Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

Cox Engine of The Month

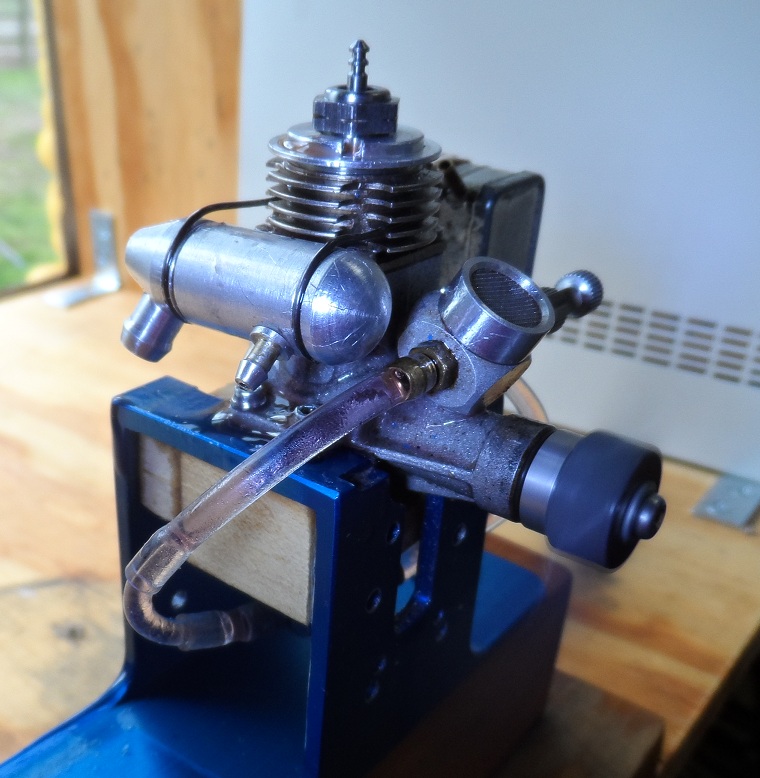

Test-Running My Swap-Meet MIG .049

Page 1 of 1

Test-Running My Swap-Meet MIG .049

Test-Running My Swap-Meet MIG .049

Test-Ran my Swap Meet MIG .049 today with rather anemic results...top RPM's in the high 9's on 25%. Good, steady run, just not much ZIP !!!! Figure it to be the head that I used to replace the bad insert that came with the engine.

Still, it ran, and I ought to be able to squeeze a few more RPM out of it when I get back to messing with it...

Still, it ran, and I ought to be able to squeeze a few more RPM out of it when I get back to messing with it...

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: Test-Running My Swap-Meet MIG .049

Re: Test-Running My Swap-Meet MIG .049

stick a standard cox on it Kim

John Goddard- Diamond Member

- Posts : 2447

Join date : 2011-11-24

Age : 60

Location : Leyton North East London

Re: Test-Running My Swap-Meet MIG .049

Re: Test-Running My Swap-Meet MIG .049

Hey Kim I always thought that the norvels were a bit more pokey than a cox reedie but rpm would depend on prop as well maybe your losing a bit of compression with the head what size prop are u using ?

Dizzyman2011- Gold Member

- Posts : 391

Join date : 2012-11-21

Age : 43

Location : Newbury Berkshire uk

Re: Test-Running My Swap-Meet MIG .049

Re: Test-Running My Swap-Meet MIG .049

Looks kinda mean in a stubby way too.

And in case you Norvel boys still need convincing it's a 1/3rd of a gram lighter too.

And in case you Norvel boys still need convincing it's a 1/3rd of a gram lighter too.

John Goddard- Diamond Member

- Posts : 2447

Join date : 2011-11-24

Age : 60

Location : Leyton North East London

Re: Test-Running My Swap-Meet MIG .049

Re: Test-Running My Swap-Meet MIG .049

Is it a BigMig or an AME?

Put a 5x3 prop on it and reduce the Nitro level, until you get a feel for the engine and see that it runs the way it should. It should do around 20krpm on a 5x3 on 10%nitro (use full castor 20-25%). When it is fully run in you can begin to play with higher nitro and different glowheads/plugs.

Also try to see through the intake screen at full throttle, it is important that the barrel has been correctly assembled onto the threads or it will limit the full throttle. The barrel can actually go past fully open too as the throttle stop is the same screw that limits the full throttle position.

Edit; if it is CL you dont have to check the barrel, I got a bit confused with the two images/engines.

Put a 5x3 prop on it and reduce the Nitro level, until you get a feel for the engine and see that it runs the way it should. It should do around 20krpm on a 5x3 on 10%nitro (use full castor 20-25%). When it is fully run in you can begin to play with higher nitro and different glowheads/plugs.

Also try to see through the intake screen at full throttle, it is important that the barrel has been correctly assembled onto the threads or it will limit the full throttle. The barrel can actually go past fully open too as the throttle stop is the same screw that limits the full throttle position.

Edit; if it is CL you dont have to check the barrel, I got a bit confused with the two images/engines.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Test-Running My Swap-Meet MIG .049

Re: Test-Running My Swap-Meet MIG .049

Pokey, no. I put an APC 5.5"x2.5" on one of mine and it ran 28,800 RPM on the bench. Kim, Bernie's head clamps and drop-in plugs are almost identical to the Norvel head. Meanwhile a Tee Dee head and 2 shims ought to light it up.Dizzyman2011 wrote:Hey Kim I always thought that the norvels were a bit more pokey than a cox reedie but rpm would depend on prop as well maybe your losing a bit of compression with the head what size prop are u using ?

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Test-Running My Swap-Meet MIG .049

Re: Test-Running My Swap-Meet MIG .049

Finally a not very scientific observation.....

I stuck a td with 1 gasket on my ame061 and got a sort of bit of 'interest'.......

I stuck a standard cox on it and if fired second flip.

I stuck a td with 1 gasket on my ame061 and got a sort of bit of 'interest'.......

I stuck a standard cox on it and if fired second flip.

John Goddard- Diamond Member

- Posts : 2447

Join date : 2011-11-24

Age : 60

Location : Leyton North East London

Re: Test-Running My Swap-Meet MIG .049

Re: Test-Running My Swap-Meet MIG .049

That is one of the earlier versions with AAN construction. The turned intake screen retainer, turned thrust plate and glued in carb were characteristic of older models. That looks like a Galbreath head/NELSON plug combination --- if it is, you should be turning better RPMs.

That's the first muffler I've seen that had the pressure tap pointing down and toward the front of the muffler. It looks almost as if someone may have swapped endcaps. Notice in John's picture the tap orientation --- pointing upward and near the stinger. This is the typical position. These engines also run better on muffler pressure. Make sure the relief on the side of the muffler fits the boss on the side of the case and that it is not obstructed.

Generally, these engines are ported to turn up, so a 5x3 or 5.25x3 will let them spin enough to get into the power band. Also, like SK mentioned, be sure that the throttle is not over rotated and that you are getting a full open setting.

Unless this engine is just worn out, 9K is too low.

andrew

That's the first muffler I've seen that had the pressure tap pointing down and toward the front of the muffler. It looks almost as if someone may have swapped endcaps. Notice in John's picture the tap orientation --- pointing upward and near the stinger. This is the typical position. These engines also run better on muffler pressure. Make sure the relief on the side of the muffler fits the boss on the side of the case and that it is not obstructed.

Generally, these engines are ported to turn up, so a 5x3 or 5.25x3 will let them spin enough to get into the power band. Also, like SK mentioned, be sure that the throttle is not over rotated and that you are getting a full open setting.

Unless this engine is just worn out, 9K is too low.

andrew

Re: Test-Running My Swap-Meet MIG .049

Re: Test-Running My Swap-Meet MIG .049

I agree, I think that muffler is put together backwards. I'm not sure if the retaining spring is in the right groove, it may be. But make sure the muffler is seated properly over the port and not blocking the exhaust. I know sometimes when I check mine after a rough outing, it will click back in place.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Test-Running My Swap-Meet MIG .049

Re: Test-Running My Swap-Meet MIG .049

The tight new ones are easy to start with a Bee head. That's how I finally got my new one going after much mad flipping. After a run or two, it starts much more easily and you can go back to the high compression head..John Goddard wrote:Finally a not very scientific observation.....

I stuck a td with 1 gasket on my ame061 and got a sort of bit of 'interest'.......

I stuck a standard cox on it and if fired second flip.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Test-Running My Swap-Meet MIG .049

Re: Test-Running My Swap-Meet MIG .049

Kim wrote:Test-Ran my Swap Meet MIG .049 today with rather anemic results...top RPM's in the high 9's on 25%. Good, steady run, just not much ZIP !!!! Figure it to be the head that I used to replace the bad insert that came with the engine.

Still, it ran, and I ought to be able to squeeze a few more RPM out of it when I get back to messing with it...

If you take the head off you will see either three bypass ports (AME) or five bypass ports (Big Mig).

The muffler is a three piece unit. Just pull the spring loose enough to pull the muffler loose and reverse the middle part and you can position the pressure tap in the rear, preferably pointing up. The rear section can be rotated to position the exhaust where you want it. The whole assembly is held together by the mounting spring.

Keep the venturi velocity up by using a smallish prop for higher RPM if you want to run it without muffler.

The .061 has a higher power/CI than the .049, but both are much more powerful than most reedies.

Good luck with it.

George

gcb- Platinum Member

- Posts : 908

Join date : 2011-08-11

Location : Port Ewen, NY

Re: Test-Running My Swap-Meet MIG .049

Re: Test-Running My Swap-Meet MIG .049

Try some sideways thinking...

Pull the head, muffler, and if easy back plate. Wash out the motor with fuel and hand prop it with these parts missing, does it flip in an expected manner or is it acting like it is stiff or rough or excessively loose? Did the wash remove any unusual looking debris?

ABC, ABN, and I think ceramic coated engines should have "pinch" at the top when hand propped cold with an open head. The prop should be noticeably stiffer in certain parts of the rotation, specifically as the engine comes to TDC.

Look at the top of the cylinder liner. These are ABC (aluminum piston, chrome plated brass liner) or ceramic coated. There should be no brass showing, if there is the liner is worn out.

If it all looks good, then reassemble and try running it and see if something flushed out. If the liner is worn out maybe you can order a new one.

Phil

Pull the head, muffler, and if easy back plate. Wash out the motor with fuel and hand prop it with these parts missing, does it flip in an expected manner or is it acting like it is stiff or rough or excessively loose? Did the wash remove any unusual looking debris?

ABC, ABN, and I think ceramic coated engines should have "pinch" at the top when hand propped cold with an open head. The prop should be noticeably stiffer in certain parts of the rotation, specifically as the engine comes to TDC.

Look at the top of the cylinder liner. These are ABC (aluminum piston, chrome plated brass liner) or ceramic coated. There should be no brass showing, if there is the liner is worn out.

If it all looks good, then reassemble and try running it and see if something flushed out. If the liner is worn out maybe you can order a new one.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Test-Running My Swap-Meet MIG .049

Re: Test-Running My Swap-Meet MIG .049

Since it came with a non-standard head I would guess that it has already been run. Flushing it out is always a good idea though.pkrankow wrote:Try some sideways thinking...

...ABC, ABN, and I think ceramic coated engines should have "pinch" at the top when hand propped cold with an open head. The prop should be noticeably stiffer in certain parts of the rotation, specifically as the engine comes to TDC.

I haven't had my early ones apart lately but I don't remember any brass. They are ABN or ABC plated, however, and have high silicon aluminum pistons.Look at the top of the cylinder liner. These are ABC (aluminum piston, chrome plated brass liner) or ceramic coated. There should be no brass showing, if there is the liner is worn out.

The REVLITE (ceramic) versions use an aluminum cylinder with a hard anodized aluminum oxide surface. They are easily identified because the cylinders look different. They are non-conductive by the way so don't try a standard type glow clip with them. They also use a high silicon aluminum piston.

ALL NORVEL engines I have were extremely tight at TDC when new...two (an .061 and a .15) had to be lapped before I could turn them over. They all also started and ran much better after a few runs.

George

gcb- Platinum Member

- Posts : 908

Join date : 2011-08-11

Location : Port Ewen, NY

Re: Test-Running My Swap-Meet MIG .049

Re: Test-Running My Swap-Meet MIG .049

gcb wrote:

The muffler is a three piece unit. Just pull the spring loose enough to pull the muffler loose and reverse the middle part and you can position the pressure tap in the rear, preferably pointing up. The rear section can be rotated to position the exhaust where you want it. The whole assembly is held together by the mounting spring.

The muffler is a two-piece thing and this is simply how the early ones are/were made.

There's nothing wrong with the position of the pressure tap, in fact it can be an advantage as there are less tubes sticking out in the draft...

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Test-Running My Swap-Meet MIG .049

Re: Test-Running My Swap-Meet MIG .049

I just reread parts of "2-stroke glow engines" by C. David Gierke. He indicates that ABC setups the aluminum piston is much softer than the hard chrome, so the piston can wear out without the liner being damaged, or even showing signs of wear. ABN the nickle wears at a more similar rate to the piston.

He also indicted that for an overly tight fitting ABC or ABN engine to heat the head and top of the engine with a heat gun prior to starting for break-in as the material choices allows the parts to expand at different rates, which is why the cylinder is brass and the piston aluminum.

I have a new AP .15 needing run in that will probably require use of the heat gun prior to starting for run-in. I can't prop it over by hand it is so tight at the top.

Phil

He also indicted that for an overly tight fitting ABC or ABN engine to heat the head and top of the engine with a heat gun prior to starting for break-in as the material choices allows the parts to expand at different rates, which is why the cylinder is brass and the piston aluminum.

I have a new AP .15 needing run in that will probably require use of the heat gun prior to starting for run-in. I can't prop it over by hand it is so tight at the top.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Test-Running My Swap-Meet MIG .049

Re: Test-Running My Swap-Meet MIG .049

Phil,

Pre-heating the cylinder is a good thing for ABC engines. If not pre-heating the head, the engine should be run up to operating temp ASAP and run just on the rich side of peak for the first couple of minutes. Not only is this good for the piston/cylinder fit but it also decreases stress on the conrod bushings, which normally seat in the first couple of minutes of run time.

Early ABC engines had a tighter taper than most newer ones.

George

Pre-heating the cylinder is a good thing for ABC engines. If not pre-heating the head, the engine should be run up to operating temp ASAP and run just on the rich side of peak for the first couple of minutes. Not only is this good for the piston/cylinder fit but it also decreases stress on the conrod bushings, which normally seat in the first couple of minutes of run time.

Early ABC engines had a tighter taper than most newer ones.

George

gcb- Platinum Member

- Posts : 908

Join date : 2011-08-11

Location : Port Ewen, NY

Re: Test-Running My Swap-Meet MIG .049

Re: Test-Running My Swap-Meet MIG .049

Surfer_kris wrote:The muffler is a two-piece thing and this is simply how the early ones are/were made.

There's nothing wrong with the position of the pressure tap, in fact it can be an advantage as there are less tubes sticking out in the draft...

My apologies, you are correct. For some reason I remembered it as three piece. My early NORVEL mufflers have the exhaust exit straight back. The next ones (of mine) have the side exhaust but no pressure tap. The REVLITE ones have a side exhaust muffler with pressure tap facing up ~1/4" from the rear of the front part. The rear part is rotatable and held on by the spring.

While checking mufflers, I noticed that the rear of the .074 is held on by an "O" ring since the muffler is bolted on.

George

gcb- Platinum Member

- Posts : 908

Join date : 2011-08-11

Location : Port Ewen, NY

Re: Test-Running My Swap-Meet MIG .049

Re: Test-Running My Swap-Meet MIG .049

No problem, I just though I could clarify.

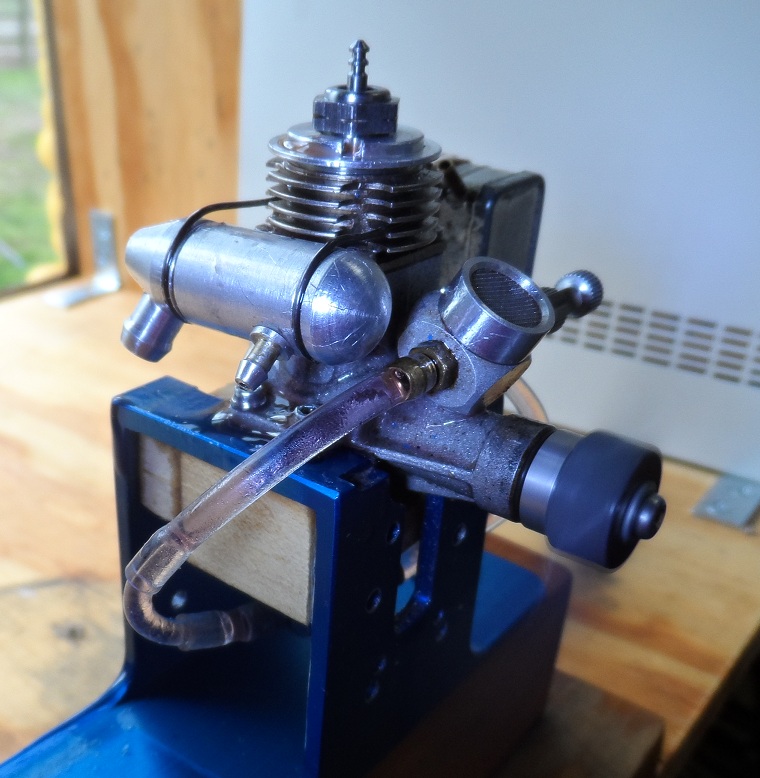

Here is a little timeline of the different version (oldest to the left hand side) and an example of the "new" and awkward placement of the pressure tap...

Here is a little timeline of the different version (oldest to the left hand side) and an example of the "new" and awkward placement of the pressure tap...

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Test-Running My Swap-Meet MIG .049

Re: Test-Running My Swap-Meet MIG .049

Surfer_kris wrote:No problem, I just though I could clarify.

Here is a little timeline of the different version (oldest to the left hand side) and an example of the "new" and awkward placement of the pressure tap...

The one on the left is (AFAIK) an AME Zeus. It has a regular 1/4"x32 plug and no muffler facility. It was designed for Combat. I got mine from Ed Carlson, don't think it was sold as NORVEL (Northern Velocity)...could be wrong.

Here are mine, first with the rear outlet, second with no pressure taps. I do not have your second and third type mufflers on non-Revlites. I got my first NORVEL engines when they were introducing the "new" Freedom plug. My first two came with the old heads/adapters installed and the "Freedom" heads/adapters in a bag in the engine box. Most of mine are CL Big Mig engines.

George

gcb- Platinum Member

- Posts : 908

Join date : 2011-08-11

Location : Port Ewen, NY

Re: Test-Running My Swap-Meet MIG .049

Re: Test-Running My Swap-Meet MIG .049

Yes, the first engine above is a Zeus, but they have to be linked to the Norvel somehow...

Another odd fact, the AP wasp is/was a copy of the early Norvel. The pressure tap is pointing down and they even copied the little hole in the mounting lug for the Norvel spring starter.

Another odd fact, the AP wasp is/was a copy of the early Norvel. The pressure tap is pointing down and they even copied the little hole in the mounting lug for the Norvel spring starter.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Test-Running My Swap-Meet MIG .049

Re: Test-Running My Swap-Meet MIG .049

Surfer_kris wrote:Yes, the first engine above is a Zeus, but they have to be linked to the Norvel somehow...

The same company made both. Northern Velocity (NORVEL) is the name of the company created by an importer in Ohio. He eventually sold that part of his company to SIG. AFAIK he only imported AME and Big Mig engines but that may not be correct.

Another odd fact, the AP wasp is/was a copy of the early Norvel. The pressure tap is pointing down and they even copied the little hole in the mounting lug for the Norvel spring starter.

I do not have any AP engines but I understand that they also added a bronze bushing for the crankcase.

interesting point about that hole in the mounting lug. When I got my first Big Migs that hole was only on the "Start Up" versions that came with a tank and a starter spring. There was a notch in the tank to accept the spring. If you were not using the tank you needed to notch your mount.

George

gcb- Platinum Member

- Posts : 908

Join date : 2011-08-11

Location : Port Ewen, NY

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules