Log in

Search

Latest topics

» Chocolate chip cookie dough.........by rsv1cox Today at 10:20 am

» Tee Dee .020 combat model

by rsv1cox Today at 10:07 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Purchased the last of any bult engines from Ken Enya

by getback Yesterday at 12:05 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

Cox Engine of The Month

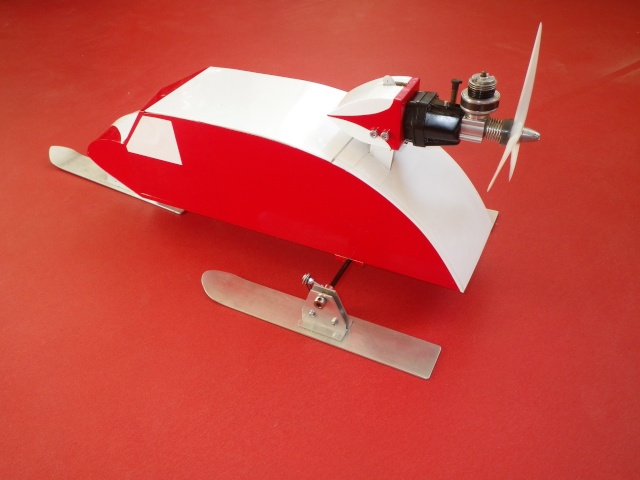

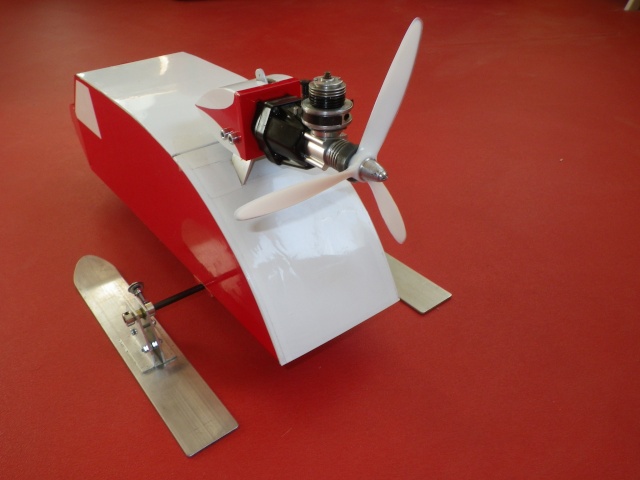

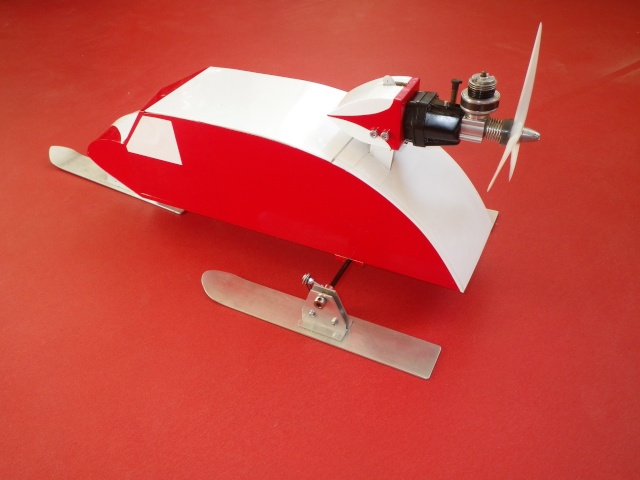

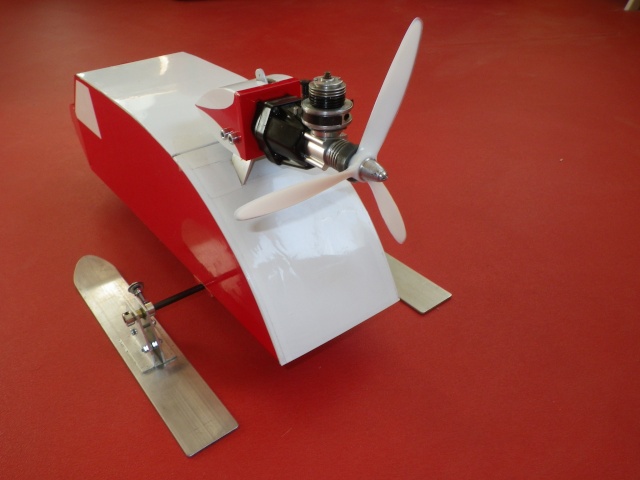

Snowplane, radio gear

Page 3 of 3

Page 3 of 3 •  1, 2, 3

1, 2, 3

Re: Snowplane, radio gear

Re: Snowplane, radio gear

Well done Lieven !!!

Hope you can try it on snow soon !!!

Hope you can try it on snow soon !!!

navion34- Gold Member

- Posts : 208

Join date : 2012-09-09

Age : 61

Location : France

Re: Snowplane, radio gear

Re: Snowplane, radio gear

The build looks really Lieven , Yes I think get the engine up to rpms and I would get me a left hand prop instead of running one backwards . Let it snow for you

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Snowplane, radio gear

Re: Snowplane, radio gear

Leiven, though I haven't commented, I've enjoyed following your progress on this project.

It has inspired me to perhaps persue something I've been thinking about for a couple of years now.

The Leyat Helica. What do you think?

Bob

It has inspired me to perhaps persue something I've been thinking about for a couple of years now.

The Leyat Helica. What do you think?

Bob

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: Snowplane, radio gear

Re: Snowplane, radio gear

Thanks guys, for your comments and support.

I ordered a replacement crankcase assembly to rebuild the Dragonfly. I will glue keels on the bottom of the skis so the model resists better against the engine torque; I think Roddie mentioned that already before. The Call Air snowcar with the .35 engine has got them as well

http://www.rcgroups.com/forums/showpost.php?p=18221066&postcount=3894

Also I better fit a cable to the front ski to prevent it from going nose down and digging into the snow. I'm going to do that on the rear skis as well because the support is in fact glued too much to the rear of the skis: when you lift the whole thing up, the front of the skis go down. I also could glue a coin or washer to the skis' rear for balance instead. I only need about 8g.

Roddie, The prop in the video is an 6x4. I broke the old Cox 6x3 when stopping the engine with a rag.

The Leyat is an interesting vehicle and much info and documentation was preserved over the years, Not because many were made of but because it's such a unique vehicle. I saw one once in real life. It was during one of the Air cooled Days at Brooklands in april 2000 or 2001. If I remember well, it was a replica. They steer with the rear wheels, that's a bit dodgy and olso, in turns they lift one rear wheel. It would be a nice and interesting project Bob. I hope you'll start soon!!

Lieven

I ordered a replacement crankcase assembly to rebuild the Dragonfly. I will glue keels on the bottom of the skis so the model resists better against the engine torque; I think Roddie mentioned that already before. The Call Air snowcar with the .35 engine has got them as well

http://www.rcgroups.com/forums/showpost.php?p=18221066&postcount=3894

Also I better fit a cable to the front ski to prevent it from going nose down and digging into the snow. I'm going to do that on the rear skis as well because the support is in fact glued too much to the rear of the skis: when you lift the whole thing up, the front of the skis go down. I also could glue a coin or washer to the skis' rear for balance instead. I only need about 8g.

Roddie, The prop in the video is an 6x4. I broke the old Cox 6x3 when stopping the engine with a rag.

The Leyat is an interesting vehicle and much info and documentation was preserved over the years, Not because many were made of but because it's such a unique vehicle. I saw one once in real life. It was during one of the Air cooled Days at Brooklands in april 2000 or 2001. If I remember well, it was a replica. They steer with the rear wheels, that's a bit dodgy and olso, in turns they lift one rear wheel. It would be a nice and interesting project Bob. I hope you'll start soon!!

Lieven

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Snowplane, radio gear

Re: Snowplane, radio gear

I love it. I might have to copy it in case we get some snow. I could play with it maybe once a year, or even run the sprinkler on a freezing night to ice up the yard.

I have a question for you guys that run pushers. I noticed when one of my Bees started backwards, and I somehow didn't notice(I'm a little slow on the uptake sometimes), it began to bog and I had to turn it much richer after it first peakd to regain a full 2-stroke; I assume because the piston and cylinder begin to tighten from the heat. Do engines used like this have a significantly shorter life due to higher heat induced friction?

Rusty

I have a question for you guys that run pushers. I noticed when one of my Bees started backwards, and I somehow didn't notice(I'm a little slow on the uptake sometimes), it began to bog and I had to turn it much richer after it first peakd to regain a full 2-stroke; I assume because the piston and cylinder begin to tighten from the heat. Do engines used like this have a significantly shorter life due to higher heat induced friction?

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Snowplane, radio gear

Re: Snowplane, radio gear

Good question Rusty. Might be cause for a heat sink.RknRusty wrote:Do engines used like this have a significantly shorter life due to higher heat induced friction?

Rusty

I have a few for the finned heads(P#1970).

PM me your address, and I'll pop one in the mail for you.

Bob

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: Snowplane, radio gear

Re: Snowplane, radio gear

OVERLORD wrote:

Also I better fit a cable to the front ski to prevent it from going nose down and digging into the snow. I'm going to do that on the rear skis as well because the support is in fact glued too much to the rear of the skis: when you lift the whole thing up, the front of the skis go down. I also could glue a coin or washer to the skis' rear for balance instead. I only need about 8g.

Lieven, how about installing a rubber band instead of cable? If you make the rubber band a bit short, so that when you lift the model off the ground, the tips of the skis would point up, and when you put it back on the ground the rubber bands would be under tension. That way (I think) in soft snow, the front ends of the skis would stay above the surface better. Maybe:huh:

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Snowplane, radio gear

Re: Snowplane, radio gear

Lieven, I'm curious as to why you're replacing the crankcase on the engine? What were you running for fuel in those vids? Are you able to obtain good fresh 1/2A fuel in your region.. with at least 25% nitro?

I really like this model.. it's very cool.. and you did a great job building it!! I honestly wouldn't worry about the way that the skis balance on their pivots. The mounts look like they're in good positions to me. The front tips of all three skis should naturally ride-up over snow.. and not "dig in". They should by design; "float" over moguls .. the way you've built their mounts.

Maybe a single radiussed central "keel" on the front ski (just below where it pivots/steers) would assist tracking/steering, without stress-loading a servo too much. It wouldn't need to be very long or deep to be effective.. similar in cross-section; to a curved x-acto blade.. but only 3-4mm below the ski. The added weight of radio components will help keep it planted and tracking straight, until steering-input is given.

Have you got the engine-throttle design worked-out yet? The roof of the craft looks like it was sealed-up for your test-runs. Will you be hinging it at the front, so it opens for access to the cabin and radio components? You could make a vertical stand-off servo-mount from 3mm plywood, that extends up through a slot in the roof.. with a 90 degree bellcrank at the top (outside) for your throttle pushrod. You could adopt the "Ace" method of using a short piece of tight-fitting fuel line (sleeve) for fine-tuning a 2-piece pushrods'-throw.

One more point that I mentioned previously.. some "down-thrust" would definitely lessen the surface-tension on the rear-skis. You could accomplish this by simply shimming-out the "top" two engine mounts between the firewall with some flat-washers.

Rusty asked about "pusher" engines.. (engine forward of prop).. I don't know for sure.. but with conventional "tractor" props that "pull" the engine/model.. there is ample internal lubrication in the fuel for the crank to be "pulling" toward the front of the case. With a "pusher".. there is friction where the drive-plate meets the nose of the case.. where there's pretty much "no" lubrication. This is why using an electric starter can wear-down the nose of the case.. if you're heavy-handed with it. Marine-modelers use a thrust-washer in their drive-lines for this very reason.

I really like this model.. it's very cool.. and you did a great job building it!! I honestly wouldn't worry about the way that the skis balance on their pivots. The mounts look like they're in good positions to me. The front tips of all three skis should naturally ride-up over snow.. and not "dig in". They should by design; "float" over moguls .. the way you've built their mounts.

Maybe a single radiussed central "keel" on the front ski (just below where it pivots/steers) would assist tracking/steering, without stress-loading a servo too much. It wouldn't need to be very long or deep to be effective.. similar in cross-section; to a curved x-acto blade.. but only 3-4mm below the ski. The added weight of radio components will help keep it planted and tracking straight, until steering-input is given.

Have you got the engine-throttle design worked-out yet? The roof of the craft looks like it was sealed-up for your test-runs. Will you be hinging it at the front, so it opens for access to the cabin and radio components? You could make a vertical stand-off servo-mount from 3mm plywood, that extends up through a slot in the roof.. with a 90 degree bellcrank at the top (outside) for your throttle pushrod. You could adopt the "Ace" method of using a short piece of tight-fitting fuel line (sleeve) for fine-tuning a 2-piece pushrods'-throw.

One more point that I mentioned previously.. some "down-thrust" would definitely lessen the surface-tension on the rear-skis. You could accomplish this by simply shimming-out the "top" two engine mounts between the firewall with some flat-washers.

Rusty asked about "pusher" engines.. (engine forward of prop).. I don't know for sure.. but with conventional "tractor" props that "pull" the engine/model.. there is ample internal lubrication in the fuel for the crank to be "pulling" toward the front of the case. With a "pusher".. there is friction where the drive-plate meets the nose of the case.. where there's pretty much "no" lubrication. This is why using an electric starter can wear-down the nose of the case.. if you're heavy-handed with it. Marine-modelers use a thrust-washer in their drive-lines for this very reason.

Re: Snowplane, radio gear

Re: Snowplane, radio gear

Lieven. Maybe just replace the prop driver plate with a brass one. Sure Starts are sold that way as a pusher. I think Cox International has them.

Rod.

Rod.

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Snowplane, radio gear

Re: Snowplane, radio gear

Roddie,

The Dragonfly was bought 2nd hand. I didn't know his condition. It's something you cannot tell from looking at the outside. It might have been started by an electric starter during its previous life or maybe run on fuel with synthetic oïl only. I don't know. As the word 1/2A is extiguished over here, I mix my fuel myself. I have Dyna Glo with 25% nitro, 8% synthetic oïl and 2% castor. With that I add 10% extra castor.

In one way or another, I have to make sure to front of the ski's don't go down too much when the surface is uneven. The points would easily dig into the snow that way. So, I need to come up with something like a linkage cable or a spring or a combination of both or a rubber band as Kari mentioned. Concerning the, keels, A depth of 3 to 4 mm would be OK indeed. I'll follow the kind of keels mentioned on the Call Air plan. For the roof, I still need to make a lock for the hatch. The hole for the throttle connection will be behind the hatch, also still to make.

Rusty, As mentioned in my post with the video's, I noticed that the revs went down after some running and I also had to play with the needle. I don't think the piston and cylinder tighten from heat. With the given clearances Cox made their cylinders, you would soon have metal to metal contact and seizing of both parts: the engine would immediately stop and cylinder/piston assy would be ready for the bin.

Because there is not such a forced air stream as with a tractor prop, I think the cylinder expands by the heat and the compression will become less. You have maybe more blow-by and the efficiency of the engine goes down. Also, and I had this twice, after I had emptied a tank, the cylinder head could be unscrewed by hand, although it was done up before with a spanner. This might also indicate that the cylinder expands by the heat and this due to the exhaust gasses in the cylinder and the evacuation of exhaust gasses through the exhaust port.

By the way, and just to compare, on the Enya .09 and .19 marine engines, only the cylinder between the head and the exhaust port is watercooled and not the head itself. in this way, certain expansion of the cylinder is avoided:

On a Cox pusher, and definitely in my case with the snow plane, where there is a very reduced air stream, a heat sink will be necessary, but more one that is clamped to the cylinder fins and not to the head. I'm going to try to make a heat sink and do a test.

Rod, I ordered a crankcas and crank with a hex drive washer in brass from Matt. I hope that this will restist enough.

Lieven

The Dragonfly was bought 2nd hand. I didn't know his condition. It's something you cannot tell from looking at the outside. It might have been started by an electric starter during its previous life or maybe run on fuel with synthetic oïl only. I don't know. As the word 1/2A is extiguished over here, I mix my fuel myself. I have Dyna Glo with 25% nitro, 8% synthetic oïl and 2% castor. With that I add 10% extra castor.

In one way or another, I have to make sure to front of the ski's don't go down too much when the surface is uneven. The points would easily dig into the snow that way. So, I need to come up with something like a linkage cable or a spring or a combination of both or a rubber band as Kari mentioned. Concerning the, keels, A depth of 3 to 4 mm would be OK indeed. I'll follow the kind of keels mentioned on the Call Air plan. For the roof, I still need to make a lock for the hatch. The hole for the throttle connection will be behind the hatch, also still to make.

RknRusty wrote:I love it. I might have to copy it in case we get some snow. I could play with it maybe once a year, or even run the sprinkler on a freezing night to ice up the yard.

I have a question for you guys that run pushers. I noticed when one of my Bees started backwards, and I somehow didn't notice(I'm a little slow on the uptake sometimes), it began to bog and I had to turn it much richer after it first peakd to regain a full 2-stroke; I assume because the piston and cylinder begin to tighten from the heat. Do engines used like this have a significantly shorter life due to higher heat induced friction?

Rusty

Rusty, As mentioned in my post with the video's, I noticed that the revs went down after some running and I also had to play with the needle. I don't think the piston and cylinder tighten from heat. With the given clearances Cox made their cylinders, you would soon have metal to metal contact and seizing of both parts: the engine would immediately stop and cylinder/piston assy would be ready for the bin.

Because there is not such a forced air stream as with a tractor prop, I think the cylinder expands by the heat and the compression will become less. You have maybe more blow-by and the efficiency of the engine goes down. Also, and I had this twice, after I had emptied a tank, the cylinder head could be unscrewed by hand, although it was done up before with a spanner. This might also indicate that the cylinder expands by the heat and this due to the exhaust gasses in the cylinder and the evacuation of exhaust gasses through the exhaust port.

By the way, and just to compare, on the Enya .09 and .19 marine engines, only the cylinder between the head and the exhaust port is watercooled and not the head itself. in this way, certain expansion of the cylinder is avoided:

On a Cox pusher, and definitely in my case with the snow plane, where there is a very reduced air stream, a heat sink will be necessary, but more one that is clamped to the cylinder fins and not to the head. I'm going to try to make a heat sink and do a test.

Rod, I ordered a crankcas and crank with a hex drive washer in brass from Matt. I hope that this will restist enough.

Lieven

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Snowplane, radio gear

Re: Snowplane, radio gear

Lieven, you've gotten a really interesting and fun project going.

The Cox prop rod streamlined racer car with pusher prop used a standard Babe Bee engine without any additional cooling fins. Once started, it was set into motion and run on hard packed dirt or concrete would build up speed providing extra cooling.

By getting rid of that poor running condition and operating the car on a more slippery surface would provide greater cooling air to the engine. Once your snow car is in motion at a brisk pace, the cooling issue will disappear. I don't know if using a car/heli cooling head with heat sink might cool it too much, since you would be operating it in the snow and cold.

To trouble shoot the run problems, you could run it in tractor mode with prop air stream over the engine. Then after that is fixed, reverse starting direction for test runs, doing the runs over a more slippery surface.

A Texaco head may be a better choice.

The Cox prop rod streamlined racer car with pusher prop used a standard Babe Bee engine without any additional cooling fins. Once started, it was set into motion and run on hard packed dirt or concrete would build up speed providing extra cooling.

By getting rid of that poor running condition and operating the car on a more slippery surface would provide greater cooling air to the engine. Once your snow car is in motion at a brisk pace, the cooling issue will disappear. I don't know if using a car/heli cooling head with heat sink might cool it too much, since you would be operating it in the snow and cold.

To trouble shoot the run problems, you could run it in tractor mode with prop air stream over the engine. Then after that is fixed, reverse starting direction for test runs, doing the runs over a more slippery surface.

A Texaco head may be a better choice.

GallopingGhostler- Top Poster

Posts : 5722

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Snowplane, radio gear

Re: Snowplane, radio gear

On the other hand, "typical" operational temperature for a snow plane is around or below freezing temp, that should also help.

For a pusher application a thrust washer might be a good addition. My second-hand QRC came with a 3-blade pusher attached and its crank has a noticeable end play. It also has an aluminum drive plate. Although I am not sure what is an acceptable or safe amount of end play.

For a pusher application a thrust washer might be a good addition. My second-hand QRC came with a 3-blade pusher attached and its crank has a noticeable end play. It also has an aluminum drive plate. Although I am not sure what is an acceptable or safe amount of end play.

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: Snowplane, radio gear

Re: Snowplane, radio gear

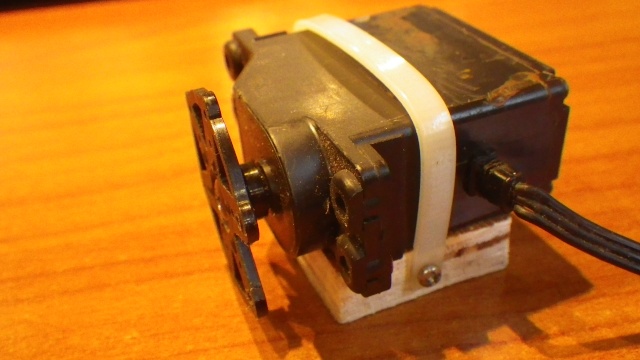

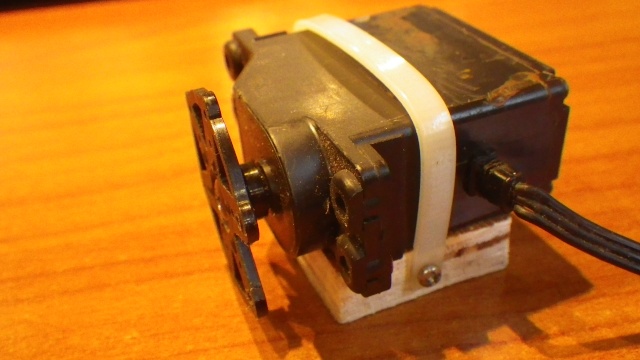

Here's a small update about the rear ski's. I managed to make something to lift the front of the ski's when they should leave the surface. It takes actually longer to think about it than to make it. It's done with bolts an nuts and 2 rubber bands "borrowed" from my daughter's Rainbow Loom kit.

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Snowplane, radio gear

Re: Snowplane, radio gear

That's a great invention! I've seen bags of those colorful rubber bands at the craft stores and was trying to figure out how to adapt them to a hobby application. Yours is ingenious!

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: Snowplane, radio gear

Re: Snowplane, radio gear

Good news. I received my parts today

I rebuilt the engine with a new crankcase and crankshaft assembly, a new tank gasket and I added a new snap starter. I left the 6x4 behind and mounted a 6x3 3 bladed pusher prop

I did some trials this afternoon. The difference is remarkable. It suddenly became a very fast machine. I hope I still can try it on snow this winter

This is with reduced throttle:

https://www.youtube.com/watch?v=bbuqstoPoQA

And this is full throttle (Birkin style) but not for long!!

https://www.youtube.com/watch?v=6PXTNaLRJAA&feature=youtu.be

Lieven

I rebuilt the engine with a new crankcase and crankshaft assembly, a new tank gasket and I added a new snap starter. I left the 6x4 behind and mounted a 6x3 3 bladed pusher prop

I did some trials this afternoon. The difference is remarkable. It suddenly became a very fast machine. I hope I still can try it on snow this winter

This is with reduced throttle:

https://www.youtube.com/watch?v=bbuqstoPoQA

And this is full throttle (Birkin style) but not for long!!

https://www.youtube.com/watch?v=6PXTNaLRJAA&feature=youtu.be

Lieven

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Snowplane, radio gear

Re: Snowplane, radio gear

With the repair parts installed, your snow car really scoots now, Lieven. Just think, when you have snow to try it on, then it will really move out. Plus if it flips, the snow will be gentler on your prop.

GallopingGhostler- Top Poster

Posts : 5722

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Snowplane, radio gear

Re: Snowplane, radio gear

Looks good!

Is the radio installed yet? You might have to throttle down in the corners now...

We had a windy day today here and lots of snow;

Is the radio installed yet? You might have to throttle down in the corners now...

We had a windy day today here and lots of snow;

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Snowplane, radio gear

Re: Snowplane, radio gear

Yes nice lieven , now for some snow I hope you get to try it out it came out looking great . It going to be 65 degrees here today they say wanting to get some fly time in shot some rifles yesterday . bring on the FUN !!! Eric

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Snowplane, radio gear

Re: Snowplane, radio gear

NICE job on the snowplane.

akjgardner- Diamond Member

Posts : 1601

Join date : 2014-12-28

Age : 65

Location : Greensberg Indiana

Re: Snowplane, radio gear

Re: Snowplane, radio gear

Thanks guys for your comments above and also the more recent ones. Today, I installed the servos. The steering servo is bolted to an aluminium corner profile and fixed with 2 bolts to the floor. The throttle servo is fixed with a piece of plastic cut from a tie wrap, to 10mm plywood also screwed to the floor. I managed to bend a thin linkage and attach it to the throttle ring of the engine. I still have to fix batteries and the receiver. I was thinking of using Velcro for that but I don't know if there are other or better / easier methods, any ideas?

I hope with this done, we'll get some snow over here in the beginning of the year.

I hope with this done, we'll get some snow over here in the beginning of the year.

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Snowplane, radio gear

Re: Snowplane, radio gear

Hi Lieven, Merry Christmas! Velcro is probably the easiest choice. It will stick quite well to the RX and battery.. providing you first clean the mounting-surfaces with an alcohol-wipe. As for the chassis.. I would find the spot(s) where they'll fit.. and spread a thin layer of epoxy over preferably bare wood using a flat tool to spread it. When cured, clean it with an alcohol wipe too, before you stick-on the Velcro. Sticking them to a painted surface might lift the paint when you remove them later. Another approach would be to build partitions on the floor close to the nose. Is there room up there? I figure the extra weight over the front ski might help with steering?

Re: Snowplane, radio gear

Re: Snowplane, radio gear

Roddie, I got some velcro today. The battery will be located in front of the steering servo. There is no space in the nose and it's all closed as well.

The floor is only doped to prevent moisture going into the wood. Maybe the velcro would stick directly on that? I don't know. I have to try.

The floor is only doped to prevent moisture going into the wood. Maybe the velcro would stick directly on that? I don't know. I have to try.

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Page 3 of 3 •  1, 2, 3

1, 2, 3

Similar topics

Similar topics» fs no name airplane

» Pictures added Radio gear

» Snowplane test on snow !!

» Old Cox Radio

» Hobby King Mini-Stick 580mm "Electric to Cox" Conversion

» Pictures added Radio gear

» Snowplane test on snow !!

» Old Cox Radio

» Hobby King Mini-Stick 580mm "Electric to Cox" Conversion

Page 3 of 3

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules