Log in

Search

Latest topics

» Retail price mark-up.. how much is enough?by gkamysz Today at 9:29 pm

» Happy 77th birthday Andrew!

by roddie Today at 9:22 pm

» Roger Harris revisited

by rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

Cox Engine of The Month

Crankcase Pressure Fitting use with Tee Dee Engines.

Page 1 of 1

Crankcase Pressure Fitting use with Tee Dee Engines.

Crankcase Pressure Fitting use with Tee Dee Engines.

So, what's the deal with using the Pressure Fitting on Tee Dee engines? I never drilled out the fitting on any of my Tee Dees since they all put out more than enough power for my sport flying needs.

However the Tee Dee .15 I recently bought had the fitting drilled when I received it (noticed bubbles coming out of it while running). I capped it with a rivet and clear plastic tube. Is it worth the effort to use it to pressurize the Tee Dee's tank?

I feel like I should know more about this after messing with them for decades, but this subject has escaped my attention 'till now.

Thanks, Kim

However the Tee Dee .15 I recently bought had the fitting drilled when I received it (noticed bubbles coming out of it while running). I capped it with a rivet and clear plastic tube. Is it worth the effort to use it to pressurize the Tee Dee's tank?

I feel like I should know more about this after messing with them for decades, but this subject has escaped my attention 'till now.

Thanks, Kim

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Its worth it for most engines as it really improves fuel draw and that means you get note consistently reliable runs.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Ok, say you want more performance out of your Tee Dee in competition. The Venturi is a fixed speed carby. You could drill out the venturi to let more air and fuel in. But, as you increase the venturi diameter the fuel drawing capability drops. So to counteract this problem you use a pressure feed. Muffler pressure doesnt work on these because there is no muffler. You could use a pressure bladder, or you can use crankcase pressure. (either tapped off the backplate or at the Tee Dee pressure nipple.)

If you have a look at the Tee Dee instructions section on Pressurizing, you see they mention the correct size drill to use to drill out the pressure fitting and also the drill to use for increasing the venturi diameter.

Warning: This mod is a one way mod. You cant go back once it is done, unless you block off the pressure nipple and change back to an un-drilled venturi. The engine will also be a lot more sensitive to the needle setting on pressure. If you are going to run on pressure you should also consider using a fine thread needle valve. This feature is for competition use where peak performance is required.

If you have a look at the Tee Dee instructions section on Pressurizing, you see they mention the correct size drill to use to drill out the pressure fitting and also the drill to use for increasing the venturi diameter.

Warning: This mod is a one way mod. You cant go back once it is done, unless you block off the pressure nipple and change back to an un-drilled venturi. The engine will also be a lot more sensitive to the needle setting on pressure. If you are going to run on pressure you should also consider using a fine thread needle valve. This feature is for competition use where peak performance is required.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Thank You Guys!

I've thought about ordering a couple of the NV assemblies for this and one of my other TeeDees. I may put it back on the stand and just for the heck of it, see if hooking it up makes any difference there.

Thanks again!

I've thought about ordering a couple of the NV assemblies for this and one of my other TeeDees. I may put it back on the stand and just for the heck of it, see if hooking it up makes any difference there.

Thanks again!

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Though I've never tried it myself, those who have seem to say that using the Cox timed crankcase pressure (which is what you get from the nipple on the side of the crankcase) is more hassle than it's worth. The consensus is that the pressure is way too much, and also that it's next to impossible to get a pressure line to stay on that little nipple. The recommended alternative is either a bladder tank, or backplate pressure, as described in this post from RCG poster fit90:

" If you choose to use crank case pressure I suggest not drilling through the nipple on the venturi body but instead tapping the backplate for pressure. I have had luck making my own pressure tapped back plates by using a short section of fuel tube (1/8 or smaller), soldering a fuel barb on one end, filling the other with silver solder to a depth of about 1/4", drilling a hole in the middle of the back plate that is a few thousands of an inch smaller than the fuel tube and than pressing the tube into the back plate, I typically just use a bench vise for this. When the tube is in then drill a small hole through the solder. I use a #65 or smaller bit. Some expeimentation may be necessary here. However, if you make the hole too big you can just refill it with solder."

I have tried this method, though I used a pressure backplate from Ace R/C. It didn't help the problem I was trying to fix (engine going rich when lowering the airplane's nose) so I pretty much gave up on it.

" If you choose to use crank case pressure I suggest not drilling through the nipple on the venturi body but instead tapping the backplate for pressure. I have had luck making my own pressure tapped back plates by using a short section of fuel tube (1/8 or smaller), soldering a fuel barb on one end, filling the other with silver solder to a depth of about 1/4", drilling a hole in the middle of the back plate that is a few thousands of an inch smaller than the fuel tube and than pressing the tube into the back plate, I typically just use a bench vise for this. When the tube is in then drill a small hole through the solder. I use a #65 or smaller bit. Some expeimentation may be necessary here. However, if you make the hole too big you can just refill it with solder."

I have tried this method, though I used a pressure backplate from Ace R/C. It didn't help the problem I was trying to fix (engine going rich when lowering the airplane's nose) so I pretty much gave up on it.

tubebass- Silver Member

- Posts : 75

Join date : 2011-08-11

Age : 71

Location : Saint John, N.B, Canada

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Thanks! I don't see myself drilling out any of my other Tee Dee engines for this purpose. The Tee Dee .15 I recently bought came with the fitting drilled, so I thought I might mess with it just for fun. During it's first runs, I capped the nipple with a piece of plastic tubing and a small rivet.

Anyway, something new (for me) to learn.

Anyway, something new (for me) to learn.

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

So the consensus is to leave it alone untapped,or bladder tank it along with using the fine thread NV assemblys?.

How about a TD with the r/c carb?

How about a TD with the r/c carb?

PV Pilot- High Tech Balsa Basher

- Posts : 1854

Join date : 2011-08-11

Age : 57

Location : The ragged end of the Universe.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

PV Pilot wrote:So the consensus is to leave it alone untapped,or bladder tank it along with using the fine thread NV assemblys?.

How about a TD with the r/c carb?

A "real" carb or airbleed?

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Not sure about the R/C carb, I have one and will try the backplate pressure with it next time I get to run any engines. Meanwhile, Kim, I'd like to hear about your experience if you try the .15 with timed pressure.

tubebass- Silver Member

- Posts : 75

Join date : 2011-08-11

Age : 71

Location : Saint John, N.B, Canada

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Maybe

but I use the timed pressure on one of my .010s and it's great.the problem with backplate pressure is that it's uneven and you get both under and over pressure at different times.

but I use the timed pressure on one of my .010s and it's great.the problem with backplate pressure is that it's uneven and you get both under and over pressure at different times.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

tubebass wrote:Not sure about the R/C carb, I have one and will try the backplate pressure with it next time I get to run any engines. Meanwhile, Kim, I'd like to hear about your experience if you try the .15 with timed pressure.

Will do. Just keep in mind that I'm purely a Sport Flyer...so it's gonna be on a pretty simple level.

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

microflitedude wrote:PV Pilot wrote:So the consensus is to leave it alone untapped,or bladder tank it along with using the fine thread NV assemblys?.

How about a TD with the r/c carb?

A "real" carb or airbleed?

The carb that Bernie sells for the TD's. it's looks like a idle adjust and airbleed ajust. Don't have it in my hands yet.

http://coxengines.ca/product.php?productid=521&cat=0&page=1

Reason I ask is that I have a used TD 051 and have a ebay alum carb body headed this way for it. Dont know if I want to bore a hole in that alum body, but if I have to,,,

PV Pilot- High Tech Balsa Basher

- Posts : 1854

Join date : 2011-08-11

Age : 57

Location : The ragged end of the Universe.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

I have an .049 Tee Dee that I did mod and used the pressure fitting on. This was about 17 years ago, but the reason I did it was when the plane was inverted or on steep angles the engine would sputter and almost cut out. Once I drilled and tapped off the fitting my problems went away. There may have been other forces at play but the instructions that came with my Tee Dee said it could be done. I guess you just need to see how it goes. I think that if given a choice I would rather drill in the spot Cox specified than drilling through the back plate. Not knocking anyone who has drilled the back plate btw and In reality putting a new backplate on completely reverses the mod wheras the pressure fitting is permanent. Just my thoughts.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

I will also say that one thing I did was put a file nipple over the pressure nipple so the line has a better fit,

This ma help people doing this on smaller engines but make sure there is a good seal.

This ma help people doing this on smaller engines but make sure there is a good seal.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

The pre tapped after market back plates are readily available. They have a very fine hair width hole in them and a decent fitting for a fuel line to attach. This would be the way to go IMO. That way you can run on pressure or suction simply by changing the back plate and the venturi over. As has been mentioned, drilling the crankcase is permanent, the pressure nipple is not very good and it can cause problems if an air leak develops in the carb body.

Cheers

Cheers

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

warrenlead wrote:The pre tapped after market back plates are readily available. They have a very fine hair width hole in them and a decent fitting for a fuel line to attach. This would be the way to go IMO.

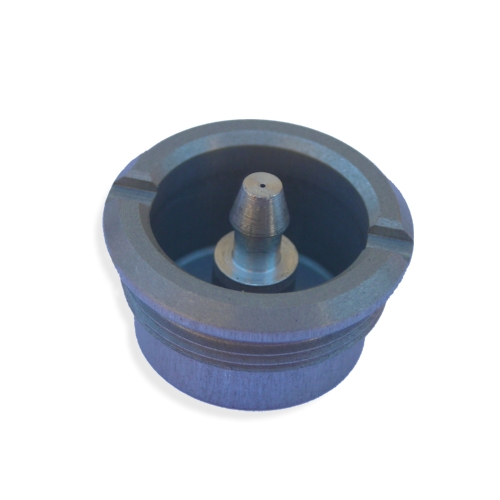

I have not found a ready source for the COX tapped backplates --- it's unfortunate that the NORVEL backplates won't fit since they are available thru NV Engines. Here's a pic of the NORVEL backplate to give you an image to go with Warren's description.

The pressure tap on the Tee Dee is timed pressure, i.e., it supplies only pressure and no vacuum. Backplate pressure taps are subject to both crankcase pressure and vacuum, so the tank pressure is lower. A low pressure checkvalve on the pressure line could raise tank pressure, but I'm not sure by how much. I've often wondered how backplate taps can supply net pressure since they are not timed and work without a checkvalve.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

They work because the crankcase will always have somewhat of a postive pressure over the negetive pressure. The hole is large enough for the pressure to build in the tank, but also small enough for it to not let the pressure to rush back into the crankcase between strokes. It takes a few seconds for the engine to build pressure in the tank like that.

It is not only the hole size that does it, it is also that the hole comming from inside the crankcase has a lead-in to the small hole, a ramp sort of speak, where the outside of the nipple going back to the motor is blunt which helps slow the speed of the air trying to escape back into it.

It is not only the hole size that does it, it is also that the hole comming from inside the crankcase has a lead-in to the small hole, a ramp sort of speak, where the outside of the nipple going back to the motor is blunt which helps slow the speed of the air trying to escape back into it.

jetpack- Gold Member

- Posts : 173

Join date : 2011-08-15

Age : 61

Location : Hobart, Indiana

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

On the upstroke the valve opens the crankcase to ambient atmospheric pressure plus the suction of the rising piston. But the piston induced vacuum is relieved by the venturi. Air accelerating through the constricted orifice creates a strong local vacuum(local to the venturi throat) to draw in the fuel. The whole crankcase however only drops slightly lower than the ambient atmospheric pressure, proportional to the piston's displacement of pressure.andrew wrote:I've often wondered how backplate taps can supply net pressure since they are not timed and work without a checkvalve.

However on the downstroke the valve is closed and all of the building pressure of the descending piston is contained by an enclosed crankcase with no relief to the outside world except through the minuscule pressure tap in the backplate. There is also the additional pressure created at the very beginning of the downstroke by the sub piston induction, if so equipped, which is a slingshot of air mixed with exhaust sucked in by the sudden exposure of outside air to the momentary sub piston gap. So the total pressure consists of the full displacement of the piston's action plus the SPI charge.

Me ruminating:I go back and forth between thinking i understand SPI and thinking I don't. I thought I had that tucked away until I found out the rotary valve TD had it too. I cannot for the life of me figure out how it doesn't hinder the process... unless that pressure is assisting the piston on the upstroke. I always imagined it helped create a burst to make the reeds open more quickly and fully. Bit that's irrelevant to a rotary.

EDIT: I was writing this while Jetpack was posting. We said more or less the same thing.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

RknRusty wrote:On the upstroke the valve opens the crankcase to ambient atmospheric pressure plus the suction of the rising piston. But the piston induced vacuum is relieved by the venturi.

Eureka!!! "Slightly lower than ambient" did the trick.

Eureka!!! "Slightly lower than ambient" did the trick.Thanks ....

More on SPI

More on SPI

Okay, I got to thinking about it, and this makes more sense. If anyone can find some written explanation explaining SPI, that would be wonderful. Until then, this will have to let me sleep. Yes, I wake up wondering about this stuff.

Okay, SPI:

On the upstroke the crankcase pressure is relieved, and the piston is on the way to compressing and burning the previously introduced charge. The drop in crankcase pressure releases the reed which finally opens fully drawn by the vacuum displacement of the rising piston. Fuel/air has entered the crankcase through the venturi behind the reed. As the skirt clears the bottom of the port during SPI, fresh air rushes into the crankcase creating additional pressure along with the increasing pressure of the now descending piston(yep, the poston compresses in both directions), forced to mix with the rest of the freshly introduced fuel/air mix.* This gives the crankcase a belly full of extra pressurized premix ready for the next charge. This can begin any time during the downstroke, continuing into some of the upstroke(I think) as all that pressure forces the mix to scoot up through the bypass ports. Kaboom, and it's a wild cycle.

*Obviously, surprising the premix from the venturi with bonus air pressure leans out the mixture. The clueless sucker with his fingers on the needle valve has to open it more to let in more fuel.

Voila, a supercharger. Get it... it charges the crankcase with ordinary fuel/air mix, pressurized by the descending piston. That's the charge. More air gets rammed in adding to the charge, plus the extra fuel to balance the A/F ratio, now you have a super charge in the crankcase.

Please do not quote me, I'm sleeping... and I just made all that Cr@p up

Edit: in real life, a super-charge actually refers to the charge in the combustion chamber, not the crankcase. But it sounded good.

Okay, SPI:

On the upstroke the crankcase pressure is relieved, and the piston is on the way to compressing and burning the previously introduced charge. The drop in crankcase pressure releases the reed which finally opens fully drawn by the vacuum displacement of the rising piston. Fuel/air has entered the crankcase through the venturi behind the reed. As the skirt clears the bottom of the port during SPI, fresh air rushes into the crankcase creating additional pressure along with the increasing pressure of the now descending piston(yep, the poston compresses in both directions), forced to mix with the rest of the freshly introduced fuel/air mix.* This gives the crankcase a belly full of extra pressurized premix ready for the next charge. This can begin any time during the downstroke, continuing into some of the upstroke(I think) as all that pressure forces the mix to scoot up through the bypass ports. Kaboom, and it's a wild cycle.

*Obviously, surprising the premix from the venturi with bonus air pressure leans out the mixture. The clueless sucker with his fingers on the needle valve has to open it more to let in more fuel.

Voila, a supercharger. Get it... it charges the crankcase with ordinary fuel/air mix, pressurized by the descending piston. That's the charge. More air gets rammed in adding to the charge, plus the extra fuel to balance the A/F ratio, now you have a super charge in the crankcase.

Please do not quote me, I'm sleeping... and I just made all that Cr@p up

Edit: in real life, a super-charge actually refers to the charge in the combustion chamber, not the crankcase. But it sounded good.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

nitroairplane wrote:I will also say that one thing I did was put a file nipple over the pressure nipple so the line has a better fit,

This ma help people doing this on smaller engines but make sure there is a good seal.

I modified mine as well, I used a brass rivet that had the same ID as the factory fitting. Line has not slipped off since. Of course if I knew Cox would stop producing engines I probably wouldn't have done that. Oh well I have an .051 that is brand new and unmodified.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

You guys think too much. lol

The crankcase only ever has a partial vacuum; on the up stroke. Air/fuel mixture is sucked in via the much larger hole in the intake/venturi at this time, so very little if anything gets sucked back through the tiny hole in the pressure nipple.

On the down stroke, the air fuel is forced in all directions but can only escape, back up through the transfer ports and a small amount out the pressure nipple.

You're right though, the timed pressure nipple off the crankshaft is more efficient.

On larger high performance engines using pressure, like the 2.5cc Super Tigre G15 with bath tub venturi, pressure is required in order for the engine to be any use at all. The guys using this setup on Vintage Combat models use a one way valve in the pressure line to stop the engine flooding. ie fuel running back in through the pressure line when the engine is not running.

As for where to get the tapped back plates, combatalbert has them from time to time on eBay but his stocks must be getting low by now. You just have to keep an eye out. I only have 1 or two in my stock so cant help sorry.

Also, have a good look at Texas Timers. http://www.texastimers.com/ They have all sorts of goodies in their backplates, and odds & ends sections including fine thread NVAs for Cox.

Cheerz

The crankcase only ever has a partial vacuum; on the up stroke. Air/fuel mixture is sucked in via the much larger hole in the intake/venturi at this time, so very little if anything gets sucked back through the tiny hole in the pressure nipple.

On the down stroke, the air fuel is forced in all directions but can only escape, back up through the transfer ports and a small amount out the pressure nipple.

You're right though, the timed pressure nipple off the crankshaft is more efficient.

On larger high performance engines using pressure, like the 2.5cc Super Tigre G15 with bath tub venturi, pressure is required in order for the engine to be any use at all. The guys using this setup on Vintage Combat models use a one way valve in the pressure line to stop the engine flooding. ie fuel running back in through the pressure line when the engine is not running.

As for where to get the tapped back plates, combatalbert has them from time to time on eBay but his stocks must be getting low by now. You just have to keep an eye out. I only have 1 or two in my stock so cant help sorry.

Also, have a good look at Texas Timers. http://www.texastimers.com/ They have all sorts of goodies in their backplates, and odds & ends sections including fine thread NVAs for Cox.

Cheerz

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

Re: Crankcase Pressure Fitting use with Tee Dee Engines.

At first glance, the KK backplate looks to have a 6-32 pressure fitting.

http://www.mh-aerotools.de/airfoils/cox_3rdparty.htm

http://www.mh-aerotools.de/airfoils/cox_3rdparty.htm

PV Pilot- High Tech Balsa Basher

- Posts : 1854

Join date : 2011-08-11

Age : 57

Location : The ragged end of the Universe.

Similar topics

Similar topics» Tee dee .049/.051 crankcase pressure

» Running up my Ebay AND Travis' Conquest .15's !

» Cox Engine Fuel Tubing Elbow Fitting?

» Tips and tricks for getting that tinyt fuel line on the tiny fitting on the back of all.049s HELP!

» Tee Dee pressure tap ??????

» Running up my Ebay AND Travis' Conquest .15's !

» Cox Engine Fuel Tubing Elbow Fitting?

» Tips and tricks for getting that tinyt fuel line on the tiny fitting on the back of all.049s HELP!

» Tee Dee pressure tap ??????

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules