Log in

Search

Latest topics

» Tee Dee .020 combat modelby rdw777 Today at 5:07 pm

» Free Flight Radio Assist

by rdw777 Today at 4:51 pm

» My N-1R build log

by akjgardner Today at 12:39 pm

» Purchased the last of any bult engines from Ken Enya

by getback Today at 12:05 pm

» Funny what you find when you go looking

by rsv1cox Yesterday at 3:21 pm

» Landing-gear tips

by 1975 control line guy Yesterday at 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» My latest doodle...

by TD ABUSER Mon Nov 18, 2024 11:30 am

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

Cox Engine of The Month

Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Page 15 of 30

Page 15 of 30 •  1 ... 9 ... 14, 15, 16 ... 22 ... 30

1 ... 9 ... 14, 15, 16 ... 22 ... 30

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Last edited by 1/2A Nut on Tue Mar 27, 2018 12:28 am; edited 3 times in total

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Pretty densely built up fuse interior. You utilize the space very efficiently.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thank you, yes not much wiggle room, I rapped tape around both servos then mounted them with the

supplied screws to the hardwood block just on the back side this enough to keep them from moving.

The benefit it there is enough room to use 80mah 4.8v or 150mah batteries as there is no front

hardwood block in the way. The switch will be on the left side of the fuselage laid down on top of

the battery to keep it from moving the remainder of the void above the switch is for the aileron servo.

The fuselage is only 22mm wide on the inside where the servos are.

supplied screws to the hardwood block just on the back side this enough to keep them from moving.

The benefit it there is enough room to use 80mah 4.8v or 150mah batteries as there is no front

hardwood block in the way. The switch will be on the left side of the fuselage laid down on top of

the battery to keep it from moving the remainder of the void above the switch is for the aileron servo.

The fuselage is only 22mm wide on the inside where the servos are.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thanjs good idea with the servos banded together. Placing and fixing the servos takes almost as much build time for me as the whole fuselage.

I also place the switch on the fuse side on balsa planes using doubler under the switch . I put it on the fuse back on the TeeDeeVooDoo though not wanting to weaken to fuse on the side with a cutout.

I also place the switch on the fuse side on balsa planes using doubler under the switch . I put it on the fuse back on the TeeDeeVooDoo though not wanting to weaken to fuse on the side with a cutout.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

I was a bit shocked the switch would not stack on top of the battery missed it by

1.5mm, the aileron servo was just poking down too deep into the fuselage.

This actually worked out fine as there was enough deck height to stack it on top of

the fuel tank / just barely fit under the front wing dowel whew. The wire gauge looks

beefy inside this very small fuselage.

1.5mm, the aileron servo was just poking down too deep into the fuselage.

This actually worked out fine as there was enough deck height to stack it on top of

the fuel tank / just barely fit under the front wing dowel whew. The wire gauge looks

beefy inside this very small fuselage.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Speaking of battery I clipped off the existing plug and direct soldered it's

leads to the switch harness as the black plastic plug eats up too much space.

I charged the new NiMh it took 83mah peak to include whatever was already

in the cell after a 15 min. rest I topped off a secondary peak for another 10 mah

maxing it out to 93 mah with what was already in the cells it equates to over

100 mah not bad for a 80mah nominal battery. Should get 3 flights with it safely,

will do two flights with it on maiden day then see what it takes to top it back off.

The Nano II with 1S servos only draws 14 mah per flight the 1.7g servos sip on

the juice lol. Hitec Ultra Nano servos with the HD metal gear perhaps 20mah a

flight. Charger was set at .1 amp this is really fast charging the cells in 52 mins.

The cells stayed cool the entire time at the end of the charge cycle I could just

feel a hint of warming it was hard to feel the difference. Last pic look at that

plug weight / space saved at 1.4g almost the weight of one servo in the Nano II!

leads to the switch harness as the black plastic plug eats up too much space.

I charged the new NiMh it took 83mah peak to include whatever was already

in the cell after a 15 min. rest I topped off a secondary peak for another 10 mah

maxing it out to 93 mah with what was already in the cells it equates to over

100 mah not bad for a 80mah nominal battery. Should get 3 flights with it safely,

will do two flights with it on maiden day then see what it takes to top it back off.

The Nano II with 1S servos only draws 14 mah per flight the 1.7g servos sip on

the juice lol. Hitec Ultra Nano servos with the HD metal gear perhaps 20mah a

flight. Charger was set at .1 amp this is really fast charging the cells in 52 mins.

The cells stayed cool the entire time at the end of the charge cycle I could just

feel a hint of warming it was hard to feel the difference. Last pic look at that

plug weight / space saved at 1.4g almost the weight of one servo in the Nano II!

Last edited by 1/2A Nut on Fri Mar 30, 2018 12:48 pm; edited 1 time in total

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

1.7 gram servos? I didn't know you could get something that light in a case.

706jim- Gold Member

- Posts : 472

Join date : 2013-11-29

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Yes very small Jim I have a 1.7g for the elevator and a 1.9g for the ailerons /TD .010 Nano II.

Today I finally got around to putting a pressure tap on one of my TD .020

It can also act as a post for a spring starter should I want to do so. When

turning over the engine you could hear air being cycled through before

setting up the pressure line. Very small pressure nipple here has the same

thread size as the as the prop hex bolt. I have never ran pressure off the

carb body before should be interesting to see if it works good. One thing is

for sure the barb on the nipple holds the pressure line great!

Today I finally got around to putting a pressure tap on one of my TD .020

It can also act as a post for a spring starter should I want to do so. When

turning over the engine you could hear air being cycled through before

setting up the pressure line. Very small pressure nipple here has the same

thread size as the as the prop hex bolt. I have never ran pressure off the

carb body before should be interesting to see if it works good. One thing is

for sure the barb on the nipple holds the pressure line great!

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

very interesting friend this process! ... what measure of thread is the nipple?

Brad, surely you swing these propellers, since so many high rpm so require, which method do you use to balance your propellers ??

Brad, surely you swing these propellers, since so many high rpm so require, which method do you use to balance your propellers ??

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thank you Mauricio!!!!!!!! Greenie for you too!

Yes see pic for size:

Bench tested the setup it actually works, bit more touchy though as the pressure needs to build up

to it's peak then your ok to launch. Think in the air it will of course unload more and pressure will

build a bit more to compensate for the fuel demand.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thanks for the information Brad! ... I invite you to see what happened to me:

https://www.coxengineforum.com/t11743-vibrations-vibrations-and-vibrations#149661

https://www.coxengineforum.com/t11743-vibrations-vibrations-and-vibrations#149661

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Sneaked in a bench test today prior to doing BBQ with the family.

Results.

Tested the all carbon 3x3, it has done 37.3k rpm /106 mph down wind with

the 5oz dry weight Lil Speedy which weighs 1oz more then the Nano IV nor

near as lanky and has mush less squares on the wing. Weather pending look

forward to test flying next weekend.

Uploaded on Apr 1, 2018

Carbon 3x3 / RC Carb TD .020 / 29,231 rpm / 83 mph pitch speed

Did dump the first charge out of the 80mah battery ran it till the RX stopped

working leaving 4.45v in the pack after it recovered.

Here is the results after a full charge quite stellar way over nominal.

Held 118 mAh / took 74.21 mins to charge at .1 mAh

Should be good for 3 flights per outing.

The above efforts are par for the course must know the unknowns to avoid stupid mistakes in the field like

running out of battery or doing a maiden launch without enough thrust.

Results.

Tested the all carbon 3x3, it has done 37.3k rpm /106 mph down wind with

the 5oz dry weight Lil Speedy which weighs 1oz more then the Nano IV nor

near as lanky and has mush less squares on the wing. Weather pending look

forward to test flying next weekend.

Uploaded on Apr 1, 2018

Carbon 3x3 / RC Carb TD .020 / 29,231 rpm / 83 mph pitch speed

Did dump the first charge out of the 80mah battery ran it till the RX stopped

working leaving 4.45v in the pack after it recovered.

Here is the results after a full charge quite stellar way over nominal.

Held 118 mAh / took 74.21 mins to charge at .1 mAh

Should be good for 3 flights per outing.

The above efforts are par for the course must know the unknowns to avoid stupid mistakes in the field like

running out of battery or doing a maiden launch without enough thrust.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

33 mph winds today but Sunday is the day the winds will be down will test fly the NANO IV.

Parts will be sent my way Monday to test various manifold types with headers, will post vids, another add on for

the TD .020 a engine that has become more popular with the small RC gear we have now and for CL.

One of the manifolds allow breathing from both exhausts another type blocks 1 exhaust port to mimic a traditional single port.

The header tip is round to use silicon tube for an exhaust diverter or to add a aluminum extension tube to run the goo

past the wing saddle. There will be an optional bolt on muffler at some point for those who want a more traditional TD RC

version like the TD RC .049 and .09. As I have found with the NANO III and a pressure tap on the exhaust a boost of top end

rpm can be obtained yet another benefit of the manifold. As is without add on's the manifold will control the oil spray in one

direction minimizing the impact on the planes surfaces reducing clean up time between flights, surface drag from the oil spray

and less damage to the finish (such as shrink film seams / wood frame / firewall) over time.

Other add on's to follow stay tuned we are very very lucky to have a machinist on board for small IC parts. Turbo plug and RC carb

will round out the engine in the end making the TD .020 a most amazing user friendly micro engine. I plan to use a tuned pipe for

the round tip header at some point for the NANO IV.

Here is a conceptional drawing and raw milled manifold to give you an idea of what's happening.

Full breathing manifold for straight oil deflection.

Parts will be sent my way Monday to test various manifold types with headers, will post vids, another add on for

the TD .020 a engine that has become more popular with the small RC gear we have now and for CL.

One of the manifolds allow breathing from both exhausts another type blocks 1 exhaust port to mimic a traditional single port.

The header tip is round to use silicon tube for an exhaust diverter or to add a aluminum extension tube to run the goo

past the wing saddle. There will be an optional bolt on muffler at some point for those who want a more traditional TD RC

version like the TD RC .049 and .09. As I have found with the NANO III and a pressure tap on the exhaust a boost of top end

rpm can be obtained yet another benefit of the manifold. As is without add on's the manifold will control the oil spray in one

direction minimizing the impact on the planes surfaces reducing clean up time between flights, surface drag from the oil spray

and less damage to the finish (such as shrink film seams / wood frame / firewall) over time.

Other add on's to follow stay tuned we are very very lucky to have a machinist on board for small IC parts. Turbo plug and RC carb

will round out the engine in the end making the TD .020 a most amazing user friendly micro engine. I plan to use a tuned pipe for

the round tip header at some point for the NANO IV.

Here is a conceptional drawing and raw milled manifold to give you an idea of what's happening.

Full breathing manifold for straight oil deflection.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Looks great Brad..will this manifold work with all 020 cylinders or only the thick wall? Will this be up for sale to international customers?

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

- I have a few Pee Wee thin walled cylinders but prefer not to use them do you?

Like most I prefer the 2nd / 3rd gen cylinders. These days it has become rare to find a thin walled cylinder.

I will see if it fits and let you know all the same, it may work fine.

- All the products shown thus far has world wide shipping available, you just have to cover any

additional shipping cost outside the US.

This manifold and header will work out great, lucky to have a way to make the Pee Wee / TD .020

a real work horse for all types of flying styles. Castor oil spray in control, sound dampening and

finally a viable way to add pressure to the fuel tank to improve performance for RC / CL and FF efforts.

Found another prop to test by iFlight:

Nazgul 3 blade 3x6.1 racing prop, the folks at Team iFlight FPV has gone to great efforts to stay competitive

in the racing class by designing a prop that performs without loading the engine down.

Note the tip design swept up to reduce tip drag / static potential to 122mph.

Like most I prefer the 2nd / 3rd gen cylinders. These days it has become rare to find a thin walled cylinder.

I will see if it fits and let you know all the same, it may work fine.

- All the products shown thus far has world wide shipping available, you just have to cover any

additional shipping cost outside the US.

This manifold and header will work out great, lucky to have a way to make the Pee Wee / TD .020

a real work horse for all types of flying styles. Castor oil spray in control, sound dampening and

finally a viable way to add pressure to the fuel tank to improve performance for RC / CL and FF efforts.

Found another prop to test by iFlight:

Nazgul 3 blade 3x6.1 racing prop, the folks at Team iFlight FPV has gone to great efforts to stay competitive

in the racing class by designing a prop that performs without loading the engine down.

Note the tip design swept up to reduce tip drag / static potential to 122mph.

Last edited by 1/2A Nut on Sun Apr 08, 2018 3:15 am; edited 1 time in total

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

I like the thin wall cylinders because they are vintage though they are less practical with no top fin milled for the wrench.

The second I like is the stepped wall cylinders because of their look and chances are one finds early versions that have tapered bore which has worked out for me in a TD051 with very long service life. The 020 stepped wall cylinders I have do have tapered bore.

Unfortunately COX dropped the tapered bore in later stepped wall TD cylinders in pursuit of cost reduction. At least some of my NIB 049 stepped wall TD cylinders in the cardbord blister pack do not have tapered bore.

The latest thick wall TD cylinders are also OK but I guess some may have been made already in the Estes era without tapered bore and with questionable hand-matching with the piston so their longevity may be less than the tapered cylinders in my opinion. I have some new 049 thick wall cylinders where the piston almost falls through it by gravity hence I assume the compression will deteriorate with use sooner than in tapered bores. (I still expect 100+hours service life from them)

With all this said, I am still sure all COX cylinders outlive most other non-ringed piston engines... (A 049 NV manual I have says engine life is at least 6 hours....) Larry Renger wrote about a run test by COX that ended with 400 hours runtime and the engine still started up with electric starter. It may have been a normal cylinder with no taper, I am not sure..Of course we do not typically use these engines for so long...but the longer their expected service life, the better condition they remain in while one uses them...

(A 049 NV manual I have says engine life is at least 6 hours....) Larry Renger wrote about a run test by COX that ended with 400 hours runtime and the engine still started up with electric starter. It may have been a normal cylinder with no taper, I am not sure..Of course we do not typically use these engines for so long...but the longer their expected service life, the better condition they remain in while one uses them...

Did you finally tach the Dalprop Cyclone T3056 3-blade Propeller you introduced in this thread some time ago? I bought some and they are on their way to me. The stock 3" 3blade COX is easily turning 24k on my TD020 and I wonder what the larger pitch of the Dalprop prop on engine performance will be?

The second I like is the stepped wall cylinders because of their look and chances are one finds early versions that have tapered bore which has worked out for me in a TD051 with very long service life. The 020 stepped wall cylinders I have do have tapered bore.

Unfortunately COX dropped the tapered bore in later stepped wall TD cylinders in pursuit of cost reduction. At least some of my NIB 049 stepped wall TD cylinders in the cardbord blister pack do not have tapered bore.

The latest thick wall TD cylinders are also OK but I guess some may have been made already in the Estes era without tapered bore and with questionable hand-matching with the piston so their longevity may be less than the tapered cylinders in my opinion. I have some new 049 thick wall cylinders where the piston almost falls through it by gravity hence I assume the compression will deteriorate with use sooner than in tapered bores. (I still expect 100+hours service life from them)

With all this said, I am still sure all COX cylinders outlive most other non-ringed piston engines...

Did you finally tach the Dalprop Cyclone T3056 3-blade Propeller you introduced in this thread some time ago? I bought some and they are on their way to me. The stock 3" 3blade COX is easily turning 24k on my TD020 and I wonder what the larger pitch of the Dalprop prop on engine performance will be?

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

I have made a few headers in the past, mainly to reduce noise and/or to add a throttle. One thing to remember is that it does take away some of the of power while also adding weight. So it is not suitable for all types of flying. Starting the engine is also more difficult when one cannot simply prime the exhaust port. On some engines I've therefore used and easily removable muffler, such that one can prime the engine and even have it started before putting the muffler back on, just a few things to consider for those that are interested.

Here are two PeeWee versions:

And one .049 version:

Here are two PeeWee versions:

And one .049 version:

Last edited by Surfer_kris on Sun Apr 08, 2018 4:46 am; edited 1 time in total

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Yes gotcha for now the manifold are for the .020 displacement types.

The .049/.05/.051 version would be a winner too.

Yes posted a vid on my Youtube (you should subscribe to my page) so you can catch my updates to the vids.

Results:

AmpAbuser

Published on Feb 11, 2018

Cox TD .020 / Cyclone 3 blade 3x5.6 / 22,206 rpm peak

Static best peak 2.6oz thrust / 37w / 118 mph pitch speed

Little tweaking needed yet but holds 21.5k easy enough 114 mph

25% nitro / 20% castor

Kris your setups are far way more restrictive then the version being designed for the .020 class engines

and prime wont be a issue with the version shown here. I don't prime my cylinders, I push air into the

tank vent line it then loads the feed line and fills the intake with enough fuel to start the engine with spring

or with a elect starter. I have not primed a cylinder for many many years, I don't like risking over primed

cylinder bend con rods. I always flip the prop over a few times before applying voltage to the glow plug.

Kris still looking forward to a bench test vid with Valentine engine / muffler set up.

This is a performance based design:

The .049/.05/.051 version would be a winner too.

Yes posted a vid on my Youtube (you should subscribe to my page) so you can catch my updates to the vids.

Results:

AmpAbuser

Published on Feb 11, 2018

Cox TD .020 / Cyclone 3 blade 3x5.6 / 22,206 rpm peak

Static best peak 2.6oz thrust / 37w / 118 mph pitch speed

Little tweaking needed yet but holds 21.5k easy enough 114 mph

25% nitro / 20% castor

Kris your setups are far way more restrictive then the version being designed for the .020 class engines

and prime wont be a issue with the version shown here. I don't prime my cylinders, I push air into the

tank vent line it then loads the feed line and fills the intake with enough fuel to start the engine with spring

or with a elect starter. I have not primed a cylinder for many many years, I don't like risking over primed

cylinder bend con rods. I always flip the prop over a few times before applying voltage to the glow plug.

Kris still looking forward to a bench test vid with Valentine engine / muffler set up.

This is a performance based design:

Last edited by 1/2A Nut on Sun Apr 08, 2018 4:20 am; edited 4 times in total

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thanks Brad,

how do you think this 2.6oz thrust / 37w / compares, in thrust, to the stock 3" 3blade cylinder? Can I expect better thrust with the Dalprop? The larger pitch of course may mean larger thrust unless with the corresőponding lower rpm the engine shaft output drops too much...TD020-s peak out on shaft power around 24k as far as I remember..at the end it is the engine shaft power (that varies with the rpm) that translates into aerodynamic performance through the combination of thrust and airspeed through the prop.

how do you think this 2.6oz thrust / 37w / compares, in thrust, to the stock 3" 3blade cylinder? Can I expect better thrust with the Dalprop? The larger pitch of course may mean larger thrust unless with the corresőponding lower rpm the engine shaft output drops too much...TD020-s peak out on shaft power around 24k as far as I remember..at the end it is the engine shaft power (that varies with the rpm) that translates into aerodynamic performance through the combination of thrust and airspeed through the prop.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

The prop was chosen for the 4oz Nano IV not meant for heavy bulky sport planes.

I would never use the Cox 3 blade prop for my speed planes, not enough pitch and weight is too much.

For speed you need a minimum 50% thrust to weight it will reach top speed but slow into the wind.

I prefer a balance of 65% to 75% thrust to weight when possible. A 1:1 thrust ratio gives up too much

speed with the small engine displacements, the luxury is just not available. The TD .050 with stock muffler

and pressure tap worked well with a 4.22x5.5 the muffler weight is too much though, stock muffler is too thick walled.

I don't like using it for now it was all I had so dealt with it. Sportwerkz vid soon.

The .020 manifold and header is very light over all nothing more than aluminum. The round adapter is for special

purpose use and will cause some performance loss, to make it up pressure tap will help did for the TD .050 made

more static rpm then stock and gave me a 141 mph down wind pass. See vids in this thread.

I would never use the Cox 3 blade prop for my speed planes, not enough pitch and weight is too much.

For speed you need a minimum 50% thrust to weight it will reach top speed but slow into the wind.

I prefer a balance of 65% to 75% thrust to weight when possible. A 1:1 thrust ratio gives up too much

speed with the small engine displacements, the luxury is just not available. The TD .050 with stock muffler

and pressure tap worked well with a 4.22x5.5 the muffler weight is too much though, stock muffler is too thick walled.

I don't like using it for now it was all I had so dealt with it. Sportwerkz vid soon.

The .020 manifold and header is very light over all nothing more than aluminum. The round adapter is for special

purpose use and will cause some performance loss, to make it up pressure tap will help did for the TD .050 made

more static rpm then stock and gave me a 141 mph down wind pass. See vids in this thread.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

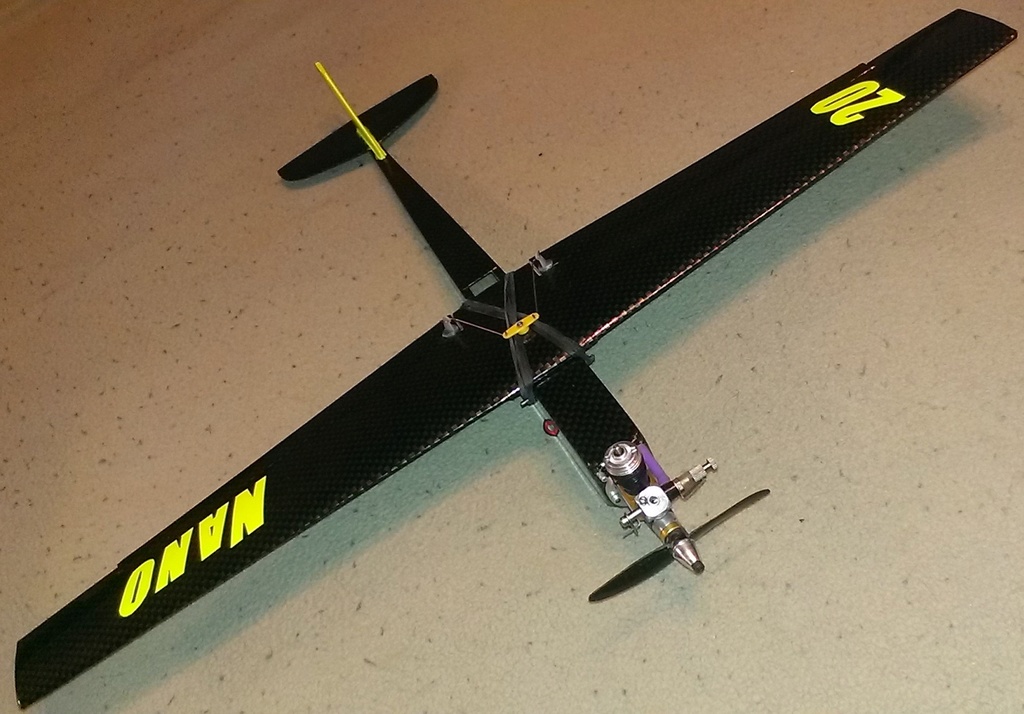

Maiden flight today with the NANO IV results:

Fly's like the bigger N-III but smaller and the black can be tricky when coming straight at you or going away.

All other angles are dominate and easy to monitor. Fly's soo smooth and fast amazing for it's size.

The rates where set low as expected that was a good move 25% on the ailerons and 30% on the elevator.

I am uploaded the maiden flight it was cut short, the 1/2A fuel line used for the pressure tap is too big

so need to use the smaller TD .010 line for the pressure line pressure was working very well but came loose

killed the engine after the first speed pass. That first pass gave me the rpm data. I think once the engine

is dialed in and I do low passes right by the camera I can squeeze out about 136 mph with the same prop.

Carbon blend HQ 3.72x4.5

Best pass 30,200 rpm / 129 mph pitch speed.

The TD .020 NANO IV has shattered the old record of 106 mph.

AmpAbuser

Published on Apr 8, 2018

Maiden Flight NANO IV / TD .020 / 3.72x4.5 / 30.2k RPM / 129 mph pitch speed.

4.2oz RTF / 19.5" Span / 44.5" Sq. In.

Static peak 20,995 rpm / 89 mph pitch speed

Front rotary valve pressure tap first flight test of this system.

AmpAbuser

Published on Apr 8, 2018

Nano IV / TD .020 / 2nd flight / Modified HQ Prop 3.72x4.5

Testing the second run confirmed my findings the 1/2A size

pressure line is not restrictive enough at speed air influx was too

much causing increased pressure in the tank making the fuel

flow too rich to the NV. The rotary induced system will work with

a smaller fuel line so waste to try a third flight till it's replaced.

Next prop to test HQ Carbon mix 3.9x4.5N should have unlimited vert.

Fly's like the bigger N-III but smaller and the black can be tricky when coming straight at you or going away.

All other angles are dominate and easy to monitor. Fly's soo smooth and fast amazing for it's size.

The rates where set low as expected that was a good move 25% on the ailerons and 30% on the elevator.

I am uploaded the maiden flight it was cut short, the 1/2A fuel line used for the pressure tap is too big

so need to use the smaller TD .010 line for the pressure line pressure was working very well but came loose

killed the engine after the first speed pass. That first pass gave me the rpm data. I think once the engine

is dialed in and I do low passes right by the camera I can squeeze out about 136 mph with the same prop.

Carbon blend HQ 3.72x4.5

Best pass 30,200 rpm / 129 mph pitch speed.

The TD .020 NANO IV has shattered the old record of 106 mph.

AmpAbuser

Published on Apr 8, 2018

Maiden Flight NANO IV / TD .020 / 3.72x4.5 / 30.2k RPM / 129 mph pitch speed.

4.2oz RTF / 19.5" Span / 44.5" Sq. In.

Static peak 20,995 rpm / 89 mph pitch speed

Front rotary valve pressure tap first flight test of this system.

AmpAbuser

Published on Apr 8, 2018

Nano IV / TD .020 / 2nd flight / Modified HQ Prop 3.72x4.5

Testing the second run confirmed my findings the 1/2A size

pressure line is not restrictive enough at speed air influx was too

much causing increased pressure in the tank making the fuel

flow too rich to the NV. The rotary induced system will work with

a smaller fuel line so waste to try a third flight till it's replaced.

Next prop to test HQ Carbon mix 3.9x4.5N should have unlimited vert.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

The efforts where spuratic at best mostly learning as I go with what works that and the engine was

not singing like it should. The best noted rpm was off camera at 30.442 rpm yields 130 mph pitch speed.

I did take two vids this is the best clip of me trying to learn to fly with a tripod and radar gun. I should have

followed my original plan fly like normal doing up close passes right to left with the plane passes right in front.

But I screwed up and left the ball cap in the car I was already set up with all the gear and was not willing to pack

up and go get the hat. For now on the hat stays in the field box! Besting reading on radar 112 mph is good with

the 4.5P prop I would need to make 26,282 rpm pitch speed minimal.

The engine does over 30k with the right prop / pass I should bust 34k. I am done trying to make the rotary pressure

tap work for now will put a hex head screw in place of the nipple. Manifold should be in this week will bench test it.

Here's the vid all new different perspective for me. A one off as I am going back to the cap you are getting the Radar

view with the sports cam rubber banded to the top of the gun. I was like a proud new papa wanting to monitor the

radar gun to insure I don't hit it but was not a issue, just threw me off my routine. Engine never really got up to a

full song here but least the Nano is under steady power more so than last week and was picked up by radar will do

better next time as I improve my routine.

not singing like it should. The best noted rpm was off camera at 30.442 rpm yields 130 mph pitch speed.

I did take two vids this is the best clip of me trying to learn to fly with a tripod and radar gun. I should have

followed my original plan fly like normal doing up close passes right to left with the plane passes right in front.

But I screwed up and left the ball cap in the car I was already set up with all the gear and was not willing to pack

up and go get the hat. For now on the hat stays in the field box! Besting reading on radar 112 mph is good with

the 4.5P prop I would need to make 26,282 rpm pitch speed minimal.

The engine does over 30k with the right prop / pass I should bust 34k. I am done trying to make the rotary pressure

tap work for now will put a hex head screw in place of the nipple. Manifold should be in this week will bench test it.

Here's the vid all new different perspective for me. A one off as I am going back to the cap you are getting the Radar

view with the sports cam rubber banded to the top of the gun. I was like a proud new papa wanting to monitor the

radar gun to insure I don't hit it but was not a issue, just threw me off my routine. Engine never really got up to a

full song here but least the Nano is under steady power more so than last week and was picked up by radar will do

better next time as I improve my routine.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Page 15 of 30 •  1 ... 9 ... 14, 15, 16 ... 22 ... 30

1 ... 9 ... 14, 15, 16 ... 22 ... 30

Similar topics

Similar topics» CG on Speed Contest Planes

» Anyone here into Giant Scale R/C Planes? Post Pics of your Planes.

» Fellow speed freaks, help me build a pair of speed Bees.

» CL planes...

» How many cox planes do you have?

» Anyone here into Giant Scale R/C Planes? Post Pics of your Planes.

» Fellow speed freaks, help me build a pair of speed Bees.

» CL planes...

» How many cox planes do you have?

Page 15 of 30

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules