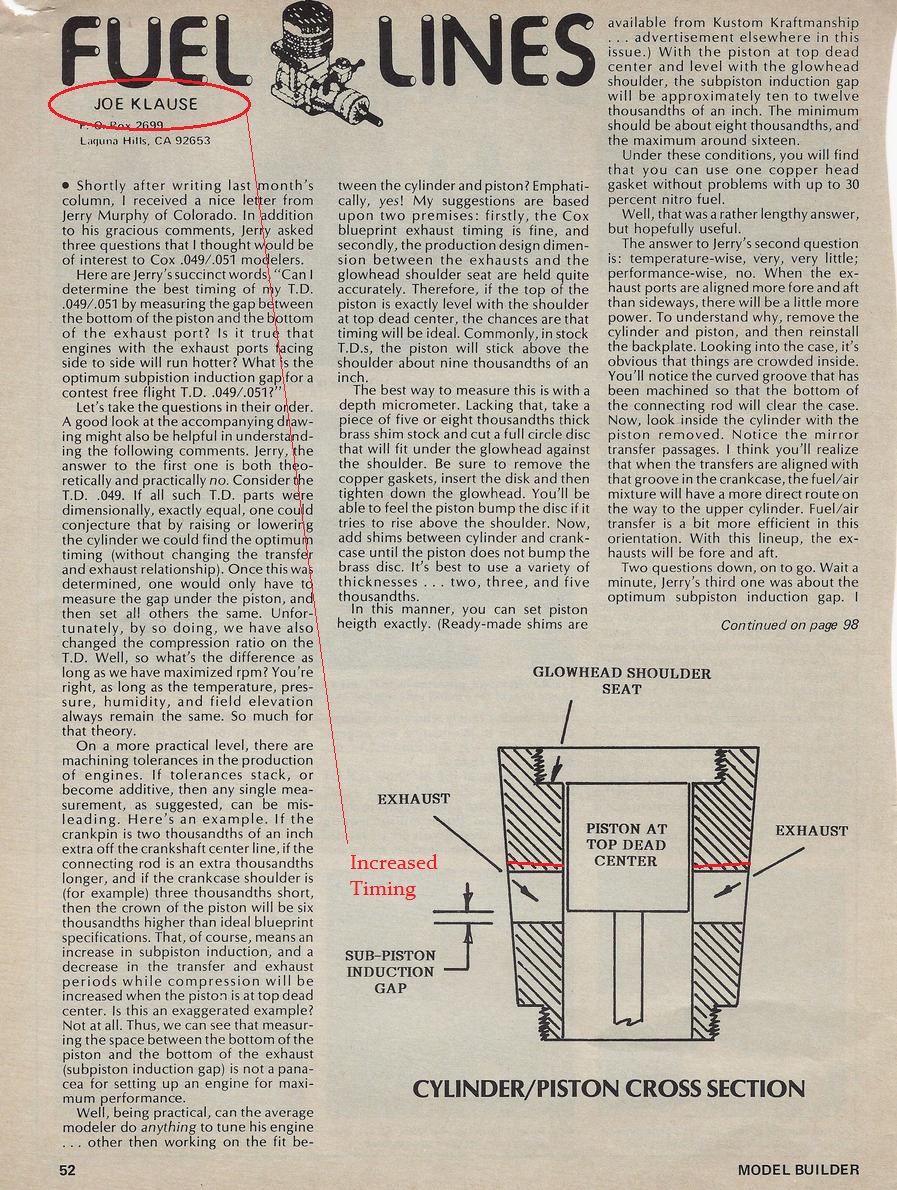

Okej, I've checked the maths for an exhaust duration of 130°, which is about right for the cox .049 engines I think (I haven't measured mine). By totally neglecting the influence of a conrod (i.e. assuming an infinitely long rod) we get an error of about 10% in the piston height (for a 1° rotation around the exhaust port closing/opening). To me this is negligible, but it means that we should move the cylinder about 10% more than what we think from looking at the vertical movement of the crank-pin only.

So a cylinder shim of .0046" will change the port timing by about 1.5° (and the duration by 3°) using the approximation, while a more correct calculation gives that about .005" is needed for that timing change.

The crudest and quickest calculation is to simply look at the movement around 90° ABDC. The required shim thickness is then simply: 0.386"/2*sin(1.5°)≈0.00505"

So, again this is close enough for some practical trial and error testing, as I see it.

So a cylinder shim of .0046" will change the port timing by about 1.5° (and the duration by 3°) using the approximation, while a more correct calculation gives that about .005" is needed for that timing change.

The crudest and quickest calculation is to simply look at the movement around 90° ABDC. The required shim thickness is then simply: 0.386"/2*sin(1.5°)≈0.00505"

So, again this is close enough for some practical trial and error testing, as I see it.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

If you are making a relative change, yes. Making a relative change I don't think anyone cares about the actual angle, you just add a shim and see what happens. So who would bother calculating anything?

Calculating duration from geometry while neglecting rod angle results in a large error.

Calculating duration from geometry while neglecting rod angle results in a large error.

gkamysz- Gold Member

- Posts : 414

Join date : 2018-02-22

Location : Chicagoland

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Some pilots talk about timing degrees for say exhaust. Lowering the cylinder from 0.0 to say 0.025 (in 0.005 increments) I wanted to see the timing difference in degree and % numbers. So I just need the conrod length to work out the numbers, weird its not easily found with google.

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

It is easier just to use a timing wheel.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

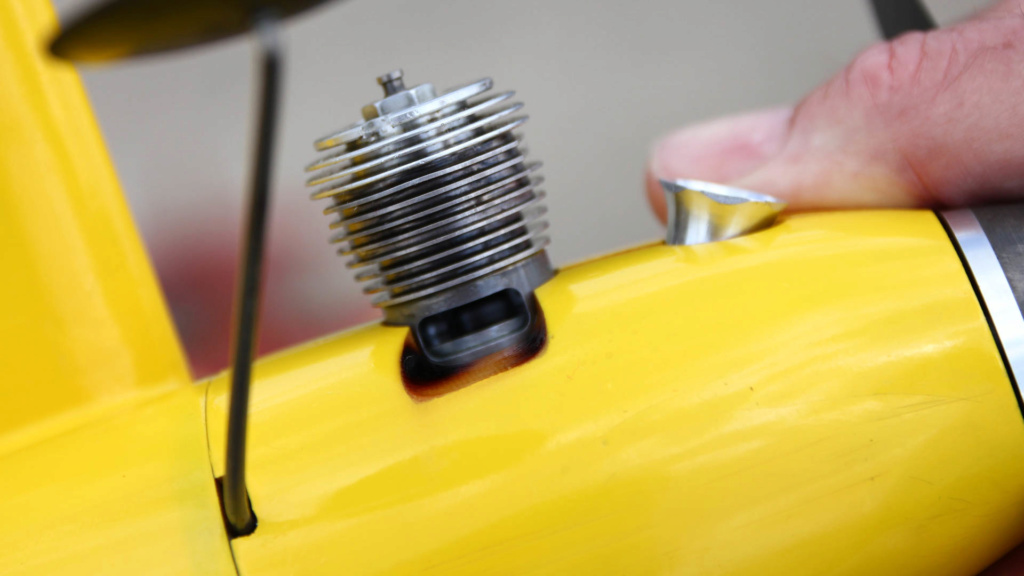

The best way to get a good jump in timing is to file the exhaust port on the top side.

You can march along removing a given amount until the prop rpm levels off.

At 170° really is the limit with these simple Cox engines. I use a starter so no big deal.

With a tuned pipe a angled cut is best to shove in as much charge density as possible.

Nothing on page 98 but a rap up, a few words and thanks for the questions.

A bundle of articles on my speed thread at RCG. Huge efforts to gain engine performance and with tune pipes.

Today all that is needed is good machined sealed cnc manifold header and a Profi pipe with zero mods to a SPI engine.

++A double tap system is in play the pipe is feeding the engine through the SPI gate too / two fold power induction.

Plug and play now for what consumed hundreds of hours in the 70's of trial and error.

https://www.rcgroups.com/forums/showthread.php?2684743-Speed-Planes-010-to-15-Size-Engines/page9#post37321755

3rd flight and already blown away anything ever done with the TD. Yes it's fun to mess with the engines, design the planes but

if you are not getting out under the blue skies flying you've missed out on the cream of the hobby experience. I am guilty of

proof of concept and moving on to the next challenge myself. Kris still looking forward to your VA .020 project flying with that

lovely DIY exhaust system.

You can march along removing a given amount until the prop rpm levels off.

At 170° really is the limit with these simple Cox engines. I use a starter so no big deal.

With a tuned pipe a angled cut is best to shove in as much charge density as possible.

Nothing on page 98 but a rap up, a few words and thanks for the questions.

A bundle of articles on my speed thread at RCG. Huge efforts to gain engine performance and with tune pipes.

Today all that is needed is good machined sealed cnc manifold header and a Profi pipe with zero mods to a SPI engine.

++A double tap system is in play the pipe is feeding the engine through the SPI gate too / two fold power induction.

Plug and play now for what consumed hundreds of hours in the 70's of trial and error.

https://www.rcgroups.com/forums/showthread.php?2684743-Speed-Planes-010-to-15-Size-Engines/page9#post37321755

3rd flight and already blown away anything ever done with the TD. Yes it's fun to mess with the engines, design the planes but

if you are not getting out under the blue skies flying you've missed out on the cream of the hobby experience. I am guilty of

proof of concept and moving on to the next challenge myself. Kris still looking forward to your VA .020 project flying with that

lovely DIY exhaust system.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Yes, if you file the exhaust, that is the only change being made, everything else stays the same.

I spend the day at a local CL speed event hosted by Bill Hughes. I got to watch Sasha Valishev fly his F2A at 305kph and get a taste what it takes to make that kind of performance consistently. All the Profi F2A engines are guaranteed to go 290, but essentially none are winners out of the box. There is a tremendous amount of work, tuning, and testing that goes into being a world class competitor.

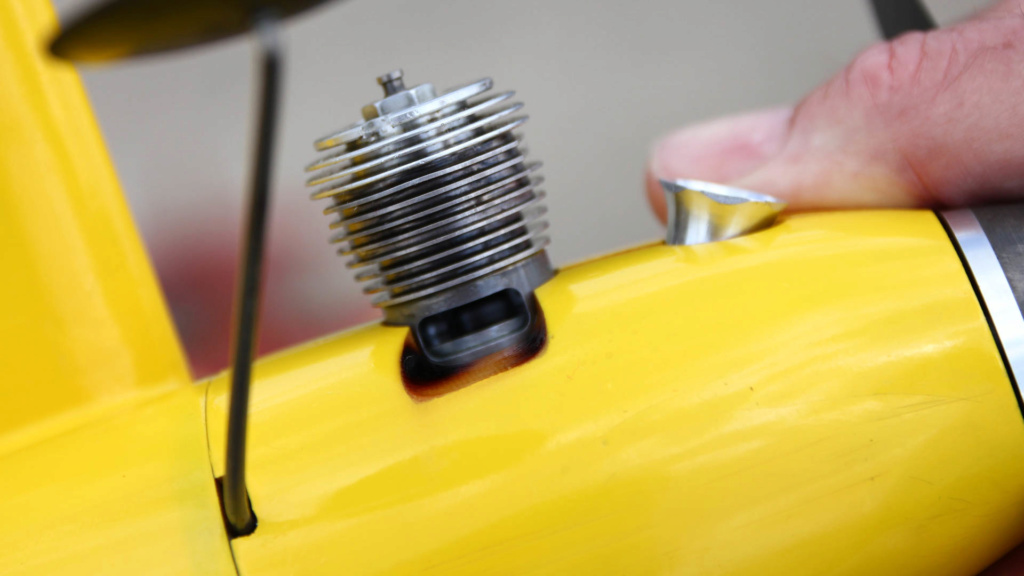

Want to see some magic, true Cox unobtanium? An AAC schneurle TD .15 made by Carl Dodge. Carl made the parts Henry Nelson did the chrome.

I spend the day at a local CL speed event hosted by Bill Hughes. I got to watch Sasha Valishev fly his F2A at 305kph and get a taste what it takes to make that kind of performance consistently. All the Profi F2A engines are guaranteed to go 290, but essentially none are winners out of the box. There is a tremendous amount of work, tuning, and testing that goes into being a world class competitor.

Want to see some magic, true Cox unobtanium? An AAC schneurle TD .15 made by Carl Dodge. Carl made the parts Henry Nelson did the chrome.

gkamysz- Gold Member

- Posts : 414

Join date : 2018-02-22

Location : Chicagoland

gkamysz- Gold Member

- Posts : 414

Join date : 2018-02-22

Location : Chicagoland

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Yes once the engine is set up for best deck height and cylinder orientation.

A simple first effort is to round off all outside edges of the exhaust port to

improve influx and top and sides on the inside.

My goal was to show whats possible bone stock so anyone could repeat the

effort given the right prop and plane size / weight. Kamtechnik ruled the day

with two key parts.

Once you start mods to the engine folks write if off as mystical magic / cheats for speed.

All the same at some point I want to increase timing to evaluate the differences.

At 160° the NV should still be quite tame if the intake is not over bored. I may add

a pressure tap to the pipe if the venturi gets drilled out.

Thank you for sharing Greg,

Great examples of form and function = IC candy.

Shame the engines have to be covered up but understandable.

Regarding the .15

I wonder what sort of power out and prop was used. May have a

lower case with bearings too. Bummer part of competition is

everyone minimizes exposure to keep an edge. Doing a search

nothing came up.

Carl in action going through the motions.

Carl Dodge F2A CL Speed model (1972, 1976, 1982)

Published on Apr 24, 2016

This is the model that Carl Dodge flew in the 1972, 1976 and 1982 FAI World Championships in F2A speed.

You will probably notice the format of the model has changed over the years. Now the models typically have

the single wing on the left side of the model. Carl was the 2014 World Champion in F2A speed.

Carl flew 139 mph on this flight imagine the amount of power / speed lost to the lines.

Carl Dodge shares how he got involved in model aviation and what got him started in Control Line

A simple first effort is to round off all outside edges of the exhaust port to

improve influx and top and sides on the inside.

My goal was to show whats possible bone stock so anyone could repeat the

effort given the right prop and plane size / weight. Kamtechnik ruled the day

with two key parts.

Once you start mods to the engine folks write if off as mystical magic / cheats for speed.

All the same at some point I want to increase timing to evaluate the differences.

At 160° the NV should still be quite tame if the intake is not over bored. I may add

a pressure tap to the pipe if the venturi gets drilled out.

Thank you for sharing Greg,

Great examples of form and function = IC candy.

Shame the engines have to be covered up but understandable.

Regarding the .15

I wonder what sort of power out and prop was used. May have a

lower case with bearings too. Bummer part of competition is

everyone minimizes exposure to keep an edge. Doing a search

nothing came up.

Carl in action going through the motions.

Carl Dodge F2A CL Speed model (1972, 1976, 1982)

Published on Apr 24, 2016

This is the model that Carl Dodge flew in the 1972, 1976 and 1982 FAI World Championships in F2A speed.

You will probably notice the format of the model has changed over the years. Now the models typically have

the single wing on the left side of the model. Carl was the 2014 World Champion in F2A speed.

Carl flew 139 mph on this flight imagine the amount of power / speed lost to the lines.

Carl Dodge shares how he got involved in model aviation and what got him started in Control Line

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Around 1977 Carl was using an asymmetrical plane already, and going faster than that IIRC. It used a venetian blind for a wing. He crashed it at the Canadian Nat's when the pylon pulled out of the ground. We were all using Rossi .15s, I think he built his own motor from barstock about that time. He was a bit quicker than 140 mph, I was doing around 140 +around 1979, and he was a fair bit better than me.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

soh cah toa Probably tangent opposite adjacent. I would guess the stroke and your .025" Then multiply by two for the total duration. Maybe rod length should be in the equation, even this would make me think for more than three minutes. Like I said before. A degree wheel.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Page 27 of 30 •  1 ... 15 ... 26, 27, 28, 29, 30

1 ... 15 ... 26, 27, 28, 29, 30

Similar topics

Similar topics» CG on Speed Contest Planes

» Anyone here into Giant Scale R/C Planes? Post Pics of your Planes.

» Fellow speed freaks, help me build a pair of speed Bees.

» CL planes...

» How many cox planes do you have?

» Anyone here into Giant Scale R/C Planes? Post Pics of your Planes.

» Fellow speed freaks, help me build a pair of speed Bees.

» CL planes...

» How many cox planes do you have?

Page 27 of 30

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules