Log in

Search

Latest topics

» Tee Dee .020 combat modelby getback Today at 7:14 am

» Free Flight Radio Assist

by getback Today at 7:02 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Purchased the last of any bult engines from Ken Enya

by getback Yesterday at 12:05 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

Cox Engine of The Month

Tee dee .049/.051 crankcase pressure

Page 1 of 1

Tee dee .049/.051 crankcase pressure

Tee dee .049/.051 crankcase pressure

Does anyone have experience with tee dees on crankcase pressure from the factory nipple? Is a check valve necessary? Fine thread needle valve?

Thanks guys, Jim

Thanks guys, Jim

JPvelo- Diamond Member

- Posts : 1972

Join date : 2011-12-02

Age : 57

Location : Colorado

Re: Tee dee .049/.051 crankcase pressure

Re: Tee dee .049/.051 crankcase pressure

I personally could never get this to work and that was with a check valve. Once you drill the case your committed. If any air leaks are present, the system will fail. In my opinion the instructions tell you to drill a far too big of a hole. The engine would surge violently up and down. Backplate pressure is far superior. The stock needle valve also makes setting the engine on pressure troublesome. Even with the backplate tap, the hole required for this to work properly isn't greater than the width of a pin. I was using brass pressure nipples tapped into the aluminum. I would then take a extremely fine piece of wire and place the wire into a candle to blacken it. I would solder the hole I drilled in the nipple and insert the wire. Solder won't stick to the blackened carbon on the wire. Once removed it left a very tiny hole in the nipple. The other problem you may experience is case flooding. You can't turn the engine over without it priming the venturi and this can be problematic until you find a sequence to start it. These are findings I experience so good luck. Ken

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Tee dee .049/.051 crankcase pressure

Re: Tee dee .049/.051 crankcase pressure

Ken Cook wrote: .......Even with the backplate tap, the hole required for this to work properly isn't greater than the width of a pin. I was using brass pressure nipples tapped into the aluminum. I would then take a extremely fine piece of wire and place the wire into a candle to blacken it. I would solder the hole I drilled in the nipple and insert the wire. Solder won't stick to the blackened carbon on the wire. Once removed it left a very tiny hole in the nipple............

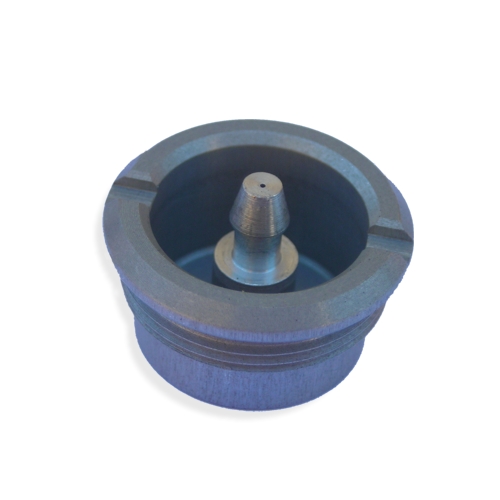

Here's a picture of a backplate tap to give you an idea how small the hole needs to be. This is a backplate from a NORVEL, but the idea is the same.

NORVEL Pressure Tap

Re: Tee dee .049/.051 crankcase pressure

Re: Tee dee .049/.051 crankcase pressure

I have never had any luck with the crankcase pressure nipple. I have had lots of good luck with backplate pressure, though. If using any crankcase pressure do as Ken suggests and use a very small hole for the pressure feed. I like to fill my pressure nipples with J B Weld or solder and drill a hole with a #75 or smaller bit. I also like to use a check valve when figuring out the needle and starting procedure. After that is figured out needing a check valve depends on your plumbing set up, starting procedure and personal preference. I have not had any luck with the stock NVA on pressure but a fine thread NVA makes everything easy and repeatable, Also, using pressure allows for the the use of enlarged venturis. If you decide to go the pressurized route good luck and keep us posted.

fit90- Diamond Member

- Posts : 1341

Join date : 2011-08-11

Location : Naples, Florida

Re: Tee dee .049/.051 crankcase pressure

Re: Tee dee .049/.051 crankcase pressure

This discussion has caused me to refrain from drilling a pressure port in the stock location.

Is a pressure-port on the backplate available from a vendor or is it a DIY proposition?

Is a pressure-port on the backplate available from a vendor or is it a DIY proposition?

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Re: Tee dee .049/.051 crankcase pressure

Re: Tee dee .049/.051 crankcase pressure

You can occasionally find backplate pressue fittings on ebay but they are an easy DIY project. I like to make them myself by taking a short (3/8" or shorter)piece of 1/8" or smaller fuel tube, fill about 1/8" of the tube with J B Weld or solder, drill a hole that is a few thousands smaller than the tube in the backplate then pressing the tube into the hole with the solder filled end going into the backplate and finally drilling your hole through the solder. I just use a table vise to do the pressing. If your fuel tube is too long it will probably bend during the pressing step. Good luck with it. It sounds like a great opportunity to use that cool new soldering iron. I have a butane Weller that I have had for close to 20 year and I absolutely love it.

fit90- Diamond Member

- Posts : 1341

Join date : 2011-08-11

Location : Naples, Florida

Re: Tee dee .049/.051 crankcase pressure

Re: Tee dee .049/.051 crankcase pressure

Just used the Weller butane torch to tighten the heat-shrink tubing on an electrical project here at home. Used the supplied heat deflector to prevent burning the heat-shrink.

Slick!

Slick!

SuperDave- Rest In Peace

- Posts : 3552

Join date : 2011-08-13

Location : Washington (state)

Pressurizing a TeeDee

Pressurizing a TeeDee

Gentlemen,

Another way I've sucessfully used is to drill & tap the existing TeeDee backplate then

screw in a (trimmed) K&B 4-40 pressure tap (hole I.D. is .025"). I imagine if you

find your needle too sensitive to set then you might consider filling it in & going down

in size...

The fine thread needle valve although nice is not absolutely necessary. What is absolutely

necessary is making sure your NVA is sealed. With the stock unit a small piece of silicone

fuel line over the whole needle valve & spring clip can help here.

Cheers, Paul

Another way I've sucessfully used is to drill & tap the existing TeeDee backplate then

screw in a (trimmed) K&B 4-40 pressure tap (hole I.D. is .025"). I imagine if you

find your needle too sensitive to set then you might consider filling it in & going down

in size...

The fine thread needle valve although nice is not absolutely necessary. What is absolutely

necessary is making sure your NVA is sealed. With the stock unit a small piece of silicone

fuel line over the whole needle valve & spring clip can help here.

Cheers, Paul

Last edited by Paulgibeault on Sun Oct 28, 2012 4:52 pm; edited 3 times in total (Reason for editing : Editing info)

Paulgibeault- Gold Member

- Posts : 259

Join date : 2011-09-24

Location : Leduc, Alberta Canada

Re: Tee dee .049/.051 crankcase pressure

Re: Tee dee .049/.051 crankcase pressure

My LHS sells pressure nipples that can be screwed into a tapped backplate. And if necessary, filled in and re-drilled to the size passage you need.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Similar topics

Similar topics» Crankcase Pressure Fitting use with Tee Dee Engines.

» Running up my Ebay AND Travis' Conquest .15's !

» Tee Dee pressure tap ??????

» Pressure on a TD .051

» .049 muffler pressure

» Running up my Ebay AND Travis' Conquest .15's !

» Tee Dee pressure tap ??????

» Pressure on a TD .051

» .049 muffler pressure

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules