Log in

Search

Latest topics

» My N-1R build logby roddie Yesterday at 9:29 pm

» Funny what you find when you go looking

by rsv1cox Yesterday at 3:21 pm

» Landing-gear tips

by 1975 control line guy Yesterday at 8:17 am

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 7:45 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» My latest doodle...

by TD ABUSER Mon Nov 18, 2024 11:30 am

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

» Free Flight Radio Assist

by rdw777 Sun Nov 17, 2024 6:03 pm

» Tribute Shoestring build

by amurphy6812 Sun Nov 17, 2024 5:43 pm

Cox Engine of The Month

Tuning an .049 reed engine with tank

Page 2 of 2

Page 2 of 2 •  1, 2

1, 2

Re: Tuning an .049 reed engine with tank

Re: Tuning an .049 reed engine with tank

Blue Eyes wrote:The tune up kit came with a read valve.

Congratulations on getting your engine running!! That must have put a smile on your face!! Did you install the new reed that came with the tune-up kit?

As I stated earlier; the reeds for these engines can be different shapes... but they all fit and work by the same principal. The older style reed that your engine probably had.. looks like a 4-pointed "star". These were made of different materials too. Some were "Copper/Beryllium" some were "Steel" and some were a transparent "Mylar" plastic which may have been clear or colored. The newer "oval" shaped reeds are available in Mylar, Steel, and Teflon. They vary slightly in thickness... but all reeds are only a few thousandths of an inch thick. Some people claim better performance/longevity with certain types.. but that's a matter of how often you run your engine.. and whether you're looking for all-out performance. For "sport" use... any of them are fine. Some people "make their own".. from the Mylar sheet material that's used in the old computer "floppy discs". This can be handy if you happen to lose or damage a reed when rebuilding or performing maintenance on an engine.

I posted a photo earlier in this thread that shows two tank-style back-plates with their fuel pick-up tube orientations. If you look closely.. you'll see that their needles have a short piece of small size silicone fuel tubing and a stop-washer installed. (the one on the left shows it more clearly) If your needle feels "loose" or becomes "loose-fitting" over time... it will leak air.. (may also float) and cause erratic engine runs. Making this modification will help/cure that condition.

Where you purchased/installed a "new" back-plate... you might not have this trouble for a while. Is the new back-plate a plastic one? I don't have any of those.. and am curious about how the needle-valve threads are formed. If the needle "self-taps" into the plastic... it may seal quite well.

Here's another photo (courtesy of Paul Gibeault) that clearly shows that needle-valve modification on the back-plate that's in the center. This seals air-leaks around the needle. The "spring" has been discarded.

Re: Tuning an .049 reed engine with tank

Re: Tuning an .049 reed engine with tank

Roddie, the black plastic backplates have a brass spraybar pressed into the plastic, and possibly glued. I replace the spring with silicon tube on all Cox needle valves regardless of whether they seem to have a leak or not.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

RE Tuning an .049 reed engine with tank

RE Tuning an .049 reed engine with tank

I used the medal back plate. I will have to replace the needle valve witch I have ordered from Cox. I can't seem to fine tune the engine.

Blue Eyes- Bronze Member

- Posts : 49

Join date : 2014-03-27

Age : 73

Location : Roseville, Califonia

Re: Tuning an .049 reed engine with tank

Re: Tuning an .049 reed engine with tank

While cleaning my 10 Euro Babe Bee, I polished the reed with copper polish and I made sure the seat was clean. I also replaced the spring by a silicon tube. The engine runs at a constant speed and starts without priming or starter spring.

Lieven

Lieven

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: Tuning an .049 reed engine with tank

Re: Tuning an .049 reed engine with tank

OVERLORD wrote:While cleaning my 10 Euro Babe Bee, I polished the reed with copper polish and I made sure the seat was clean. I also replaced the spring by a silicon tube. The engine runs at a constant speed and starts without priming or starter spring.

Lieven

That's a nice smooth runner!!! I've never heard of polishing the Copper reed, but I can certainly understand why that could make a difference. The least resistance on the path that the fuel/air charge travels on it's way through the engine; both pre/post ignition is said to improve performance. Racing engines are often treated to their intake/exhaust ports being ported/polished. The only reason why this isn't done on most mass-produced engines is because of the extra cost.

I believe that there is/was a patented process called extrude-hone, which involved flowing an abrasive media through the ports of intake/exhaust manifolds and cylinder head parts while mounted to a fixture, using a high pressure pump. This process basically polishes the inside of the cast surfaces on the path that the fuel charge follows through the engine.

Re: Tuning an .049 reed engine with tank

Re: Tuning an .049 reed engine with tank

Polishing should give a perfect seal on the valve seat.

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

RE Tuning an .049 reed engine with tank

RE Tuning an .049 reed engine with tank

I polished the seat with some fine steel wool. Then I re seated the reed valve. I got it to a much louder scream. But I have another problem there is fuel leaking from the front of the engine in between the crank shaft and the crank case is that normal? Do need to get a new crank case and crank shaft? I purchased a Cox #4505 Dragon Fly .049 engine I paid 39.99 for it. Do you think I paid too much for it?

Blue Eyes- Bronze Member

- Posts : 49

Join date : 2014-03-27

Age : 73

Location : Roseville, Califonia

Re: Tuning an .049 reed engine with tank

Re: Tuning an .049 reed engine with tank

More than likely the case is worn and not the crank itself. I have seen prepped engines leak out of the nose. Is it normal? No, but not always a show stopper.

Can't say if $40 is too much for a Dragonfly, but if you had let us know you had a problem I could have sent you a crankcase for free...

Ron

Can't say if $40 is too much for a Dragonfly, but if you had let us know you had a problem I could have sent you a crankcase for free...

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

RE Tuning an .049 reed engine with tank

RE Tuning an .049 reed engine with tank

I did not know that i had that problem until today. What i could do is use another crankcase that i have to see if that solves the problem.

Blue Eyes- Bronze Member

- Posts : 49

Join date : 2014-03-27

Age : 73

Location : Roseville, Califonia

Re: Tuning an .049 reed engine with tank

Re: Tuning an .049 reed engine with tank

If there's a lot (excessive) of "play" in the crankshaft.. then your case is worn. Fuel shouldn't "pour" out of the front of the engine when it's not running... but some will come out when it is running... If you don't have excessive play in the crankshaft... I wouldn't worry about it. The oils contained in the fuel are meant to lubricate all of the internal moving parts.

Keep a small container of "3-in-one" oil (or any light machine-oil) in your flight box. Before you start your engine.. place a few drops of oil where the prop drive-plate meets the case... and flip the prop once or twice before you connect the battery. This is especially important if you use an electric starter like I sometimes do. Only use quick/short bursts if you do use an electric starter... i.e. "one second" is way too long on a small Cox engine... and would quickly wear-out the aluminum case from the friction/heat produced.

Keep a small container of "3-in-one" oil (or any light machine-oil) in your flight box. Before you start your engine.. place a few drops of oil where the prop drive-plate meets the case... and flip the prop once or twice before you connect the battery. This is especially important if you use an electric starter like I sometimes do. Only use quick/short bursts if you do use an electric starter... i.e. "one second" is way too long on a small Cox engine... and would quickly wear-out the aluminum case from the friction/heat produced.

RE Tuning an .049 reed engine with tank

RE Tuning an .049 reed engine with tank

How thick should the piece of ply wood be when attaching the engine?

Last edited by Blue Eyes on Sun Apr 13, 2014 9:22 pm; edited 1 time in total (Reason for editing : To expand the question.)

Blue Eyes- Bronze Member

- Posts : 49

Join date : 2014-03-27

Age : 73

Location : Roseville, Califonia

re: dragonfly for $39.99

re: dragonfly for $39.99

Blue Eyes wrote:I polished the seat with some fine steel wool. Then I re seated the reed valve. I got it to a much louder scream. But I have another problem there is fuel leaking from the front of the engine in between the crank shaft and the crank case is that normal? Do need to get a new crank case and crank shaft? I purchased a Cox #4505 Dragon Fly .049 engine I paid 39.99 for it. Do you think I paid too much for it?

I just recently read your thread and to answer you question about the price of the cox dragonfly engine. Prices are relative to condition of the engine, muffler or not, condition of the box and what all came in the package. Some of the complete dragonfly engines in the original box come with a replacement gasket kit and a tank extension that enables the tank to hold more fuel. I recently purchased a dragonfly in the original box, but parts of the muffler were missing and the tank extension kit was also missing. The price was about $20.00. I actually tried to sell it to one of the CEF members, but he changed his mind.

happydad

happydad- Rest In Peace

- Posts : 1592

Join date : 2012-05-28

Age : 79

Location : Escondido, CA

RE Tuning an .049 reed engine with tank

RE Tuning an .049 reed engine with tank

The engine is used it was frozen, i soaked it in alcohol that freed up the engine inside the was very dirty the bolts that holds on the back of the were gummed up with old caster oil. The bolts are cleaned. All I need to know how thick the ply wood should be.

Blue Eyes- Bronze Member

- Posts : 49

Join date : 2014-03-27

Age : 73

Location : Roseville, Califonia

Re: Tuning an .049 reed engine with tank

Re: Tuning an .049 reed engine with tank

If you referring to bench running an engine then the wood thickness is up to you. I use a block of maple.

Plywood will absorb castor quickly and will weaken and eventually the mounting bolts will pull free. Unless you protect it. For that I would go 1/4" or more.

If you are making an engine mount for a plane then 1/8" would be sufficient. It too must be protected for the same reason. Thinned epoxy works well.

Hope that answers your question.

Ron

Plywood will absorb castor quickly and will weaken and eventually the mounting bolts will pull free. Unless you protect it. For that I would go 1/4" or more.

If you are making an engine mount for a plane then 1/8" would be sufficient. It too must be protected for the same reason. Thinned epoxy works well.

Hope that answers your question.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

RE Tuning an .049 reed engine with tank

RE Tuning an .049 reed engine with tank

Thank you i will buy a sheet of 1/4 of an inch.

Blue Eyes- Bronze Member

- Posts : 49

Join date : 2014-03-27

Age : 73

Location : Roseville, Califonia

Re: Tuning an .049 reed engine with tank

Re: Tuning an .049 reed engine with tank

Birch is good and hard. Hobby shops and Hobby Lobby sell it. My local HL has good balsa as well. I bought some that was beautiful light contest grade for my Skyray ribs, I couldn't believe I found it there. They had the full range up to hard balsa.Blue Eyes wrote:Thank you i will buy a sheet of 1/4 of an inch.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Tuning an .049 reed engine with tank

Re: Tuning an .049 reed engine with tank

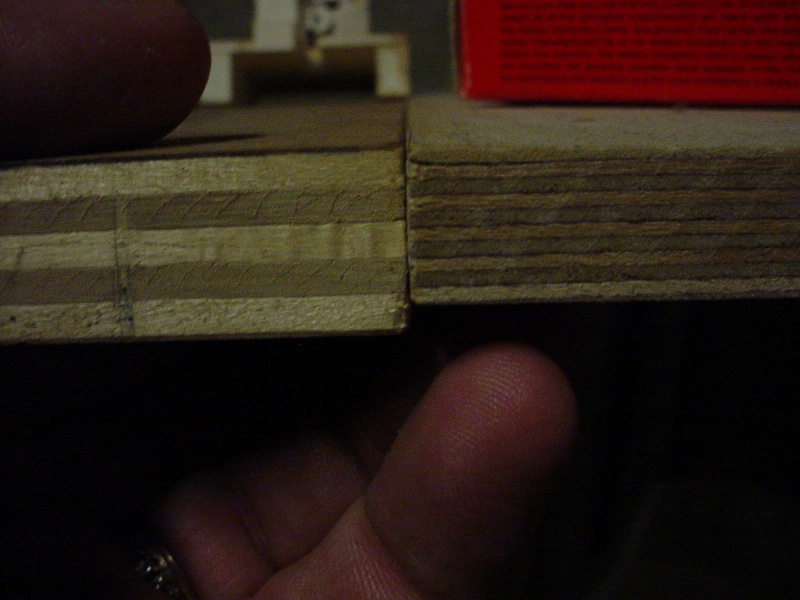

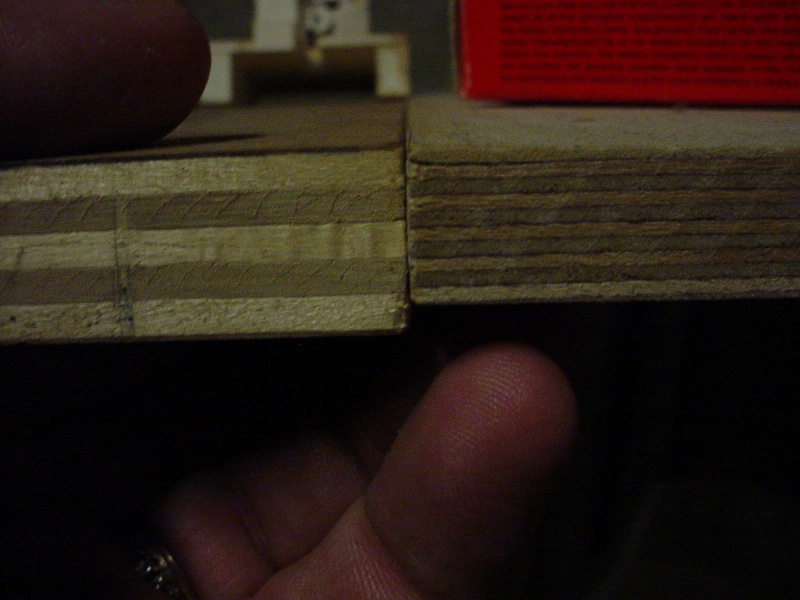

BlueEyes, Here's an example of two different types of plywood. These are thicker than you'd ever need for most modeling applications... but they're being shown for comparison purposes only. Note that they are of slightly different thicknesses.. but their laminations are clearly different. The sample on the "left" is standard lamination plywood. The one on the right is referred to as "Baltic Birch".. which has thinner laminations, but has TWICE as many. Aircraft plywood is similar to Baltic Birch in this way. More "plys" mean more strength and more resistance to warping too.

Standard 1/4" plywood has 4 plys of approx. 1/16" laminations each.. whereas 1/4" Aircraft plywood would have 7-8 plys of 1/32" laminations. (It's like "Baltic-Birch" only in miniature) The Aircraft plywood is a modeling application found at hobby supply stores and is generally a 6" x 12" size. It's better suited for holding the small wood screws that we typically use for a radial-mount engine firewall. It's more expensive.. i.e. a 6" x 12" piece of 1/4" thickness Aircraft plywood may cost as much as a 2' x 2' square of standard 1/4" plywood.

Small 1/2A profile airplane kits generally furnish a 1/16" plywood "plate" for mounting a "radial-mount" engine (Cox Babe Bee) along with balsa "cheek-blocks" behind it for support.

Hobby plywood can be as thin as 1/64" and can be cut with scissors. This size is generally used for "sheeting" a foam-wing.

Standard 1/4" plywood has 4 plys of approx. 1/16" laminations each.. whereas 1/4" Aircraft plywood would have 7-8 plys of 1/32" laminations. (It's like "Baltic-Birch" only in miniature) The Aircraft plywood is a modeling application found at hobby supply stores and is generally a 6" x 12" size. It's better suited for holding the small wood screws that we typically use for a radial-mount engine firewall. It's more expensive.. i.e. a 6" x 12" piece of 1/4" thickness Aircraft plywood may cost as much as a 2' x 2' square of standard 1/4" plywood.

Small 1/2A profile airplane kits generally furnish a 1/16" plywood "plate" for mounting a "radial-mount" engine (Cox Babe Bee) along with balsa "cheek-blocks" behind it for support.

Hobby plywood can be as thin as 1/64" and can be cut with scissors. This size is generally used for "sheeting" a foam-wing.

Re: Tuning an .049 reed engine with tank

Re: Tuning an .049 reed engine with tank

I didn't know that, Roddie. When I was writing the above post, i looked up the birch ply at Hobby Lobby, and it is indeed Baltic birch ply.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Tuning an .049 reed engine with tank

Re: Tuning an .049 reed engine with tank

RknRusty wrote:I didn't know that, Roddie. When I was writing the above post, i looked up the birch ply at Hobby Lobby, and it is indeed Baltic birch ply.

Rusty

Rusty I only learned about Baltic Birch plywood about 10 years ago.. through my music hobby. EAW pro-audio quality speaker cabinets (made here in New England) use it exclusively in their cabs construction. Even their small wedge-shape floor monitors are built with 25mm (1") Baltic Birch panels and internal bracing... making them INCREDIBLY strong (touring grade) and HEAVY. A single small floor wedge weighs between 30 and 70 lbs.. depending on the size of it's driver(s).. and have been known to fall from moving vehicles at highway speeds.. and stay intact... and still work. Our band uses EAW mains.. they're expensive.. but they're the best.

Re: Tuning an .049 reed engine with tank

Re: Tuning an .049 reed engine with tank

Going back to the OP's question on the amount of turns to open the needle valve initially for starting, glad to see he got it to start and run. I had one old engine, a field find by my son, probably from the early to 1967 that required opening the needle to 4 turns, to run. Other reed valve tank engines, it varied from 2-1/2 to 3-1/2 turns.

Regarding the nose dripper with fuel, it could be worn out or simply some corrosion that set in, which when removed caused excessive play. Cox International and a few others have replacement crankcases that could be possibly used, if one is not interested in maintaining historic looks. May require a replacement crankshaft as well. If minor, may be more of a nuisance than needing replacement. YMMV (your mileage may vary)

Regarding the nose dripper with fuel, it could be worn out or simply some corrosion that set in, which when removed caused excessive play. Cox International and a few others have replacement crankcases that could be possibly used, if one is not interested in maintaining historic looks. May require a replacement crankshaft as well. If minor, may be more of a nuisance than needing replacement. YMMV (your mileage may vary)

GallopingGhostler- Top Poster

Posts : 5721

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

RE Tuning an .049 reed engine with tank

RE Tuning an .049 reed engine with tank

I have decided to work on my Dragon Fly .049 in stead. I also won an .049 off of eBay it is an integrated tank on it.

Blue Eyes- Bronze Member

- Posts : 49

Join date : 2014-03-27

Age : 73

Location : Roseville, Califonia

Page 2 of 2 •  1, 2

1, 2

Similar topics

Similar topics» cox rc cars gtp 049 mod

» New in OEM package .049 Reed valve tank kit

» Help! Need Reed valve retainer spring for Cox 010 engine

» A prototype Cox Reed-valve marine engine

» Reed valve engine video clip

» New in OEM package .049 Reed valve tank kit

» Help! Need Reed valve retainer spring for Cox 010 engine

» A prototype Cox Reed-valve marine engine

» Reed valve engine video clip

Page 2 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules