Log in

Search

Latest topics

» My N-1R build logby GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

Cox Engine of The Month

Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Page 5 of 31

Page 5 of 31 •  1, 2, 3, 4, 5, 6 ... 18 ... 31

1, 2, 3, 4, 5, 6 ... 18 ... 31

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

[quote="Surfer_kris"]

Then I would suggest that you learn how to tune and use the engine on commercially available model-diesel fuel. That should give you experience with how to operate a model diesel engine. Other fuels are a little futile especially on an engine like the cox sure start.

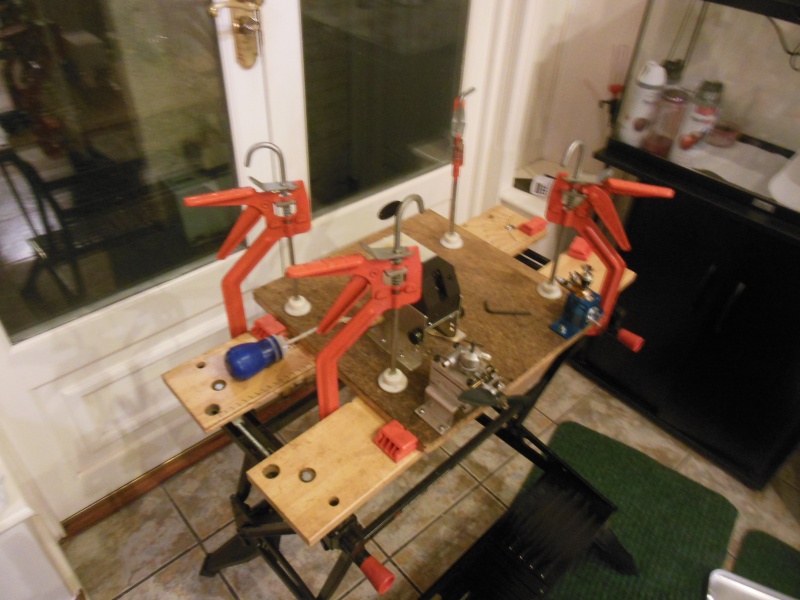

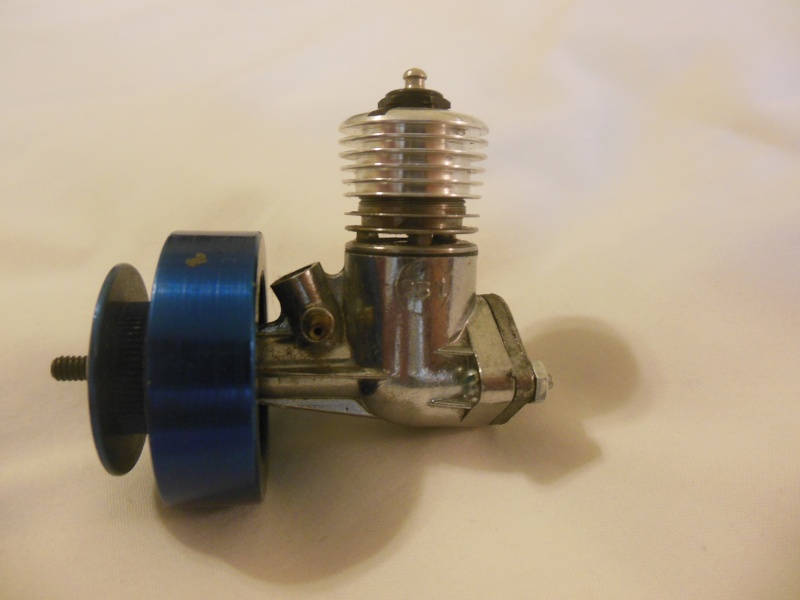

For hints on the engine (Cox sure start on diesel, with muffler, cold start valve and proper RC carburator etc), you can read here for instance; This is how it looks;

This is what I have been doing and I think I have solved most problems or all with the Cox recommended diesel.

As far as the video is concerned, the microphone is too sensitive ( can hear the wind and the whispers ) and hence the engine sounds very loud but is not as loud under real circumstances ( without a microphone or with some sound reference ).

Also, this engine does not use a Cox muffler.

StevenStanleyBayes wrote:

However, because the other problems are stupid, I wish to concentrate the help which I would like to get from this forum on the engine.

Then I would suggest that you learn how to tune and use the engine on commercially available model-diesel fuel. That should give you experience with how to operate a model diesel engine. Other fuels are a little futile especially on an engine like the cox sure start.

For hints on the engine (Cox sure start on diesel, with muffler, cold start valve and proper RC carburator etc), you can read here for instance; This is how it looks;

This is what I have been doing and I think I have solved most problems or all with the Cox recommended diesel.

As far as the video is concerned, the microphone is too sensitive ( can hear the wind and the whispers ) and hence the engine sounds very loud but is not as loud under real circumstances ( without a microphone or with some sound reference ).

Also, this engine does not use a Cox muffler.

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

[quote="Surfer_kris"]

Then I would suggest that you learn how to tune and use the engine on commercially available model-diesel fuel. That should give you experience with how to operate a model diesel engine. Other fuels are a little futile especially on an engine like the cox sure start.

For hints on the engine (Cox sure start on diesel, with muffler, cold start valve and proper RC carburator etc), you can read here for instance;

This is how it looks;

As far as the barrel muffler goes, this is one of the ways to make a muffler. Everything depends on how big the holes are, how wide and long the barrel is. Some may need to put some barriers to the path of the fluids in the barrel.

Just a simple barrel would decrease the noise to some extent but there are other ways.

StevenStanleyBayes wrote:

However, because the other problems are stupid, I wish to concentrate the help which I would like to get from this forum on the engine.

Then I would suggest that you learn how to tune and use the engine on commercially available model-diesel fuel. That should give you experience with how to operate a model diesel engine. Other fuels are a little futile especially on an engine like the cox sure start.

For hints on the engine (Cox sure start on diesel, with muffler, cold start valve and proper RC carburator etc), you can read here for instance;

This is how it looks;

As far as the barrel muffler goes, this is one of the ways to make a muffler. Everything depends on how big the holes are, how wide and long the barrel is. Some may need to put some barriers to the path of the fluids in the barrel.

Just a simple barrel would decrease the noise to some extent but there are other ways.

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Well there ya go! You don't need any help, but you obviously have things to teach all us here.StevenStanleyBayes wrote:Then I would suggest that you learn how to tune and use the engine on commercially available model-diesel fuel. That should give you experience with how to operate a model diesel engine. Other fuels are a little futile especially on an engine like the cox sure start.

Forgive me folks, but Steve is sounding more and more like a troll to me.

dinsdale- Account Deactivated by Owner

- Posts : 317

Join date : 2012-02-22

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Dins, that suggestion was a quote by Surfer Kris to Steven. However for some reason the end-quote tags in this thread keep getting dropped all over the place. Makes who-said-what very confusing. If I get time I might try to sort it out, but not tonight.dinsdale wrote:Well there ya go! You don't need any help, but you obviously have things to teach all us here.StevenStanleyBayes wrote:Then I would suggest that you learn how to tune and use the engine on commercially available model-diesel fuel. That should give you experience with how to operate a model diesel engine. Other fuels are a little futile especially on an engine like the cox sure start.

Forgive me folks, but Steve is sounding more and more like a troll to me.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Thanx Rusty, my apologies.RknRusty wrote:Dins, that suggestion was a quote by Surfer Kris to Steven. However for some reason the end-quote tags in this thread keep getting dropped all over the place. Makes who-said-what very confusing. If I get time I might try to sort it out, but not tonight.dinsdale wrote:Well there ya go! You don't need any help, but you obviously have things to teach all us here.StevenStanleyBayes wrote:Then I would suggest that you learn how to tune and use the engine on commercially available model-diesel fuel. That should give you experience with how to operate a model diesel engine. Other fuels are a little futile especially on an engine like the cox sure start.

Forgive me folks, but Steve is sounding more and more like a troll to me.

Rusty

dinsdale- Account Deactivated by Owner

- Posts : 317

Join date : 2012-02-22

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

dinsdale wrote:G'day Steve, and welcome to the friendliest forum on the web - bar none! I've just read the entire thread with a great deal of interest. Alas, as a curio I see your idea as an admirable venture, but as a commercial venture I'd have to admit that I'm with the detractors.

Just a few posts up from this one you mention that there'll be no mess to clean up because of the use of castor oil. Exactly the opposite will be true. Castor is messy - very messy! But absolutely necessary for these engines. Other engines which are happy using 100% synthetic oil are almost mess free.

You mention the amount of power you expect to get out of one of these diesel SureStarts. You say heaps, and I say very little indeed, particularly at the RPM you're talking about You said that you needed/wanted help with the engines, not the electronics, but you've steadfastly resisted all the help which has been very diplomatically put your way. Please forgive my forthright manner, but I'll put some issues plainly to you.

IC (internal combustion) engines power output (most of us don't realise it, but when we speak of power output from an IC engine we're talking about brake horse power) is a simple function of rpm and torque (and a tiny constant k). I doubt that you could even achieve a reliable steady state at 4,000 rpm, but whatever minimal rpm you can achieve there will surely be next to no torque being produced, and all that is being produced will used just to overcome the internal frictions etc so that the engine can keep running.

Also, whilst on this subject, there are numerous articles about converting Cox reed engines to diesel, and one of the first things you should do is put an upgraded crankshaft into your engine, such as this one :

These little engines are built for a purpose - port timing, compression, stroke vs bore, fuel mix for instance all play a part. These engines are NOT being abused at 17,000rpm. That's just what they're designed to do, and they do it magnificently. Like any IC engine, like you car too, if you load it up and force it to "lug" heavy loads at low rpm you'll kill it in no time. Think of a 600HP Ferrari and 600HP road train. The Ferrari can't pull 100 tonnes of trailers and the road train can't do 300KPH. The old saying is, "horses for courses".

I'd love to see video of your finished prototype, and it's the sort of thing I'd probably have a go at if I'd thought of it, but for any perceived commercial use I'd reckon you're definitely barking up the wrong tree. If I did have a go at it I'd absolutely definitely start with a different engine - probably 60 or bigger 4 stroke.

Please don't be too offended, but someone had to say it.

ALL LINKS OF THE QUOTED POST DELITED BECAUSE OF A FORUM LIMITATION. SORRY.

Whether Castor oil is messy or not depends on how the term messy is understood. Castor Oils is supposed to be blown off with the exhaust gases through the exhaust unburned. In case of so, some people may say Castor Oil is not messy because Castor Oil comes out unburned while oils which burn make smoke and blow off carbon aerosols which are messy.

Again : Castor Oil is not a problem to be released through the exhaust and blown away. In case anyone wants, a sponge or even a paper filter ( sold for kitchen or other use ), can be put near the exhaust hole of the Cox muffler. This way, all oil will get caught by the sponge or paper filter. Towel paper folded more than once as well as simple toilet paper can also do. A simple attachment can be made to keep the sponge or paper steady with the rotating propeller.

So far, I have not experienced any mess with the successful starts. TOO MUCH CETANE BOOSTER makes the exhaust nasty to breathe and smell as well as makes the eyes itchy. This is ONLY when the engine is run with a lot of Cetane Booster indoors and the user is a few cm away from the exhaust. No problems when the windows are wide open or outdoors or when used normally.

No one is supposed to kiss the exhaust when the engine is running under normal circumstances. Not even Top Gear.

I have never resisted any help and have been ONLY answering and nor fighting with people who have. I have noted most or all of the new input in the constantly updating document link to which has been posted. In case you would like, you can go and click on the link and scroll all the way to the last “ chapter “ called something like “ Corrections and Additions to the Document “. You can see a lot of information I got from the forum. Some may not have been made available there because I MAY HAVE FORGOTTEN or because I have not tested this with the engine yet ( like the biodiesel formula from the UK which works perfectly well but with another engine, for example ).

I HAVE NOT MEASURED THE AMOUNT OF POWER AS DEPENDS ON THE RPM. I do not have a way to do so BUT I can measure the overall power out of the dynamo. So far, I think NOT the engine BUT the dynamo will be very powerless. JUST WITHOUT MEASURING BUT JUST LOOKING AND OBSERVING, I AM PRETTY SURE I CAN GET 24W AT LOW RPM OUT OF THE ENGINE. I have no proof of this. Just think so. However, no one has ever published any results and measurements of the power output v RPM. All have been talking just what they think. However, there are not very many people who have run this engine at low RPM at all as most of the people on the forum are modellers and they are interested in high RPM only and have run the engines at high RPM only. Thus, the best is to wait until I assemble the generator and put a couple of car indoor dome lights ( 12V, 12W each ) and read the ampermeter and the voltmeter.

I think, just the fact the engine can reach 50W at any RPM means the engine should easily achive 24W at most any RPM. This is less than a half.

I know these engines have been designed to give high power at high RPM but I doubt they would drop more than a half. Besides, most engines in the world would have problems at high RPM and not at low as far as power is concerned, i. e., will decrease power output at high RPM tremendously because of the said reasons.

I also think the performance of power v RPM depends on the fuel as said.

Before I test the engine or anyone shows power v RPM graphics or table, I would not trust only people’s beliefs. I know these people are knowledgeable but I do not think they are as great experts on low RPM as they are on high RPM, simply because no one else in the world ( not very many ) is interested in the performance of these engines on low RPM.

Thus, as far as power at low RPM is concerned, we better wait and see. May be you are all right and I am wrong. Maybe I would be able to get only 4W at low RPM. Then, I would have to recalculate the pulleys and run the engine at high RPM which would affect engine reliability and longevity.

I saw one video posted here of a generator made in Germany where a tiny motor ( I do not know which ) with a huge pulley drove the tiny pulley of a bicycle dynamo and lit up a bicycle light. Bicycle dynamos are stiff as far as I remember. Yet enough power was generated to rotate the dynamo at high RPM when the engine must have run on lower RPM. Again, this is not the same engine.

Just by observation, the engine seems to work OK at low RPM and may or may not be as powerful as at high RPM BUT certainly does not overcome just friction.

I agree with the post where someone has said : these engines seem to put a strong punch on low RPM “. May be not, though. I do not know yet.

The crankcase seems to be a specially designed Cox Diesel Crankcase which is supposed to be stronger than Nitro but I do not know for sure. Also, I think these engines are specially made by Cox in the 90’s to be diesel engines and are not just conversion of the Nitros with just changing the head but I do not know for sure. So far, I have not had any problems with the crankshaft as well as anything although to say everything is OK is too early. I know these engines take a lot of abuse not only because of some of the post but because I can imagine what to fly one of these is. I think flying requires one hell of a strength of the engine because of the tremendous trust the model planes need to take off and fly.

I agree with you these engines are designed, with all the parameters you have listed, for high RPM, not for 17000 ( these are the Nitros ) but for 10000 to 12000 and more. However, I also think an engine is an engine. I think, whatever the engine is and whatever the design is, after a given RPM the power output would decline.

As far as the Ferrari and the train go, I understand your example, but I do not seem to agree. Again, engine is an engine. Thus, whatever they do, the only important thing is the overall energy which comes out of a given engine per load and per RPM. In case the energy at loads and RPM’s are the same, the engines would do just the same. Of course the gear conversions ( transmission ) have to be the same too.

As far as the commercial value of this project is concerned, I cannot make this project commercially viable. I cannot make this project not commercially viable either. Only a big company can do either. A big company is unlikely to be interested. With a spring start and so many controls, this generator can mainly be used by a petrol head although, when checked out and when instructions are made, the controls and the spring start is not very difficult. Still, may seem to be, some getting used to may be needed and, I think, no one wants to get used to. People want to only press a button.

Add to this the special fuel and people would not be interested at all, except some petrol heads in the UK, where this fuel is available ( all ingredients ) and inexpensive. People want only pump fuels : gasoline and or diesel. They would not want even propane butane.

Maybe this project will not be commercially viable. Then I will be happy to be one of the people who showed this project ( only a prototype ) to the world and thus created the circumstance for the rest of the world to decide what to do or to decide to do nothing. Again : after the prototype and the documentation, I do not care. One think for sure : I will not spend even a penny beyond the prototype. I would not make a company to make these even in case I had all the money necessary for this and I do not have.

I can only think a rich company may decide to just make a few alike just to see what happens as there is not much or R&D involved and most of the rich companies do not care whether they would spend this much money or not. This is like asking Bill Gates to invest in developing software which prints “ Hello World! “ on the screen. Not commercially viable but do you think anyone cares?

Again : the whole point of the project is to use a tiny micro engine. I fully agree with you a mini gasoline spark engine or mini diesel ( never seen these but know some German cars used to have a bigger than mini engines but not as big, so I would not be surprised in case anyone has built any for whatever purpose to get, as you like to say, a bigger torque ) will work perfectly well and this is given, no need to think as much, as well as some commercial versions of these have been posted here. The trick, however, is to use this micro engines which are not as powerful as the mini engines but are more powerful than them as far as energy per size ratio is concerned and, I think, micro engines would provide enough power for most of the cases. Of course, mini engines can reach 1KW but they are very large : like a briefcase ( Honda, the posted ones are tinier ) and heavy, which means they are for different applications.

Again, the idea is to make a micro generator ( when imagined to be made by a company ) and not a mini generator.

For those who want power, there are excellent 5KW generators for $200. There are excellent 5.5KW generators for $400. These are in a trolley ( cart ) and can be lifted on one side and pushed on two wheels. These are transported in a pickup truck and do not fit in a car. They are gasoline powered. I have always loved these and their prices. They are excellent for camping. In case I had a pickup I would have purchased the $200 one immediately. ( These are the prices when on sale but they are often on sale ). Except for camping, contractors purchase them to power their power tools.

The same story : there is Honda but Honda is big. No need for a pickup, can fit in a car but, regardless of how they look like, they cannot be held in hand and walked with them. They can only be moved ( usually by a man and not even by a woman ) a few meters away whatever application this may bring. Too big, too heavy.

As far as the video is concerned : videos and pictures would be posted as I go. The first would be the engine on a stand only with a muffler. Would try to make some known noise reference next to the engine to be able to compare. I have been waiting for the piston to arrive from British Columbia to Ontario for nearly a week and a half. So far, everything has been arriving for a week. I do not know why there is a delay. In comparison, mail from Ontario to anywhere in Europe goes for a half a week. Hence, mail within Canada takes twice as much as mail from Canada to Europe. Believe this or not.

One thing for sure : cannot make a video without a piston.

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

StevenStanleyBayes wrote:

ALL LINKS OF THE QUOTED POST DELITED BECAUSE OF A FORUM LIMITATION. SORRY.

Whether Castor oil is messy or not depends on how the term messy is understood. Castor Oils is supposed to be blown off with the exhaust gases through the exhaust unburned. In case of so, some people may say Castor Oil is not messy because Castor Oil comes out unburned while oils which burn make smoke and blow off carbon aerosols which are messy.

Again : Castor Oil is not a problem to be released through the exhaust and blown away. In case anyone wants, a sponge or even a paper filter ( sold for kitchen or other use ), can be put near the exhaust hole of the Cox muffler. This way, all oil will get caught by the sponge or paper filter. Towel paper folded more than once as well as simple toilet paper can also do. A simple attachment can be made to keep the sponge or paper steady with the rotating propeller.

So far, I have not experienced any mess with the successful starts. TOO MUCH CETANE BOOSTER makes the exhaust nasty to breathe and smell as well as makes the eyes itchy. This is ONLY when the engine is run with a lot of Cetane Booster indoors and the user is a few cm away from the exhaust. No problems when the windows are wide open or outdoors or when used normally.

No one is supposed to kiss the exhaust when the engine is running under normal circumstances. Not even Top Gear.

I have never resisted any help and have been ONLY answering and nor fighting with people who have. I have noted most or all of the new input in the constantly updating document link to which has been posted. In case you would like, you can go and click on the link and scroll all the way to the last “ chapter “ called something like “ Corrections and Additions to the Document “. You can see a lot of information I got from the forum. Some may not have been made available there because I MAY HAVE FORGOTTEN or because I have not tested this with the engine yet ( like the biodiesel formula from the UK which works perfectly well but with another engine, for example ).

I HAVE NOT MEASURED THE AMOUNT OF POWER AS DEPENDS ON THE RPM. I do not have a way to do so BUT I can measure the overall power out of the dynamo. So far, I think NOT the engine BUT the dynamo will be very powerless. JUST WITHOUT MEASURING BUT JUST LOOKING AND OBSERVING, I AM PRETTY SURE I CAN GET 24W AT LOW RPM OUT OF THE ENGINE. I have no proof of this. Just think so. However, no one has ever published any results and measurements of the power output v RPM. All have been talking just what they think. However, there are not very many people who have run this engine at low RPM at all as most of the people on the forum are modellers and they are interested in high RPM only and have run the engines at high RPM only. Thus, the best is to wait until I assemble the generator and put a couple of car indoor dome lights ( 12V, 12W each ) and read the ampermeter and the voltmeter.

I think, just the fact the engine can reach 50W at any RPM means the engine should easily achive 24W at most any RPM. This is less than a half.

I know these engines have been designed to give high power at high RPM but I doubt they would drop more than a half. Besides, most engines in the world would have problems at high RPM and not at low as far as power is concerned, i. e., will decrease power output at high RPM tremendously because of the said reasons.

I also think the performance of power v RPM depends on the fuel as said.

Before I test the engine or anyone shows power v RPM graphics or table, I would not trust only people’s beliefs. I know these people are knowledgeable but I do not think they are as great experts on low RPM as they are on high RPM, simply because no one else in the world ( not very many ) is interested in the performance of these engines on low RPM.

Thus, as far as power at low RPM is concerned, we better wait and see. May be you are all right and I am wrong. Maybe I would be able to get only 4W at low RPM. Then, I would have to recalculate the pulleys and run the engine at high RPM which would affect engine reliability and longevity.

I saw one video posted here of a generator made in Germany where a tiny motor ( I do not know which ) with a huge pulley drove the tiny pulley of a bicycle dynamo and lit up a bicycle light. Bicycle dynamos are stiff as far as I remember. Yet enough power was generated to rotate the dynamo at high RPM when the engine must have run on lower RPM. Again, this is not the same engine.

Just by observation, the engine seems to work OK at low RPM and may or may not be as powerful as at high RPM BUT certainly does not overcome just friction.

I agree with the post where someone has said : these engines seem to put a strong punch on low RPM “. May be not, though. I do not know yet.

The crankcase seems to be a specially designed Cox Diesel Crankcase which is supposed to be stronger than Nitro but I do not know for sure. Also, I think these engines are specially made by Cox in the 90’s to be diesel engines and are not just conversion of the Nitros with just changing the head but I do not know for sure. So far, I have not had any problems with the crankshaft as well as anything although to say everything is OK is too early. I know these engines take a lot of abuse not only because of some of the post but because I can imagine what to fly one of these is. I think flying requires one hell of a strength of the engine because of the tremendous trust the model planes need to take off and fly.

I agree with you these engines are designed, with all the parameters you have listed, for high RPM, not for 17000 ( these are the Nitros ) but for 10000 to 12000 and more. However, I also think an engine is an engine. I think, whatever the engine is and whatever the design is, after a given RPM the power output would decline.

As far as the Ferrari and the train go, I understand your example, but I do not seem to agree. Again, engine is an engine. Thus, whatever they do, the only important thing is the overall energy which comes out of a given engine per load and per RPM. In case the energy at loads and RPM’s are the same, the engines would do just the same. Of course the gear conversions ( transmission ) have to be the same too.

As far as the commercial value of this project is concerned, I cannot make this project commercially viable. I cannot make this project not commercially viable either. Only a big company can do either. A big company is unlikely to be interested. With a spring start and so many controls, this generator can mainly be used by a petrol head although, when checked out and when instructions are made, the controls and the spring start is not very difficult. Still, may seem to be, some getting used to may be needed and, I think, no one wants to get used to. People want to only press a button.

Add to this the special fuel and people would not be interested at all, except some petrol heads in the UK, where this fuel is available ( all ingredients ) and inexpensive. People want only pump fuels : gasoline and or diesel. They would not want even propane butane.

Maybe this project will not be commercially viable. Then I will be happy to be one of the people who showed this project ( only a prototype ) to the world and thus created the circumstance for the rest of the world to decide what to do or to decide to do nothing. Again : after the prototype and the documentation, I do not care. One think for sure : I will not spend even a penny beyond the prototype. I would not make a company to make these even in case I had all the money necessary for this and I do not have.

I can only think a rich company may decide to just make a few alike just to see what happens as there is not much or R&D involved and most of the rich companies do not care whether they would spend this much money or not. This is like asking Bill Gates to invest in developing software which prints “ Hello World! “ on the screen. Not commercially viable but do you think anyone cares?

Again : the whole point of the project is to use a tiny micro engine. I fully agree with you a mini gasoline spark engine or mini diesel ( never seen these but know some German cars used to have a bigger than mini engines but not as big, so I would not be surprised in case anyone has built any for whatever purpose to get, as you like to say, a bigger torque ) will work perfectly well and this is given, no need to think as much, as well as some commercial versions of these have been posted here. The trick, however, is to use this micro engines which are not as powerful as the mini engines but are more powerful than them as far as energy per size ratio is concerned and, I think, micro engines would provide enough power for most of the cases. Of course, mini engines can reach 1KW but they are very large : like a briefcase ( Honda, the posted ones are tinier ) and heavy, which means they are for different applications.

Again, the idea is to make a micro generator ( when imagined to be made by a company ) and not a mini generator.

For those who want power, there are excellent 5KW generators for $200. There are excellent 5.5KW generators for $400. These are in a trolley ( cart ) and can be lifted on one side and pushed on two wheels. These are transported in a pickup truck and do not fit in a car. They are gasoline powered. I have always loved these and their prices. They are excellent for camping. In case I had a pickup I would have purchased the $200 one immediately. ( These are the prices when on sale but they are often on sale ). Except for camping, contractors purchase them to power their power tools.

The same story : there is Honda but Honda is big. No need for a pickup, can fit in a car but, regardless of how they look like, they cannot be held in hand and walked with them. They can only be moved ( usually by a man and not even by a woman ) a few meters away whatever application this may bring. Too big, too heavy.

As far as the video is concerned : videos and pictures would be posted as I go. The first would be the engine on a stand only with a muffler. Would try to make some known noise reference next to the engine to be able to compare. I have been waiting for the piston to arrive from British Columbia to Ontario for nearly a week and a half. So far, everything has been arriving for a week. I do not know why there is a delay. In comparison, mail from Ontario to anywhere in Europe goes for a half a week. Hence, mail within Canada takes twice as much as mail from Canada to Europe. Believe this or not.

One thing for sure : cannot make a video without a piston.

1. Castor is messy! It won't just blow away. Ask ANYONE on this forum.

2. Yes, around about 4 or 5 watts will be all you'll see at idle. There are power output vs rpm charts around somewhere for these engines. You've done NO research at all on IC engines. There's untold info out there. Google is your friend.

3. Here's some of the research you should have done: power output from an IC engine (simplified for this purpose) = rpm x torque. If the torque remains constant and the rpm rises then power output rises and vice versa. If the rpm remains constant and the torque rises then the power output rises and vice versa. If the torque decreases AND the rpm decreases then power out decreases A LOT.

4. The specified operating rpm for these engines is at or very near the maximum torque and/or power. 17,000 +-1,000 rpm is around about the correct operating rpm for a SureStart engine.

5. The German generator was powered by a quite large (60 or bigger) 4 stroke GLO engine.

6. I'm entirely unaware of any purpose built Cox diesel model engines - anyone?

7. Standard "Bee" crankSHAFTS habitually break when used for diesel.

8. You can disagree all you like about the ROADtrain/Ferrari example - you're wrong!!

9. "One thing for sure : cannot make a video without a piston." I don't know what this means.

You don't like the fact that you have received "opinions" from respondents (despite those respondents having 100's of years of combined experience) yet you've done no research on even the most basic things and then peddle back opinions of your own based on nothing at all.

The above 9 points are a start for some of the research you should have done already.

I still think you're a troll!

That's it for me. I'm out of here.

dinsdale- Account Deactivated by Owner

- Posts : 317

Join date : 2012-02-22

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

dinsdale wrote:Well there ya go! You don't need any help, but you obviously have things to teach all us here.StevenStanleyBayes wrote:Then I would suggest that you learn how to tune and use the engine on commercially available model-diesel fuel. That should give you experience with how to operate a model diesel engine. Other fuels are a little futile especially on an engine like the cox sure start.

Forgive me folks, but Steve is sounding more and more like a troll to me.

I have not been teaching anyone anything as I am not the one to teach. I have been simply replying to all post because I think not to reply is offensive or impolite. In case this is the other way around, just say so and I will stop answering to every post.

I DO NEED HELP WITH THE ENGINE. I have clearly been saying what help.

1. HELP WITH THIS ENGINE AND ALTERNATIVE FUELS SUCH AS BIODIESEL. Any information for fuel with standard products and without Ether is welcome ( IN CASE THIS IS POSSIBLE, because, as some say, this may not be possible with this engine ). I thanked the post from the UK which showed an engine running on such a fuel. I may try after the project is assembled and run on standard fuel.

2. HELP WITH THIS ENGINE AND STANDARD FUEL :

2.1 WHAT KIND OF STANDARD FUEL CAN I USE. WHAT ARE THE COMPONENTS? WHAT ARE THE PERCENTAGES OF THE COMPONENTS. I have thanked Ken for the information of medicinal Kerosene as well as First Pressed Castor Oil. Also for Cetane Booster : Amil or Isopropyl Nitrate and not EthylExyl Nitrate. I cannot find these but I am thankful I will know what to look for and get should these become available here.

2.2 WHAT ARE THE START UP SETTINGS FOR A GIVEN FUEL : How much is the air valve ( throttle open )? How much is the fuel needle valve ( throttle ) open. How much is the compression screw open. How many ( very approximately ) spring starts would I need to do before the engine starts.

2.3 WHAT ARE THE SETTINGS AFTER START UP? To what extend do I have to tighten up the compression screw after start as well as the air valve ( throttle ) and the needle valve? How many seconds or minutes do I have to react and readjust these?

2.4 WHAT ARE THE SETTINGS FOR A NORMAL RUN? What is the fuel needle valve setting? What is the compression screw setting? Obviously, the air valve ( throttle ) is used from almost fully closed or fully closed to fully open.

2.5 WHAT PERCENTAGES OF THE STANDARD FUEL OR WHAT FUEL DO YOU THINK IS THE BEST FOR GETTING MORE POWER AT LOW RPM?

2.6 WHAT DO YOU THINK OF METHANOL BASED FUEL AS OPPOSED TO KEROSENE BASED FUEL?

2.7 I do not expect an answer to this question but this is the most important question : Where can I get these and other fuel components or fuels in Ottawa, Ontario, Canada? Again : I DO NOT EXPECT AN ANSWER.

3. Does anyone know of a clever way to get inexpensive Ether and or Methanol? University Supply Places, Medical Supply, Hobby Supply, Model Airplane Clubs, Racing, Truck Stops, Truckers Helping Truckers, Diesel Car Enthusiast Groups, Paint Shops, Private Airfields?

4. ENGINE RELIABILITY AND LONGEVITY AFTER A LONG CONTINUOUS ( OR APPROXIMATELY CONTINUOUS ) WORK AT ANY RPM, EVEN HIGHEST. How much do you run your engines. When you go out to fly, do you run your engines for 6 or 8 hours, tank load after tank load. How often do you go for a fly session? Do you go almost every Saturday and Sunday? Do you do competition where you have to train almost the whole week and or month? Do you abuse your engines a lot in order to perform stunts. Without keeping a log book : approximately : how long? Have your engines ever broken? What? How long after new?

5. PISTON RESETTING : How often do you do piston resetting when engine new and how often when run. I thank this responder who said the piston was only reset once when the engine was acquired ( second hand ) and than run for years under heavy abuse ( purchased for $3 ) without a problem. What are your experiences?

6. Do you know other tricks for a better start up, other than priming. What is your input on priming? Do you warm your cylinders with a blow torch? Do you keep your engines in your cars just before start up in the freeze? What is the most freezing weather you have started a diesel in? What will happen in case the engine is kept at minus 10ºC for a long while? Will the engine start? What other temperatures have you started your engines in?

7. HOW DO YOU ADJUST THE SETTINGS AS WELL AS THE FUEL PERCENTAGES IN FREEZING WEATHER AS WELL AS IN HOT?

8. WHAT IS THE TINIEST PROPELLER TO USE FOR LOW RPM? CAN I USE, SAY, A 3.5 INCH PROPELLER? HOW MANY BLADES? Remember, I do not use the propeller for flying but as a fan.

To summarise : THE HELP I NEED THE MOST HAS BEEN LISTED HERE AND BEFORE. Any help with the engine is welcome even this which says of alternative cranks. Third party carburetor prices and availability welcome for future. Taking care of the engine is also welcome.

Special thanks to :

The poster of the post on reliability of the engine and longevity.

The poster from the UK of the alternative diesel fuel with percentages and components.

The posters who have commented on low RPM : positive and negative, all.

Ken from the UK who clarified the best products to make the best Kerosene based fuel and displayed the bottles with labels to do so.

The poster who commented on the bidirectionality of the engine which was corrected in the thesis.

The posters who have posted other micro generators for a good reference.

Please, be kind posters. REFLECT ON THE ENGINE AND FUEL. Try to refrain from commercial viability or any business advices as well as electrical and electronics or, in case you must, try to be as quick on these as possible and as long as possible on the engine and fuel and other listed questions. Also, please, try to skip long comments on things which I will easily be able to find out and there is no much room for a mistake, for example : I will soon hear how loud the engine with a muffler is and will post a video. No need to post long comments on what I can hear. However, in case you would like to comment on how to improve these, you are more than welcome. In this example, in case you say how to reduce the noise ( with fuel or more muffler or the two thereof ) you are welcome.

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

StevenStanleyBayes wrote:Surfer_kris wrote:StevenStanleyBayes wrote:

However, because the other problems are stupid, I wish to concentrate the help which I would like to get from this forum on the engine.

Then I would suggest that you learn how to tune and use the engine on commercially available model-diesel fuel. That should give you experience with how to operate a model diesel engine. Other fuels are a little futile especially on an engine like the cox sure start.

For hints on the engine (Cox sure start on diesel, with muffler, cold start valve and proper RC carburator etc), you can read here for instance; This is how it looks;

This is what I have been doing and I think I have solved most problems or all with the Cox recommended diesel.

As far as the video is concerned, the microphone is too sensitive ( can hear the wind and the whispers ) and hence the engine sounds very loud but is not as loud under real circumstances ( without a microphone or with some sound reference ).

Also, this engine does not use a Cox muffler.

Obviously, more help and DIFFERENT WAYS FROM YOU ALL to start up and run the engine on standard fuel as well as different standard fuels, different kind of components, different manufacturers, different clarities are all welcome. I have read what there is to read from Cox. I want to read from you.

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Steve,

There has been several posts including mine with sound advice that you seem to chose to disavow, deny or ignore the facts.

I really think you might be better off actually building a prototype, rather then go on posting long replies based on theoretical scenarios.

I do kinda enjoys your ramblings and I suppose this post will feed you a little, but this is the last post from me.

I really do encourage you to step away from the keyboard, bolt your diesel up to a small motor and just see what it actually does! You'll learn best by doing it yourself.

Good luck,

Mark

There has been several posts including mine with sound advice that you seem to chose to disavow, deny or ignore the facts.

I really think you might be better off actually building a prototype, rather then go on posting long replies based on theoretical scenarios.

I do kinda enjoys your ramblings and I suppose this post will feed you a little, but this is the last post from me.

I really do encourage you to step away from the keyboard, bolt your diesel up to a small motor and just see what it actually does! You'll learn best by doing it yourself.

Good luck,

Mark

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

LOL

i am planning on building the same thing

what flywheel do you use?

i am planning on building the same thing

what flywheel do you use?

robot797- Platinum Member

- Posts : 787

Join date : 2013-07-28

Age : 34

Information : Alternative Main Fuel ?

Information : Alternative Main Fuel ?

Just for information : I have seen rubbing fluids product in a pharmacy where I have been to ask for Methanol rubbing fluid and has not bee available. These rubbyng fluids are either pure Ethanol ( 100% alcohol, 100% spirits ) or Isopropyl Alcohol. I think these may or may not be a good main fuel and a good replacements for Methanol.

Since Ken has suggested Isopropyl Nitrate as a good Cetane Booster, I wander whether Isopropyl Alcohol along with a standard Cetane Booster would not be an easier to flame ignite fuel.

I DO NOT KNOW AND HAVE NEVER TRIED. I JUST WALKED INTO A PHARMACY TO LOOK FOR METHANOL AND SOW THESE. DO NOT TAKE THIS AS A SUGGESTION BUT, RATHER, AS INFORMATION WHICH MAY OR MAY NOT BE ( PROBABLY NOT ) USEFUL.

Since Ken has suggested Isopropyl Nitrate as a good Cetane Booster, I wander whether Isopropyl Alcohol along with a standard Cetane Booster would not be an easier to flame ignite fuel.

I DO NOT KNOW AND HAVE NEVER TRIED. I JUST WALKED INTO A PHARMACY TO LOOK FOR METHANOL AND SOW THESE. DO NOT TAKE THIS AS A SUGGESTION BUT, RATHER, AS INFORMATION WHICH MAY OR MAY NOT BE ( PROBABLY NOT ) USEFUL.

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

ian1954 wrote:Kris - two litres is about $24 here but I am not a mother and I love the smell. Fresh and burnt! It is a wonderful aroma, it lingers longer and the rags used to clean up afterwards make good fire lighters!

If you noticed in my degumming video - I run engines in doors when it is cold, wet or windy. I do leave the door open though.

Who needs air fesheners?

Anyway - back to diesel fuel.

Cetane boosters are usually ethylhexyl nitrate whereas the ignition improver for model diesel fuel was traditionally amyl nitrate. It is now isopropyl nitrate as it is easier to get hold of even though they are alkyds that are abused. It is unusual to need more than 2% of this in model diesel fuel there is little advantage adding more.

Ether is a general term for a group of chemicals - but model fuel uses dietheyl ether (a solvent and anesthetic). The sale of this is restricted because it is used in the manufacture of illegal drugs.

The paraffin is known as liquid or medicinal paraffin. It is clear and not the fuel oil purchased from hardware stores and garages.

Again the castor oil in quality model fuel is a first pressing. Castor oil that is first pressed, filtered and then degummed has the unique lubricating properties of castor without the excessive buildup and carbon.

Model diesel fuel doesn't depend on really accurate mixes and I sometimes use heating grade paraffin.

But being heavily influenced by television advertising as a child - I would only use Esso Blue and not the lower grades one could buy.

I know quite a few chaps who have been tempted by "biodiesel" mixes and they have got the engines to run but not perform. They have got the engine warmed up and then switched to the "biodiesel" but found that the engine will "run" for a while but is not responsive and slowly peters out to a stop. It is difficult to maintain a consistent performance particularly tick over.

Back to castor oil. I only uses castor oil for lubricant in my diesel engines. Glow engines I am not fussy and I have a stock of good quality synthetic oil from the various motorbikes I have had. Synthetic certainly makes a cleaner exhaust. I use only castor as it is recommend by the engine manufactures. Even Ronald recommends it for his tiny diesels!

However, a lot must depend on the quality. Ken has difficulty in cold weather with castor oil - I don't with the stuff I use. It doesn't thicken up but the lowest temperature I have ever started a diesel was -8 deg C and I had to alter the compression significantly. I have no experience with glow engines at these temperatures.

Likewise, I have had no issues whatsoever mixing this castor oil in diethyl ether. Add it, shake it and job done. I believe the genuineness of the comments I have read and the personal experiences but I have not experienced this myself and have been mixing diesel fuel for many years.

Now back to engines. The Cox Sure start is not the toughest engine. I admire this project but I have bust many Cox 049s dieselising them. Crankshaft webs and con rods. Always through flooding.

I think the project is to be admired - using a brushless motor and escape to start to motor followed by 3 phase rectifiers (or whatever electrickery) to then use the motor as a generator.

On a diesel as small and delicate as this an electric starter is a recipe for disaster. Small diesels flood easily and hydraulic lock so some care has to be taken here.

Small diesels can be a little temperamental and do not often like slow running for long periods. They cool down, compression changes and stops them.

Larger diesels don't have this problem and are much more responsive to the throttle.

Here are two videos of larger diesels. The first one a cold weather start. They both show the slow tick over possible.

Especially for Roddie - we British don't like gloves but even I wouldn't like getting clouted by a 16x9 propeller on a .60 engine!

Sorry : I have forgotten to share with you one of the experiences I have had : You mentioned your friends tried biodiesel, started on standard, switched to biodiesel and were unable to sustain. I wonder whether much more Cetane Booster ( 10% or 5% ) would help sustain biodiesel. I have found the engine sustains better with the standard fuel and Cetane Booster than with the exactly the same fuel without Cetane Booster. Also, you have better Cetane Booster than I do. I can only hope a lot of this may solve their problem but, I think, they have already tried 10% or more as they are very knowledgeable on the issue.

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

dinsdale wrote:StevenStanleyBayes wrote:

ALL LINKS OF THE QUOTED POST DELITED BECAUSE OF A FORUM LIMITATION. SORRY.

Whether Castor oil is messy or not depends on how the term messy is understood. Castor Oils is supposed to be blown off with the exhaust gases through the exhaust unburned. In case of so, some people may say Castor Oil is not messy because Castor Oil comes out unburned while oils which burn make smoke and blow off carbon aerosols which are messy.

Again : Castor Oil is not a problem to be released through the exhaust and blown away. In case anyone wants, a sponge or even a paper filter ( sold for kitchen or other use ), can be put near the exhaust hole of the Cox muffler. This way, all oil will get caught by the sponge or paper filter. Towel paper folded more than once as well as simple toilet paper can also do. A simple attachment can be made to keep the sponge or paper steady with the rotating propeller.

So far, I have not experienced any mess with the successful starts. TOO MUCH CETANE BOOSTER makes the exhaust nasty to breathe and smell as well as makes the eyes itchy. This is ONLY when the engine is run with a lot of Cetane Booster indoors and the user is a few cm away from the exhaust. No problems when the windows are wide open or outdoors or when used normally.

No one is supposed to kiss the exhaust when the engine is running under normal circumstances. Not even Top Gear.

I have never resisted any help and have been ONLY answering and nor fighting with people who have. I have noted most or all of the new input in the constantly updating document link to which has been posted. In case you would like, you can go and click on the link and scroll all the way to the last “ chapter “ called something like “ Corrections and Additions to the Document “. You can see a lot of information I got from the forum. Some may not have been made available there because I MAY HAVE FORGOTTEN or because I have not tested this with the engine yet ( like the biodiesel formula from the UK which works perfectly well but with another engine, for example ).

I HAVE NOT MEASURED THE AMOUNT OF POWER AS DEPENDS ON THE RPM. I do not have a way to do so BUT I can measure the overall power out of the dynamo. So far, I think NOT the engine BUT the dynamo will be very powerless. JUST WITHOUT MEASURING BUT JUST LOOKING AND OBSERVING, I AM PRETTY SURE I CAN GET 24W AT LOW RPM OUT OF THE ENGINE. I have no proof of this. Just think so. However, no one has ever published any results and measurements of the power output v RPM. All have been talking just what they think. However, there are not very many people who have run this engine at low RPM at all as most of the people on the forum are modellers and they are interested in high RPM only and have run the engines at high RPM only. Thus, the best is to wait until I assemble the generator and put a couple of car indoor dome lights ( 12V, 12W each ) and read the ampermeter and the voltmeter.

I think, just the fact the engine can reach 50W at any RPM means the engine should easily achive 24W at most any RPM. This is less than a half.

I know these engines have been designed to give high power at high RPM but I doubt they would drop more than a half. Besides, most engines in the world would have problems at high RPM and not at low as far as power is concerned, i. e., will decrease power output at high RPM tremendously because of the said reasons.

I also think the performance of power v RPM depends on the fuel as said.

Before I test the engine or anyone shows power v RPM graphics or table, I would not trust only people’s beliefs. I know these people are knowledgeable but I do not think they are as great experts on low RPM as they are on high RPM, simply because no one else in the world ( not very many ) is interested in the performance of these engines on low RPM.

Thus, as far as power at low RPM is concerned, we better wait and see. May be you are all right and I am wrong. Maybe I would be able to get only 4W at low RPM. Then, I would have to recalculate the pulleys and run the engine at high RPM which would affect engine reliability and longevity.

I saw one video posted here of a generator made in Germany where a tiny motor ( I do not know which ) with a huge pulley drove the tiny pulley of a bicycle dynamo and lit up a bicycle light. Bicycle dynamos are stiff as far as I remember. Yet enough power was generated to rotate the dynamo at high RPM when the engine must have run on lower RPM. Again, this is not the same engine.

Just by observation, the engine seems to work OK at low RPM and may or may not be as powerful as at high RPM BUT certainly does not overcome just friction.

I agree with the post where someone has said : these engines seem to put a strong punch on low RPM “. May be not, though. I do not know yet.

The crankcase seems to be a specially designed Cox Diesel Crankcase which is supposed to be stronger than Nitro but I do not know for sure. Also, I think these engines are specially made by Cox in the 90’s to be diesel engines and are not just conversion of the Nitros with just changing the head but I do not know for sure. So far, I have not had any problems with the crankshaft as well as anything although to say everything is OK is too early. I know these engines take a lot of abuse not only because of some of the post but because I can imagine what to fly one of these is. I think flying requires one hell of a strength of the engine because of the tremendous trust the model planes need to take off and fly.

I agree with you these engines are designed, with all the parameters you have listed, for high RPM, not for 17000 ( these are the Nitros ) but for 10000 to 12000 and more. However, I also think an engine is an engine. I think, whatever the engine is and whatever the design is, after a given RPM the power output would decline.

As far as the Ferrari and the train go, I understand your example, but I do not seem to agree. Again, engine is an engine. Thus, whatever they do, the only important thing is the overall energy which comes out of a given engine per load and per RPM. In case the energy at loads and RPM’s are the same, the engines would do just the same. Of course the gear conversions ( transmission ) have to be the same too.

As far as the commercial value of this project is concerned, I cannot make this project commercially viable. I cannot make this project not commercially viable either. Only a big company can do either. A big company is unlikely to be interested. With a spring start and so many controls, this generator can mainly be used by a petrol head although, when checked out and when instructions are made, the controls and the spring start is not very difficult. Still, may seem to be, some getting used to may be needed and, I think, no one wants to get used to. People want to only press a button.

Add to this the special fuel and people would not be interested at all, except some petrol heads in the UK, where this fuel is available ( all ingredients ) and inexpensive. People want only pump fuels : gasoline and or diesel. They would not want even propane butane.

Maybe this project will not be commercially viable. Then I will be happy to be one of the people who showed this project ( only a prototype ) to the world and thus created the circumstance for the rest of the world to decide what to do or to decide to do nothing. Again : after the prototype and the documentation, I do not care. One think for sure : I will not spend even a penny beyond the prototype. I would not make a company to make these even in case I had all the money necessary for this and I do not have.

I can only think a rich company may decide to just make a few alike just to see what happens as there is not much or R&D involved and most of the rich companies do not care whether they would spend this much money or not. This is like asking Bill Gates to invest in developing software which prints “ Hello World! “ on the screen. Not commercially viable but do you think anyone cares?

Again : the whole point of the project is to use a tiny micro engine. I fully agree with you a mini gasoline spark engine or mini diesel ( never seen these but know some German cars used to have a bigger than mini engines but not as big, so I would not be surprised in case anyone has built any for whatever purpose to get, as you like to say, a bigger torque ) will work perfectly well and this is given, no need to think as much, as well as some commercial versions of these have been posted here. The trick, however, is to use this micro engines which are not as powerful as the mini engines but are more powerful than them as far as energy per size ratio is concerned and, I think, micro engines would provide enough power for most of the cases. Of course, mini engines can reach 1KW but they are very large : like a briefcase ( Honda, the posted ones are tinier ) and heavy, which means they are for different applications.

Again, the idea is to make a micro generator ( when imagined to be made by a company ) and not a mini generator.

For those who want power, there are excellent 5KW generators for $200. There are excellent 5.5KW generators for $400. These are in a trolley ( cart ) and can be lifted on one side and pushed on two wheels. These are transported in a pickup truck and do not fit in a car. They are gasoline powered. I have always loved these and their prices. They are excellent for camping. In case I had a pickup I would have purchased the $200 one immediately. ( These are the prices when on sale but they are often on sale ). Except for camping, contractors purchase them to power their power tools.

The same story : there is Honda but Honda is big. No need for a pickup, can fit in a car but, regardless of how they look like, they cannot be held in hand and walked with them. They can only be moved ( usually by a man and not even by a woman ) a few meters away whatever application this may bring. Too big, too heavy.

As far as the video is concerned : videos and pictures would be posted as I go. The first would be the engine on a stand only with a muffler. Would try to make some known noise reference next to the engine to be able to compare. I have been waiting for the piston to arrive from British Columbia to Ontario for nearly a week and a half. So far, everything has been arriving for a week. I do not know why there is a delay. In comparison, mail from Ontario to anywhere in Europe goes for a half a week. Hence, mail within Canada takes twice as much as mail from Canada to Europe. Believe this or not.

One thing for sure : cannot make a video without a piston.

1. Castor is messy! It won't just blow away. Ask ANYONE on this forum.

2. Yes, around about 4 or 5 watts will be all you'll see at idle. There are power output vs rpm charts around somewhere for these engines. You've done NO research at all on IC engines. There's untold info out there. Google is your friend.

3. Here's some of the research you should have done: power output from an IC engine (simplified for this purpose) = rpm x torque. If the torque remains constant and the rpm rises then power output rises and vice versa. If the rpm remains constant and the torque rises then the power output rises and vice versa. If the torque decreases AND the rpm decreases then power out decreases A LOT.

4. The specified operating rpm for these engines is at or very near the maximum torque and/or power. 17,000 +-1,000 rpm is around about the correct operating rpm for a SureStart engine.

5. The German generator was powered by a quite large (60 or bigger) 4 stroke GLO engine.

6. I'm entirely unaware of any purpose built Cox diesel model engines - anyone?

7. Standard "Bee" crankSHAFTS habitually break when used for diesel.

8. You can disagree all you like about the ROADtrain/Ferrari example - you're wrong!!

9. "One thing for sure : cannot make a video without a piston." I don't know what this means.

You don't like the fact that you have received "opinions" from respondents (despite those respondents having 100's of years of combined experience) yet you've done no research on even the most basic things and then peddle back opinions of your own based on nothing at all.

The above 9 points are a start for some of the research you should have done already.

I still think you're a troll!

That's it for me. I'm out of here.

1. I have already responded and explained how Castor Oil is not messy.

2. 4 or 5 Watts was a figure of speech. This can be seen. This power can be achieved at UNSTABLE low RPM : the RPM which are the very lowest to do the job. This may as well be around 1000 or 2000 RPM or less. 4 or 5W is so low, you can make this when you rotate the generator by fingers without any handle : just finger rotating the axel. Regardless of what you or all say, I cannot object to what I see just because you say so : I SEE THE ENGINE POWERFULL ENOUGH AT EXTREMELY LOW RPM AND GETTING HUGE POWER WITH ONLY SLIGHT INCREASE OF THE RPM AT EXTRAMELY LOW RPM TOO. The engine WILL provide 24W at low RPM FOR SURE. I can see this and I can realise this when I attempt to stop the engine by impeding the propeller with something across the movement. 24W is also a very low amount of power. There will definitely NOT be a problem at low RPM. I would prefer you to concentrate at the real help I need and not on the obvious which I already know. And, most importantly, I can see. Again, NONE OF YOU HAS EVER ATTEMPTED TO EVEN RUN THE ENGINE ON LOW RPM because you need only high RPM. THE ENGINE IS EXTREMELY POWERFUL AT LOW RPM AND THIS IS AN OBVIOUS FACT. Yes, I agree with you, when the engine stops fully, then 24W cannot be achieved. But only when stopped!

3. There are no such publications for this engine and I am not interested in others.

4. I repeat again : This engine is a diesel engine and the maximal RPM are 10000 to 12000 and more. Takes a while to find you the link but here is : http://coxengines.ca/cox-.049-rc-diesel-engine.html : read the right hand side slightly at the bottom which gives you the max RPM. AGAIN : NO ENGINE WITH INTERNAL COMBUSTION, EVEN THE ONES MADE IN MARS CAN REACH MAXIMAL POWER AT HIGH RPM. THESE ENGINES AS WELL AS ANY OTHER, EVEN THE SPECIALLY DESIGNED FORMULA 1 ENGINES, WILL START LOOSING ENERGY OUTPUT ( POWER AND TORQUE ) AT HIGH RPM AND NEITHER YOU NOR I NOR ANYONE ELSE CAN DO ANYTHING. I have outlined the reasons. May I suggest you read more on general engines with internal combustion to which this engine also belongs and conforms to the same dependencies as all engines as this is just an engine with internal combustion and nothing else. I agree two cycles are not very good at crazily low RPM. I agree the tinier the engine the higher the lowest RPM. This was why I said 24W and not 36W. THERE IS AN EASY WAY TO FIND HOW THIS ENGINE PERFORMS AT EXTREMELY LOW RPM : WAIT UNTIL I BUILD THE GENERATOR AND MEASURE THE OUTPUT. THIS IS NOT VERY SCIENTIFIC BECAUSE THE OUTPUT DEPENDS ON THE DYNAMO EVEN MORE THAN ON THE ENGINE BUT WILL GIVE SOME IDEA.

5. The German generator looked and sounded as being powered by a similar engine. Otherwise, no one would put a bicycle dynamo on a bigger engine. A single cylinder four stroke spark ignition motor would have problems with power at low RPM or needs a huge flywheel which I have not seen. I agree, however, you can recognise these engines better than I can.

6. and 7. Cox .049 SureStart Diesel Engines or Cox .049 Diesel Engines are not built by the original Cox USA but by Cox Canada in 2012. Everything, related to the diesel engines is purposely built. However, the crankshaft is not a new crankshaft but, instead, a crankshaft from Killer Bee has been used. This I agree with you. However, the KB crankshaft has been made of softer steel thus less brittle. The components of the material are well known to Cox. Thus, this crankshaft would work well with diesel. I am not sure whether the original Cox USA have built this crankshaft as a general purpose crankshaft also to be used in diesels or in case of diesel conversion or only for KB Nitro. Companies usually look ahead.

8. Train / Ferrari : ENERGY IS ENERGY and nothing can be done. Neither by Ferrari nor by the train builders. Just basic physics. Try to examine this and any other system with the ENERGY in consideration. In case you can make any kind of engine to display the same amount of energy as a Ferrari, you would be able to convert this energy into speed and or torque easily with a transmission regardless how big the transmission may be.

9. I am waiting for mail from Cox which has taken a half week longer than normal. When I receive the package, I will reassemble the engine and make a video. I cannot measure the power but, hopefully, some very general idea on power and torque will be visible. Not a scientific way. Just a use of experience which people here have.

I do like to receive opinions of all kind, even the ones which may not be correct. HOWEVER, I HAVE CLEARLY SAID WHAT I NEED TO GET AS HELP. In your case, unless you have a proof of how THIS engine performs at low RPM, I am not interested in what you say so much because you contradict with some other people who have posted. I do clearly think and say, all people here ( or most ) have not even run the engine at low RPM because of the application. I also say clearly, I have not had experience with THESE engines yet I have had enough experience and training with general purpose EIC and, I think, I can tell ROUGHLY what the power output difference between OPTIMAL, HIGH and LOW RPM is just by looking and listening and simple tests like putting something on the path of the propeller. And I know the maximal power output of the engine is 50W. I also know how to divide 50 by 2. I also have seen a lot of different power electrical but this is not related to the topic.

In case you want to post a proof, you are welcome. I will also do when I can. Other than this, I thank you for the information on low RPM which I continue to think is wrong. Still, even wrong information is information and is better than no information at all.

One think for sure : After your information as well as before, I continue to think 24W is not a problem for this engine at low RPM. To continue with a figurative way of speaking : even I newborn would be able to get more than 4W or 5W even with the tiny crank shown here.

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Mark Boesen wrote:Steve,

There has been several posts including mine with sound advice that you seem to chose to disavow, deny or ignore the facts.

I really think you might be better off actually building a prototype, rather then go on posting long replies based on theoretical scenarios.

I do kinda enjoys your ramblings and I suppose this post will feed you a little, but this is the last post from me.

I really do encourage you to step away from the keyboard, bolt your diesel up to a small motor and just see what it actually does! You'll learn best by doing it yourself.

Good luck,

Mark

As I have said, I am happy to get all kind of replies. I do consider some to be totally wrong. Most of the non engine related comments, I do consider totally wrong.

I have not seen many replies related to the engine. I am happy with all of them, although, I would like to say again I have seen this engine work and I have seen many EIC's ( none of them RC ), yet, I have been evaluating and diagnosing standard EIC for quite a long while. True, I do respect your ( meaning yours and all people in the forum ) experience strongly. Please, note, I do think ( although I may be wrong ) none or very few people here have ever run the engine on low RPM.

I understand the specificity of the design, yet, I think an engine is an engine.

I have dedicated this week on the forum because, as I have been saying, I am still waiting for the mail from Cox in order to reassemble the engine.

Please, note, only around 4 people responded on the engine. The rest is REAL RAMBLING WHICH I HAVE TO REPLY OUT OF POLITENESS TO.

I HAVE POSTED THE EXACT THINGS WITH THE ENGINE I NEED HELP WITH. I HAVE CLEARLY SAID I NEED HELP ONLY WITH THE ENGINE AND NOT ONLY ONE OR TWO THINGS WITH THE ENGINE OR MANY. I HAVE NOT RECEIVED SATISFACTORY ANSWERS. In case you don't know, just say so OR DON'T but do not switch the topic.

I will post the help I need here for you again. In case you want to help, I will be happy. In case you don't, I am used to.

HELP NEEDED :

I DO NEED HELP WITH THE ENGINE. I have clearly been saying what help.

1. HELP WITH THIS ENGINE AND ALTERNATIVE FUELS SUCH AS BIODIESEL. Any information for fuel with standard products and without Ether is welcome ( IN CASE THIS IS POSSIBLE, because, as some say, this may not be possible with this engine ). I thanked the post from the UK which showed an engine running on such a fuel. I may try after the project is assembled and run on standard fuel.

2. HELP WITH THIS ENGINE AND STANDARD FUEL :

2.1 WHAT KIND OF STANDARD FUEL CAN I USE. WHAT ARE THE COMPONENTS? WHAT ARE THE PERCENTAGES OF THE COMPONENTS. I have thanked Ken for the information of medicinal Kerosene as well as First Pressed Castor Oil. Also for Cetane Booster : Amil or Isopropyl Nitrate and not EthylExyl Nitrate. I cannot find these but I am thankful I will know what to look for and get should these become available here.

2.2 WHAT ARE THE START UP SETTINGS FOR A GIVEN FUEL : How much is the air valve ( throttle open )? How much is the fuel needle valve ( throttle ) open. How much is the compression screw open. How many ( very approximately ) spring starts would I need to do before the engine starts.

2.3 WHAT ARE THE SETTINGS AFTER START UP? To what extend do I have to tighten up the compression screw after start as well as the air valve ( throttle ) and the needle valve? How many seconds or minutes do I have to react and readjust these?

2.4 WHAT ARE THE SETTINGS FOR A NORMAL RUN? What is the fuel needle valve setting? What is the compression screw setting? Obviously, the air valve ( throttle ) is used from almost fully closed or fully closed to fully open.

2.5 WHAT PERCENTAGES OF THE STANDARD FUEL OR WHAT FUEL DO YOU THINK IS THE BEST FOR GETTING MORE POWER AT LOW RPM?

2.6 WHAT DO YOU THINK OF METHANOL BASED FUEL AS OPPOSED TO KEROSENE BASED FUEL?

2.7 I do not expect an answer to this question but this is the most important question : Where can I get these and other fuel components or fuels in Ottawa, Ontario, Canada? Again : I DO NOT EXPECT AN ANSWER.

3. Does anyone know of a clever way to get inexpensive Ether and or Methanol? University Supply Places, Medical Supply, Hobby Supply, Model Airplane Clubs, Racing, Truck Stops, Truckers Helping Truckers, Diesel Car Enthusiast Groups, Paint Shops, Private Airfields?

4. ENGINE RELIABILITY AND LONGEVITY AFTER A LONG CONTINUOUS ( OR APPROXIMATELY CONTINUOUS ) WORK AT ANY RPM, EVEN HIGHEST. How much do you run your engines. When you go out to fly, do you run your engines for 6 or 8 hours, tank load after tank load. How often do you go for a fly session? Do you go almost every Saturday and Sunday? Do you do competition where you have to train almost the whole week and or month? Do you abuse your engines a lot in order to perform stunts. Without keeping a log book : approximately : how long? Have your engines ever broken? What? How long after new?

5. PISTON RESETTING : How often do you do piston resetting when engine new and how often when run. I thank this responder who said the piston was only reset once when the engine was acquired ( second hand ) and than run for years under heavy abuse ( purchased for $3 ) without a problem. What are your experiences?

6. Do you know other tricks for a better start up, other than priming. What is your input on priming? Do you warm your cylinders with a blow torch? Do you keep your engines in your cars just before start up in the freeze? What is the most freezing weather you have started a diesel in? What will happen in case the engine is kept at minus 10ºC for a long while? Will the engine start? What other temperatures have you started your engines in?

7. HOW DO YOU ADJUST THE SETTINGS AS WELL AS THE FUEL PERCENTAGES IN FREEZING WEATHER AS WELL AS IN HOT?

8. WHAT IS THE TINIEST PROPELLER TO USE FOR LOW RPM? CAN I USE, SAY, A 3.5 INCH PROPELLER? HOW MANY BLADES? Remember, I do not use the propeller for flying but as a fan.

To summarise : THE HELP I NEED THE MOST HAS BEEN LISTED HERE AND BEFORE. Any help with the engine is welcome even this which says of alternative cranks. Third party carburetor prices and availability welcome for future. Taking care of the engine is also welcome.

Special thanks to :

The poster of the post on reliability of the engine and longevity.

The poster from the UK of the alternative diesel fuel with percentages and components.

The posters who have commented on low RPM : positive and negative, all.

Ken from the UK who clarified the best products to make the best Kerosene based fuel and displayed the bottles with labels to do so.

The poster who commented on the bidirectionality of the engine which was corrected in the thesis.

The posters who have posted other micro generators for a good reference.

Please, be kind posters. REFLECT ON THE ENGINE AND FUEL. Try to refrain from commercial viability or any business advices as well as electrical and electronics or, in case you must, try to be as quick on these as possible and as long as possible on the engine and fuel and other listed questions. Also, please, try to skip long comments on things which I will easily be able to find out and there is no much room for a mistake, for example : I will soon hear how loud the engine with a muffler is and will post a video. No need to post long comments on what I can hear. However, in case you would like to comment on how to improve these, you are more than welcome. In this example, in case you say how to reduce the noise ( with fuel or more muffler or the two thereof ) you are welcome.

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

Re: Micro 12VDC Generator with a Cox .049 Sure Start Diesel Engine

dinsdale wrote:Thanx Rusty, my apologies.RknRusty wrote:Dins, that suggestion was a quote by Surfer Kris to Steven. However for some reason the end-quote tags in this thread keep getting dropped all over the place. Makes who-said-what very confusing. If I get time I might try to sort it out, but not tonight.dinsdale wrote:Well there ya go! You don't need any help, but you obviously have things to teach all us here.StevenStanleyBayes wrote:Then I would suggest that you learn how to tune and use the engine on commercially available model-diesel fuel. That should give you experience with how to operate a model diesel engine. Other fuels are a little futile especially on an engine like the cox sure start.

Forgive me folks, but Steve is sounding more and more like a troll to me.

Rusty

Sorry, I did not see the reply. True, I did not write this. However, may I take this opportunity to say the SETTING AND TUNING are some of the main things I have joined the forum. THIS IS WHAT I NEED YOUR HELP WITH. Whoever wants to help, I will be thankful. Whoever does not, not a big deal.

THE HELP I NEED :

THE HELP I NEED :

Because of some probable misunderstandings, I have decided to post in a new reply the most important help I have been hoping to get from this forum :

I have not been teaching anyone anything as I am not the one to teach. I have been simply replaying to all post because I think not to reply is offensive or impolite. In case this is the other way around, just say so and I will stop answering to every post.

I DO NEED HELP WITH THE ENGINE. I have clearly been saying what help.

1. HELP WITH THIS ENGINE AND ALTERNATIVE FUELS SUCH AS BIODIESEL. Any information for fuel with standard products and without Ether is welcome ( IN CASE THIS IS POSSIBLE, because, as some say, this may not be possible with this engine ). I thanked the post from the UK which showed an engine running on such a fuel. I may try after the project is assembled and run on standard fuel.

2. HELP WITH THIS ENGINE AND STANDARD FUEL :