Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

Cox Engine of The Month

Pushrod testing

Page 1 of 1

Pushrod testing

Pushrod testing

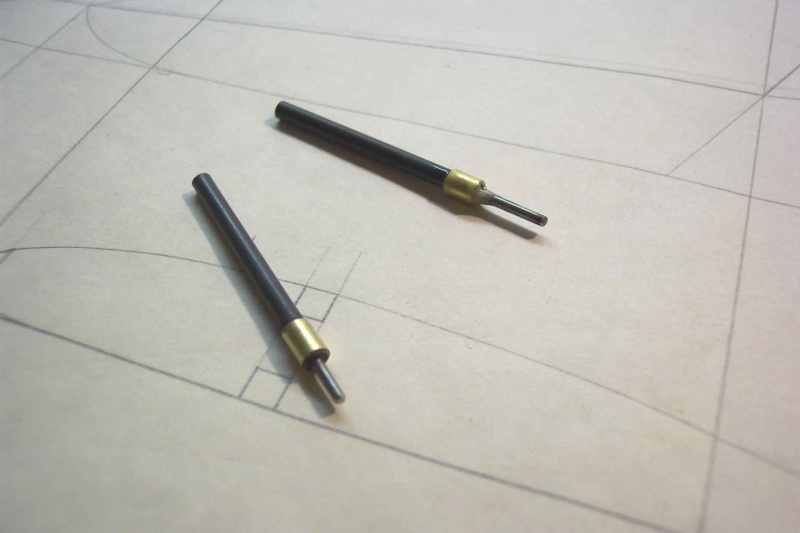

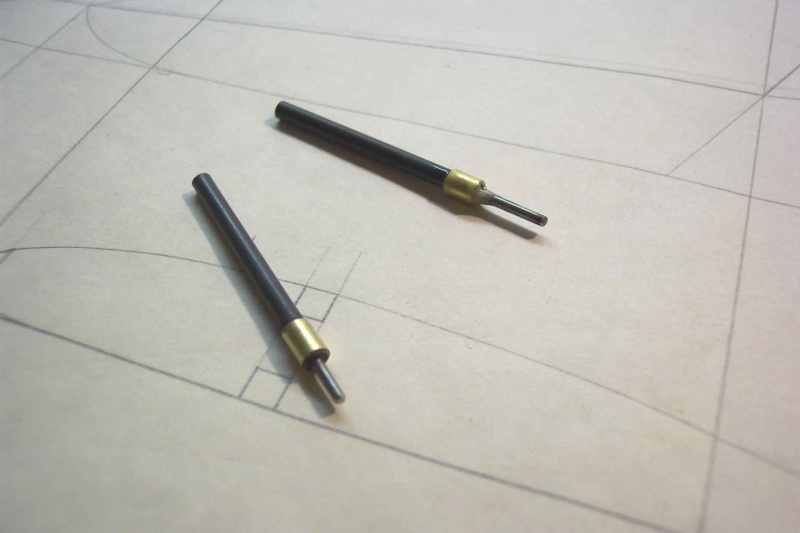

I've been using carbon fiber rod for pushrods lately. For the 1/2A stuff, I use .070 solid rod epoxied to brass ferrels. On short runs, they work without support, but need a midlength guide to prevent bowing on longer runs. There is essentially zero stretch. However, the rod is too light to use on .15 sized and up.

1/8" OD pultruded tubing seems to be about right with sufficient stiffness for larger models. However, I wasn't sure how well I could get the 1/16" wire to adhere in the ends or what might be the best adhesive. So the experiment ---

Pultruded CF Tubing: Purchased from Kitebuilder.com

ID: .068

OD: .125

Grams: 10.13

Length: 48"

Price: 3.33

I prepped the CF tubing with acetone wiping the outside and using an acetone soaked balse stick to swab the inside. I roughed up 1/16" wire with 80 grit and wiped with acetone. Brass ferrels about 3/16" long were cut and prepped. I made up two test rods, one using Elmers ProBond polyurethane and the second with 30 minute Hobby Poxy II. The wire was inserted 3/4" in both and both cured 24 hours.

I drilled a 1/8" hole in a 2x2 deep enough so that about 1/4" of tubing below the ferrel was exposed -- I wanted to see how well the wire was retained and not break the rod off. I set the 2x2 on a scale and pushed down on the wire end with a steel plate. At about 80 pounds, the epoxied wire was slowly pushed into the rod -- it was not an immediate breakdown, just slid in. I was able to load the ProBond up to 130 pounds, but it held.

Frankly, I was surprised that the ProBond beat the epoxy and that it held up at 130 pounds (tested it twice at 120 and once at 130). Bottom line is that either adhesive will produce a bond strength greater than any of the other parts on the model can withstand.

1/8" OD pultruded tubing seems to be about right with sufficient stiffness for larger models. However, I wasn't sure how well I could get the 1/16" wire to adhere in the ends or what might be the best adhesive. So the experiment ---

Pultruded CF Tubing: Purchased from Kitebuilder.com

ID: .068

OD: .125

Grams: 10.13

Length: 48"

Price: 3.33

I prepped the CF tubing with acetone wiping the outside and using an acetone soaked balse stick to swab the inside. I roughed up 1/16" wire with 80 grit and wiped with acetone. Brass ferrels about 3/16" long were cut and prepped. I made up two test rods, one using Elmers ProBond polyurethane and the second with 30 minute Hobby Poxy II. The wire was inserted 3/4" in both and both cured 24 hours.

I drilled a 1/8" hole in a 2x2 deep enough so that about 1/4" of tubing below the ferrel was exposed -- I wanted to see how well the wire was retained and not break the rod off. I set the 2x2 on a scale and pushed down on the wire end with a steel plate. At about 80 pounds, the epoxied wire was slowly pushed into the rod -- it was not an immediate breakdown, just slid in. I was able to load the ProBond up to 130 pounds, but it held.

Frankly, I was surprised that the ProBond beat the epoxy and that it held up at 130 pounds (tested it twice at 120 and once at 130). Bottom line is that either adhesive will produce a bond strength greater than any of the other parts on the model can withstand.

A second test

A second test

I made up another pushrod -- 2" of pultruded 1/8" OD CF tube, 3/16" long brass ferrels, 1/16" wire pins. The wire was well roughed up and inserted 3/4". Everything was cleaned with acetone and one end was glued with Elmer's Probond (polyurethane that activates with water); I used JB Weld on the other end. The JB weld had set up about 43 hours; the ProBond has about 30 hours.

I could not manually pull the pins out. I wanted to have some sense of how much weight it would withstand, so I suspended a pair of vice-grips from a treelimb, snapped a second pair on the other end of the pushrod and stood on a scale. I weigh 210 -- so I pulled on the pushrod until the scale read 100 pounds -- I'm assuming that the rod was carrying about 110 pounds of pull. I figured if something broke, I could have a face full of vice-grip so I stopped. I loaded the rod to 110 pounds twice.

Results:

30 min. epoxy failed at 80 pounds of push.

ProBond loaded to 130 pounds of push without failure.

JB Weld and ProBond did not fail at 110 pounds of pull.

So, with a little care in cleaning and surface prep, either JB Weld or ProBond joints will give adhesion strength greater than the structural strength of most of our planes. I'm very impressed with the performance of ProBond -- one part and easy cleanup. One note of caution: Choose your carbon fiber tubing with an ID close to the wire size to avoid too much of an adhesive bridge.

The listed rod is a little heavy for 1/2A R/C, but you can now find a lot of thin wall tubing that will work nicely. ProBond or JB Weld is a good chioce for adding threaded rod or music wire for pushrod ends.

I could not manually pull the pins out. I wanted to have some sense of how much weight it would withstand, so I suspended a pair of vice-grips from a treelimb, snapped a second pair on the other end of the pushrod and stood on a scale. I weigh 210 -- so I pulled on the pushrod until the scale read 100 pounds -- I'm assuming that the rod was carrying about 110 pounds of pull. I figured if something broke, I could have a face full of vice-grip so I stopped. I loaded the rod to 110 pounds twice.

Results:

30 min. epoxy failed at 80 pounds of push.

ProBond loaded to 130 pounds of push without failure.

JB Weld and ProBond did not fail at 110 pounds of pull.

So, with a little care in cleaning and surface prep, either JB Weld or ProBond joints will give adhesion strength greater than the structural strength of most of our planes. I'm very impressed with the performance of ProBond -- one part and easy cleanup. One note of caution: Choose your carbon fiber tubing with an ID close to the wire size to avoid too much of an adhesive bridge.

The listed rod is a little heavy for 1/2A R/C, but you can now find a lot of thin wall tubing that will work nicely. ProBond or JB Weld is a good chioce for adding threaded rod or music wire for pushrod ends.

Re: Pushrod testing

Re: Pushrod testing

Man! Another avenue...OK...guess I gots to get me some carbon rods now...!!!!!!!!!!!!

Thanks for the post! Probably gonna try this...!

Thanks for the post! Probably gonna try this...!

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Similar topics

Similar topics» Testing 123

» experimental reed-valve test 5-5-18

» Testing info

» Pushrod exit shroud

» a cheap sport muffler

» experimental reed-valve test 5-5-18

» Testing info

» Pushrod exit shroud

» a cheap sport muffler

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules