Log in

Search

Latest topics

» Purchased the last of any bult engines from Ken Enyaby sosam117 Today at 11:32 am

» Chocolate chip cookie dough.........

by rsv1cox Today at 10:20 am

» Tee Dee .020 combat model

by rsv1cox Today at 10:07 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

Cox Engine of The Month

CEF speed contest Design Discussions

Page 25 of 40

Page 25 of 40 •  1 ... 14 ... 24, 25, 26 ... 32 ... 40

1 ... 14 ... 24, 25, 26 ... 32 ... 40

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

Cut that speed in half and you'll be in our ballpark.Cribbs74 wrote:137mph, I can do that lying down.

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

It really is super fragile at that thin size. I have a large beltsander that might do the job. The only plane I have is a small hand pushtool with a blade in it. And I also have a fairly aggressive palm sander that is likely too agressive.

Another idea is to laminate the 3/32 sides together and not use the foam core. I'd have to check the rules because I would end up with 3/16 thick fuse. and I think rules say 1/4". Don't answer, I'll look back and read the rules. And the laminating glue might make the weight savings nonexistant anyway.

I'm trying to type after taking a sleeping pill and struggling mightily to work my keyboard. I'll get back to this in the AM before I start looking retarded... more-so that usual.

Signing off... Good night

Rrrruuuusssstyyyyyzzzzzzzzzzz

Another idea is to laminate the 3/32 sides together and not use the foam core. I'd have to check the rules because I would end up with 3/16 thick fuse. and I think rules say 1/4". Don't answer, I'll look back and read the rules. And the laminating glue might make the weight savings nonexistant anyway.

I'm trying to type after taking a sleeping pill and struggling mightily to work my keyboard. I'll get back to this in the AM before I start looking retarded... more-so that usual.

Signing off... Good night

Rrrruuuusssstyyyyyzzzzzzzzzzz

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

Hea Rusty , I have been experimenting with cutting my own engine mounts from some pressure treated black walnut with my table saw and noticed I can cut some really thin stuff . will need a little sanding of coarse . the width is 1 1/4 " if you would like ill cut you some strips and mail them to you no cost . PM me if u are interested with the thickness and address . And I ll see what I can do also have mahogany and I think cherry and oak maybe ? would have to dig for it  I went to the trouble and forgot

I went to the trouble and forgot

there that's better

there that's better

there that's better

there that's better

Last edited by getback on Sun Feb 23, 2014 6:39 pm; edited 1 time in total

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

JPvelo wrote:Cut that speed in half and you'll be in our ballpark.Cribbs74 wrote:137mph, I can do that lying down.

Jim

That 137 mph time was for 1/2A class. It was the 1/2A "profile/proto" class 108 mph time in division 6 that I was referring to... which is an entry level speed class. The average between the divisions for the profile class was approx. 97 mph. Like Jim says; we'll probably be averaging 65 to 75 mph with our models.

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

2-3 layers of carbon veil would be about the same thickness.

Phil

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

I was half zeed last night when I read this and didn't fully register what you were saying. That's a great Idea. I'm on it.roddie wrote:You know me Rusty... I have suggestions for everything...You could use that sheet.. (if it's the lightweight contest grade you're looking for) by edge-gluing it back together along the break, with thin CA on a sheet of wax paper.. on a flat surface (holding the pcs. firmly together for 10-15 seconds) Then cut the pc.(s) to the length you need and thumb-tack x2 pcs. of .031 music-wire on either side of the sheet.. and block-sand (with the grain) down to the music-wire, and you'll have 1/32" thick stock. It will sand easily.. so use a fine grit paper. If you can find a nice lightweight pc. of 1/16" sheet.. you could do the same, with a little less sanding. I didn't know that balsa came in 1/32" thick sheet. That's thin!

Getback, thanks, but I think I'm on track now, thanks to Roddie. Appreciate the offer though. Next time I scratch build, like the plane for my TT15 engine, I will definitely consider getting you to cut me some beams. Thanks.

That's something I've never worked with but probably should learn about. Thanks Philpkrankow wrote:2-3 layers of carbon veil would be about the same thickness.

Phil

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

I will make a sample video closer to "go time" that shows what a official flight will look like. This will include a signal from the pilot on when to start timing. I was thinking of posting the video the last day of March so we are all doing official flights over the same 18 day span.RknRusty wrote: The submission needs to come with a note saying which 10 laps are timed.

Rusty

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

Low tech is how we will do it. I am in the process of finding outside judges to time flights and then I will average times. Ideally there will be three judges with the two closest times bring averaged and the third being thrown out. In the event of a tie all three times will be averaged. I think that is the best way to keep it simple and fair.pkrankow wrote:Go low tech, get some surveyor's tape and run it out to the pilot's circle in front of the camera. If there is a "tie" I don't know how to break and have this stay a "fun" level contest.

Phil

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

I ran my engine today.. and had some problems... fuel draw/flow mostly. The little uni-flow hard-tank I built, does not flow... and I don't know why. There aren't any blockages and it's tight as a drum. I'm going to make a fridge-magnet out of it.

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

Were you trying to run it with both vents capped like that?

Jim

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

JPvelo wrote:Were you trying to run it with both vents capped like that?

Jim

No Jim. The top vent only should be capped. The upper/front is the uni-flow vent. The top is to fill, then cap. It's like there's a vacuum in the tank for some reason. I had issues filling it as well. I failed to flow-test it before trying to run it. I did "leak-test" it after I soldered it.. and it's tight as a drum.

When "full".. nothing flows out with all the tubes open. The engine only ran with the fuel that was in the feed-line.. and then bubbles would appear in the feed line. I messed something up.

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

It wasn't a good afternoon... my tach wouldn't give me a reading.. which didn't really matter, because my engine runs were all less than 20 seconds. "Screaming"... but less than 20 seconds.

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

anytime RustyRknRusty wrote:I was half zeed last night when I read this and didn't fully register what you were saying. That's a great Idea. I'm on it.roddie wrote:You know me Rusty... I have suggestions for everything...You could use that sheet.. (if it's the lightweight contest grade you're looking for) by edge-gluing it back together along the break, with thin CA on a sheet of wax paper.. on a flat surface (holding the pcs. firmly together for 10-15 seconds) Then cut the pc.(s) to the length you need and thumb-tack x2 pcs. of .031 music-wire on either side of the sheet.. and block-sand (with the grain) down to the music-wire, and you'll have 1/32" thick stock. It will sand easily.. so use a fine grit paper. If you can find a nice lightweight pc. of 1/16" sheet.. you could do the same, with a little less sanding. I didn't know that balsa came in 1/32" thick sheet. That's thin!

Getback, thanks, but I think I'm on track now, thanks to Roddie. Appreciate the offer though. Next time I scratch build, like the plane for my TT15 engine, I will definitely consider getting you to cut me some beams. Thanks.That's something I've never worked with but probably should learn about. Thanks Philpkrankow wrote:2-3 layers of carbon veil would be about the same thickness.

Phil

Rusty

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

Got my bladder tank bits from Texas Timers today, if anyone in the U.K. listening, they come highly recomended. Anyway, ran my engine on my newly built bladder. Can I just say I'm converted. I ran it a couple times, on a 5x3 then changed to my newly aquired 4.75x4. Wow, I can honestly say I've never heard an 0.49 scream like that. Can't wait to run it on some 30% nitro, once I've ran it in some more on 25%. Tell me guys, how many revs should I be getting on 25% nitro.

As the time to fly my Bugatti gets nearer, I'm now worrying that I have no rudder/engine offset. Will that be ok?

Cheers Mike,

Bladder Tanks Rule.

Bladder Tanks Rule.

As the time to fly my Bugatti gets nearer, I'm now worrying that I have no rudder/engine offset. Will that be ok?

Cheers Mike,

Bladder Tanks Rule.

Bladder Tanks Rule.

ebeneezer- Gold Member

- Posts : 282

Join date : 2012-05-22

Age : 66

Location : Banbury Oxfordshire England

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

Mike,ebeneezer wrote:Got my bladder tank bits from Texas Timers today, if anyone in the U.K. listening, they come highly recomended. Anyway, ran my engine on my newly built bladder. Can I just say I'm converted. I ran it a couple times, on a 5x3 then changed to my newly aquired 4.75x4. Wow, I can honestly say I've never heard an 0.49 scream like that. Can't wait to run it on some 30% nitro, once I've ran it in some more on 25%. Tell me guys, how many revs should I be getting on 25% nitro.

As the time to fly my Bugatti gets nearer, I'm now worrying that I have no rudder/engine offset. Will that be ok?

Cheers Mike,

Bladder Tanks Rule.

Glad you like the bladders, I can't imagine going back to a hard tank setup myself. My fast motors will turn about 21500 with the APC 4.75x4. My planes for the contest have zero rudder and zero engine offset. It's a little tricky at launch when the plane wants to tourqe roll in at you. Be ready to back up and aggressively "whip" the model to keep the lines tight until gets up to speed and centrifugal force kicks in. With 1/2 elevators and close line spacing at the handle once my planes get going they are incredibly easy to fly.

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

Roddie ; hows the tank coming get her straighten out? I have my second coat of dope on now wow wow outside!roddie wrote:It wasn't a good afternoon... my tach wouldn't give me a reading.. which didn't really matter, because my engine runs were all less than 20 seconds. "Screaming"... but less than 20 seconds.

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

Mike,

Lot of variables going on there. My suggestion would be to tach it with 25% and then again at 30%

No real way of knowing from one engine to the next.

Ron

Lot of variables going on there. My suggestion would be to tach it with 25% and then again at 30%

No real way of knowing from one engine to the next.

Ron

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

getback wrote:Roddie ; hows the tank coming get her straighten out? I have my second coat of dope on now wow wow outside!roddie wrote:It wasn't a good afternoon... my tach wouldn't give me a reading.. which didn't really matter, because my engine runs were all less than 20 seconds. "Screaming"... but less than 20 seconds.

My tank? Oh.. you mean the "fridge magnet".. because that's what it is now. It's holding up the $700.00+ fuel-oil bill.

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

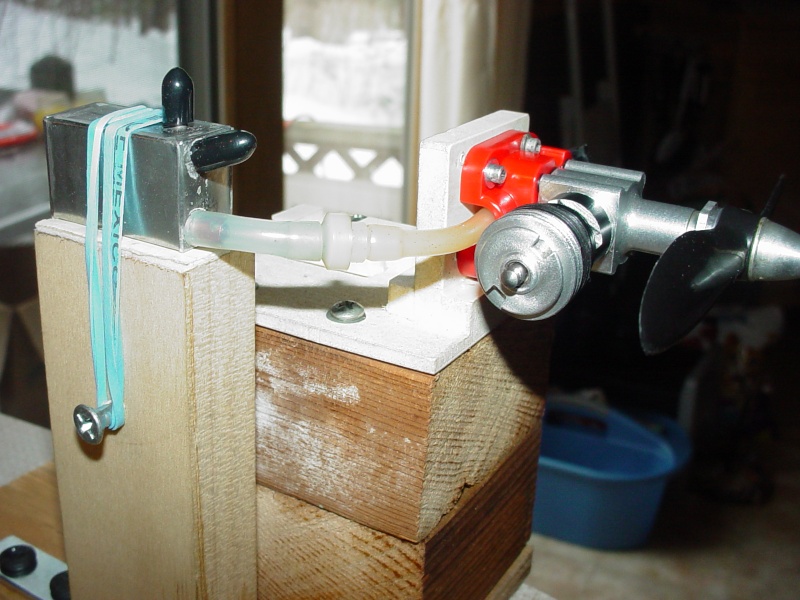

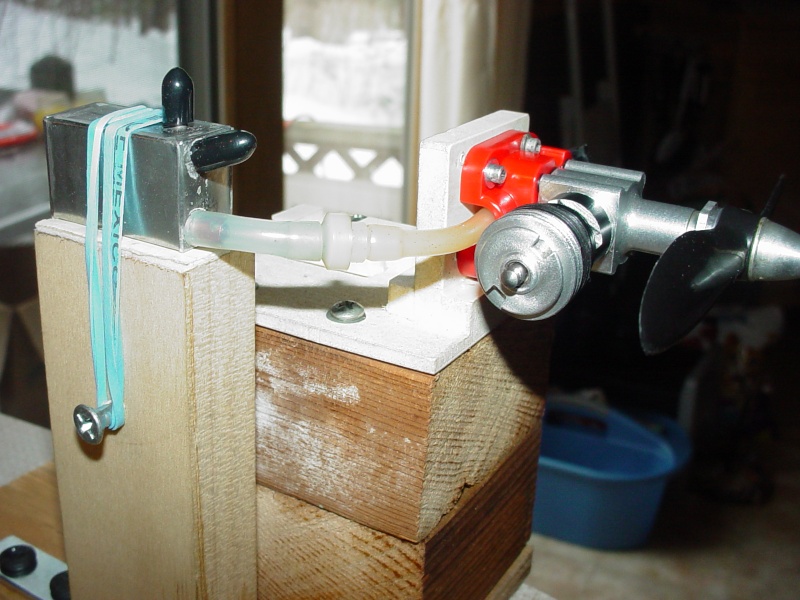

roddie wrote:I ran my engine today.. and had some problems... fuel draw/flow mostly. The little uni-flow hard-tank I built, does not flow... and I don't know why. There aren't any blockages and it's tight as a drum. I'm going to make a fridge-magnet out of it.

I would guess that you are not getting enough pressure for the uni-flow tank - the vent seems to be too far from the engine. (My interpretation of the photo but I could be wrong)

I found this as an example for CL set up.

The uni-flow pipe has been extended inboard to improve the flow.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

I'm actually having trouble getting the tank to "fill" (fuel squirts out the vent almost immediately.. whether I fuel through the top fill tube or the uniflow tube) and once there "is" fuel in the tank, it doesn't flow out.. even when all tubes are open and the tank is sitting level. I have to pressurize it to empty it... which shouldn't be. There are no clogged tubes.. I can blow through all 3.. and the shank-end of a drill bit; to fit the tubes' i.d., passes through.. all the way to the tank walls (I measured) It's like a "vapor-lock" or vacuum is taking place... and I have to wonder if it's the uni-flows' orientation to the pick-up, that could be causing that kind of condition?

I can't say I wasn't warned about the problems associated with getting tanks to work right.

Here's a photo of the uni-flow and pick-up orientation.

I can't say I wasn't warned about the problems associated with getting tanks to work right.

Here's a photo of the uni-flow and pick-up orientation.

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

Roddie,

Tip it up on its tail end and fill through the uniflow while you pinch off the feed line. Lose that coupling and run the biggest line you can straight to the engine, and move it right next to the engine like Ian said. That's my two cents worth anyway.

Jim

Tip it up on its tail end and fill through the uniflow while you pinch off the feed line. Lose that coupling and run the biggest line you can straight to the engine, and move it right next to the engine like Ian said. That's my two cents worth anyway.

Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

Looks like it should draw to me. There's nothing wrong with that arrangement. I agree with Jim, ditch the filter and filter when you draw the fuel out of the bottle if you want to. Run it with the vent capped and the uni open. I'm sure you know that.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

The pickup and the vent are too close together. It will never feed clean. Tiny tanks do not benefit from uni-flow, sorry.

Phil

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

pkrankow wrote:The pickup and the vent are too close together. It will never feed clean. Tiny tanks do not benefit from uni-flow, sorry.

Phil

I am suspect of that position of the uni-flow to the pick-up.. and pick-up to the rear cap distance. They are almost equidistant from each other. This could and probably "is" as you say; sucking air down the uni-flow and introducing bubbles into the pick-up.

I think that the uni-flow "principal" still applies; regardless of the size of the tank. Tank volume theoretically should not matter. I'm making some mods to this tank tomorrow, and soldering up a 2nd tank with a further-forward uni-flow position as well.

Paul G. noticed that my vertical fill-tube runs to the tank floor. This explains the trouble with filling. The "air" in the tank has to go somewhere when the "fuel" goes in. As soon as the fuel-level reached the uni-flow.. there was nowhere for the "air" to go.. so fuel spurts out through the uni-flow. If alternately I filled through the uni-flow.. fuel would squirt out the fill-tube in the same way. I was only getting fuel into the bottom of the tank. So simple that I feel very stupid.

We'll get this resolved... and I appreciate everyone's suggestions. I'll let you know how my mods work out.

Thanks everyone!

Re: CEF speed contest Design Discussions

Re: CEF speed contest Design Discussions

Sucking the floor can be solved by angling the end of the tube with a file or sandpaper, or just cutting deliberately crooked. You still need a clearance space but the angled end makes it set up a clearance space.

Fluids have surface tension, which will regulate the smallest free-forming air bubble. Draw forms a current which can capture the smallest free-forming air bubble. There is a theoretical minimum separation based on these values. For larger engines it seems an inch (25mm) of separation is desired.

Phil

Fluids have surface tension, which will regulate the smallest free-forming air bubble. Draw forms a current which can capture the smallest free-forming air bubble. There is a theoretical minimum separation based on these values. For larger engines it seems an inch (25mm) of separation is desired.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Page 25 of 40 •  1 ... 14 ... 24, 25, 26 ... 32 ... 40

1 ... 14 ... 24, 25, 26 ... 32 ... 40

Similar topics

Similar topics» CEF speed contest Design Discussions (2014)

» CEF T-Shirt Design Contest

» *VOTE* CEF T-Shirt Design Contest

» Cox Engine Forum Speed Contest 2018!!!

» Speed Contest

» CEF T-Shirt Design Contest

» *VOTE* CEF T-Shirt Design Contest

» Cox Engine Forum Speed Contest 2018!!!

» Speed Contest

Page 25 of 40

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules