Log in

Search

Latest topics

» Purchased the last of any bult engines from Ken Enyaby Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» TEE DEE Having issues

by TD ABUSER Yesterday at 9:43 pm

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» Retail price mark-up.. how much is enough?

by Ken Cook Yesterday at 1:37 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

Cox Engine of The Month

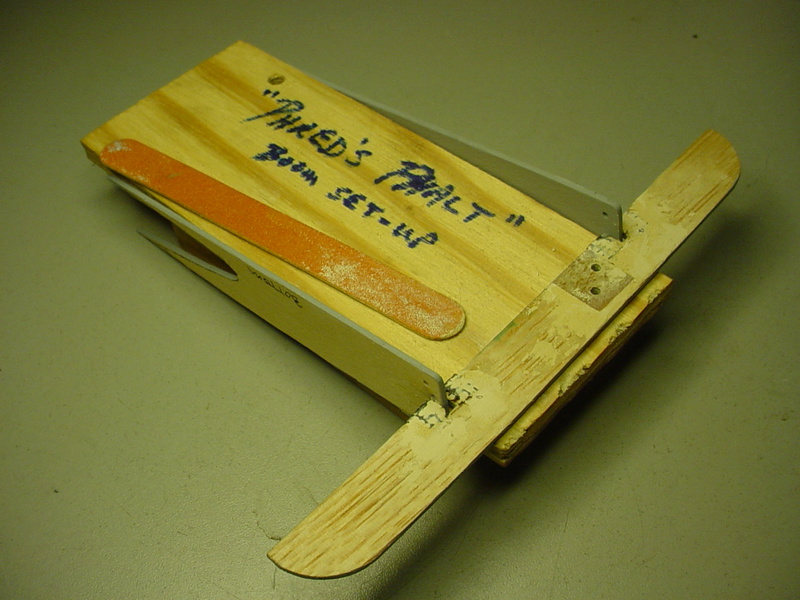

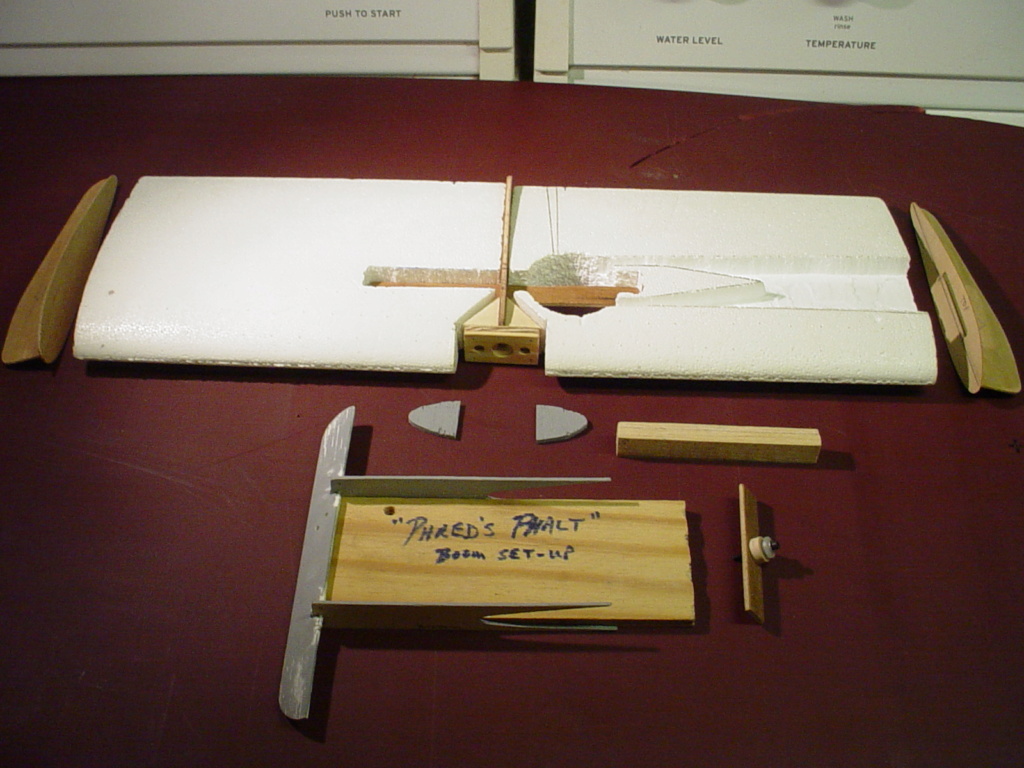

"Phred's Phault"

Page 6 of 7

Page 6 of 7 •  1, 2, 3, 4, 5, 6, 7

1, 2, 3, 4, 5, 6, 7

Re: "Phred's Phault"

Re: "Phred's Phault"

KariFS wrote:roddie wrote:I'd really like to be the first guy that I've seen here; since "I've" been a CEF member.. to utilize a postage-stamp backplate in a scratch-built model!

Don't worry, there's a good chance that you will...

I've been considering my own version of Dale Kirn's "290 Special" for a few months, it is on "the list" but knowing me, it'll take a few months more even though I do have an engine already cleaned up for it

EDIT: here's a link to the plan:

http://www.outerzone.co.uk/plan_details.asp?ID=6104

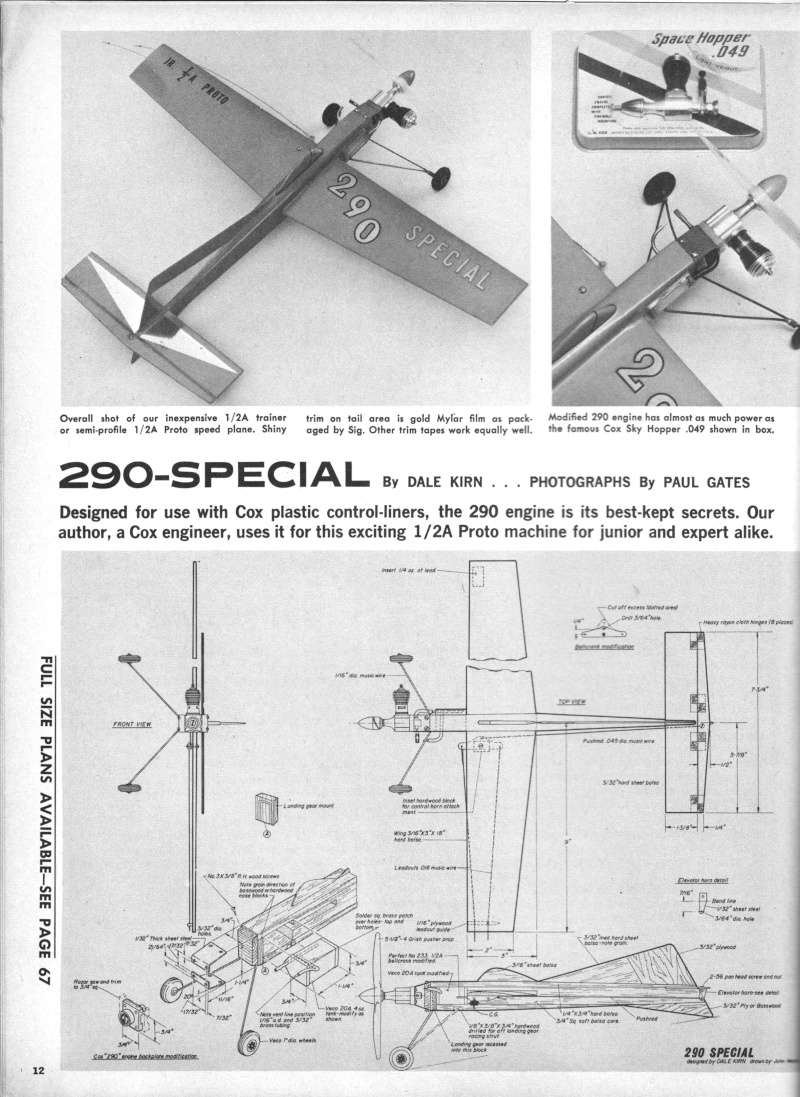

Hi Kari, I had previously gathered info on the 290 Special. Some of this info derived from a MAN June 1967 issue, highlights the engine in particular.

Here's some MAN page-scans from that issue, provided by our CEF member GWillieFox. (I wish I had the entire article)

So.. citing the above; if you're assembling a "repro" 290 engine from parts.. the backplate is just one part of the equation. You'd also need a dual-ported cylinder. This was really Cox's first high-performance reed-valve engine.. designed as a replacement engine for their "heavier" RTF plastic airplanes. In "stock" form, it had more power than a Babe Bee.. and if fitted with a high-compression glow-head, would turn 16K rpm on a 6 x 3 prop with Cox Racing Fuel.

It's handicap.. as most of us know; was it's lack of a practical mount for installing in a balsa-wood airframe. Dale Kirn's model shows trimming of the engine's back-plate. That's one way to do it.. (for streamlining) but not necessary for mounting in general.

I hope "you" find the time to build yours.. and I'd be very interested in the progress.

Re: "Phred's Phault"

Re: "Phred's Phault"

Thanks for the info Roddie. I have a total of 4 or 5 postage stamp engines, I think they are all from crashed plastic planes. The one I had cleaned up earlier for this build has a single-bypass #2 of course. But I have another one, it's a late model unit with the thick neck crankcase and thick-wall #1 cylinder. Just need to clean it up and find a new needle valve for it (pretty sure I have one somewhere).

I think I will do the streamlining too as one of the backplates is a bit chewed up from the edges. I am also thinking about making the mounting plates out of aluminum and the shape will probably be "curved" or with a larger-radius bend instead of the sharp bend shown in the plan.

I think I will do the streamlining too as one of the backplates is a bit chewed up from the edges. I am also thinking about making the mounting plates out of aluminum and the shape will probably be "curved" or with a larger-radius bend instead of the sharp bend shown in the plan.

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: "Phred's Phault"

Re: "Phred's Phault"

There's something about these engines that's endearing to me.

So many were thrown away.. or their back-plates cannibalized for their fine-thread needles. Granted.. the Goldberg retrofit mounts are hard to find.. but custom mounts are not that hard to make. After all.. that's how most old hotrods were built. You know.. custom engine-mounts and Moon-tanks!

So many were thrown away.. or their back-plates cannibalized for their fine-thread needles. Granted.. the Goldberg retrofit mounts are hard to find.. but custom mounts are not that hard to make. After all.. that's how most old hotrods were built. You know.. custom engine-mounts and Moon-tanks!

Re: "Phred's Phault"

Re: "Phred's Phault"

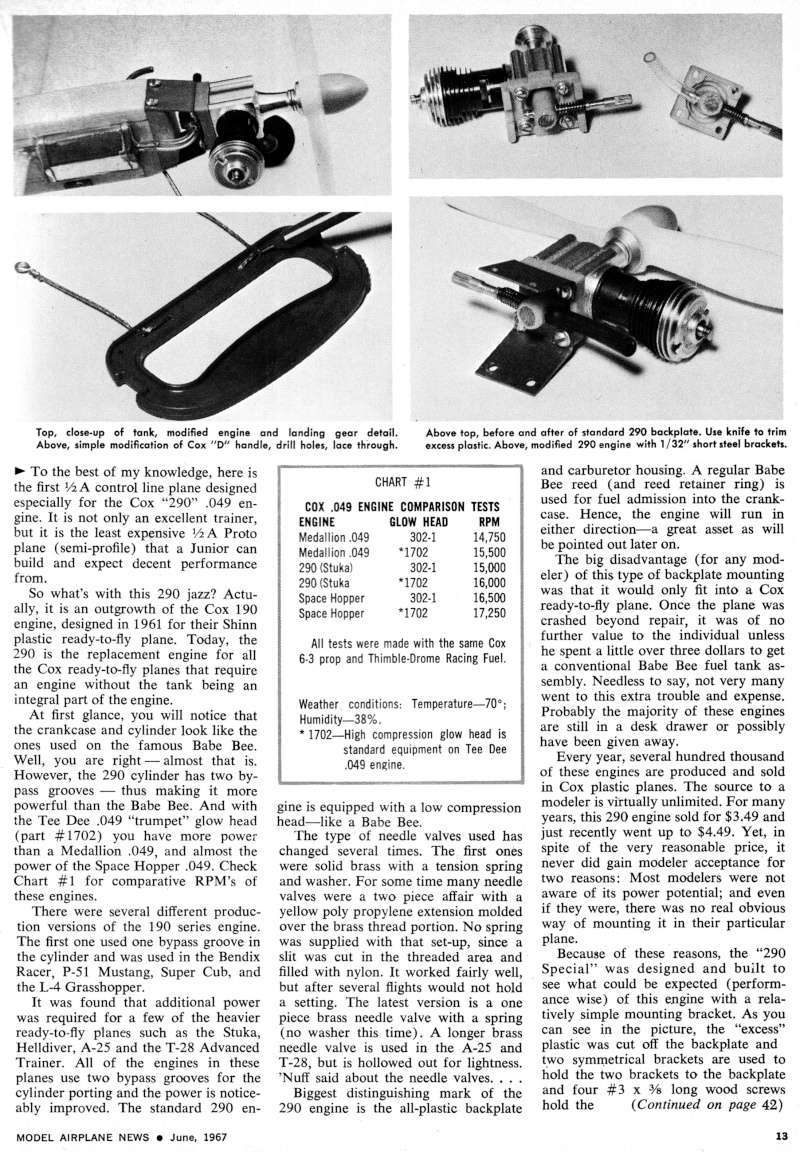

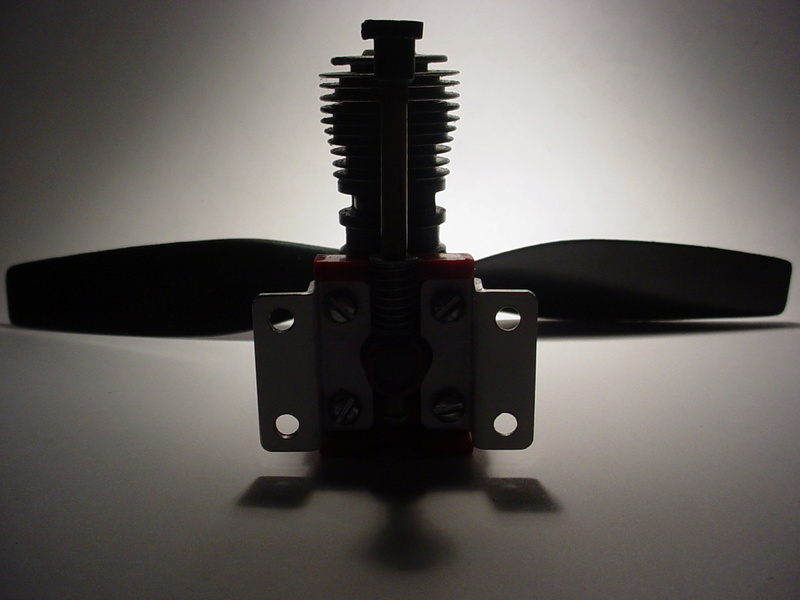

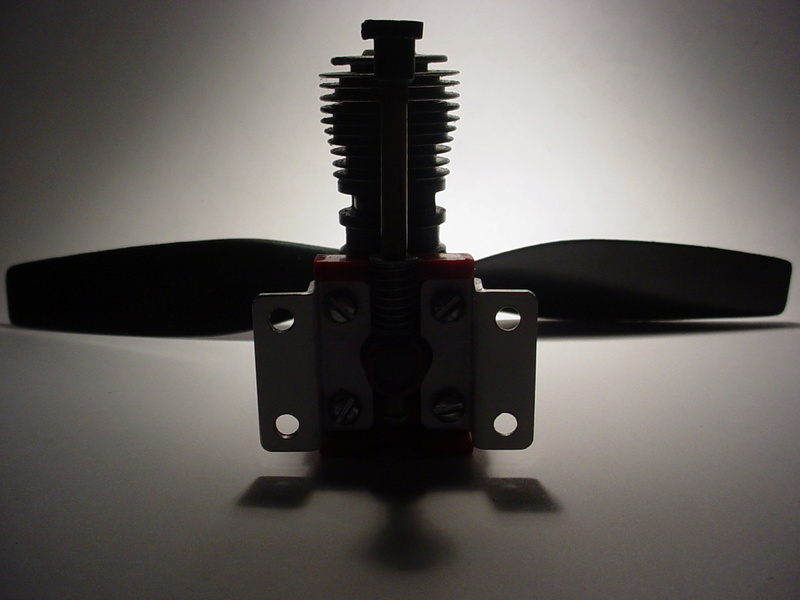

Nice picture! Here's one of mine:

I often take the side of the "underdog" and also have a soft spot for the poor old postage stamp engines Although I did steal the thin wall dual-bypass cylinder from the one in the picture for my otherwise perfect "Silver Bee"

Although I did steal the thin wall dual-bypass cylinder from the one in the picture for my otherwise perfect "Silver Bee"

I often take the side of the "underdog" and also have a soft spot for the poor old postage stamp engines

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

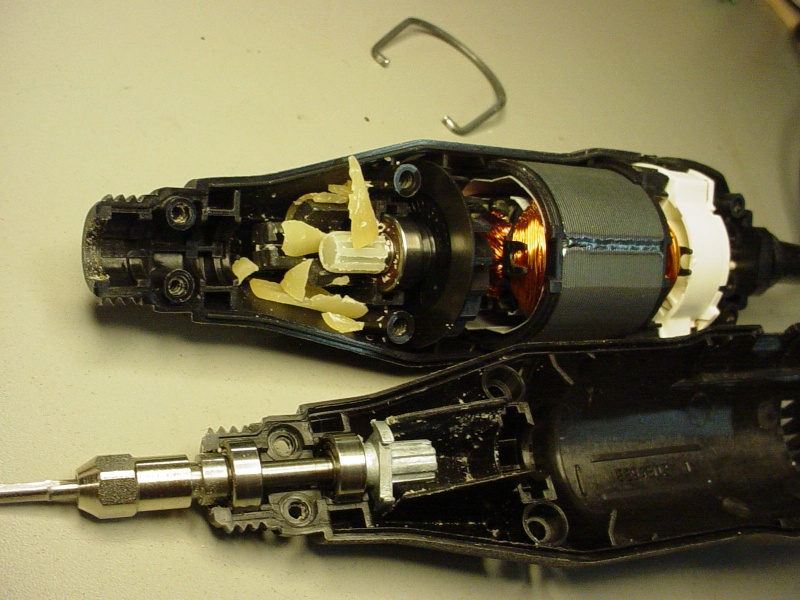

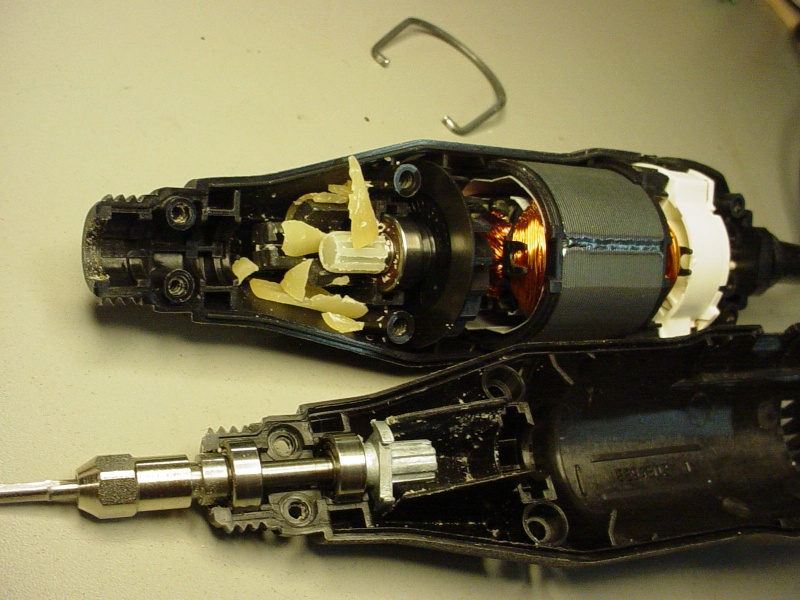

Dremel repair

Dremel repair

Well I finally got around to replacing my Dremel model 395 moto-tool's coupler. Thanks again to Lieven for the spare-parts link.  This couldn't have been easier to do. Tools required were Torx T-10 and T15 drivers.

This couldn't have been easier to do. Tools required were Torx T-10 and T15 drivers.

Remove (unscrew by hand) the plastic spindle-collar/ring and pull-off the tool's wire hanger hoop.. then remove the 6 case screws. (two T-10's on the spindle-end and four T-15's for the main body)

Here's what the old coupling looked like.. disintegrated.

New coupling slips onto motor/spindle shafts effortlessly. Reassemble/Done!

This couldn't have been easier to do. Tools required were Torx T-10 and T15 drivers.

This couldn't have been easier to do. Tools required were Torx T-10 and T15 drivers. Remove (unscrew by hand) the plastic spindle-collar/ring and pull-off the tool's wire hanger hoop.. then remove the 6 case screws. (two T-10's on the spindle-end and four T-15's for the main body)

Here's what the old coupling looked like.. disintegrated.

New coupling slips onto motor/spindle shafts effortlessly. Reassemble/Done!

Re: "Phred's Phault"

Re: "Phred's Phault"

Congrats on a well done repair! Thanks for the pictures and dialog. I know one of mine will die just as I'm half way thru a project. That's why I have a back up and now I know how to fix it when I does break....of old age!!

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: "Phred's Phault"

Re: "Phred's Phault"

Marleysky wrote:Congrats on a well done repair! Thanks for the pictures and dialog. I know one of mine will die just as I'm half way thru a project. That's why I have a back up and now I know how to fix it when I does break....of old age!!

Thanks much! I'd been straight-out with music-gigs for the last few weekends.. and just no energy during the week after work to get anything done. I've cleared a little workspace in the shop.. which does help to motivate when I get the urge. It was time to try out the newly repaired tool today. The depth setting in the router attachment was unchanged.. and I had not loosened the spindle-nut with router-bit installed.. so I just grabbed the wing and finished the slot for the lead-outs.

The tail-booms/elevator assy. had gotten some filler applied last week to the underside of the elevator where the horn-mount-plate is located and the fiberglass-screen hinges lay. I've been using Elmer's wood-filler (comes in a squeeze-tube) and seems to sand easily using an emery-board. To apply the filler, I chose to make a spreader-tool from some heavy clear packaging material. For stiffness; I cut-out a piece along a radius-edge, which worked well for the small/narrow area I had to work in.

More filling/sanding needs to be done.. but I hate that crap..

Here is the planned balloon fuel-cell again.. it's the only part of the model that will have a significant impact on it's aerodynamics. It naturally needs to have a mounting-provision that will not cause it to shift rearward when scrubbing the ground on landing.

I may attach a strip of "sacrificial" material (tape) to the bottom of the capsule to prevent abrasion.. but it depends on the capsule's method of attachment to the belly.

If I use hook-and-loop strips.. I can attach the belly-strip permanently by sewing-it into a thin 1/64" ply-plate as part of the belly-mount, and epoxying it securely. This will alleviate the worry of an adhesive failure "there". If the capsule-strips' adhesive degrades.. I can merely clean it and apply a new piece. A pin/block behind the capsule should prevent any rearward shifting when the model lands.. (hopefully on its belly..)

If I use hook-and-loop strips.. I can attach the belly-strip permanently by sewing-it into a thin 1/64" ply-plate as part of the belly-mount, and epoxying it securely. This will alleviate the worry of an adhesive failure "there". If the capsule-strips' adhesive degrades.. I can merely clean it and apply a new piece. A pin/block behind the capsule should prevent any rearward shifting when the model lands.. (hopefully on its belly..)Thanks for staying tuned..

Re: "Phred's Phault"

Re: "Phred's Phault"

Good to see you got the dremel going and back at the airplane ,, sounds like you got it figured out for the tube tank with the strip of ply. You might want to try a drop of water with that filler it makes it go on a lot smoother with less sanding to do , to much and will wipe right off though  I need some plane building therapy about now with all this heat and the garden wants to wilt or something from the every day rain storms .

I need some plane building therapy about now with all this heat and the garden wants to wilt or something from the every day rain storms .

I need some plane building therapy about now with all this heat and the garden wants to wilt or something from the every day rain storms .

I need some plane building therapy about now with all this heat and the garden wants to wilt or something from the every day rain storms .

getback- Top Poster

Posts : 10442

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: "Phred's Phault"

Re: "Phred's Phault"

If there is a clear area on the underside of the wing, I would probably draw out the fuel tube shape, and carefully recess it half diameter into the wing held by goop or a good layer of double sided tape then accept the bottom hump UNDER the covering with a opening in the rear to replace balloon if needed

I would shape the recess with a soldering iron carefully melting the recess..... try it on a scrap piece of foam and you can see it is pretty easy to form the foam a bit better than using knives or sand paper

I would shape the recess with a soldering iron carefully melting the recess..... try it on a scrap piece of foam and you can see it is pretty easy to form the foam a bit better than using knives or sand paper

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: "Phred's Phault"

Re: "Phred's Phault"

getback wrote:Good to see you got the dremel going and back at the airplane ,, sounds like you got it figured out for the tube tank with the strip of ply. You might want to try a drop of water with that filler it makes it go on a lot smoother with less sanding to do , to much and will wipe right off thoughI need some plane building therapy about now with all this heat and the garden wants to wilt or something from the every day rain storms .

Yea.. the Dremel runs nice and smooth now.. I can hear the difference. Thanks for the tip on thinning the wood-filler. I really over-complicated this model.

Re: "Phred's Phault"

Re: "Phred's Phault"

fredvon4 wrote:If there is a clear area on the underside of the wing, I would probably draw out the fuel tube shape, and carefully recess it half diameter into the wing held by goop or a good layer of double sided tape then accept the bottom hump UNDER the covering with a opening in the rear to replace balloon if needed

I would shape the recess with a soldering iron carefully melting the recess..... try it on a scrap piece of foam and you can see it is pretty easy to form the foam a bit better than using knives or sand paper

Phred, I wanted to keep the balloon-capsule centered because I have a suction-feed. The feed-line would need to be longer.. and turn inward to the back-plate. It might not be as critical where I have a reed-valve induction.. but I might be fighting g-forces more if I offset the capsule, than with a short straight-shot on center. As planned; the feed-line only needs to be about an inch long.

Re: "Phred's Phault"

Re: "Phred's Phault"

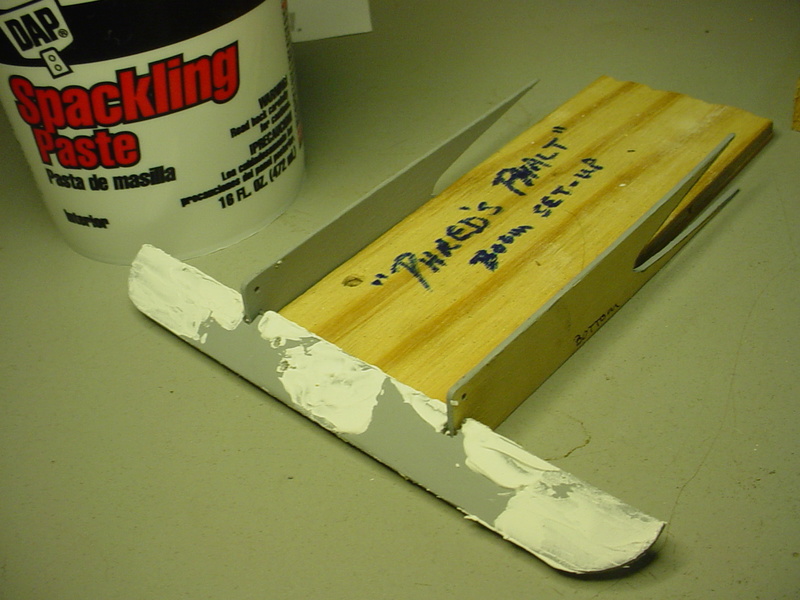

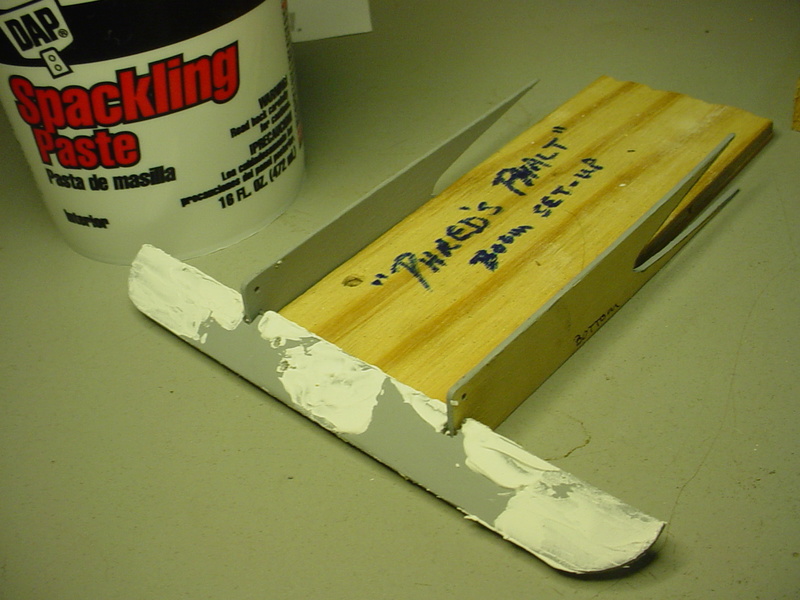

A few nights ago I decided to try filling my stab surfaces with spackle, to smooth-out some balsa grain-lines and blend-in the raised hinge-material and 1/64" ply-plates for the horn-mount.

Looks a little scary here.. (bottom side)

(top side, which had previously been primed grey.. along with only one side of the booms)

I allowed the spackle to dry for a couple of days.. then being very careful and patient, I used an 8"L. 1/4" x 3/4" stick with 240 grit paper wrapped around it, to feather-sand smooth. The sandpaper is 3M 413Q TRI-M-ITE. It cut through the DAP-brand spackle with ease.. even though I used very light strokes with the sanding-stick. The size of the stick helped prevent me from being too heavy-handed with it. Supporting-well with my free-hand's fingers underneath the stab helped to keep the work-piece steady.

(bottom side sanded)

(top side sanded)

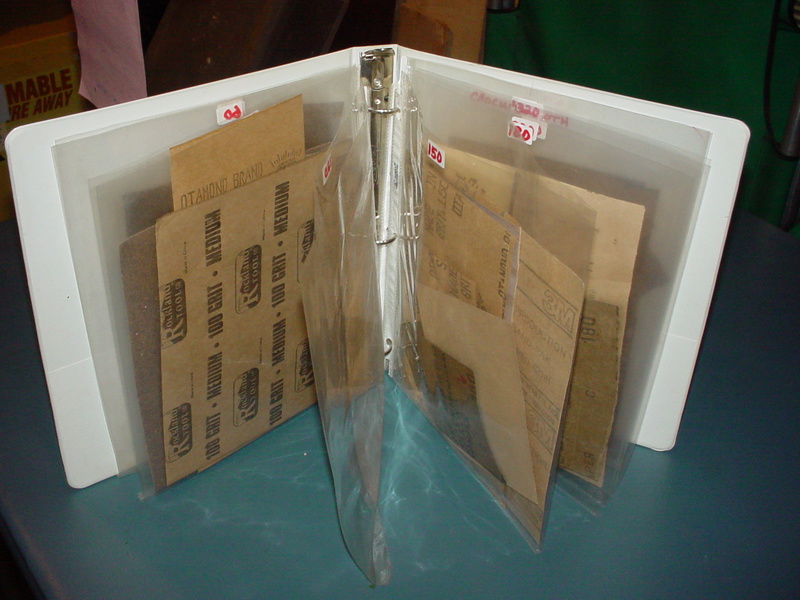

Sorry that there's not more to report.. but I figured that some of you might see the value in making a satisfactory sanding tool for a particular purpose. You simply can't have enough sanding tools (sticks, blocks, dowels etc..) faced with altering-grit paper. I'll generally make 3 of every size/shape that I want.. and face them with fine, med. and coarse grades. Once made.. they last a long time.. and are always ready to tackle a specific sanding job with much better results.. than grabbing any old random block off the shelf.

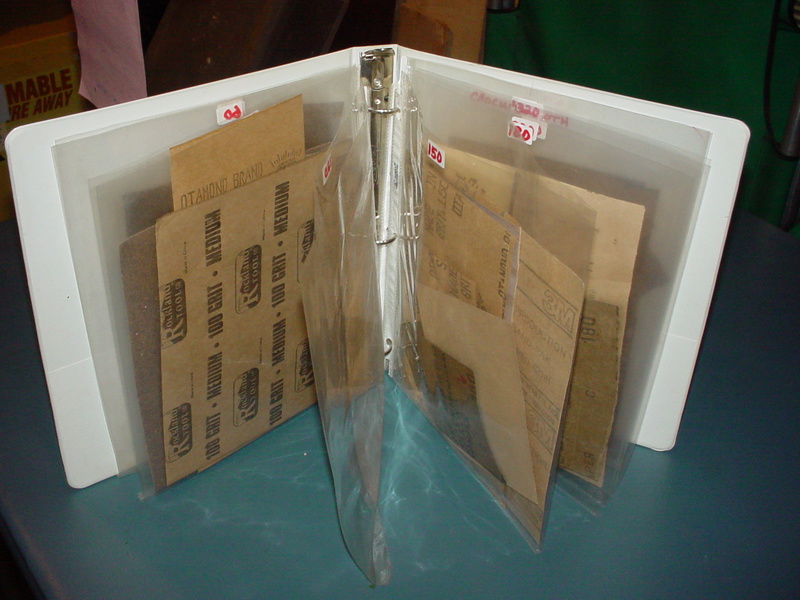

Remember my sandpaper-remnant 3-ring binder?

I use it for when I cut a piece from a full sheet. Full-sheets I organize in envelopes graded by fine, med. and coarse.

Make-up a sanding-tool box some night when you have nothing to do.. you'll be glad you did.

Looks a little scary here.. (bottom side)

(top side, which had previously been primed grey.. along with only one side of the booms)

I allowed the spackle to dry for a couple of days.. then being very careful and patient, I used an 8"L. 1/4" x 3/4" stick with 240 grit paper wrapped around it, to feather-sand smooth. The sandpaper is 3M 413Q TRI-M-ITE. It cut through the DAP-brand spackle with ease.. even though I used very light strokes with the sanding-stick. The size of the stick helped prevent me from being too heavy-handed with it. Supporting-well with my free-hand's fingers underneath the stab helped to keep the work-piece steady.

(bottom side sanded)

(top side sanded)

Sorry that there's not more to report.. but I figured that some of you might see the value in making a satisfactory sanding tool for a particular purpose. You simply can't have enough sanding tools (sticks, blocks, dowels etc..) faced with altering-grit paper. I'll generally make 3 of every size/shape that I want.. and face them with fine, med. and coarse grades. Once made.. they last a long time.. and are always ready to tackle a specific sanding job with much better results.. than grabbing any old random block off the shelf.

Remember my sandpaper-remnant 3-ring binder?

I use it for when I cut a piece from a full sheet. Full-sheets I organize in envelopes graded by fine, med. and coarse.

Make-up a sanding-tool box some night when you have nothing to do.. you'll be glad you did.

Re: "Phred's Phault"

Re: "Phred's Phault"

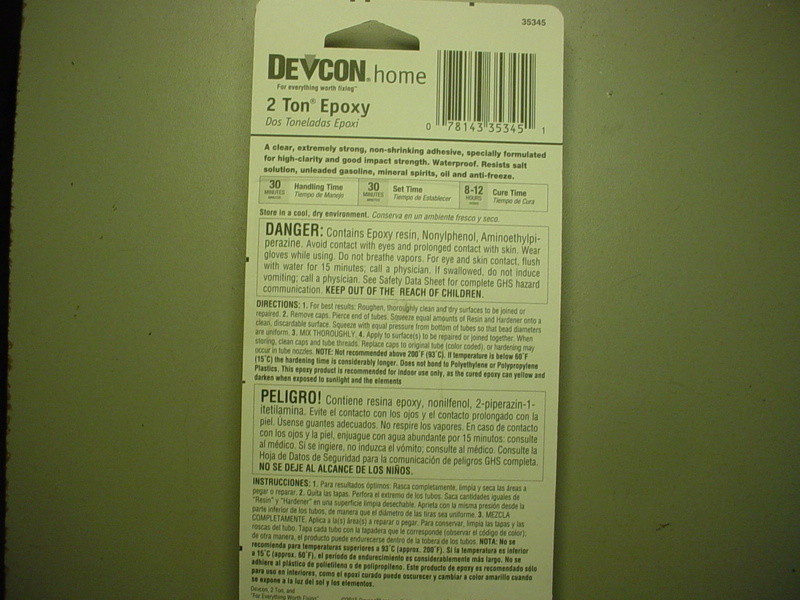

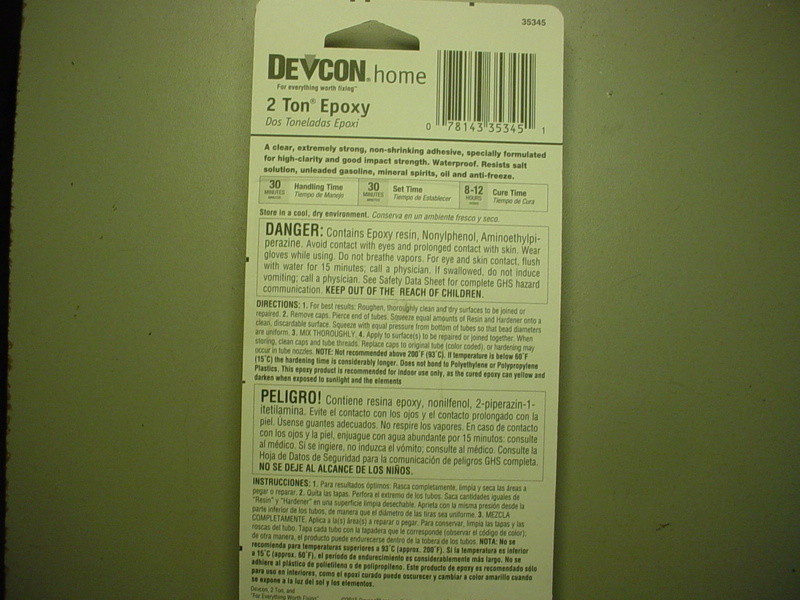

I can't let another year pass.. before finishing this airplane. It's been on my mind.. (along with other uncompleted modeling-projects) my bad.. but I bought some slow-cure epoxy a few days ago.. with the intent of gluing this thing together.

Above.. is a photo of what I bought.. which is what I wanted. Slow-cure epoxy (it's considerably cheaper than the fast-set stuff.. as well as stronger) I need to join two foam wing-halves.. and I want to have some time to get the alignment correct before the glue sets. I have a center frame-structure that will be glued to one wing-panel first. The second wing-panel alignment will be critical, because there will be a pair of tail-booms extending back from each panel.. that will support the stabilator.

I don't really like working with epoxy.. I never really know how much to mix; for the job I need to do. I always over-estimate.. and hate wasting material. OTOH.. I love the strength that it provides. I'm "stuck" with it for this build though. There isn't much else that will glue foam together, that I have experience with. I don't want to experiment with polyurethane adhesives at this stage.

I'll feel better when I get the wing-halves joined and the tail-booms straight. This airplane has been in pieces in a bag.. for quite a while. I'm going to put it together.

Above.. is a photo of what I bought.. which is what I wanted. Slow-cure epoxy (it's considerably cheaper than the fast-set stuff.. as well as stronger) I need to join two foam wing-halves.. and I want to have some time to get the alignment correct before the glue sets. I have a center frame-structure that will be glued to one wing-panel first. The second wing-panel alignment will be critical, because there will be a pair of tail-booms extending back from each panel.. that will support the stabilator.

I don't really like working with epoxy.. I never really know how much to mix; for the job I need to do. I always over-estimate.. and hate wasting material. OTOH.. I love the strength that it provides. I'm "stuck" with it for this build though. There isn't much else that will glue foam together, that I have experience with. I don't want to experiment with polyurethane adhesives at this stage.

I'll feel better when I get the wing-halves joined and the tail-booms straight. This airplane has been in pieces in a bag.. for quite a while. I'm going to put it together.

Re: "Phred's Phault"

Re: "Phred's Phault"

A long distance pat on the back and a Greenie for you!

It's nice to know I'm not alone in having a workshop full of good intentions and partially started/half finished planes! I'm not sure if it's short attention span, or onset memory loss. ( more than likely it's job/family priorities getting pushed in front of hobby time) yeah, well my other excuse is I don't want to rush thru the build, I want to enjoy the experience.

Congratulation on getting one step closer to completion!!

IMPORTANT PS: just re read your post.....please make sure the epoxy is "foam safe"

I've seen some build logs where the builder was inserting a CF rod and the glue ate (melted) the foam wing. Test a small patch on a unused foam piece.

It's nice to know I'm not alone in having a workshop full of good intentions and partially started/half finished planes! I'm not sure if it's short attention span, or onset memory loss. ( more than likely it's job/family priorities getting pushed in front of hobby time) yeah, well my other excuse is I don't want to rush thru the build, I want to enjoy the experience.

Congratulation on getting one step closer to completion!!

IMPORTANT PS: just re read your post.....please make sure the epoxy is "foam safe"

I've seen some build logs where the builder was inserting a CF rod and the glue ate (melted) the foam wing. Test a small patch on a unused foam piece.

Last edited by Marleysky on Mon Mar 27, 2017 10:18 pm; edited 1 time in total (Reason for editing : Caution on foam)

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: "Phred's Phault"

Re: "Phred's Phault"

Sure hope this note is in time to prevent some frustration

That epoxy you show is 5 min set stuff and much too fast

I use 30 to 90 min epoxy for anything I need time to get fit and alignments correct

That epoxy you show is 5 min set stuff and much too fast

I use 30 to 90 min epoxy for anything I need time to get fit and alignments correct

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: "Phred's Phault"

Re: "Phred's Phault"

fredvon4 wrote:Sure hope this note is in time to prevent some frustration

That epoxy you show is 5 min set stuff and much too fast

I use 30 to 90 min epoxy for anything I need time to get fit and alignments correct

I made that connection too Fred, but I figured that roddie was experienced enough to know the difference.

Time and temperture, I have learned to gauge both when working with the five minute stuff which is responsible for 90% of my repairs. I have used 30 minute in the past, but I'm an impatient person and get antsy waiting. For me, the 5 minute epoxy is slow cure. I do have some 1 minute epoxy but after Eric's caution regarding it's use I have not used it. Preparation is the key.

Also X2 on that "foam safe". There is a foam safe CA but regular CA will eat foam right now.

Bob

rsv1cox- Top Poster

Posts : 11250

Join date : 2014-08-18

Location : West Virginia

Re: "Phred's Phault"

Re: "Phred's Phault"

I like to use the 30 to 90 minute stuff for covering engine mounts, tank compartments and such, where it is good to have extra time to work. For general use I like the 5-minute kind, it gives enough time to align the parts but is quick enough so that any complex jigs or clamps are usually not necessary.

I am currently in the middle of a styrofoam wing build, I used carpenter's glue (pva I think) for leading and trailing edges and also for gluing the top and bottom halves together. It sticks quite well to both styro and balsa. Still use epoxy for critical parts such as bellcrank mount and wingtips. The left tip obviously has the adjustable lead-out guide and the right one will carry the wingtip weight.

The reason for using the carpenter's glue instead of epoxy is that my wife can't stand the smell of epoxy I barely notice the scent but she regognizes it even if it has been a while. Well, she puts up with (among other things) me building planes on the dining table and sanding them in the bathroom, so until my shop is ready, white glue it will be... If I absolutely need to use epoxy, I can borrow my son's shop, but I can't sand there as the dust will ruin his paintjobs. All this gives me extra motivation to clean up&declutter the garage

I barely notice the scent but she regognizes it even if it has been a while. Well, she puts up with (among other things) me building planes on the dining table and sanding them in the bathroom, so until my shop is ready, white glue it will be... If I absolutely need to use epoxy, I can borrow my son's shop, but I can't sand there as the dust will ruin his paintjobs. All this gives me extra motivation to clean up&declutter the garage

I am currently in the middle of a styrofoam wing build, I used carpenter's glue (pva I think) for leading and trailing edges and also for gluing the top and bottom halves together. It sticks quite well to both styro and balsa. Still use epoxy for critical parts such as bellcrank mount and wingtips. The left tip obviously has the adjustable lead-out guide and the right one will carry the wingtip weight.

The reason for using the carpenter's glue instead of epoxy is that my wife can't stand the smell of epoxy

I barely notice the scent but she regognizes it even if it has been a while. Well, she puts up with (among other things) me building planes on the dining table and sanding them in the bathroom, so until my shop is ready, white glue it will be... If I absolutely need to use epoxy, I can borrow my son's shop, but I can't sand there as the dust will ruin his paintjobs. All this gives me extra motivation to clean up&declutter the garage

I barely notice the scent but she regognizes it even if it has been a while. Well, she puts up with (among other things) me building planes on the dining table and sanding them in the bathroom, so until my shop is ready, white glue it will be... If I absolutely need to use epoxy, I can borrow my son's shop, but I can't sand there as the dust will ruin his paintjobs. All this gives me extra motivation to clean up&declutter the garage

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: "Phred's Phault"

Re: "Phred's Phault"

Wow.. I feel a little embarrassed.. It sure enough states "5 minute" on the tube. I looked at some other different tubes on the store-rack.. and they clearly stated "Quick-bond".. so I assumed that this was the slower stuff. I have some unused NOS tubes in my glue-box that I know are slow-setting. My intention was to buy some fresh-stock. Does unmixed epoxy have a shelf-life? My glue-box is also buried under a pile of stuff.

Luckily I haven't done anything yet. I thought that most epoxies were foam-safe. I'll be sure to test first with scrap pieces.

Thanks as always for the comments and advice.

Luckily I haven't done anything yet. I thought that most epoxies were foam-safe. I'll be sure to test first with scrap pieces.

Thanks as always for the comments and advice.

Re: "Phred's Phault"

Re: "Phred's Phault"

Roddie, Most consumable goods, the mfgr prints or stamps a "best by date" or "Sell by date" on the product, just to assure the user they are using fresh or current production products. My experience on those dates are important on things I'm gonna eat.

On items like paint, glue or caulk the "production" date may be of importance to the end user, it ( shelf life) may not be printed on the can or tube but you can assume 12 to 18 months on products properly stored in a "cool dry place"

Here is a short list of stuff I've bought on sale for "future use" and the end result when I did use/open it years later:

Two part Epoxy glue: purchased 1980+/- ...........Still in use 2017. Not much left.

HobbyPox part A and Part B and

JB weld purchased late 80's early 90's .................still in use 2017.

Still have one unopened pkg as a back-up

Any type of CA glue thin,medium,thick have hardened in the package (1-2years)

Aerosol spray paint. These usually lose the propellant over a few months once used the first time. ( I then open the can and pour the contents into tight sealing glass jars)

White painters caulk/ Black roofing sealer/ liquid nails/ concrete patch/RTV sealer, in a tube anything in a caulk gun tube..........I bought a bunch of each of these when "HandyAndy" went out of business. When used fresh worked great, after 5-10 years in storage they all turned into a tube of dried hard product, or dried flexible product in the case of thr RTV sealer! I assume the products cured in place because the tubes are not airtight.

So, I do believe the epoxy glues do last a much longer time in storage. You don't have a "fresh batch" until you mix part A with part B or resin with hardener.

Yup, another two parter Bondo and hardner and fiberglass resin and hardener are still in usable liquid state until mixed....ahh, love that Bondo smell, just about as good a nitro!

,

On items like paint, glue or caulk the "production" date may be of importance to the end user, it ( shelf life) may not be printed on the can or tube but you can assume 12 to 18 months on products properly stored in a "cool dry place"

Here is a short list of stuff I've bought on sale for "future use" and the end result when I did use/open it years later:

Two part Epoxy glue: purchased 1980+/- ...........Still in use 2017. Not much left.

HobbyPox part A and Part B and

JB weld purchased late 80's early 90's .................still in use 2017.

Still have one unopened pkg as a back-up

Any type of CA glue thin,medium,thick have hardened in the package (1-2years)

Aerosol spray paint. These usually lose the propellant over a few months once used the first time. ( I then open the can and pour the contents into tight sealing glass jars)

White painters caulk/ Black roofing sealer/ liquid nails/ concrete patch/RTV sealer, in a tube anything in a caulk gun tube..........I bought a bunch of each of these when "HandyAndy" went out of business. When used fresh worked great, after 5-10 years in storage they all turned into a tube of dried hard product, or dried flexible product in the case of thr RTV sealer! I assume the products cured in place because the tubes are not airtight.

So, I do believe the epoxy glues do last a much longer time in storage. You don't have a "fresh batch" until you mix part A with part B or resin with hardener.

Yup, another two parter Bondo and hardner and fiberglass resin and hardener are still in usable liquid state until mixed....ahh, love that Bondo smell, just about as good a nitro!

,

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: "Phred's Phault"

Re: "Phred's Phault"

Thanks Rene!  I kinda' figured that the 2-part glues were fairly stable, pretty much indefinitely. "Elmer's" use to sell epoxy (slow and fast-cure) in small .25oz. tubes. I've had two packages of both types for over 25 years. I've never used the "fast-cure".. but the slow-cure has been used several times.. and as recent as 2 years ago. I only mix-up a button's-worth at a time.

I kinda' figured that the 2-part glues were fairly stable, pretty much indefinitely. "Elmer's" use to sell epoxy (slow and fast-cure) in small .25oz. tubes. I've had two packages of both types for over 25 years. I've never used the "fast-cure".. but the slow-cure has been used several times.. and as recent as 2 years ago. I only mix-up a button's-worth at a time.

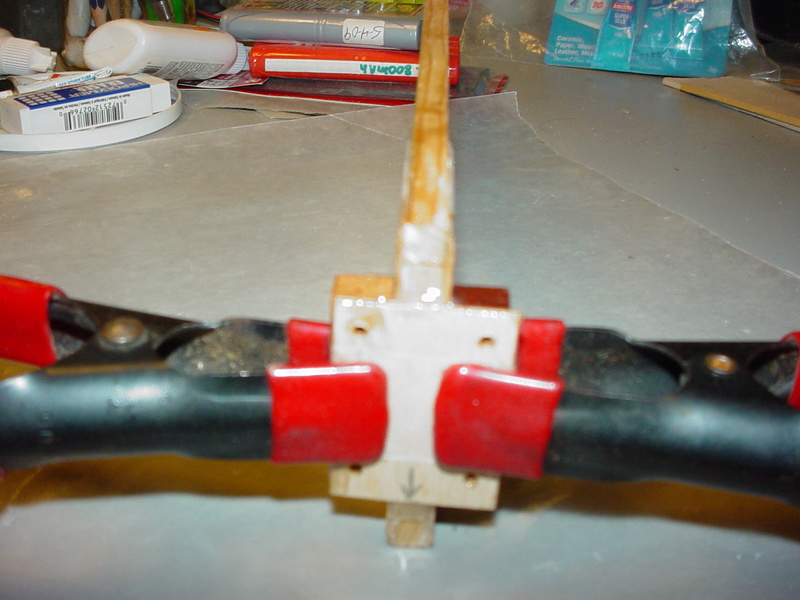

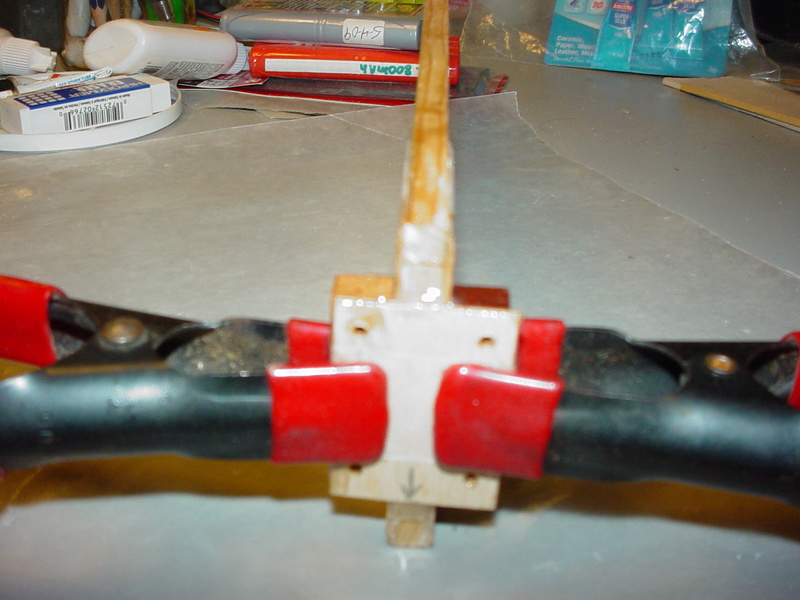

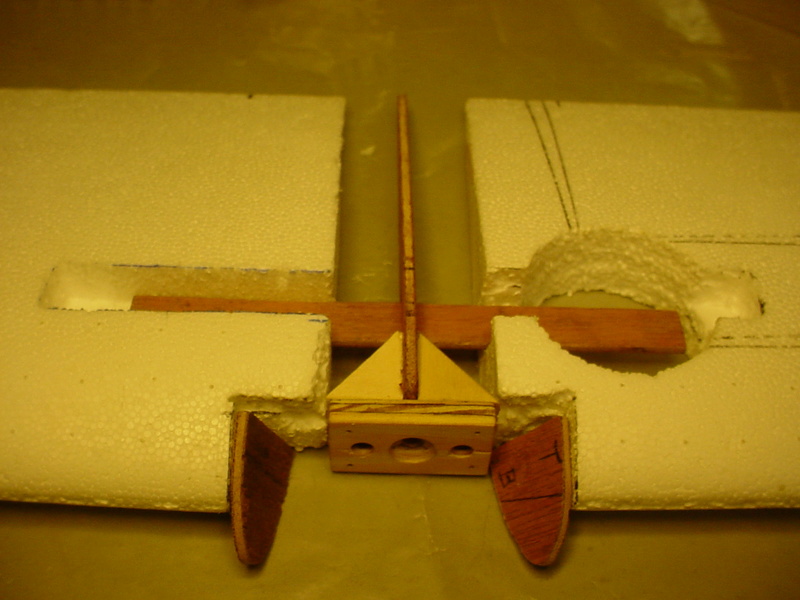

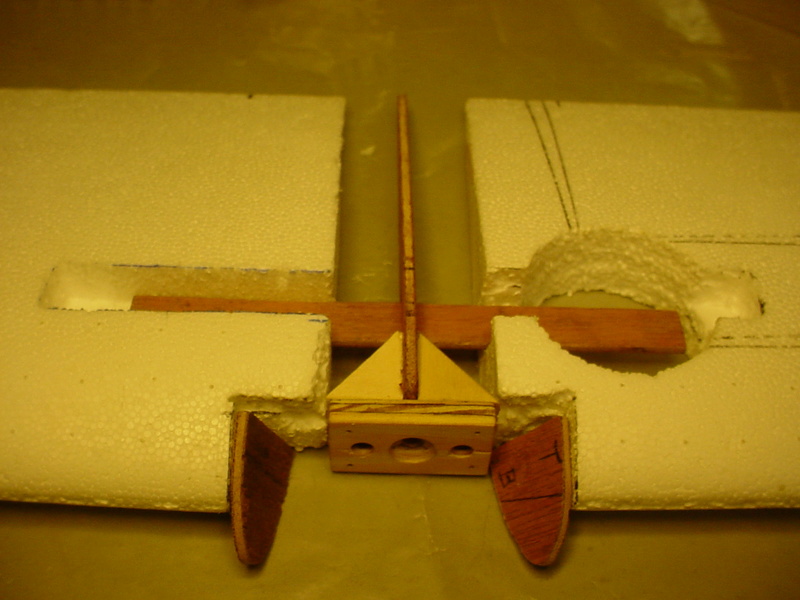

I like to assemble my 1/2A radial firewalls with it. That's really the only place I use it. Makes for a good strong nose. I usually laminate a couple ply-plates together.. with hardwood cheek-blocks behind. This assembly keys-into/onto a profile-fuse with either 1/32" or 1/64" ply doublers installed. The doublers are generally glued-on with thick CA-glue.

Here's a photo of my Rare Bear's firewall being glued-up with epoxy and clamps. The cheek-blocks are 3/8" sq. cherry-wood.

I've always overbuilt the noses of my little airplanes. It's the area that will inevitably be smacked-hard at some point. I always figured that any extra weight there; would be more of a benefit.. than a penalty. Sometimes the nose of a model is fairly "short".. especially with a scale-like design. An external fuel tank (which I often use) is located rearward; closer to the center of gravity. I like having the fuel-tank there actually. The main landing-gear can be a weight-adjustment-point.. by both; angular-adjustment and the weight of the wheels used, but wheel-"weight" is better to alter.. than gear-angle. You don't want to locate a "too-far rearward" main-gear on a tail-dragger. If so; you may experience "nose-overs" when R.O.G.-launching.. as well as "nose-overs" when landing. There's a "balance" that needs to be achieved.. for the environment in which the model will be flown.

I personally like to have landing-gear on my models. This poses some issues. I've flown 1/2A models exclusively.. and I have all kinds of wheels. I've made my own wheels to deal with the rigors of rough runways.. and grass. To me; it's fun to be able to have a model airplane "roll-out into flight" and "land on it's wheels".. without nosing-over.

I kinda' figured that the 2-part glues were fairly stable, pretty much indefinitely. "Elmer's" use to sell epoxy (slow and fast-cure) in small .25oz. tubes. I've had two packages of both types for over 25 years. I've never used the "fast-cure".. but the slow-cure has been used several times.. and as recent as 2 years ago. I only mix-up a button's-worth at a time.

I kinda' figured that the 2-part glues were fairly stable, pretty much indefinitely. "Elmer's" use to sell epoxy (slow and fast-cure) in small .25oz. tubes. I've had two packages of both types for over 25 years. I've never used the "fast-cure".. but the slow-cure has been used several times.. and as recent as 2 years ago. I only mix-up a button's-worth at a time.I like to assemble my 1/2A radial firewalls with it. That's really the only place I use it. Makes for a good strong nose. I usually laminate a couple ply-plates together.. with hardwood cheek-blocks behind. This assembly keys-into/onto a profile-fuse with either 1/32" or 1/64" ply doublers installed. The doublers are generally glued-on with thick CA-glue.

Here's a photo of my Rare Bear's firewall being glued-up with epoxy and clamps. The cheek-blocks are 3/8" sq. cherry-wood.

I've always overbuilt the noses of my little airplanes. It's the area that will inevitably be smacked-hard at some point. I always figured that any extra weight there; would be more of a benefit.. than a penalty. Sometimes the nose of a model is fairly "short".. especially with a scale-like design. An external fuel tank (which I often use) is located rearward; closer to the center of gravity. I like having the fuel-tank there actually. The main landing-gear can be a weight-adjustment-point.. by both; angular-adjustment and the weight of the wheels used, but wheel-"weight" is better to alter.. than gear-angle. You don't want to locate a "too-far rearward" main-gear on a tail-dragger. If so; you may experience "nose-overs" when R.O.G.-launching.. as well as "nose-overs" when landing. There's a "balance" that needs to be achieved.. for the environment in which the model will be flown.

I personally like to have landing-gear on my models. This poses some issues. I've flown 1/2A models exclusively.. and I have all kinds of wheels. I've made my own wheels to deal with the rigors of rough runways.. and grass. To me; it's fun to be able to have a model airplane "roll-out into flight" and "land on it's wheels".. without nosing-over.

Re: "Phred's Phault"

Re: "Phred's Phault"

K... I bought some more glue yesterday..  I really wanted to find the larger 4.25oz. vessels of the Devcon 2-part SLOW-cure epoxy.. but could only find the 5-min. variety locally (I shopped two hdwe. stores..)

I really wanted to find the larger 4.25oz. vessels of the Devcon 2-part SLOW-cure epoxy.. but could only find the 5-min. variety locally (I shopped two hdwe. stores..)

K... so I bought a Loctite "syringe" (.85oz. combined..) of "extra time" (60 min./translucent yellow) for $4+change at my local "Lowes" home-center. (my 1st stop..)

so I bought a Loctite "syringe" (.85oz. combined..) of "extra time" (60 min./translucent yellow) for $4+change at my local "Lowes" home-center. (my 1st stop..)

K... so.. there's a "Leeway" (agricultural/True-Value) outlet on my drive home. They're "pricey".. but they're one of those hdwe. stores where you can still find the cool stuff that the "big-box" stores don't bother with. (it's where I found the "Ruby Fluid" paste-flux for hard-soldering my fuel-tanks together..) I walk in.. and within 15 seconds; a young man asks what I'm looking for. "Epoxy" I exclaimed.. He directs me to the "glue-aisle".. where I found some "slow-cure" Devcon epoxy in .5oz. tubes (1oz. combined..) again.. for about $4+change.. This was progress.. and I'll explain why. My experience with epoxies isn't what one would call "expansive".. "Elmer's" had a line that I've mentioned using.. that was sold in separate tubes.. that I really liked. It just seemed to be easier to dispense equal-amounts of resin and hardener for mixing. Our "Rusty" knows 1st-hand what I'm saying here.

"Elmer's" had a line that I've mentioned using.. that was sold in separate tubes.. that I really liked. It just seemed to be easier to dispense equal-amounts of resin and hardener for mixing. Our "Rusty" knows 1st-hand what I'm saying here.

Aren't photos great? It sucks reading.. without any "eye-candy"..

Some of the epoxies that I've bought over the years have included some good tools for the mixing of components. I thought it'd be worthwhile to post a photo.

"Rusty" mentions using "graph-paper" to gage/mix resin/hardener. The above photo shows a re-useable graduated "palette" for measuring.. and also a "comb-type" spreader.. which I think is a terrific mixing tool. A plastic "fork-utensil" would also work well. The more "complete" that you can mix 2-part glues.. the stronger their bond will be. That's why I'd rather use the slow-set variety.

Oh yea... I forgot to mention; while at "Lowes".. I also bought an 8oz. container of "Titebond-III".. ultimate wood-glue.

I forgot to mention; while at "Lowes".. I also bought an 8oz. container of "Titebond-III".. ultimate wood-glue.

I may end-up using the Titebond if it doesn't react unfavorably with the foam. The reason being; my wife (Lynne) gets SEVERE migraine-headaches that are triggered by even "slight" solvent-type odors. I have to be real careful with that. She takes the prescription-med Imitrex (Sumatriptan-Succinate..) to relieve her migraines. "Excedrine" can work.. if she catches the onset early. It's the caffeine/Acetaminophen mix in the Excedrine that can be effective against the start of a migraine.

So... "Phred's Phault" needs to be finished with that in mind. The good news is.. the weather's getting warmer and I can glue-up some parts outside if I have to. I want to use the epoxy mainly on the center-structure for strength.

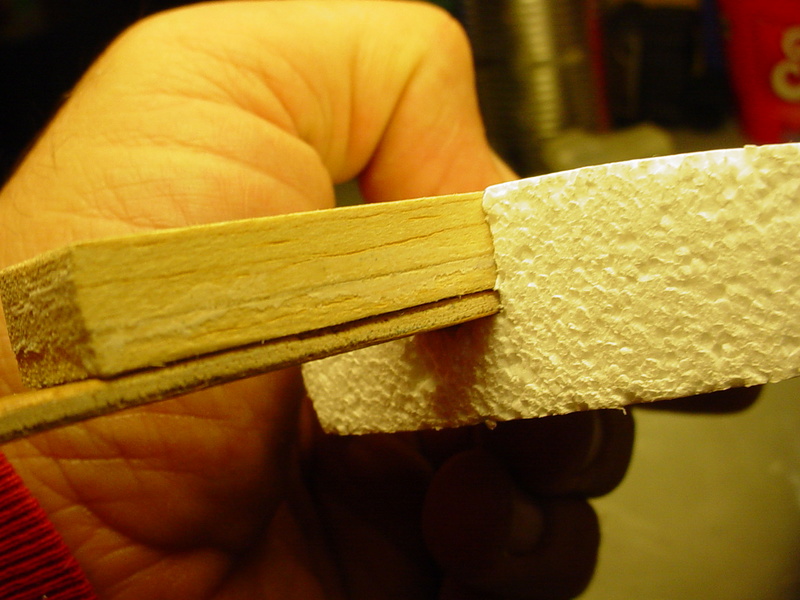

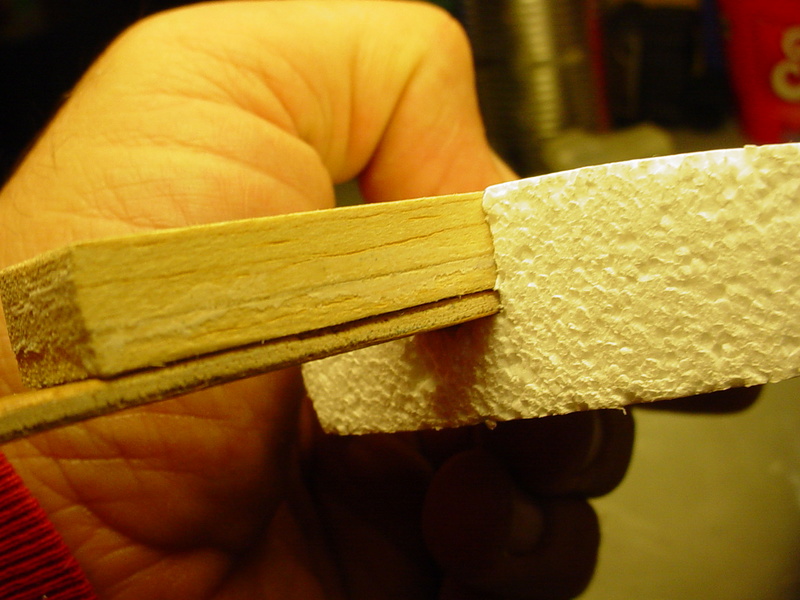

I made some balsa filler-blocks to cap the plywood T-spar for the channel that I cut in the wing-cores. These will come-up "flush" to the top-surface of the foam-cores.

"Phred's Phault" will be finished for this season.

K...

so I bought a Loctite "syringe" (.85oz. combined..) of "extra time" (60 min./translucent yellow) for $4+change at my local "Lowes" home-center. (my 1st stop..)

so I bought a Loctite "syringe" (.85oz. combined..) of "extra time" (60 min./translucent yellow) for $4+change at my local "Lowes" home-center. (my 1st stop..)

K... so.. there's a "Leeway" (agricultural/True-Value) outlet on my drive home. They're "pricey".. but they're one of those hdwe. stores where you can still find the cool stuff that the "big-box" stores don't bother with. (it's where I found the "Ruby Fluid" paste-flux for hard-soldering my fuel-tanks together..) I walk in.. and within 15 seconds; a young man asks what I'm looking for. "Epoxy" I exclaimed.. He directs me to the "glue-aisle".. where I found some "slow-cure" Devcon epoxy in .5oz. tubes (1oz. combined..) again.. for about $4+change.. This was progress.. and I'll explain why. My experience with epoxies isn't what one would call "expansive"..

Aren't photos great? It sucks reading.. without any "eye-candy"..

Some of the epoxies that I've bought over the years have included some good tools for the mixing of components. I thought it'd be worthwhile to post a photo.

"Rusty" mentions using "graph-paper" to gage/mix resin/hardener. The above photo shows a re-useable graduated "palette" for measuring.. and also a "comb-type" spreader.. which I think is a terrific mixing tool. A plastic "fork-utensil" would also work well. The more "complete" that you can mix 2-part glues.. the stronger their bond will be. That's why I'd rather use the slow-set variety.

Oh yea...

I may end-up using the Titebond if it doesn't react unfavorably with the foam. The reason being; my wife (Lynne) gets SEVERE migraine-headaches that are triggered by even "slight" solvent-type odors. I have to be real careful with that. She takes the prescription-med Imitrex (Sumatriptan-Succinate..) to relieve her migraines. "Excedrine" can work.. if she catches the onset early. It's the caffeine/Acetaminophen mix in the Excedrine that can be effective against the start of a migraine.

So... "Phred's Phault" needs to be finished with that in mind. The good news is.. the weather's getting warmer and I can glue-up some parts outside if I have to. I want to use the epoxy mainly on the center-structure for strength.

I made some balsa filler-blocks to cap the plywood T-spar for the channel that I cut in the wing-cores. These will come-up "flush" to the top-surface of the foam-cores.

"Phred's Phault" will be finished for this season.

It really is Phred's fault..

It really is Phred's fault..

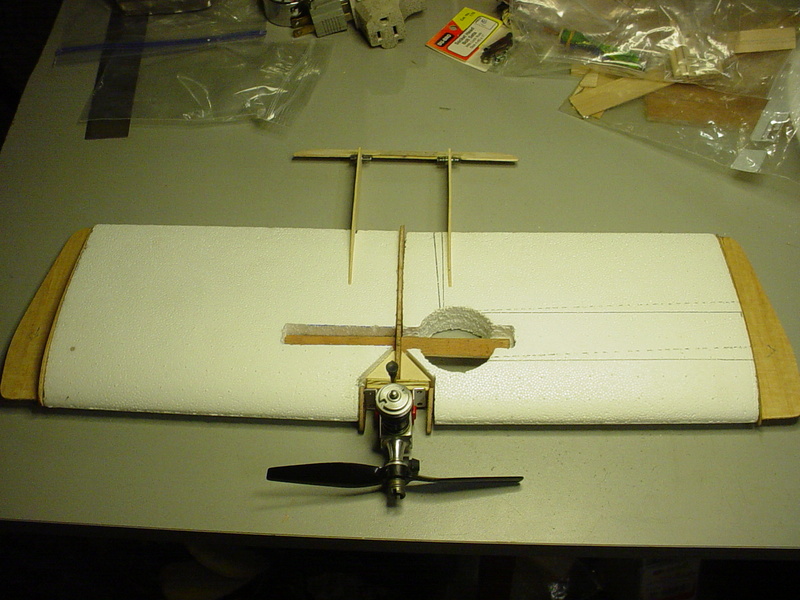

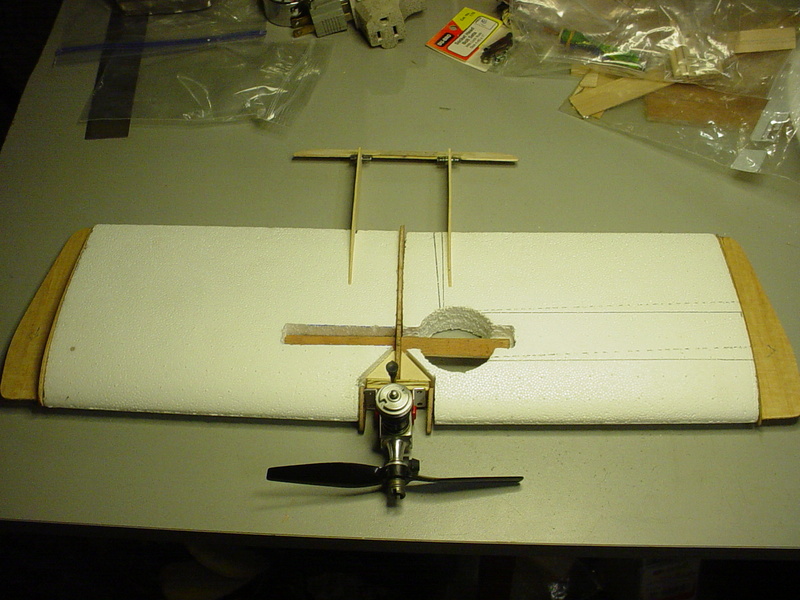

CEF member fredvon4 was the original inspiration for this model/thread. Fred's currently trying to quit smoking. I'm resurrecting this thread in support of Fred's efforts. He needs distractions.. and I'm hoping that this thread can be one. This design/build has been languishing in the bowels of CEF for far too long.

Some construction-hurdles had stalled me on this self-designed model.. but I've never forgotten about its original "scope". To re-cap; it's been designed as a 50% scale-model of the Riley Wooten/Carl Goldberg kit G13-295 "VOODOO" for combat/stunt.

Here are the major assemblies.. laid-out. I just need to "get-back" to it..

Some construction-hurdles had stalled me on this self-designed model.. but I've never forgotten about its original "scope". To re-cap; it's been designed as a 50% scale-model of the Riley Wooten/Carl Goldberg kit G13-295 "VOODOO" for combat/stunt.

Here are the major assemblies.. laid-out. I just need to "get-back" to it..

Re: "Phred's Phault"

Re: "Phred's Phault"

Nice gesture roddie. Part of the CEF's support structure.

Ian participated in this thread too. Perhaps he will see it and chime in also.

Ian participated in this thread too. Perhaps he will see it and chime in also.

rsv1cox- Top Poster

Posts : 11250

Join date : 2014-08-18

Location : West Virginia

Re: "Phred's Phault"

Re: "Phred's Phault"

Thanks brother

After your note, I went way back to page one and took my time reading and remembering

After your note, I went way back to page one and took my time reading and remembering

fredvon4- Top Poster

Posts : 4012

Join date : 2011-08-26

Age : 69

Location : Lampasas Texas

Re: "Phred's Phault"

Re: "Phred's Phault"

wanted to mention that this was off a Helldiver or A-25, the yellow needle was only made for a year or so.

Page 6 of 7 •  1, 2, 3, 4, 5, 6, 7

1, 2, 3, 4, 5, 6, 7

Page 6 of 7

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules