Log in

Search

Latest topics

» Tee Dee .020 combat modelby Ken Cook Today at 6:23 am

» My latest doodle...

by batjac Today at 12:47 am

» My N-1R build log

by roddie Yesterday at 11:50 pm

» Free Flight Radio Assist

by rdw777 Yesterday at 7:51 pm

» Purchased the last of any bult engines from Ken Enya

by getback Yesterday at 3:05 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 6:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 11:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 9:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 3:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 9:08 am

» My current avatar photo

by roddie Tue Nov 19, 2024 12:05 am

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 9:40 pm

Cox Engine of The Month

a cheap sport muffler

Page 1 of 5

Page 1 of 5 • 1, 2, 3, 4, 5

Re: a cheap sport muffler

Re: a cheap sport muffler

Roddie, did you ever look at different ways to assemble the rubber shroud?

I'm looking at it and thinking that turning it inside out would make it look a little cleaner (if it would still fit around the inner pipe. Also, maybe gluing the two rubber disks together with the patch cement for tire repairs instead of stapling. It would make installing it over any tubes or pipes harder - just some thoughts that popped into my head looking at your design.

I'm looking at it and thinking that turning it inside out would make it look a little cleaner (if it would still fit around the inner pipe. Also, maybe gluing the two rubber disks together with the patch cement for tire repairs instead of stapling. It would make installing it over any tubes or pipes harder - just some thoughts that popped into my head looking at your design.

VUgearhead- Gold Member

- Posts : 155

Join date : 2013-07-03

Age : 57

Location : Boynton Beach, FL

Re: a cheap sport muffler

Re: a cheap sport muffler

Excellent points... I took your "turning the rubber body inside-out" suggestion, and attempted it. It resulted in a smaller "triangular" shape... "neat looking"... but would cause problems with the inner-chamber "fit"; because of the rubber seam being on the inside.VUgearhead wrote:Roddie, did you ever look at different ways to assemble the rubber shroud?

I'm looking at it and thinking that turning it inside out would make it look a little cleaner (if it would still fit around the inner pipe. Also, maybe gluing the two rubber disks together with the patch cement for tire repairs instead of stapling. It would make installing it over any tubes or pipes harder - just some thoughts that popped into my head looking at your design.

The "joining-method" of the rubber; using your suggested "inner-tube cement" may work... I haven't tried it. What I "can" tell you; is that the staples hold up to extreme "stretching" (as witnessed by turning the rubber inside-out...) The cement may peel apart... and may not be impervious to the exhaust wastes/heat.

Having the rubber seam on the "outside" creates an environment for the inner-chamber to "self-center" itself, inside the "pocket" and hold it in position; once inserted.

You also don't want to compromise the "design-seal" that the finished muffler makes, around the engine cylinder. Attempting to "stretch" the rubber body beyond the way I designed it, will affect this seal.

Thanks for your interest though... There's obviously many different ways to design/re-design something; to make it better, neater, lighter, stronger etc.

Re: a cheap sport muffler

Re: a cheap sport muffler

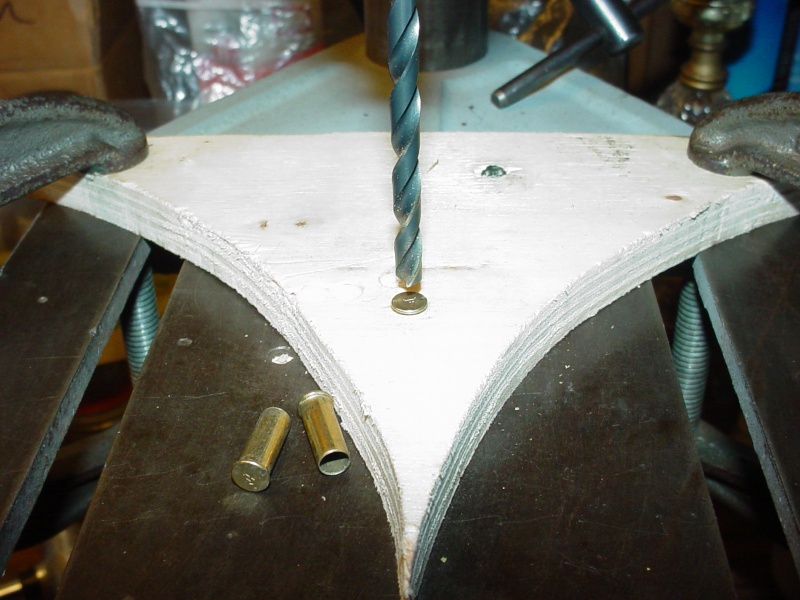

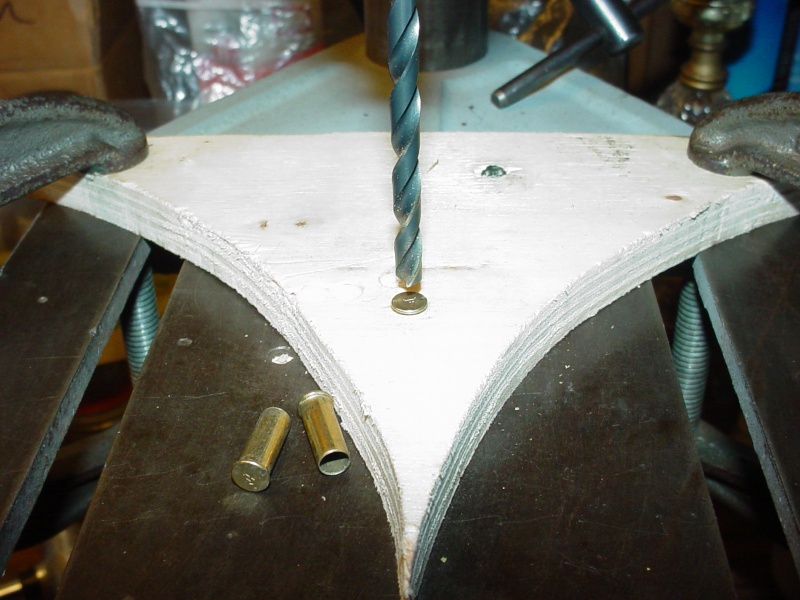

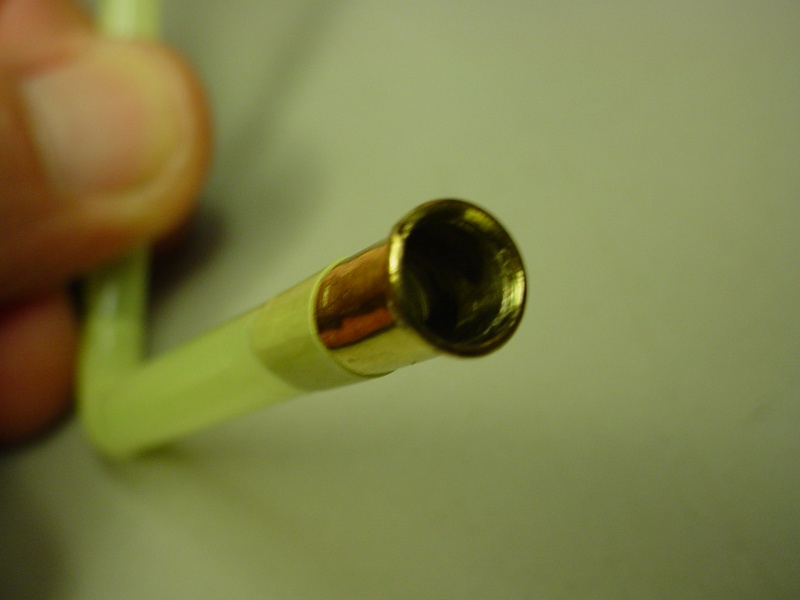

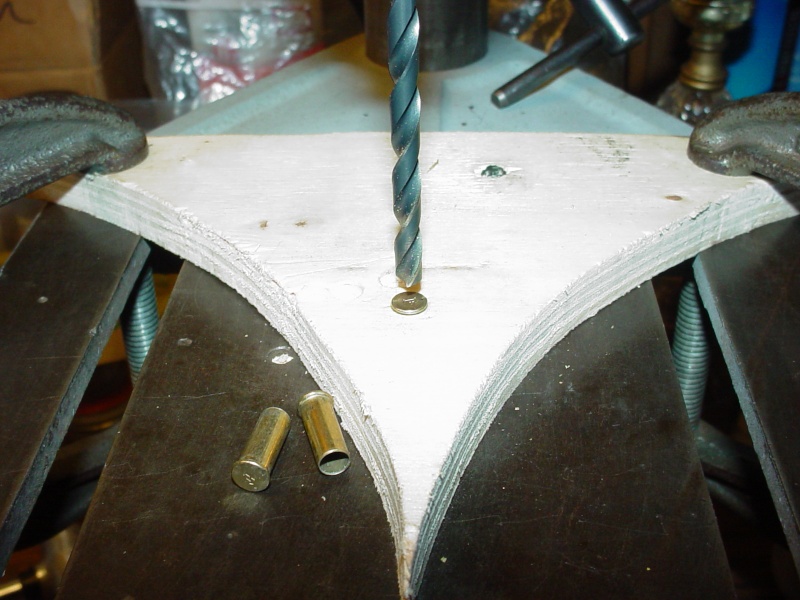

I finally found some .22 cal. shell casings to use as exhaust-pipes for this muffler. The rim acts as the flare did on my other pipes made from plumbing supply compression fittings... (which are .250" dia. and wide-open) These shell casings are .228" dia. and the closed "primer-cap" on the rim end, can be drilled-out for varying degrees of back-pressure.

Most of you are familiar with the original Cox .049 muffler... not much adjustability there... Think about the size of the openings in your cylinder's exhaust ports... you probably wouldn't want to restrict those too much... if you didn't have to... in order to quiet your engine down a few notches.

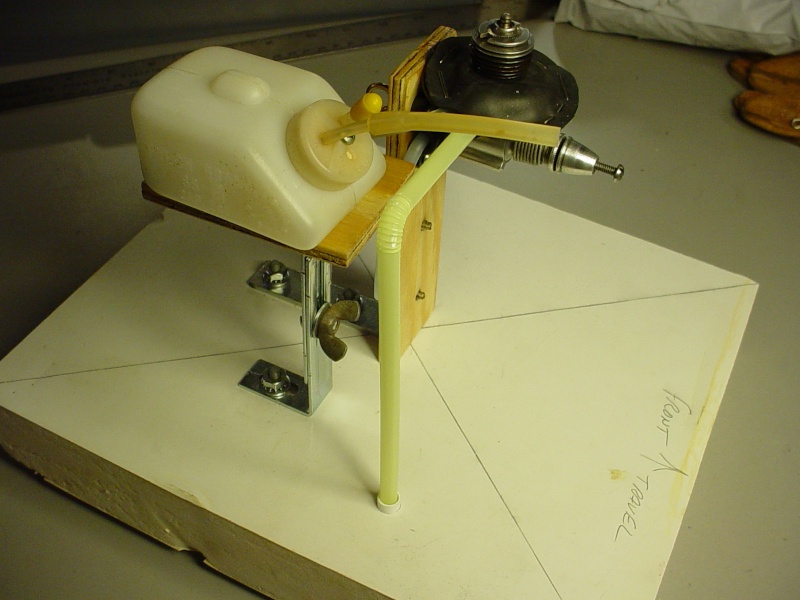

My muffler design has a larger expansion chamber than the original Cox muffler.. and does not require engine disassembly. A pressure tap is an option. The exhaust note is "directional" as with any muffler... but with this design, it can be rotated 360 degrees.. and attaching a "drinking straw" of the appropriate diameter to the exhaust pipe... routes exhaust-wastes wherever you want them to go.

If utilizing a "pressure-to-tank" line... there will be a "back-pressure" differential.. depending on the muffler's main-pipe orifice size.

I hope to be able to produce a descent sport muffler that will have the "adjustability" for multiple applications.

Most of you are familiar with the original Cox .049 muffler... not much adjustability there... Think about the size of the openings in your cylinder's exhaust ports... you probably wouldn't want to restrict those too much... if you didn't have to... in order to quiet your engine down a few notches.

My muffler design has a larger expansion chamber than the original Cox muffler.. and does not require engine disassembly. A pressure tap is an option. The exhaust note is "directional" as with any muffler... but with this design, it can be rotated 360 degrees.. and attaching a "drinking straw" of the appropriate diameter to the exhaust pipe... routes exhaust-wastes wherever you want them to go.

If utilizing a "pressure-to-tank" line... there will be a "back-pressure" differential.. depending on the muffler's main-pipe orifice size.

I hope to be able to produce a descent sport muffler that will have the "adjustability" for multiple applications.

Re: a cheap sport muffler

Re: a cheap sport muffler

I have drilled out the .22 cal. shell casings which have an o.d. of .228" and an i.d. of .205" to 11 different sizes from .144" to .204" (approx. .005/.007" graduations) for varied degrees of exhaust flow. The shell casing serves as the "main muffler pipe". The aluminum (1" tube) inner-muffler chamber/ring is center-drilled to .228" to accept any of the shell-casing pipes, which are installed from the "inside-out".. of the chamber.. the shell casings' "rim" acts as a stop for the pipe. When the muffler is installed (merely "pushed-on" over the Cox .049's cylinder..) the main exhaust pipe is held captive... (same for the flared pressure-tap insert; except it receives fuel tubing on the outside wall of the chamber.. to hold it captive. This fuel tubing can either be plugged.. or plumbed to a tank-vent for muffler pressure.

Different configurations can be tested.. all having the benefit of reduced SPL's.. (which is the main objective to using a muffler)... but with this design; it gives you performance options. Maximum performance is achieved by running dual "wide-open" (.204" drilled) pipes... with the option of a pressure-line to a tank.

Anyone interested in more info... feel free to ask.

Roddie

Different configurations can be tested.. all having the benefit of reduced SPL's.. (which is the main objective to using a muffler)... but with this design; it gives you performance options. Maximum performance is achieved by running dual "wide-open" (.204" drilled) pipes... with the option of a pressure-line to a tank.

Anyone interested in more info... feel free to ask.

Roddie

Re: a cheap sport muffler

Re: a cheap sport muffler

I'll be doing some testing on one with different pipe configurations soon. First I'll fly it with a Tee Dee on my Streak. And after the CEF Speed Freakout, I'll use it on my mustang racer for tank pressure evaluation.

Regarding the above picture, you might find it's more stable and drains the tank better if you shim the rear end of it away from the fuse so that it's oriented tangent to the circle rather than yawing out with the plane.

Rusty

Regarding the above picture, you might find it's more stable and drains the tank better if you shim the rear end of it away from the fuse so that it's oriented tangent to the circle rather than yawing out with the plane.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: a cheap sport muffler

Re: a cheap sport muffler

RknRusty wrote:I'll be doing some testing on one with different pipe configurations soon. First I'll fly it with a Tee Dee on my Streak. And after the CEF Speed Freakout, I'll use it on my mustang racer for tank pressure evaluation.

Regarding the above picture, you might find it's more stable and drains the tank better if you shim the rear end of it away from the fuse so that it's oriented tangent to the circle rather than yawing out with the plane.

Rusty

OK Rus.. now that the "CEF Speed Freakout" is behind us..

Just to re-cap for anyone who missed this thread; (and not to beat a dead horse.. honestly) this homemade muffler design for Cox .049 engines is easy and cheap to make.. it's lightweight and has dozens of configurations that you can try. You can even tap it for pressure.. and make extensions to route exhaust wastes away from your model.

Materials are; x1 pc. of 1" thin-wall aluminum tubing, about 1/2" long, to form a ring.. (shower curtain-rod, etc.)

x1 sheet (2" x 4") of bicycle tire inner-tube material

A "few" (preferably a dozen) .22 cal. (spent) ammo shell-casings (get em' at your local shooting range.. they're

not re-loadable.. and people toss them) These will be your header pipe(s)

Tools needed;

*Tubing cutter (or saw) to cut the 1" aluminum thin-wall tubing to approx. 1/2" long

*a standard paper-stapler

*a 1/2" diameter round punch (make from 1/2" round thin-wall metal tubing.. approx. 2" long)

*a small wood block (for the punch)

*a 15/64" drill-bit and electric-drill

*drill bits varying in size; from .204" diameter and smaller; depending on how many different pipes you want to

experiment with. A single wide-open header-pipe has a .204" inside diameter.

If you want to make a pressure-tap, you'll also need some small metal tubing (fuel-line nipple size) and a means to flare one end. A "half-A" lead-out guide already has a flare, is the perfect length (about 1/2") and works perfectly if you already have one. Attach sm. size fuel line to run to your tank vent.

If you want to make an exhaust extension; standard "bendy" plastic drinking straws fit tightly on a .22 cal. shell-casing "header-pipe", and can be routed down and wire-tied to a l/g strut.. or along the fuse and straight out the back, keeping oil off your model.

Most conventional mufflers are a compromise. This design installs/removes easily without any engine disassembly, allows for varying degrees of back-pressure by drilling different size holes in the header-pipes (which can be swapped-out quickly).. might possibly improve your stunt engine runs; through use of the pressure-tap.. and let's not forget; it will make your engine quieter.. even with wide-open headers (VS. running "open-face")

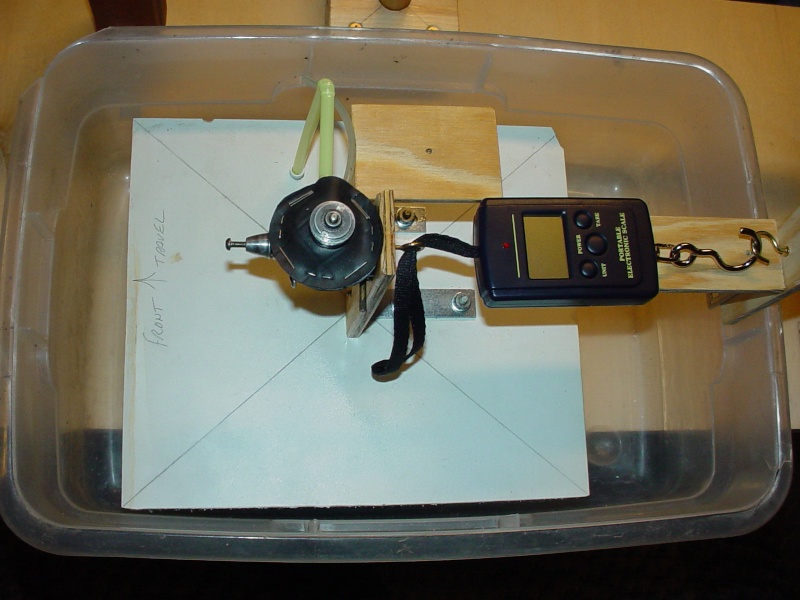

If the weather's decent tomorrow, I'll try running an engine with muffler on my dyno using an exhaust extension.. and post a vid of the results. I have one almost ready to go.

Re: a cheap sport muffler

Re: a cheap sport muffler

That's Cool man very inexpensive way to have pressure system////the noise part or restriction of power I can do without

I know when I took the muffler ring off the 049 medallion made it come to life like hade not seen ...being I had not ran the only one I had no other way

I know when I took the muffler ring off the 049 medallion made it come to life like hade not seen ...being I had not ran the only one I had no other way  Thanks Roddie.....Eric

Thanks Roddie.....Eric

I know when I took the muffler ring off the 049 medallion made it come to life like hade not seen ...being I had not ran the only one I had no other way

I know when I took the muffler ring off the 049 medallion made it come to life like hade not seen ...being I had not ran the only one I had no other way

getback- Top Poster

Posts : 10439

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: a cheap sport muffler

Re: a cheap sport muffler

Yeah Roddie, I'll dig up that Altoids box and give it a try. I tried to try it, but found it won't fit on a Tee Dee. I'll put one on the Reed Speed plane. At least we have a baseline for how fast it flies without a muffler.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: a cheap sport muffler

Re: a cheap sport muffler

RknRusty wrote:Yeah Roddie, I'll dig up that Altoids box and give it a try. I tried to try it, but found it won't fit on a Tee Dee. I'll put one on the Reed Speed plane. At least we have a baseline for how fast it flies without a muffler.

Rusty

Yea... there isn't too much clearance between the cylinder and venturi on a Tee Dee.. The rubber muffler housing is very flexible though.. and it's flap "should" flex up (or down..) and tuck in between. The inner aluminum ring is free-floating and only has a .050" wall thickness. There is the added thickness of the rubber too.. but the rubber will compress. Of course; you definitely wouldn't want to "force" it to fit. There isn't much clearance in between a reedie's needle/cylinder using a horseshoe backplate either, but the rubber flexes easily to fit with clearance to spare.

Re: a cheap sport muffler

Re: a cheap sport muffler

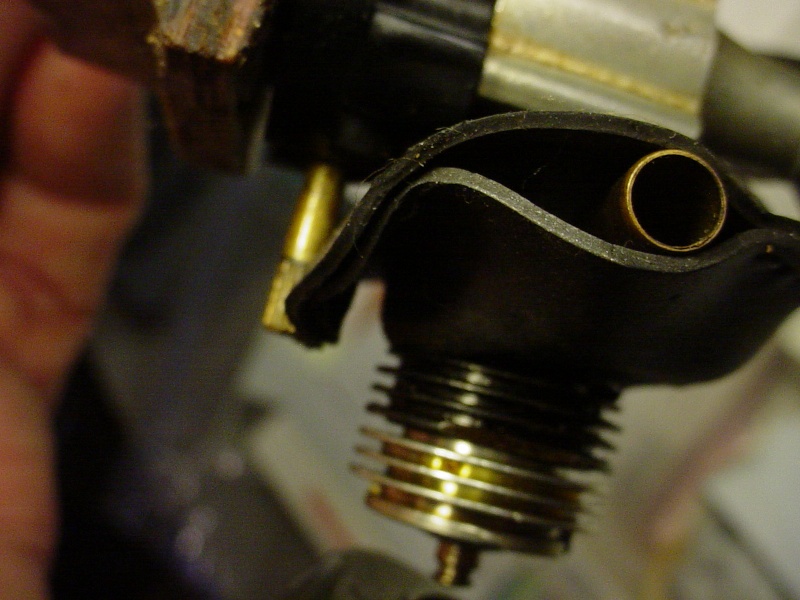

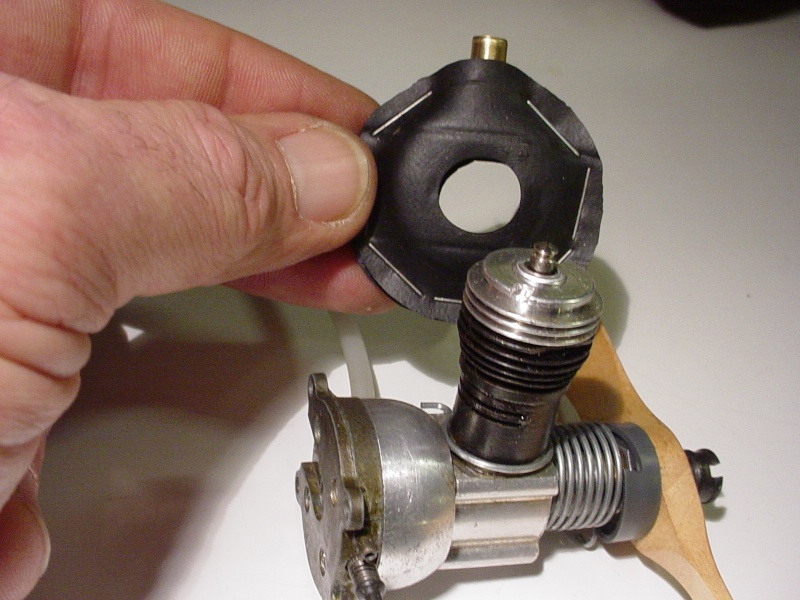

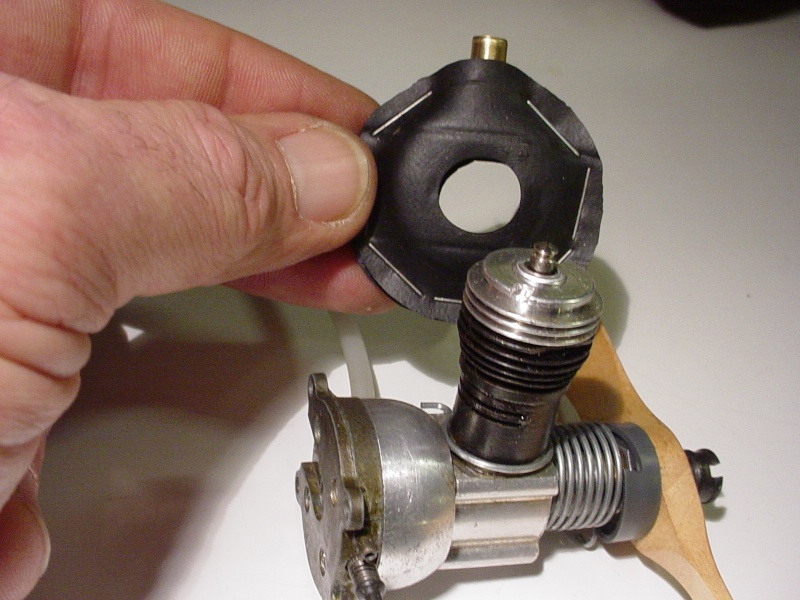

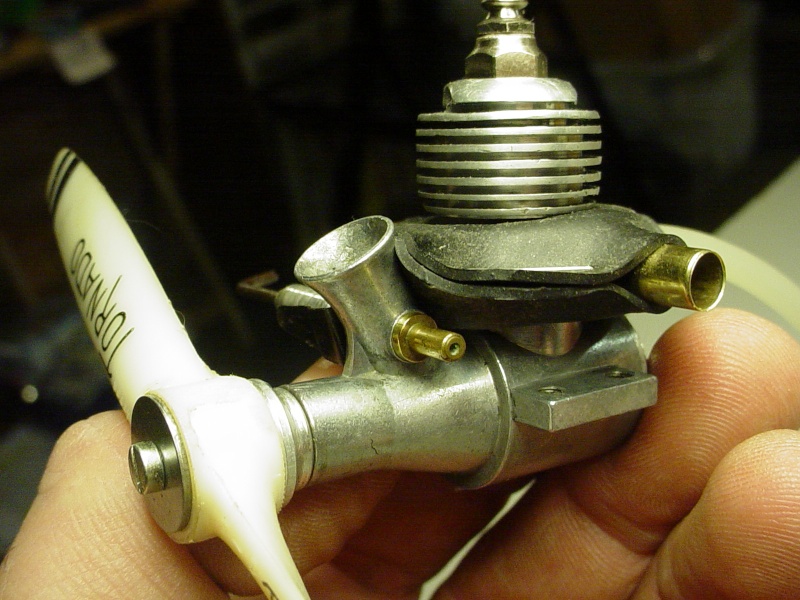

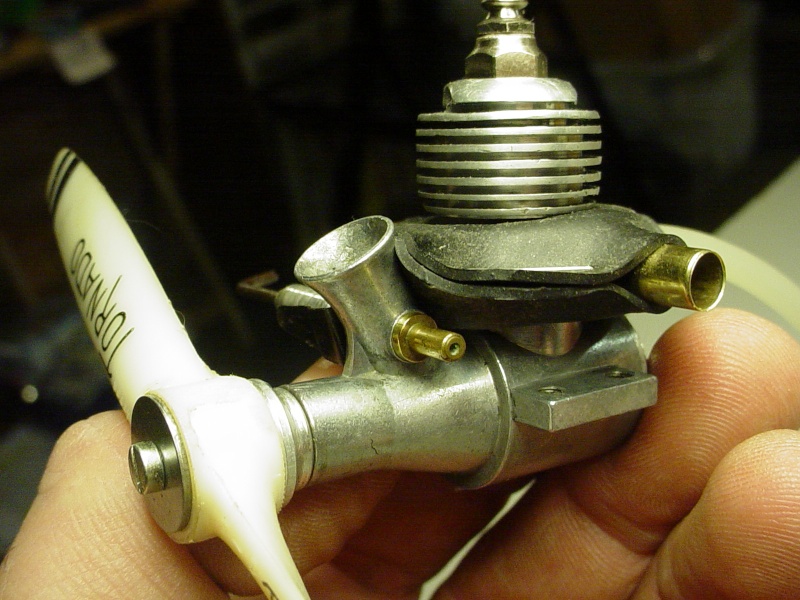

Bumping this thread to show a smaller diameter muffler body (outer rubber discs) and ease of fit.

This version may fit between the cylinder/venturi on a non-SPI front rotary-valve engine.. although I don't have any Cox's to try. It has a single pipe of .205" inside diameter, which is the maximum it can be drilled-out.. and also allows for an exhaust-port prime using a short piece of small size fuel tubing on your priming bulb/syringe.. as there's no shoulder on the inside of the pipe for the tubing to catch on. Just feed the primer tube extension through the pipe until it hits the cylinder wall and give a little squirt.

The .205" pipes are naturally the least restrictive, and running duals is even less restrictive. Does anyone know the total area of the exhaust ports on certain .049 cylinders? It would be interesting to have some figures for test purposes.

This version may fit between the cylinder/venturi on a non-SPI front rotary-valve engine.. although I don't have any Cox's to try. It has a single pipe of .205" inside diameter, which is the maximum it can be drilled-out.. and also allows for an exhaust-port prime using a short piece of small size fuel tubing on your priming bulb/syringe.. as there's no shoulder on the inside of the pipe for the tubing to catch on. Just feed the primer tube extension through the pipe until it hits the cylinder wall and give a little squirt.

The .205" pipes are naturally the least restrictive, and running duals is even less restrictive. Does anyone know the total area of the exhaust ports on certain .049 cylinders? It would be interesting to have some figures for test purposes.

Re: a cheap sport muffler

Re: a cheap sport muffler

I have Ron's fuel test Bee on a test stand ready to crank. I'll put one of your mufflers on it and see how it does.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: a cheap sport muffler

Re: a cheap sport muffler

Some interesting numbers on a #2 .049 engine cylinder's exhaust port area. The port-area is 0.0336" (ea. side) and a .204" ID muffler-pipe's area is 0.033"... so running dual-pipes theoretically offers near zero back-pressure.

A #3 cylinder (twin-slit exhaust ports) area is 0.0165" (ea. side) and running a single .204" ID pipe would also theoretically offer zero back-pressure.

A #1 cylinder's area is 0.037" (ea. side) and has the largest ports of any of my cylinders.

This gives a more scientific base-line for testing pipes having different size openings. For example; fitting a #2 cylinder with a single .204" pipe will create a 50% reduction in exhaust gas flow.

I used this calculator along with my vernier-calipers to arrive at these figures.

https://www.easycalculation.com/area/circle.php

A #3 cylinder (twin-slit exhaust ports) area is 0.0165" (ea. side) and running a single .204" ID pipe would also theoretically offer zero back-pressure.

A #1 cylinder's area is 0.037" (ea. side) and has the largest ports of any of my cylinders.

This gives a more scientific base-line for testing pipes having different size openings. For example; fitting a #2 cylinder with a single .204" pipe will create a 50% reduction in exhaust gas flow.

I used this calculator along with my vernier-calipers to arrive at these figures.

https://www.easycalculation.com/area/circle.php

Re: a cheap sport muffler

Re: a cheap sport muffler

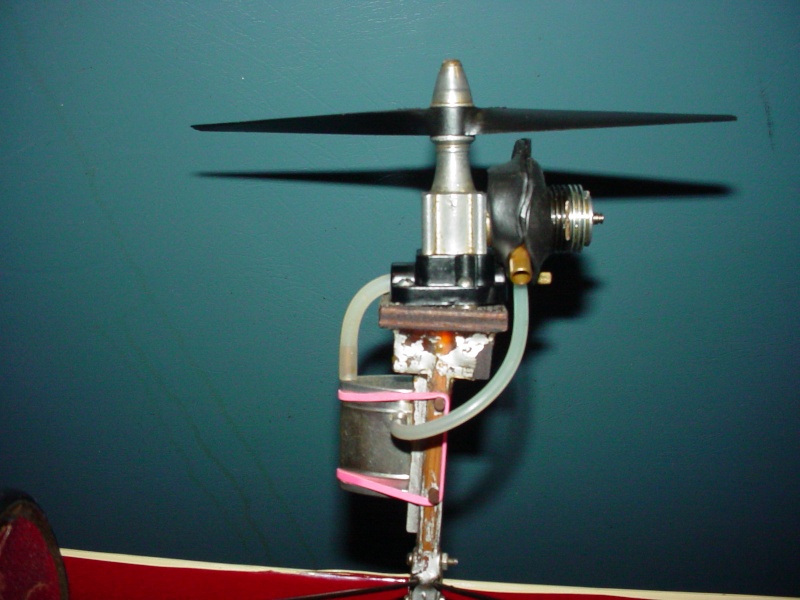

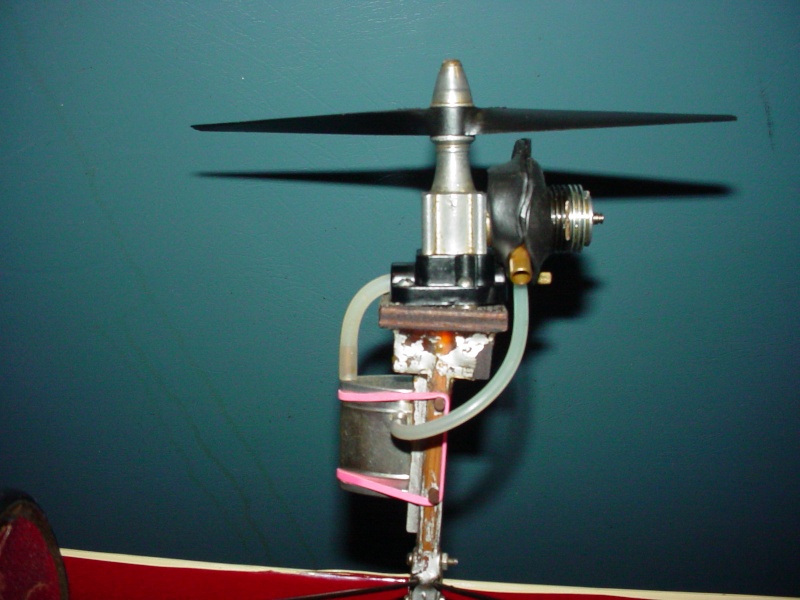

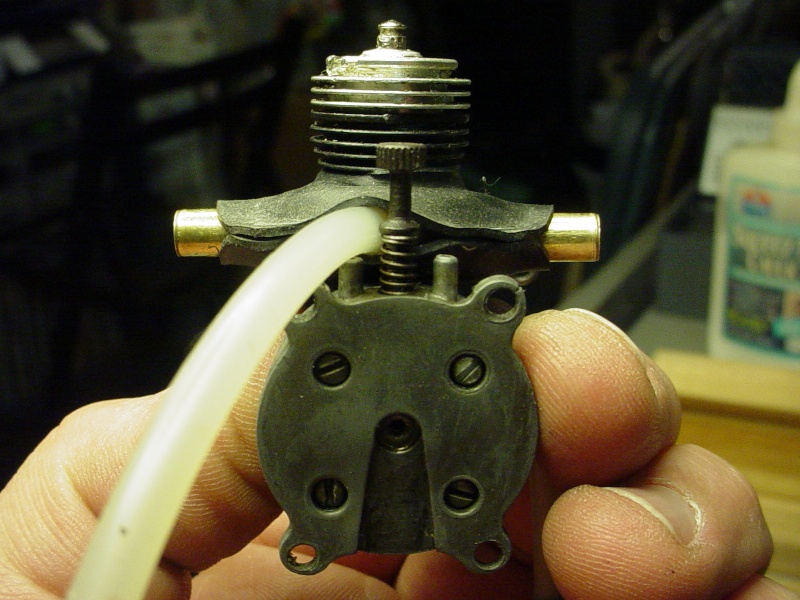

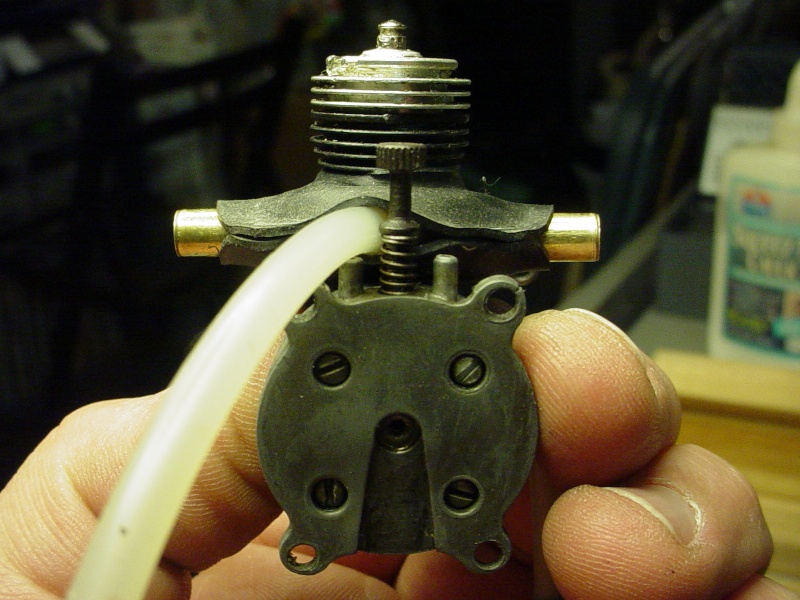

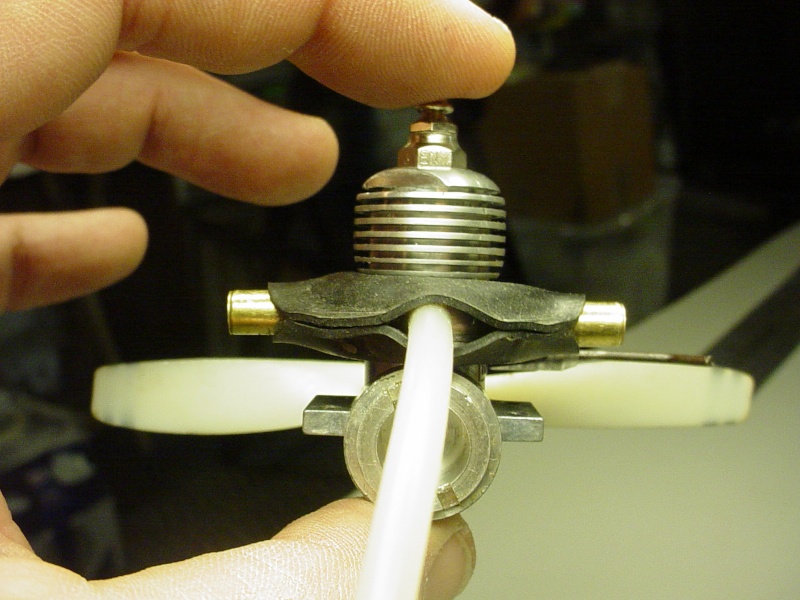

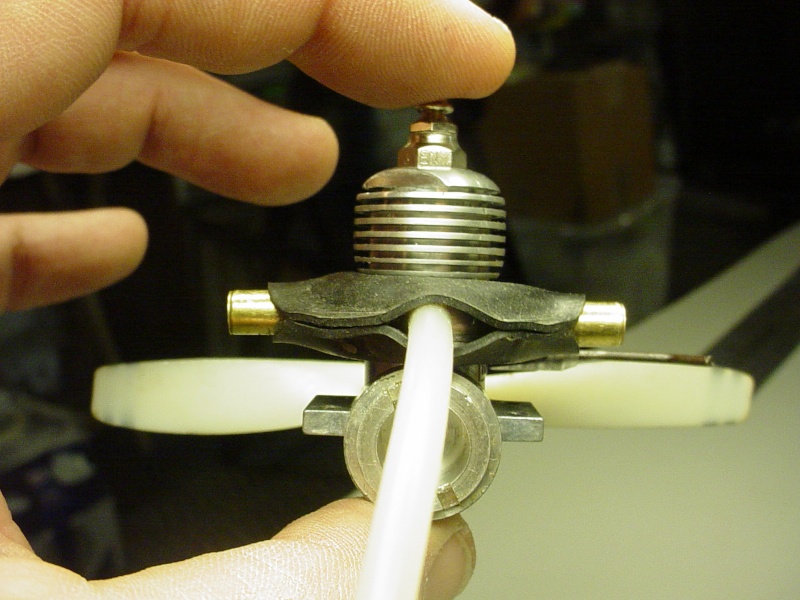

My wild Saturday night consisted of making another homemade muffler. This one is smaller still. I used the same 1.000" dia./.050" wall alum. tube (ring) on the inside.. but cut it to a length just over 5/16" (.320" to be exact..) which is about as small as I can go and still have room for drilling the holes for header pipe(s). This one is a 180 degree dual-header exit design with a pressure-tap exiting at the rear.

Again.. once assembled; it pushes right on over the glow-head.

I tried a different type of rubber.. (same .040" thickness) but encountered a tear when installing the inner alum. ring. so I remade the rubber-body from inner-tube (bicycle) rubber which is very tough. The two rubber discs are 1.625" dia. and the holes in the center are punched-out 7/16" dia. They are simply stapled together around the edge.. with common paper-staples.. leaving gaps where the pipes exit.

Although shown installed on a Babe Bee, this pressure-line would run back to an external hard-tank for running a horseshoe or postage-stamp backplate.

These headers are max-drilled to .205"

No problem when using small fuel tubing, to squirt some fuel into the pipe for an exhaust-prime.

Again.. once assembled; it pushes right on over the glow-head.

I tried a different type of rubber.. (same .040" thickness) but encountered a tear when installing the inner alum. ring. so I remade the rubber-body from inner-tube (bicycle) rubber which is very tough. The two rubber discs are 1.625" dia. and the holes in the center are punched-out 7/16" dia. They are simply stapled together around the edge.. with common paper-staples.. leaving gaps where the pipes exit.

Although shown installed on a Babe Bee, this pressure-line would run back to an external hard-tank for running a horseshoe or postage-stamp backplate.

These headers are max-drilled to .205"

No problem when using small fuel tubing, to squirt some fuel into the pipe for an exhaust-prime.

Last edited by roddie on Tue Mar 21, 2023 2:02 pm; edited 1 time in total (Reason for editing : corrected the stated pipe dia. from .750" to 1.000")

Re: a cheap sport muffler

Re: a cheap sport muffler

Roddie - it is this that matters.

On my last visit to a club in the North - they were strictly enforcing 82db at various positions around the model before allowing flight.

So I bought one of these to check my engines, quite a few of them fail until I stuff steel wool in the exhaust (that was a tip from the club). I haven't tried it on any Bees yet.

Gone are the days - I can be deafened by screaming rug rats but the beautiful sound of IC engines is no longer acceptable!

On my last visit to a club in the North - they were strictly enforcing 82db at various positions around the model before allowing flight.

So I bought one of these to check my engines, quite a few of them fail until I stuff steel wool in the exhaust (that was a tip from the club). I haven't tried it on any Bees yet.

Gone are the days - I can be deafened by screaming rug rats but the beautiful sound of IC engines is no longer acceptable!

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: a cheap sport muffler

Re: a cheap sport muffler

I hope that's the one your sending me to try even though I don't have to worry about the wonderful sound of screaming bee's I am looking forward to tring it out as we had spoke before , I PROMISE NOT TO PULL A RUSTY ON YOU AND STICK YOUR MUFFLER DESIGN IN A DRAW  I WANT TO GET MY STUNTMAN 23IN THE AIR WITH THAT Madellion on it and that may will bee the test . After I test stand run just to get the hand of whats going on ! The Thankful Eric

I WANT TO GET MY STUNTMAN 23IN THE AIR WITH THAT Madellion on it and that may will bee the test . After I test stand run just to get the hand of whats going on ! The Thankful Eric

getback- Top Poster

Posts : 10439

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: a cheap sport muffler

Re: a cheap sport muffler

ian1954 wrote:Roddie - it is this that matters.

On my last visit to a club in the North - they were strictly enforcing 82db at various positions around the model before allowing flight.

So I bought one of these to check my engines, quite a few of them fail until I stuff steel wool in the exhaust (that was a tip from the club). I haven't tried it on any Bees yet.

Gone are the days - I can be deafened by screaming rug rats but the beautiful sound of IC engines is no longer acceptable!

I'd be very interested to know the db#'s that Cox engines average at varying distances.

A meter similar to yours (if not the same exact model) is selling on Amazon currently for less than $20.00+ shipping. It's their best-seller with a ton of reviews.

Amazon offering

I could try steel-wool (#0000-grade) stuffed pipes..

Yes Eric.. I'm putting a kit together for you. It should work on your Medallion.. but "as-is".. this muffler doesn't seem to fit between the cylinder/carb. on a Tee Dee, because of the NVA/housing being in-between. I'm thinking about designing something that would.. but it would involve a smaller inner-ring that wouldn't fit over the glow-head. Installation/removal would require removing the cylinder from the engine. That would greatly hinder swapping-out different pipes to experiment with.

I have an assortment of pipes with smaller holes drilled in them too. This one is the smallest at .144"

Here's the complete assortment.

I mentioned to Rusty; the possibility of mixing different diameter dual-pipes to see if it might produce a cross-flow "scavenging" effect. For instance; installing a .204" orifice pipe 180 degrees from a .102" orifice one? It would be an interesting experiment. Who knows.. it might exhibit SPI-type performance with a non-SPI cylinder? I'm curious whether the pipe-indexing in relation to the exhaust ports on the cylinder would matter? It's easy enough to rotate the assembly while running the engine to see if it has any effect on performance. In this mode, we'd be looking more at exhaust "tuning" rather than noise-reduction.

Re: a cheap sport muffler

Re: a cheap sport muffler

That is the same meter as mine - mine was £14.40 - free shipping - next day delivery from Amazon Prime.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 70

Location : England

Re: a cheap sport muffler

Re: a cheap sport muffler

Eric, I'll make/send a .102" orifice pipe from a blank and include it in the kit for you to try with a .204" pipe. I reckon that you or a friend has a .22cal pistol or rifle? Save the shell-casings in case you want to drill them out to different sizes than what I'm sending you. They can't be re-loaded by law.. so most people just throw them away. I got mine at a shooting-club. I asked one of the officers first.. and he said to help myself to anything I could find on the ground or in the trash-barrel. I gathered-up a handful and put them in a coffee-cup!

Re: a cheap sport muffler

Re: a cheap sport muffler

Ok Great I have a few 22s lying around , I am hoping it will fit the medallion , I think the carb. assy. is lower than a TD. About to get started on some rebuilding so I will catch you later , That's a pretty good assortment of 22 drilled casings  Eric

Eric

Eric

Eric

getback- Top Poster

Posts : 10439

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: a cheap sport muffler

Re: a cheap sport muffler

Just an FYI.. I'm using .22cal "long" type for my header-pipes. They have an avg. case-length of .613". "Shorts" are .421" and "Winchesters" are 1.055". The Winchester is too long for installation inside the 1.000" OD alum. ring. Shorts "could" be used for less wind-resistance I suppose. Drilling the casings out to their max ID requires a holding-fixture and a #5 (.205") drill. The casing OD is .228" (avg.).. but I found that a "B" (letter-size .238") makes clearance for swapping-out pipes much easier. This can be done without taking the muffler apart. With it "off" of the engine; just push the existing pipes inward and they will drop out through either hole in the rubber that seals the cylinder. Installing pipes takes a little "fiddling" but not what I'd call tedious. That's why I drill the holes for them .010" oversize. Once the pipes are installed, pull "outward" on them; seating the rim against the inner ring.. and hold while pushing-on over the cylinder/glow-head. This prevents the inner-rims of the pipes from snagging on the head. Once installed, the pipes won't fall out.

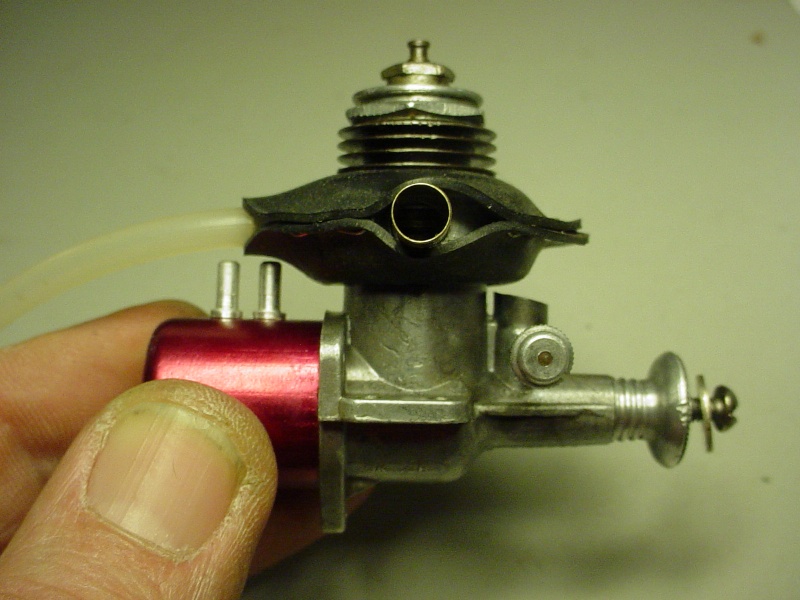

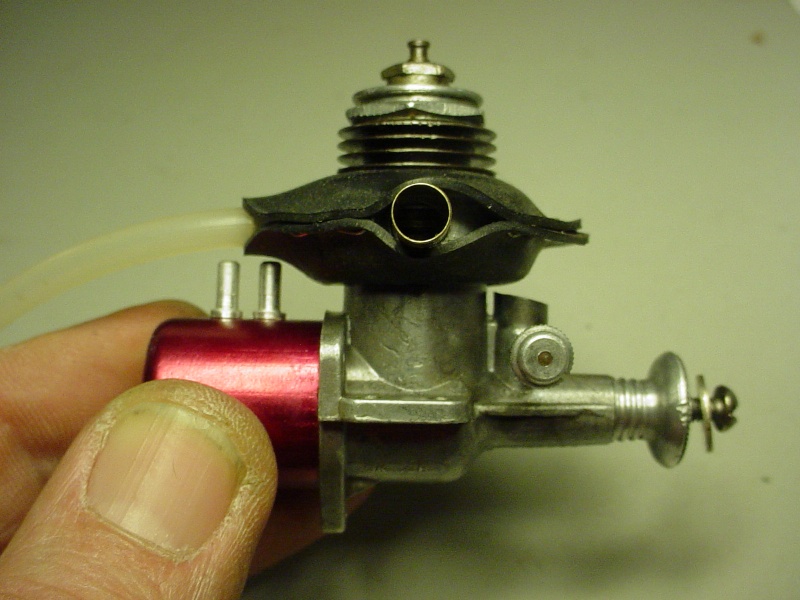

Here's an example of the clearance you have inside on installation (pipes fully-seated) over an .049 glow-head. Note that the pipes shown are "blanks" that haven't been drilled-out yet.

Here's an example of the clearance you have inside on installation (pipes fully-seated) over an .049 glow-head. Note that the pipes shown are "blanks" that haven't been drilled-out yet.

Last edited by roddie on Tue Mar 21, 2023 2:12 pm; edited 1 time in total (Reason for editing : Corrected stated alum. ring/pipe size from .750" to 1.000")

Re: a cheap sport muffler

Re: a cheap sport muffler

getback wrote:Ok Great I have a few 22s lying around , I am hoping it will fit the medallion , I think the carb. assy. is lower than a TD. About to get started on some rebuilding so I will catch you later , That's a pretty good assortment of 22 drilled casingsEric

Haha... yes; the assortment of pipes I made (with ID-size etched on each) is definitely the work of a sick mind..

On the Medallion, the muffler's rubber-body could obstruct airflow to the venturi.. but it's flange/"lip" will easily flex up or down.. and be tucked behind it. Who knows.. if the rubber-part flexes "up"... it may provide a ram-air induction effect.

The inner-ring's clearance shouldn't be a problem.

The inner-ring's clearance shouldn't be a problem.  Re: a cheap sport muffler

Re: a cheap sport muffler

Hopefully this muffler will fit Eric's .049 Medallion. It fits this DC .049 beautifully (Thank you Ian) without disassembly or obstructing the venturi.

This OK Cub .049 would be hard to choke.. but would probably run fine with it.

The rubber body of this expansion-chamber is stretchy. Once it's pushed-on over the cylinder; stretching the rubber by pulling at the edges where it's stapled, seats the rubber like a "boot" around the bottom of the cylinder, as well as pulling the top down below the fins on the upper-cylinder. Think of it as like putting on galoshes over you shoes.. (remember those? ) and stretching them to fit. The inner-tube type rubber that I use is butyl-rubber which is fairly resistant to heat and tearing. I haven't found it to be adversely affected by glow-fuel.. (I have 10 year-old fuel-soaked mufflers that show no signs of deterioration.) The staples hold the two rubber discs together extremely well.. and the oil from the fuel keeps them from rusting. I've twisted/stretched the rubber open at the center-holes to install the inner alum. ring with no signs of splitting or staples pulling-out.. and the staples are very close to the edge.

) and stretching them to fit. The inner-tube type rubber that I use is butyl-rubber which is fairly resistant to heat and tearing. I haven't found it to be adversely affected by glow-fuel.. (I have 10 year-old fuel-soaked mufflers that show no signs of deterioration.) The staples hold the two rubber discs together extremely well.. and the oil from the fuel keeps them from rusting. I've twisted/stretched the rubber open at the center-holes to install the inner alum. ring with no signs of splitting or staples pulling-out.. and the staples are very close to the edge.

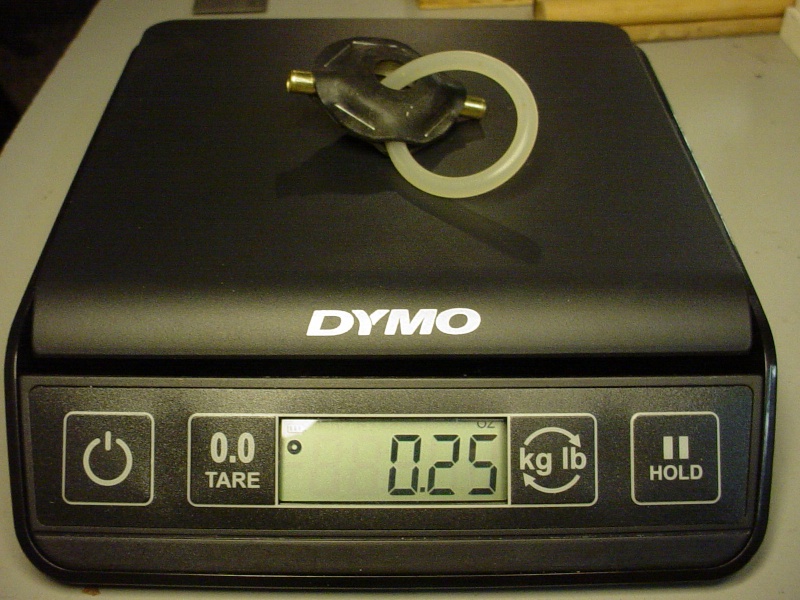

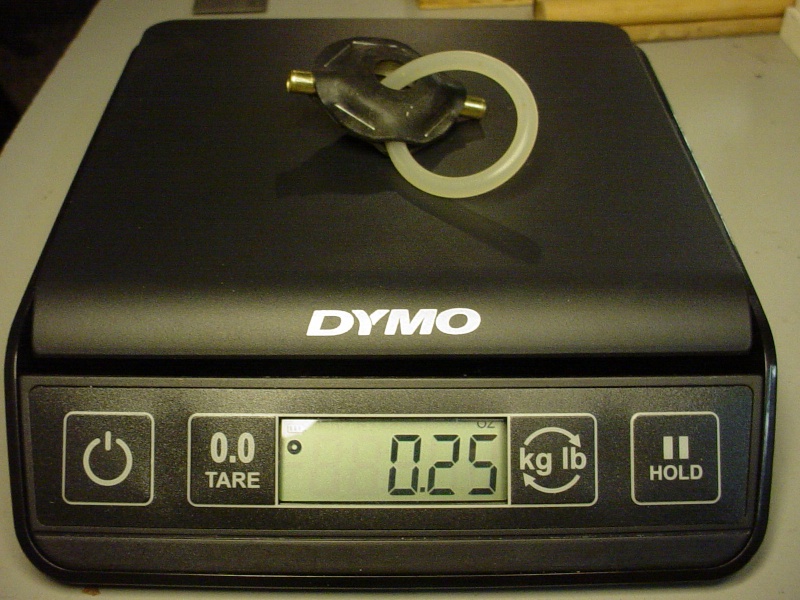

Not much weight to it either.

This OK Cub .049 would be hard to choke.. but would probably run fine with it.

The rubber body of this expansion-chamber is stretchy. Once it's pushed-on over the cylinder; stretching the rubber by pulling at the edges where it's stapled, seats the rubber like a "boot" around the bottom of the cylinder, as well as pulling the top down below the fins on the upper-cylinder. Think of it as like putting on galoshes over you shoes.. (remember those?

Not much weight to it either.

Re: a cheap sport muffler

Re: a cheap sport muffler

Roddie!

I now realize that I made contact with you long ago, when I saw a video where you showed the progress of a Cox 049 engine and you controlled with a needle speed!

We made contact via email, remember!?, I am happy to greet you hereby !, thanks for sharing your knowledge.

Remember me?

Greetings, Mauricio,.

I now realize that I made contact with you long ago, when I saw a video where you showed the progress of a Cox 049 engine and you controlled with a needle speed!

We made contact via email, remember!?, I am happy to greet you hereby !, thanks for sharing your knowledge.

Remember me?

Greetings, Mauricio,.

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-17

Age : 53

Location : ARG

Re: a cheap sport muffler

Re: a cheap sport muffler

MauricioB wrote:Roddie!

I now realize that I made contact with you long ago, when I saw a video where you showed the progress of a Cox 049 engine and you controlled with a needle speed!

We made contact via email, remember!?, I am happy to greet you hereby !, thanks for sharing your knowledge.

Remember me?

Greetings, Mauricio,.

Hi Mauricio! Yes.. I remember. You have some very nice model airplanes my friend!

This is the vid that shows my 1st-generation muffler being used with the "Ace" (Ralph Cooney designed) throttle for Bee-style Cox engines.

I've never tried editing a video..

YouTube link

The instructions that came with the throttle recommended the use of a muffler to achieve lower rpm's. The dual-pipes on this muffler are not made from .22cal shell-casings. They came from a plumbing-parts package that included a flared brass tube measuring .220" OD/.185" ID.. but were limited to flowing through that "fixed" .185" dia. orifice. My current design has the option to flow up to a .205" diameter orifice by using the shell-casings drilled out to their max. ID. This size I have calculated to be equal in area to a #2 Cox .049 cylinder's exhaust-port.. which would be minimally-restrictive in a dual-pipe configured muffler.

I have not tried running smaller-orifice pipes yet. At some point of exhaust-restriction, there could be blow-by through the areas where the rubber body seats. If so; any further restriction of the pipes would have no effect. We may find that restricting the flow may not provide any noise-reduction benefits.. while at the expense of reduced performance.

I think that running dual-pipes 180 degrees apart, provides for better performance experimentation. As I previously mentioned; "cross-flow" tests using different sizes on opposite sides.. and/or rotation of the muffler to see if this alters timing?

Then there's a noise-reduction test that "Ian" turned me on to. Adopting it for my muffler-design would involve stuffing a pair of full-flowing pipes with #0000 (super-fine) steel-wool. No way to accurately measure the back-pressure though. It would depend on how tightly the pipes were stuffed. Would the steel-wool blow-out immediately? Maybe a drop of thin CA would hold the steel-wool in the pipe?

The most difficult part of making this muffler is accurately drilling the holes for and "in" the pipes. For one; you really need a machinist's drill index assortment. Most people don't have one.. but you can get by with a single "B" (.238") size for drilling the inner alum. ring holes that accept the pipes. This is best accomplished using a drill-press and fixture of some sort to hold the ring. An ideal fixture would index the ring 180 degrees for drilling the 2nd hole by means of a "pin" for the 1st one to fit over. I hold my rings with locking-pliers fitted with rubber pads.. but I want to make something better than that.

The shell-casings (pipes) are tedious to drill-out. I used a piece of plywood with a hole pre-drilled for a press-fit of the shell-casing. The problem is.. the casing will start to slip and spin-out when drilling, as the hole wears after drilling-out a couple of pipes.

A better solution would be a small alum. block having a .228" diameter hole for the casing to drop into (#1 drill) with a side-hole tapped for a small set-screw.

I'm going to make better fixtures soon.. along with a more accurate way to cut the "length" of the ring. I've been using a plumbing-type pipe-cutter thus far. A band/cut-off saw would be ideal.. but I can't justify the cost. I may be able to use the one at the machine-shop where I used to work.

Page 1 of 5 • 1, 2, 3, 4, 5

Similar topics

Similar topics» NorVel .061 muffler wanted...cheap!

» Super sport 049

» Why are Tee Dee 010 so expensive?

» Cox Sandblaster clean-up

» RC flying on the cheap........................

» Super sport 049

» Why are Tee Dee 010 so expensive?

» Cox Sandblaster clean-up

» RC flying on the cheap........................

Page 1 of 5

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules