Log in

Search

Latest topics

» Kofuku Maru Fishing Boat Modelby rsv1cox Today at 9:47 am

» My current avatar photo

by TD ABUSER Today at 12:50 am

» TEE DEE Having issues

by GallopingGhostler Yesterday at 11:38 pm

» It's the X Wing that has a canard

by 1975 control line guy Yesterday at 10:35 pm

» Cox 020 PeeWee rebuild questions

by 706jim Yesterday at 9:32 pm

» Free Flight Radio Assist

by TD ABUSER Yesterday at 2:58 pm

» Pathé Modeling Videos

by Levent Suberk Yesterday at 2:10 pm

» New Model Build

by rdw777 Yesterday at 10:28 am

» My latest doodle...

by layback209 Yesterday at 1:20 am

» Drones, pretty nifty...........

by rsv1cox Tue Nov 12, 2024 6:55 pm

» Project Cox .049 r/c & Citabrian Champion

by roddie Tue Nov 12, 2024 6:20 pm

» My N-1R build log

by roddie Tue Nov 12, 2024 3:27 pm

Cox Engine of The Month

Thoughts on a homemade regulator

Page 1 of 2

Page 1 of 2 • 1, 2

Thoughts on a homemade regulator

Thoughts on a homemade regulator

We are all familiar with the advantages/challenges involved with forcing fuel into an engine... and the effects on needling. Crankcase pressure to a hard-tank vent can be regulated by decreasing the hole size in either the tank vent or the case's nipple... correct? I was thinking about small engines running a bladder.. A super-simple in-line regulator could be made by using a short brass connector-tube. Find a very small common-pin or perhaps a piece of .015" dia. music-wire.. "wax-it" and insert into the tube with JB weld. When the epoxy sets.. pull out the pin with needle-nose pliers. Now you have a regulator that may allow for better needling with a coarse-thread unit. You could make-up a couple different sizes to try.. using different diameter pins. It also serves as a fueling coupler in your line.

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

A true regulator will maintain fuel pressure within a given +/- tolerance as long as varying fuel pressure is within its operating range, until it drops off below the regulated pressure. Seems to me that fuel flow would varying with your orifice restrictor idea, but then I have no experience with model fuel pressure systems.

I'd say give it a shot. If it works giving you more consistent runs, I'd say your experiment was a success. If it doesn't despite efforts tweaking it, then I'd think it's time for another approach or maintain status quo. However with these smallest engines and relatively light airframes, I don't know how much weight a true fuel pressure regulator would add. May be they are out there, I just never heard of anyone using such, but then I've not been around fliers using bladder systems. Having been at motocross events, though unrelated but in a similar vein, it's amazing the trouble and expense that folks go through to be competitive.

I'd say give it a shot. If it works giving you more consistent runs, I'd say your experiment was a success. If it doesn't despite efforts tweaking it, then I'd think it's time for another approach or maintain status quo. However with these smallest engines and relatively light airframes, I don't know how much weight a true fuel pressure regulator would add. May be they are out there, I just never heard of anyone using such, but then I've not been around fliers using bladder systems. Having been at motocross events, though unrelated but in a similar vein, it's amazing the trouble and expense that folks go through to be competitive.

GallopingGhostler- Top Poster

Posts : 5706

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

I have to confess that I don't see any point in adding another fixed restriction in the fuel line. Sounds like you are after a remote needle?

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

Surfer_kris wrote:I have to confess that I don't see any point in adding another fixed restriction in the fuel line. Sounds like you are after a remote needle?

I'm not sure my thinking is correct on this.. but let me ask a question.. When pressurizing a tank or running a bladder set-up, There is now positive pressure to the feed-line. How much pressure? Is it important to know how much? I feel it's important to know..how much.. is "too much". Let's use the un-throttled Cox .049 reedy running a horseshoe backplate with stock 80 TPI needle, as an example. Running a bladder is generally problematic.. unless a finer NVA is installed. What this tells me; is there's too much pressure. There's a balance between how much fuel the engine requires "pulling on suction".. to having fuel forced into it. These two types of fuel-feed are miles apart.. in function, with no variable in between. We typically just add pressure.. and let the needle deal with it.. is what I'm saying.

Kris, when you mentioned a "remote needle".. if you meant "2nd needle".. that's sort of what my concept is.. but in the form of a simple connector tube in the feed-line, with a greatly reduced inside diameter. Perhaps a few with varied sizes to experiment with. I would think that even the "slightest amount" of pressure above a suction feed.. would improve reliability.. Who knows.. it may even prevent surges on a throttled engine running on muffler pressure.. and possibly improve throttle response? Of course.. running a fuel filter before the reduction-fitting would be imperative.

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

A problem in a bladder system can be too much pressure. However most of us trying to use bladder pressure usually seek out the very fine thread NVS to help set and hold the right setting.

The range from rich to lean is too small for the coarser thread NVS to resolve. In other words with a 80-TPI it is very hard to hit and then hope it holds the setting. 1/8 to 1/4 turn on a 128-TPI needle valve has very little liner movement of the needle. The 80-TPI needle moves in or out a longer distance.

I think most of the fuel line reducing efforts are focused on regulating the air into the fuel cell;

Or manage the exhaust or crank case pulsing pressure; Also I know sometimes the recommendation to "restrict" the crank case nipple is to try and prevent flooding of the CC.

The range from rich to lean is too small for the coarser thread NVS to resolve. In other words with a 80-TPI it is very hard to hit and then hope it holds the setting. 1/8 to 1/4 turn on a 128-TPI needle valve has very little liner movement of the needle. The 80-TPI needle moves in or out a longer distance.

I think most of the fuel line reducing efforts are focused on regulating the air into the fuel cell;

Or manage the exhaust or crank case pulsing pressure; Also I know sometimes the recommendation to "restrict" the crank case nipple is to try and prevent flooding of the CC.

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

Roddie, rather than filling and resizing, an assortment of tube like this will give you a ton of orifice options.

I have a sack of this stuff which is a mix of brass, aluminum and copper, and it's one of the handiest purchases I have ever made. The smallest will barely accept one strand of .027 leadout wire. In fact last night I used it to crimp my new leadout line to the old leads being replaced and pull it through the wing on my Oriental.

You could try inserting different sizes and see what happens.

http://www.ebay.com/itm/like/291268619718?lpid=82

Shop around, I don't see a lot of copper in that example.

Rusty

I have a sack of this stuff which is a mix of brass, aluminum and copper, and it's one of the handiest purchases I have ever made. The smallest will barely accept one strand of .027 leadout wire. In fact last night I used it to crimp my new leadout line to the old leads being replaced and pull it through the wing on my Oriental.

You could try inserting different sizes and see what happens.

http://www.ebay.com/itm/like/291268619718?lpid=82

Shop around, I don't see a lot of copper in that example.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

Just for reference, when running readies or tee dees on crank case pressure I drill the hole in the pressure fees with a #70 drill bit. This has been very effective for .049's, .051's and .061's, at least for me. Good luck.

fit90- Diamond Member

- Posts : 1341

Join date : 2011-08-11

Location : Naples, Florida

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

What size is a #70 drillbit?

I don't think the issue is too much pressure, as much as it is a too coarse needle. Even on suction alone the setting can be tricky, just holdong the needle in ones fingers can change the running...

A remote needle would be easy to install in series with the regular needle. If the remote needle is fine enough it could do all the regulation/restriction with the regular one still in place but well open.

I've stocked up a bit on old OS needle valve assemblies (for the .10-.15 RC), with the intention of using them as remote needles, but haven't tried them with a bladder tank.

I don't think the issue is too much pressure, as much as it is a too coarse needle. Even on suction alone the setting can be tricky, just holdong the needle in ones fingers can change the running...

A remote needle would be easy to install in series with the regular needle. If the remote needle is fine enough it could do all the regulation/restriction with the regular one still in place but well open.

I've stocked up a bit on old OS needle valve assemblies (for the .10-.15 RC), with the intention of using them as remote needles, but haven't tried them with a bladder tank.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

#70

0.028 inches

0.711 mm

0.028 inches

0.711 mm

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

RknRusty wrote:Roddie, rather than filling and resizing, an assortment of tube like this will give you a ton of orifice options.

I have a sack of this stuff which is a mix of brass, aluminum and copper, and it's one of the handiest purchases I have ever made. The smallest will barely accept one strand of .027 leadout wire. In fact last night I used it to crimp my new leadout line to the old leads being replaced and pull it through the wing on my Oriental.

You could try inserting different sizes and see what happens.

http://www.ebay.com/itm/like/291268619718?lpid=82

Shop around, I don't see a lot of copper in that example.

Rusty

Hi Rusty, Yes.. not much Copper.. I bought a similar assortment (K & S) through Tower this past season. Very useful indeed. That small piece you mentioned is the same ID size that "fit90" refers to having success with, for case-pressure on his reedies and Tee Dee's. A #70 drill is .028". Perhaps this is the smallest restriction one could use; before fuel-starving an .049 running at maximum speed? I tend to doubt it though.. because the same size restriction is recommended on a "improvements-sheet" for the C.G. "VooDoo's" hard tank vent.. running a MUCH larger engine on case-pressure.

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

You may be on to something Roddie. I can't bladder a reedie without using a fuel filter to step down the line size. Even then any more than 1/2oz floods it whereas I can put a full oz in a tee dee bladder and it runs fine. I may try this.

Jim

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 56

Location : Colorado

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

JPvelo wrote:You may be on to something Roddie. I can't bladder a reedie without using a fuel filter to step down the line size. Even then any more than 1/2oz floods it whereas I can put a full oz in a tee dee bladder and it runs fine. I may try this.

Jim

Like I said Jim, my thinking could be all wrong on this.. because I haven't tried it.. and I've never tried a bladder.. or any other form of pressure feed for that matter. It just makes sense to me.. that a "little" fuel-pressure would be more than enough.. to run an engine that was designed to run on suction alone.. so why apply full pressure, which is only limited by your feed-line's ID alone.. on the needle/seat? If the pressure in the feed-line can be regulated just slightly higher than atmospheric.. then there should be sufficient fuel at the needle regardless of attitude... without forcing it into the engine.. and possible flooding trouble when starting. Why apply more fuel pressure than the engine can possibly burn? A simple test might be to fill a bladder with your usual amount of fuel for a given duration of run-time. Place a restrictor tube in the feed-line and point it back into the fuel bottle. Release the bladder-clip and note how long it takes to empty. If it takes longer than.. say 10-15 seconds, then the restriction may be too small.. and your engine would either run lean, or eventually stall from fuel starvation.

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

Now I want to swage/fuller/neck a piece of brass onto a piece of fine music wire, then extract the wire, and see if the restriction means a bladder can run on a regular needle!

This might have to wait a bit.

Phil

This might have to wait a bit.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

pkrankow wrote:Now I want to swage/fuller/neck a piece of brass onto a piece of fine music wire, then extract the wire, and see if the restriction means a bladder can run on a regular needle!

I doubt you'll be able to make that restriction at excactly the right diameter on the first go...

The whole will have to be very tiny, you might as well start with no whole at all and then drill from there until you get it right.

I think the idea is sound, but it would be much better to make the restriction tunable, i.e. to use a fine threaded needle in series with the regular one. This aditional needle could then make the regular needle much less sensitive, and perhaps even obsolete.

So one needle for a coarse adjustment and another for the fine tuning, sounds great.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

Surfer_kris wrote:pkrankow wrote:Now I want to swage/fuller/neck a piece of brass onto a piece of fine music wire, then extract the wire, and see if the restriction means a bladder can run on a regular needle!

I doubt you'll be able to make that restriction at excactly the right diameter on the first go...

The whole will have to be very tiny, you might as well start with no whole at all and then drill from there until you get it right.

I think the idea is sound, but it would be much better to make the restriction tunable, i.e. to use a fine threaded needle in series with the regular one. This aditional needle could then make the regular needle much less sensitive, and perhaps even obsolete.

So one needle for a coarse adjustment and another for the fine tuning, sounds great.

I think the 2nd needle idea has merit.. except that there's no precise medium in which to conduct the experiment because of the variable orifice. The added weight of a 2nd NVA on a tiny engine is also another consideration. Maybe it would be "trick" for larger displacement engines.. Think of this simple design as an in-line "metering-jet" that is always consistent.. (whether it works or not..

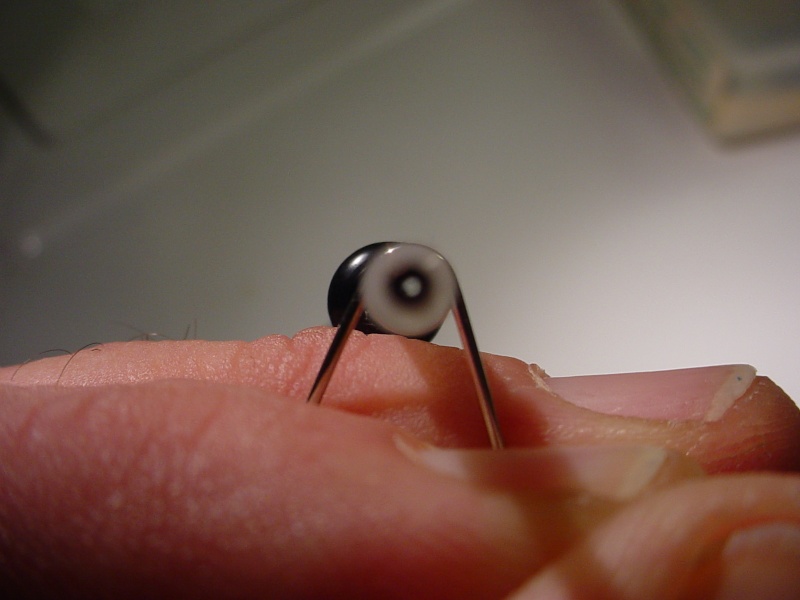

Here's an example of how simple; shown are sm. size Dubro silicone fuel line.. with a short piece of K & S 1/16" OD Copper tube inserted. It's a fairly tight fit too..

Going smaller can be done using a larger diameter tube (enough to get epoxy into..) and using pins smaller than .028". I have .015" music-wire. .013" fiber-optic.. and if you have sm. gage stranded-Copper wire on hand.. you may have a variety of choices by stripping the insulation off.. and measuring individual strands with a vernier-caliper/micrometer.

Maybe this a lot of "fuss'... but imagine being able to make your standard 80 tpi needle in your Cox Prod. engine, work with a bladder.. and at the same time; reduce the chances of flooding the engine when you release the hemostat/clip.

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

You would have to go a lot smaller then that tube in order to see any effect...

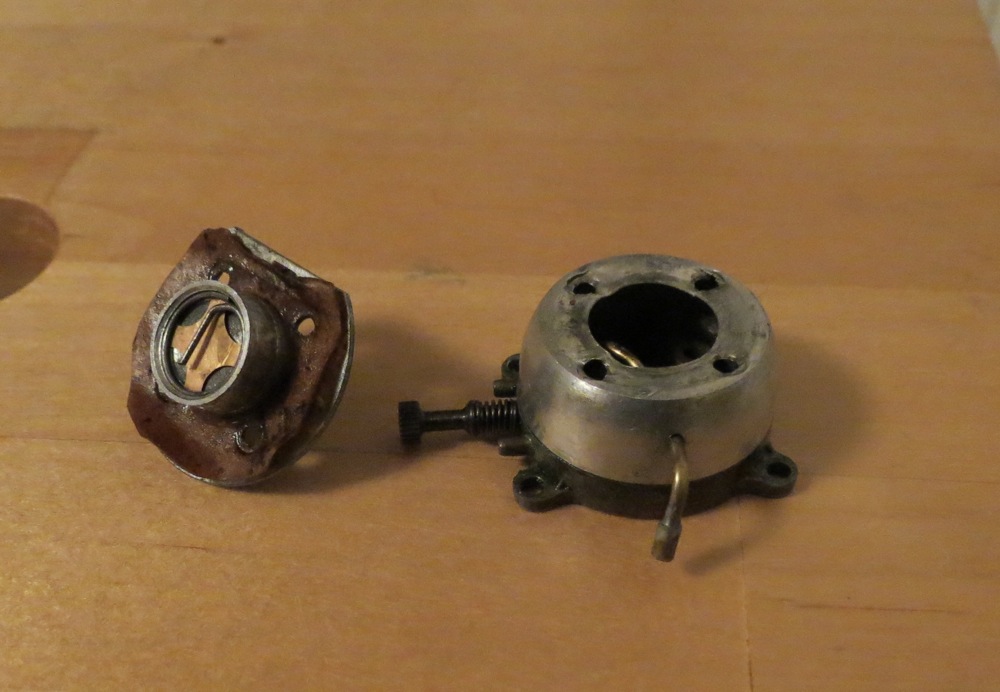

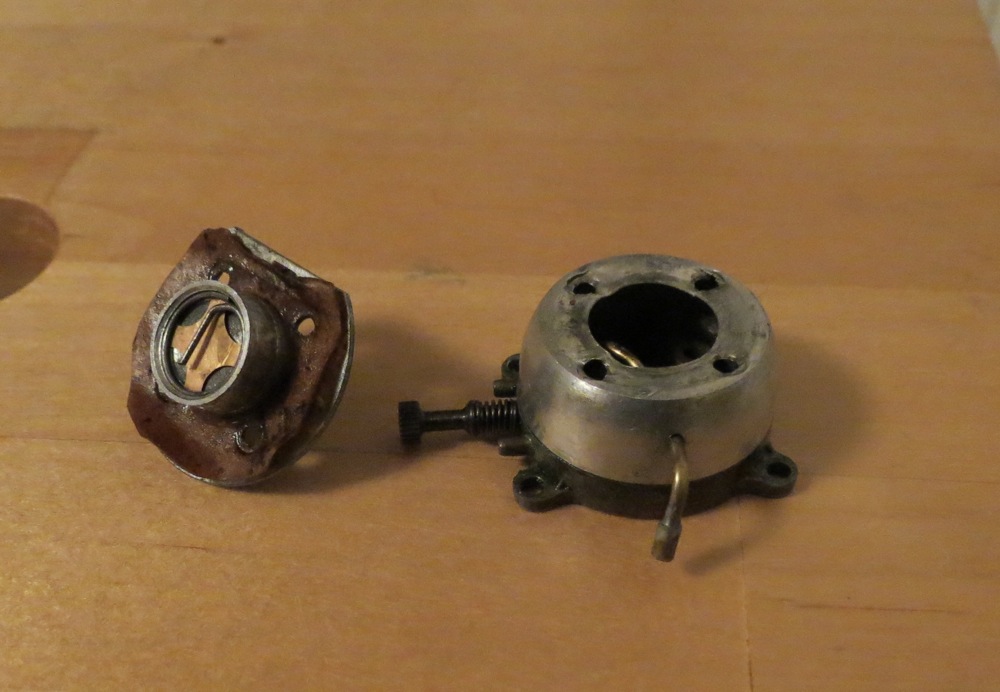

I have used some very small brass tubes in the past to get an external tank on a regular Babe Bee. Even on suction alone there is no problem drawing fuel through the tiny pipe (shown below), the needling did work very well though, much better than with the integral tank as I remember it. That was about 30 years ago though, maybe I should give it run again...

Oh, by the way, has anyone else ever had an engine with such a wafer thin front end of the tank?

(and yes the tank separated into two parts)

I have used some very small brass tubes in the past to get an external tank on a regular Babe Bee. Even on suction alone there is no problem drawing fuel through the tiny pipe (shown below), the needling did work very well though, much better than with the integral tank as I remember it. That was about 30 years ago though, maybe I should give it run again...

Oh, by the way, has anyone else ever had an engine with such a wafer thin front end of the tank?

(and yes the tank separated into two parts)

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

Wow.. I've never seen an integral tank with a separate reed-holder..  Where did you get that engine?

Where did you get that engine?

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

I guess it was a monday morning (or friday afternoon?) product. The front of the tank had been machined so thin that it broke off....

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

I just bumped up an old thread in the cox discussions area that might be a little helpful here. You know, maybe, maybe not, but hopefully. It is titled "starting a pressurized cox."

fit90- Diamond Member

- Posts : 1341

Join date : 2011-08-11

Location : Naples, Florida

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

Don't mess with epoxy, swage it down on a lubricated mandrel!

Phil

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

pkrankow wrote:Don't mess with epoxy, swage it down on a lubricated mandrel!

Phil

That will work with hardened-steel wire.. but how small a diameter can be obtained.. (both with the mandrel and the tubing?) I have .015" K & S... but that's the smallest I have on hand. It would be interesting to experiment with hypodermic-tubing.. set in a 1/16" Copper coupler-tube, using solder. Again.. "filtering" the fuel upstream would be a must.

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

Soft copper tubing in these sized can be sealed. Soft aluminum too I am sure. Both metals can be annealed if needed, the copper is easier to anneal if needed: heat to dull red in dim light and cool by any means. I would have to look up for aluminum, but it is slightly different for different grades.

I would use a mandrel of music wire and roll the tube between two pieces of cold roll steel till the mandrel started to be grabbed by the tube, so I could get it out still.

I stretched copper tube quite a bit trying to make some pop-pop boat motors, never tried shrinking it though.

Phil

I would use a mandrel of music wire and roll the tube between two pieces of cold roll steel till the mandrel started to be grabbed by the tube, so I could get it out still.

I stretched copper tube quite a bit trying to make some pop-pop boat motors, never tried shrinking it though.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

I'm greatly confused as to the purpose of this experiment. What are you trying to yield here? You will gain no more power nor would you regulate speed doing so. In other words, it either works or it doesn't. The needle valve is the essential piece of the puzzle. Running crank pressure is a pain in the neck . Yes, it works, it also can be more problematic that what it's worth. It doesn't magically give the engine more power, what it does though is that it allows you to run a larger venturi which can be beneficial in generating more power. One thing it can do in addition is allow for the use of the stock needle assembly. Realize something here, if it was good to use, it would still be in use today. Very few that I know of use crank case pressure in control line aside from the vintage combat crowd. The vintage stuff uses it due to the engine arrangement and tanks. My engine for instance came with the backplate already tapped for pressure. I've gone and soldered some of the fittings back up and used either bladder or suction.

I sometimes feel the need to use a retrictor in my fuel line due to the bladders I use. Temperature is a critical factor in bladder use. I use a natural latex with little pressure in the hot summer, in the winter however I need to use the highest thickest wall bladders I can use. The wall thickness is 1/8" and these are being used for 1/2A. Again, you use it if you need it. Installing a restrictor just to use a stock needle may work if that's your goal, but your not going to benefit from using it. The threads are too coarse and generally the taper of the needle isn't very good. This is the problem with the remote needles that are offered on the OS LA series engines.As soon as the engine starts to lean, it falls on it's face due to fuel starvation . Even though the needles are o-ring sealed allowing for high pressure use like a bladder, you don't get the finite adjustment that you would receive from a high quality replacement.

I sometimes feel the need to use a retrictor in my fuel line due to the bladders I use. Temperature is a critical factor in bladder use. I use a natural latex with little pressure in the hot summer, in the winter however I need to use the highest thickest wall bladders I can use. The wall thickness is 1/8" and these are being used for 1/2A. Again, you use it if you need it. Installing a restrictor just to use a stock needle may work if that's your goal, but your not going to benefit from using it. The threads are too coarse and generally the taper of the needle isn't very good. This is the problem with the remote needles that are offered on the OS LA series engines.As soon as the engine starts to lean, it falls on it's face due to fuel starvation . Even though the needles are o-ring sealed allowing for high pressure use like a bladder, you don't get the finite adjustment that you would receive from a high quality replacement.

Ken Cook- Top Poster

- Posts : 5634

Join date : 2012-03-27

Location : pennsylvania

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

Ken Cook wrote: I'm greatly confused as to the purpose of this experiment. What are you trying to yield here? You will gain no more power nor would you regulate speed doing so. In other words, it either works or it doesn't. The needle valve is the essential piece of the puzzle. Running crank pressure is a pain in the neck . Yes, it works, it also can be more problematic that what it's worth. It doesn't magically give the engine more power, what it does though is that it allows you to run a larger venturi which can be beneficial in generating more power. One thing it can do in addition is allow for the use of the stock needle assembly. Realize something here, if it was good to use, it would still be in use today. Very few that I know of use crank case pressure in control line aside from the vintage combat crowd. The vintage stuff uses it due to the engine arrangement and tanks. My engine for instance came with the backplate already tapped for pressure. I've gone and soldered some of the fittings back up and used either bladder or suction.

I sometimes feel the need to use a retrictor in my fuel line due to the bladders I use. Temperature is a critical factor in bladder use. I use a natural latex with little pressure in the hot summer, in the winter however I need to use the highest thickest wall bladders I can use. The wall thickness is 1/8" and these are being used for 1/2A. Again, you use it if you need it. Installing a restrictor just to use a stock needle may work if that's your goal, but your not going to benefit from using it. The threads are too coarse and generally the taper of the needle isn't very good. This is the problem with the remote needles that are offered on the OS LA series engines.As soon as the engine starts to lean, it falls on it's face due to fuel starvation . Even though the needles are o-ring sealed allowing for high pressure use like a bladder, you don't get the finite adjustment that you would receive from a high quality replacement.

Hi Ken, The purpose mainly.. is to reduce the pressure in a "pressurized" line.. (like any fuel regulator) so that there is some pressure at the needle.. but not so much; where it becomes "touchy" to adjust... or easily floods the engine while trying to start it. (and yes.. the possibility of using a stock NVA.. rather than having to purchase and install an aftermarket fine-thread unit.)

These thoughts are targeted more on our small/non-throttled Cox engines, running at w.o.t. and utilizing a forced bladder-feed.. rather than crankcase-pressure, which is generally regulated somewhere between the crankcase pressure-fitting and a tank-vent.. as you know.

What I "don't know".. is the fuel-demand for a given engine.. before fuel consumption exceeds the available fuel-flow through the feed-line. This is something that would need to be experimented with.

I realize that there would be no performance gains.. per se'.. but there may be a lot to gain from a reliability standpoint.. without having to modify the engine at all.

Another option for producing a tiny "jet" is to use "guitar strings" for a mandrel.. which are as small as .007" in diameter.. and progress larger in increments of .001" to .002"

Re: Thoughts on a homemade regulator

Re: Thoughts on a homemade regulator

Why not emulate the NVA but without the needle and use a drilled hole to restrict the flow. Number drills can be had quite cheaply.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Page 1 of 2 • 1, 2

Similar topics

Similar topics» RE: Thoughts on a homemade regulator

» homemade gaskets

» Homemade Tether Car

» Homemade Washers

» Here's One of My homemade Robots.

» homemade gaskets

» Homemade Tether Car

» Homemade Washers

» Here's One of My homemade Robots.

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules