Log in

Search

Latest topics

» Free Flight Radio Assist by GallopingGhostler Today at 12:54 pm

» My N-1R build log

by akjgardner Today at 12:39 pm

» Purchased the last of any bult engines from Ken Enya

by getback Today at 12:05 pm

» Funny what you find when you go looking

by rsv1cox Yesterday at 3:21 pm

» Landing-gear tips

by 1975 control line guy Yesterday at 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» My latest doodle...

by TD ABUSER Mon Nov 18, 2024 11:30 am

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

» Tribute Shoestring build

by amurphy6812 Sun Nov 17, 2024 5:43 pm

Cox Engine of The Month

Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Page 29 of 30

Page 29 of 30 •  1 ... 16 ... 28, 29, 30

1 ... 16 ... 28, 29, 30

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thanks, Brad,

yes, exactly as you advised, I chamfered the header entry.

Why do we use 140 for the timing here, instead of the 160 used in the earlier formula? Even if SPI, the exhaust timing remains the same as in a non-SPI cylinder??

I also noted, that the Kyosho muffler may not allow the cylinder thread to fully bottom out in the crankcase, and it may slightly reduce the compression ratio to some extent, albeit not so much that would justify the limping of the engine well below 20k. I did not want to force the cylinder to fully screw in against the Kyosho muffler, but will see if repeated spanning of the cylinder will cause the aluminum header to yield/wear some and the components will finally settle..

yes, exactly as you advised, I chamfered the header entry.

Why do we use 140 for the timing here, instead of the 160 used in the earlier formula? Even if SPI, the exhaust timing remains the same as in a non-SPI cylinder??

I also noted, that the Kyosho muffler may not allow the cylinder thread to fully bottom out in the crankcase, and it may slightly reduce the compression ratio to some extent, albeit not so much that would justify the limping of the engine well below 20k. I did not want to force the cylinder to fully screw in against the Kyosho muffler, but will see if repeated spanning of the cylinder will cause the aluminum header to yield/wear some and the components will finally settle..

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

That was an example using another engine, you must know timing per engine type.

TD timing is typically 140 degrees, but can vary between 140 - 145

Per post:

1/2A Nut on Sun Oct 04, 2020 10:41 pm

Formula to sort out setting up the pipe example:

- 1675(wave speed) x 160(timing) ÷ 8.5 (pipe length) = 31.53K rpm

Constant:

1675(wave speed) x ___(timing) ÷ ____ (pipe length) = ____rpm

For the cylinder mark location when it seats without the manifold on.

Can very carefully flat sand the manifold - adjusted / small amounts or

you risk loss of a tight seal. Set the manifold tight just before the marked location.

Or allow it to wear in Kyosho did the right thing

to have it a bit off to insure all engines seal the manifold.

Forget your poor results with the wrong prop.

Do you have a 4x4 / 4.2x4 / 4.4x3 / 4.6x3 to properly test the pipe on the bench?

TD timing is typically 140 degrees, but can vary between 140 - 145

Per post:

1/2A Nut on Sun Oct 04, 2020 10:41 pm

Formula to sort out setting up the pipe example:

- 1675(wave speed) x 160(timing) ÷ 8.5 (pipe length) = 31.53K rpm

Constant:

1675(wave speed) x ___(timing) ÷ ____ (pipe length) = ____rpm

For the cylinder mark location when it seats without the manifold on.

Can very carefully flat sand the manifold - adjusted / small amounts or

you risk loss of a tight seal. Set the manifold tight just before the marked location.

Or allow it to wear in Kyosho did the right thing

to have it a bit off to insure all engines seal the manifold.

Forget your poor results with the wrong prop.

Do you have a 4x4 / 4.2x4 / 4.4x3 / 4.6x3 to properly test the pipe on the bench?

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

How many head shims are you using?

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thanks Brad. Will check if I have the exact same props hou mentioned. I use 1 shim only but suspect that the cylinder does not bottom out. However I will look at the exact position through the cylinder top before and after the Kyosho is added.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Yes good to know just where the cylinder is at, 1 shim is good to make up for the variance.

With the plug off you can check the deck height with one shim.

With the plug off you can check the deck height with one shim.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Kamtechnik Nelson Plug Turbo Plug Adapters has been tested and now

the web site has been updated with new product slots opening up soon

to have stock in hand perhaps by this week.

https://kamtechnik.com/shop/

Kamtechnik Nelson Plug adapter test / Piped 1996 Killer Bee .049

APC 4.6x3 prop / best static 22,609 / 10.4oz thrust / 64 mph PS

.111hp - 82w / if this prop is used to fly it will unload and stage

on the pipe likely boost to unload at 27.5 -28k / 80mph PS

For speed a 4.4x4.5N 120 mph PS expected.

the web site has been updated with new product slots opening up soon

to have stock in hand perhaps by this week.

https://kamtechnik.com/shop/

Kamtechnik Nelson Plug adapter test / Piped 1996 Killer Bee .049

APC 4.6x3 prop / best static 22,609 / 10.4oz thrust / 64 mph PS

.111hp - 82w / if this prop is used to fly it will unload and stage

on the pipe likely boost to unload at 27.5 -28k / 80mph PS

For speed a 4.4x4.5N 120 mph PS expected.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

All the .020 turbo heads sold out already  totally missed out on the first batch.

totally missed out on the first batch.

Jason_WI- Top Poster

Posts : 3123

Join date : 2011-10-09

Age : 49

Location : Neenah, WI

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

I guess the out of stock on his website means the stock has not been filled yet...Greg wrote in a post here that he just starts the 020 and 090 turbo head serial production after the prototypes tested well.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

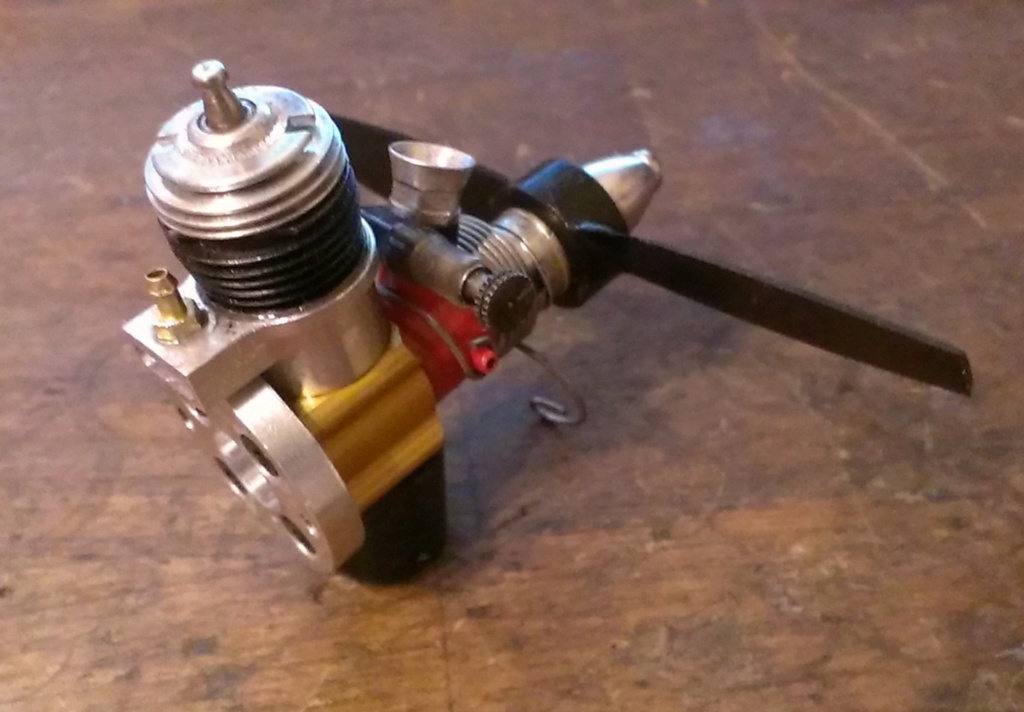

Now that the magic dust has been applied to the Cox.020 displacement Greg

is going into mill time and is willing to sort out an adapter replacement for the VA .020.

Extra power will likely be had by following the current .020 chamber design.

Best rpm sticking to two shims with the APC 4.2x2 each engine will be a

bit different in shim count older engines will only need 1 shim.

Some of my findings during testing:

Compression volume is not the only factor once a given ratio is found,

chamber shape improves and squeaks out further power. The number of

samples tested and those modified helped to sniff out which direction to

go keeping perseverance alive and suitable use of the prototypes around

14 in total. The cox 4.5x2 is a real challenge to hit 19k some engine out

of the box can hit that number, 20k static is possible with further efforts

to improve the timing / deck height of the piston. The crank window can

be sharpened on the rotation side to improve intake.

What mattered beyond compression ratio,

-Proximity of the element to piston face

-Transition shape from shim line to plug face

-Charge concentration across a given percentage of the piston face / what best serves the load of the 4.5x2

-Improvements by sound distinction / variances the adapter shape makes / loud, hollow thru peaky sharp notes.

-Full spread vs narrow concentration of force pressure to piston face, horn, cone and bowl shape diameters all

have their attributes. Providing enough spread to counter the load leaves the rest of blast rate to focus on ramping

up best possible time / rpm.

I am looking forward to testing speed props with the product adapter.

So far with a previous prototype modified for suitable use:

This is J4 the one that has finally brought out the last bit of rpm out of the test

engine. It has been widely used for all the prototypes. A fresh piston cylinder

with good seal will likely hit 19k + Shown with a Cox grey 4.5x2

is going into mill time and is willing to sort out an adapter replacement for the VA .020.

Extra power will likely be had by following the current .020 chamber design.

Best rpm sticking to two shims with the APC 4.2x2 each engine will be a

bit different in shim count older engines will only need 1 shim.

Some of my findings during testing:

Compression volume is not the only factor once a given ratio is found,

chamber shape improves and squeaks out further power. The number of

samples tested and those modified helped to sniff out which direction to

go keeping perseverance alive and suitable use of the prototypes around

14 in total. The cox 4.5x2 is a real challenge to hit 19k some engine out

of the box can hit that number, 20k static is possible with further efforts

to improve the timing / deck height of the piston. The crank window can

be sharpened on the rotation side to improve intake.

What mattered beyond compression ratio,

-Proximity of the element to piston face

-Transition shape from shim line to plug face

-Charge concentration across a given percentage of the piston face / what best serves the load of the 4.5x2

-Improvements by sound distinction / variances the adapter shape makes / loud, hollow thru peaky sharp notes.

-Full spread vs narrow concentration of force pressure to piston face, horn, cone and bowl shape diameters all

have their attributes. Providing enough spread to counter the load leaves the rest of blast rate to focus on ramping

up best possible time / rpm.

I am looking forward to testing speed props with the product adapter.

So far with a previous prototype modified for suitable use:

This is J4 the one that has finally brought out the last bit of rpm out of the test

engine. It has been widely used for all the prototypes. A fresh piston cylinder

with good seal will likely hit 19k + Shown with a Cox grey 4.5x2

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

First off The Pipes look really Good for the Mark .15 that should bee interesting ,, The TD .020 was screaming !!! Thats cool the hd. will bee avaible soon Thanks for letting us Know

getback- Top Poster

Posts : 10439

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

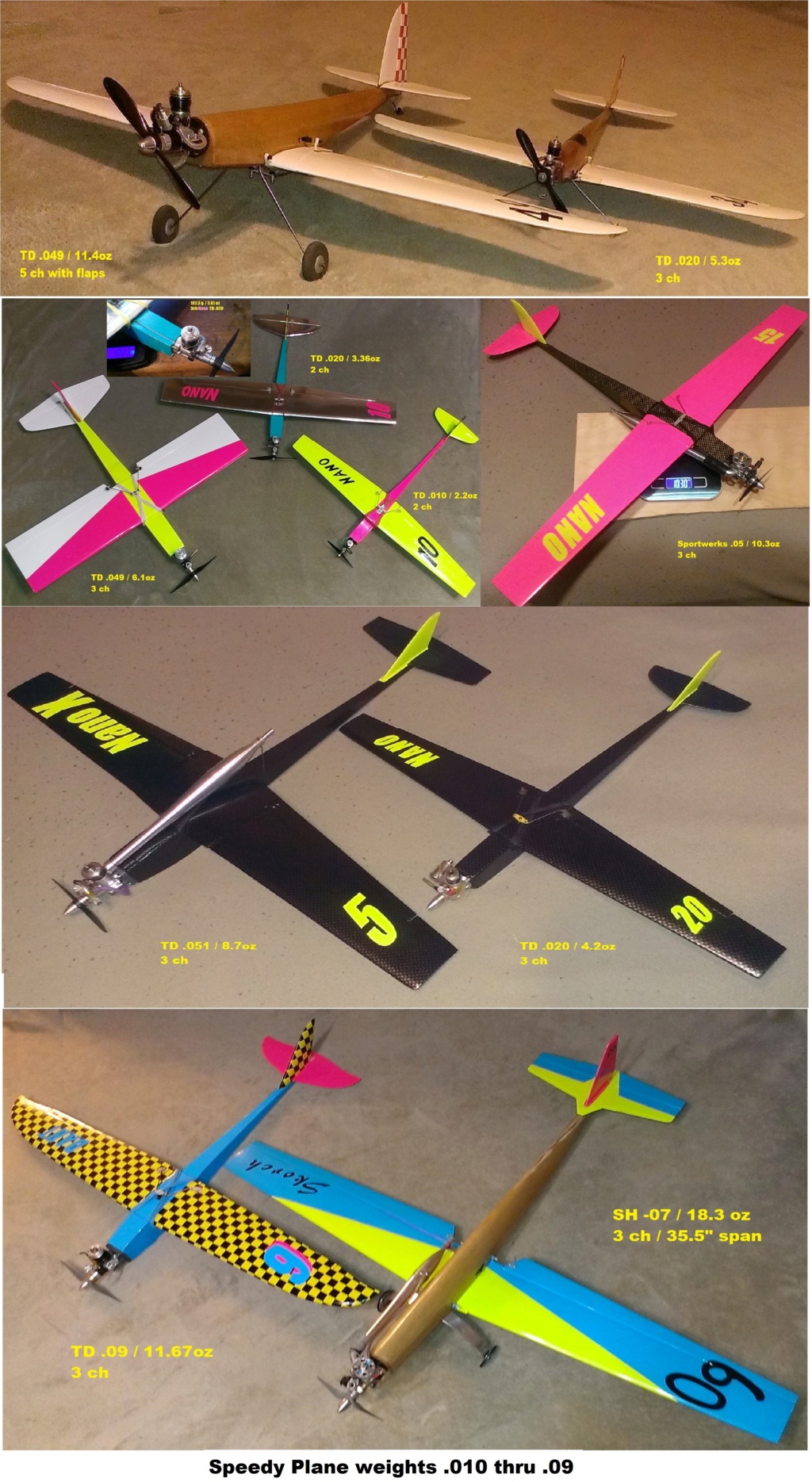

Thank you Gents looks like the ball is rolling again!

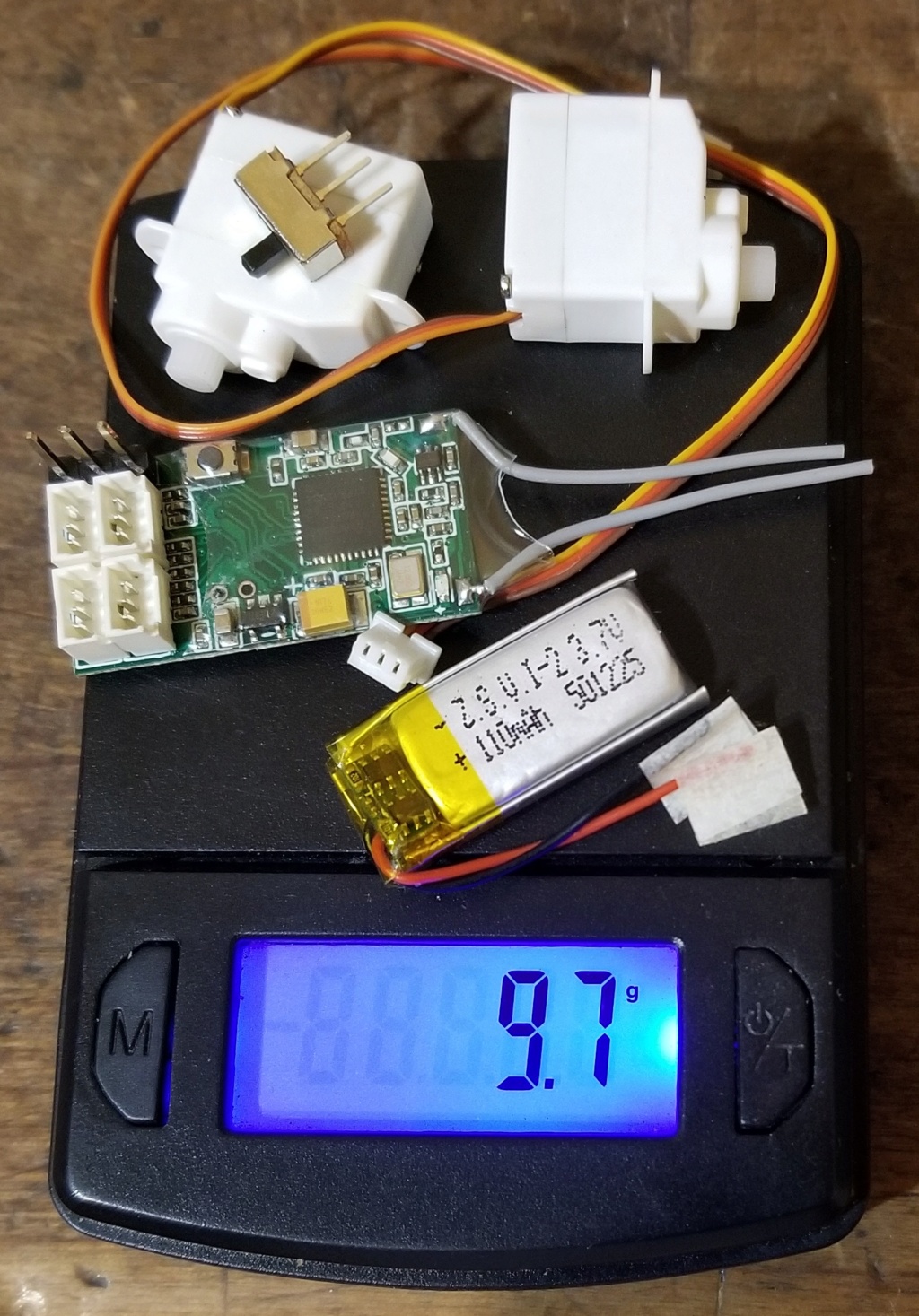

I was given 4 items in the last package sent to finalize, 3 down one more to test.

Some good ole goo control to help keep .020 projects cleaner and it adds a bit of

back pressure for RC carbs. Fit is important for a leak free seal. I have documented

results with this engine prop and will see what the difference is in rpm with only

the manifold header add.

Some positive tank pressure:

[/url

[/url

I was given 4 items in the last package sent to finalize, 3 down one more to test.

Some good ole goo control to help keep .020 projects cleaner and it adds a bit of

back pressure for RC carbs. Fit is important for a leak free seal. I have documented

results with this engine prop and will see what the difference is in rpm with only

the manifold header add.

Some positive tank pressure:

[/url

[/url

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Oct 27, 2020

Kamtechnik Header / Manifold .020 Prototype Testing

Cox TD .020 APC 4.2x2N

Open exhaust: 22.2k rpm 42 mph PS

Manifold and header: 19.9k rpm 38 mph PS

OS P4 Turbo Plug

-Reduces piercing tone

-Adds back pressure for RC carbs

-Single exhaust goo control

-Can use a pressure tap

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

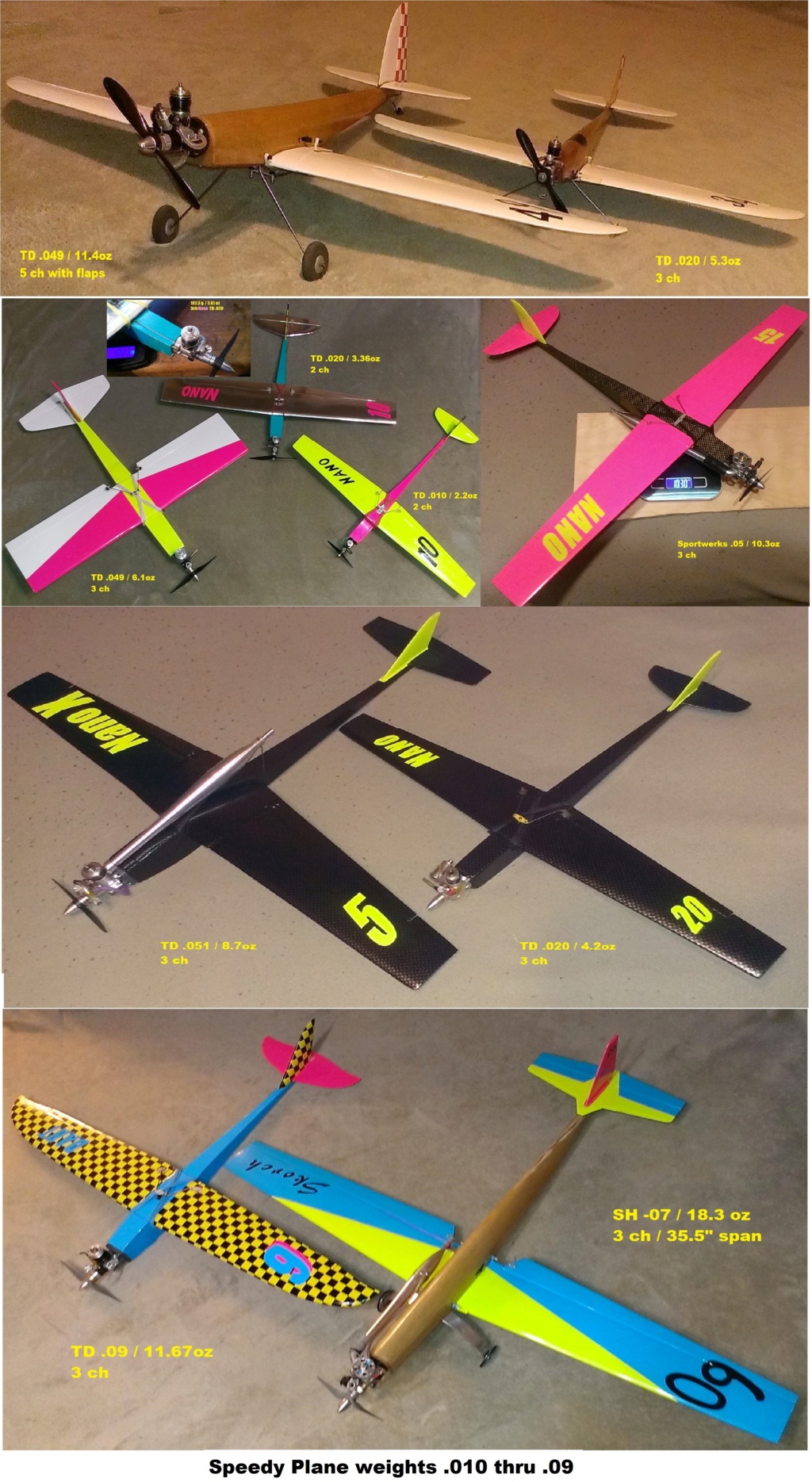

Bump to an old thread, 1/2A nut I ran across this thread looking for a cool airplane to build for an 049. I have been into RC since the early 2000s and started out with a cox 049 to pull my glider up. Never played with them much since then, but I recently came across some more 049s and would like to build something around them. Your speedsters here are too cool, I love fast planes - keeps me from getting bored (I used to do pylon racing). Just amazing how fast these little ones you've built are. Most of the discussion here has been the 020 and 010, do you have a specific design you recommend for 049? Would like to leverage your expertise a bit if possible to build something fast and cool... looks like you're using 1/32 ply for the fuse and solid balsa wings? Thanks for any direction you can give, I'll keep digging through posts on here...

Elijah- New Member

- Posts : 3

Join date : 2021-10-05

Location : Prescott AZ

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

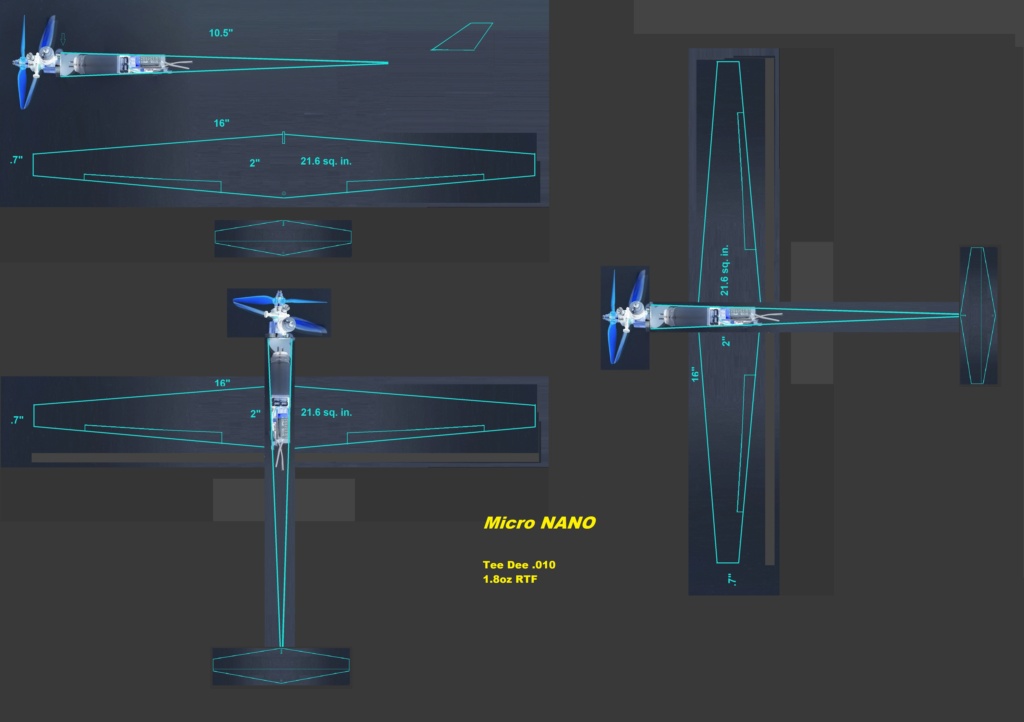

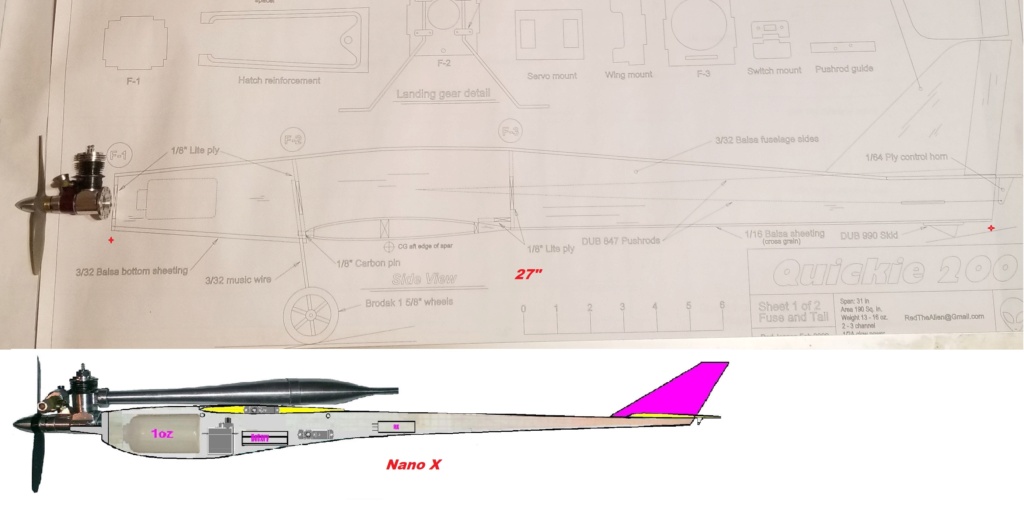

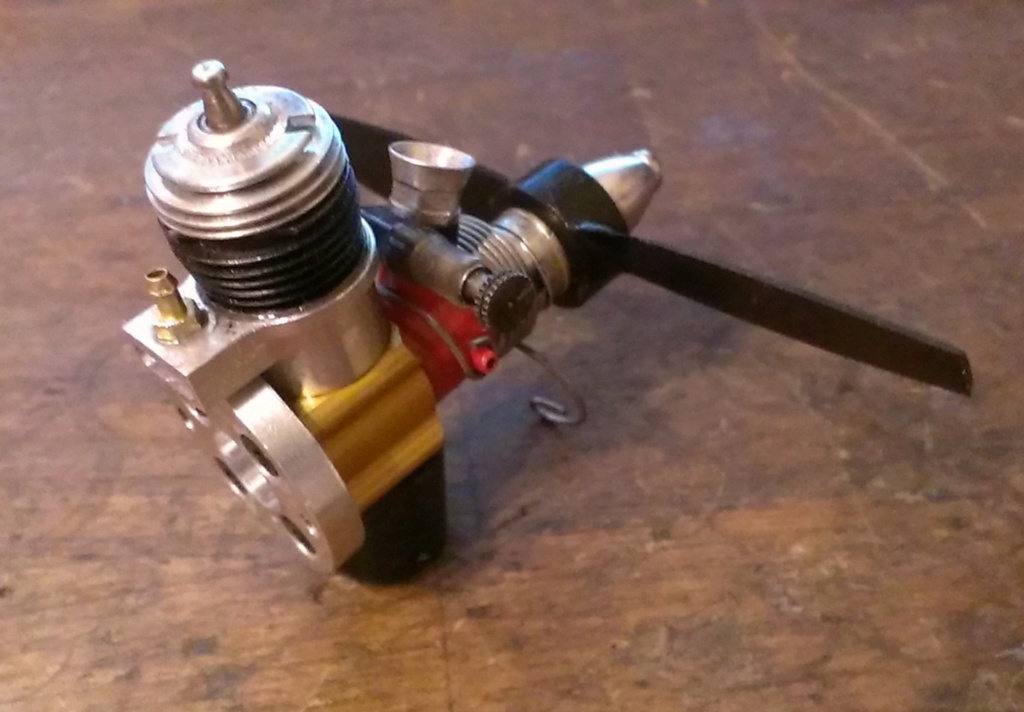

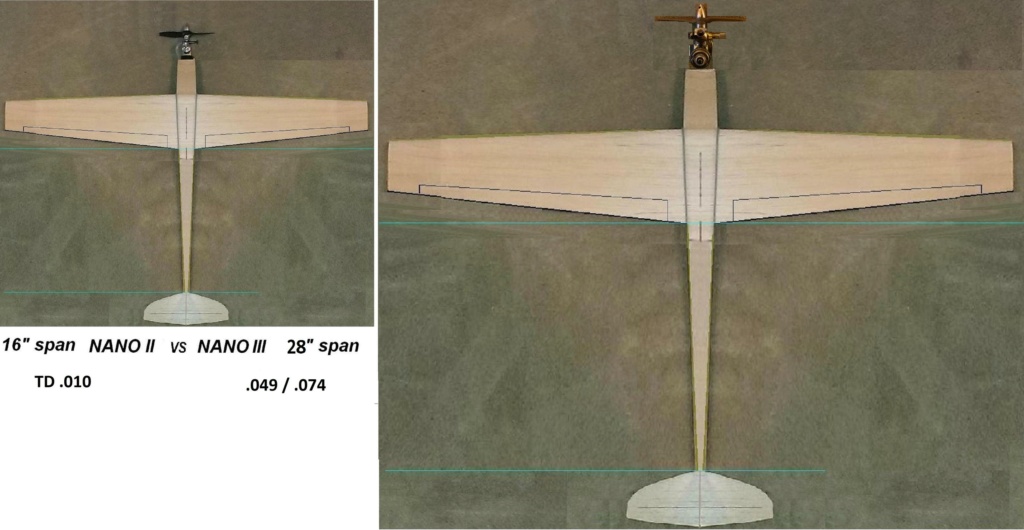

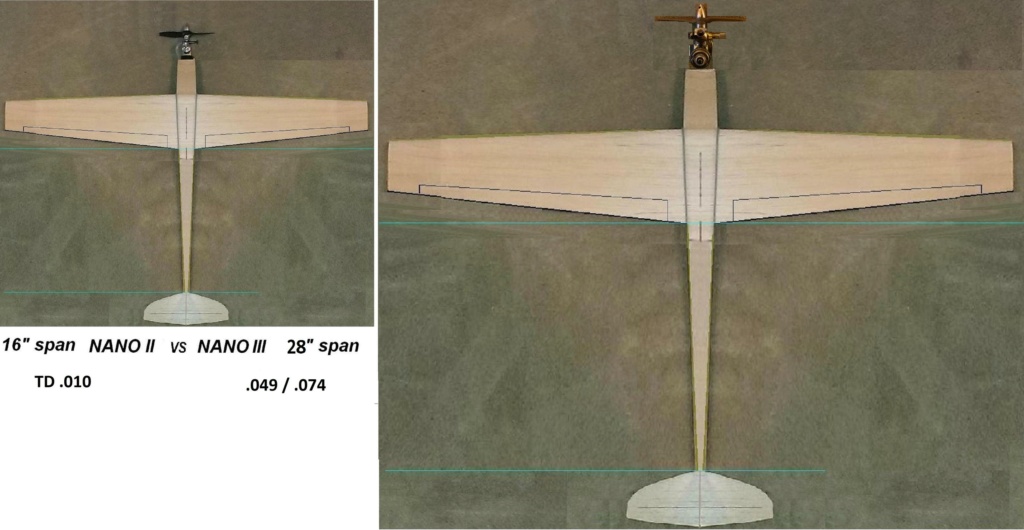

Thank you Elijah, yes as described in this thread with photos and drawings led to the Nano design for

.010 / .020 /.049 /.09 / .15 engines as my easy method to achieve top speeds.

Another thread here:

https://www.rcgroups.com/forums/showthread.php?2684743-Speed-Planes-010-to-15-Size-Engines

https://www.rcgroups.com/forums/thumbgallery.php?t=2684743&do=threadgallery

NANO X 3ch Speed Plane Cox Tee Dee .051 -149.7 mph pitch speed Tuned Pipe 4.3 x 5.5N

.010 / .020 /.049 /.09 / .15 engines as my easy method to achieve top speeds.

Another thread here:

https://www.rcgroups.com/forums/showthread.php?2684743-Speed-Planes-010-to-15-Size-Engines

https://www.rcgroups.com/forums/thumbgallery.php?t=2684743&do=threadgallery

NANO X 3ch Speed Plane Cox Tee Dee .051 -149.7 mph pitch speed Tuned Pipe 4.3 x 5.5N

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thanks for the thread links, I think I've found most the stuff I need. Drew the templates out in AutoCAD tonight, gonna order some of the airfoil balsa. What do you make the tail feathers out of, 1/8" balsa? Also what prop do you like to start with? I notice you mostly use the tee dee style cox engines, the ones I have here have the integral fuel tank. I remember the teedee style had more power but hopefully this will still make it go pretty good

Elijah- New Member

- Posts : 3

Join date : 2021-10-05

Location : Prescott AZ

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Yes 1/8th if you sculpt in a airfoil. APC 4.2 x 4 will be a good test prop.

.020 version was reproduced by a Jordan Kearney- from New Zealand

Jordan Kearney- from New Zealand

Published on Feb 8, 2018

Cox Pee Wee .020

Cox 4.5x4 prop "for an .049" tested

5.5cc internal tank 20% nitro /20% castor

Notes from Jordan:

This one does has a spruce leading edge and it’s covered in heavy ultracote, still it

comes in at 3.42 oz dry + a 5.5cc tank. I use digital high voltage servos so I can run

them directly from a 2s 180mah lipo. Also the fuse is 1/16 quarter grain balsa with

1/64 ply doubled along the sides from the engine mount to just past the trailing edge.

.020 version was reproduced by a Jordan Kearney- from New Zealand

Jordan Kearney- from New Zealand

Published on Feb 8, 2018

Cox Pee Wee .020

Cox 4.5x4 prop "for an .049" tested

5.5cc internal tank 20% nitro /20% castor

Notes from Jordan:

This one does has a spruce leading edge and it’s covered in heavy ultracote, still it

comes in at 3.42 oz dry + a 5.5cc tank. I use digital high voltage servos so I can run

them directly from a 2s 180mah lipo. Also the fuse is 1/16 quarter grain balsa with

1/64 ply doubled along the sides from the engine mount to just past the trailing edge.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Again, thanks for the info. Got the fuse sides cut out and the tail feathers made up. How do you do the hinges? I was thinking to do some real light glass cloth to make a skin hinge. Maybe monokote alone is enough for a hinge?

Elijah- New Member

- Posts : 3

Join date : 2021-10-05

Location : Prescott AZ

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Nice little racer for an .020.

I would loose sight of that plane so fast it would still have 7/8 of a full tank after the crash.

I would loose sight of that plane so fast it would still have 7/8 of a full tank after the crash.

FlipStart- Gold Member

- Posts : 161

Join date : 2018-09-05

Location : Phoenix, Arizona

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

I simply cover the bottom with up elevator then cover the top with down elevator.

Once done you have full movement no gaps easy clean up after a run.

Thank you FlipStart!

Once done you have full movement no gaps easy clean up after a run.

Thank you FlipStart!

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

That is so cool! Where did you find the transparent propeller? And what speed have you achieved with this latest iteration?

706jim- Gold Member

- Posts : 472

Join date : 2013-11-29

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thank you Jim,

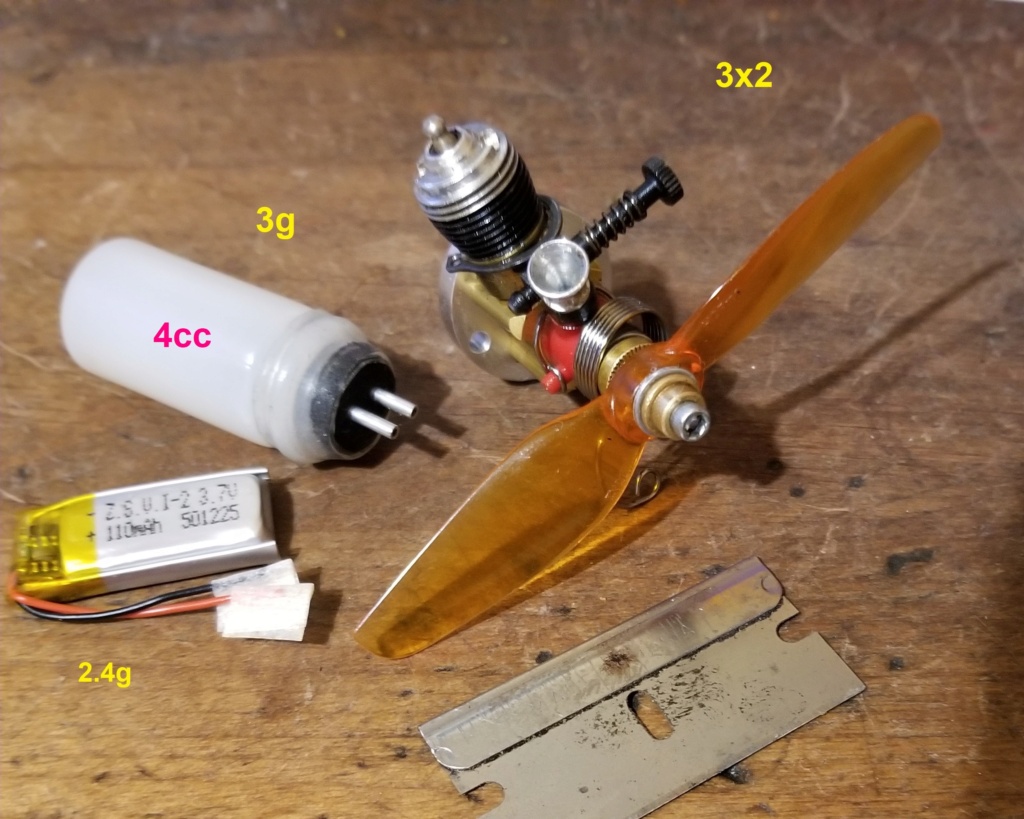

I have been collecting gear for the next TD .010 project.

Testing HQ T series props etc. Will post build pics and flight

vid per the norm when it happens. These props are not for

straight line speeds / good sport flying with more speed than

a stock prop. 2.56x4 gets down wind over 140 mph pitch

speed with the last Nano design. The 4cc tank dia. is less

than the previous 7cc tank used with the last project. Less

weight and allows a smaller fuselage.

I have been collecting gear for the next TD .010 project.

Testing HQ T series props etc. Will post build pics and flight

vid per the norm when it happens. These props are not for

straight line speeds / good sport flying with more speed than

a stock prop. 2.56x4 gets down wind over 140 mph pitch

speed with the last Nano design. The 4cc tank dia. is less

than the previous 7cc tank used with the last project. Less

weight and allows a smaller fuselage.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Link to CEF member Tobaiies build thread.

https://www.coxengineforum.com/t16251-cox-peewee-micro-speeder#212143

Last edited by 1/2A Nut on Sun Jun 12, 2022 12:06 pm; edited 1 time in total

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Page 29 of 30 •  1 ... 16 ... 28, 29, 30

1 ... 16 ... 28, 29, 30

Similar topics

Similar topics» CG on Speed Contest Planes

» Anyone here into Giant Scale R/C Planes? Post Pics of your Planes.

» Fellow speed freaks, help me build a pair of speed Bees.

» CL planes...

» How many cox planes do you have?

» Anyone here into Giant Scale R/C Planes? Post Pics of your Planes.

» Fellow speed freaks, help me build a pair of speed Bees.

» CL planes...

» How many cox planes do you have?

Page 29 of 30

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules