Log in

Search

Latest topics

» Purchased the last of any bult engines from Ken Enyaby getback Today at 12:05 pm

» My N-1R build log

by getback Today at 11:53 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» Funny what you find when you go looking

by rsv1cox Yesterday at 3:21 pm

» Landing-gear tips

by 1975 control line guy Yesterday at 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» My latest doodle...

by TD ABUSER Mon Nov 18, 2024 11:30 am

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

» Tribute Shoestring build

by amurphy6812 Sun Nov 17, 2024 5:43 pm

Cox Engine of The Month

Stuka woes, when the unthinkable becomes thinkable

Page 1 of 1

Stuka woes, when the unthinkable becomes thinkable

Stuka woes, when the unthinkable becomes thinkable

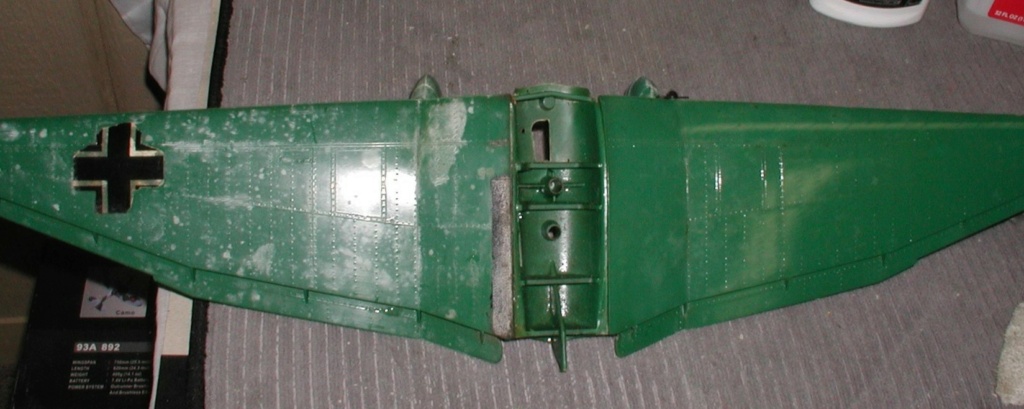

With five of the eight corners of the engines saddle broken off I have no choice but to cement the postage stamp in. I knew when I got it with the engine floating around that there would be trouble. Something that I have never seen. Garbage in garbage out. Oh well. I'm not harvesting King Tut's tomb here.

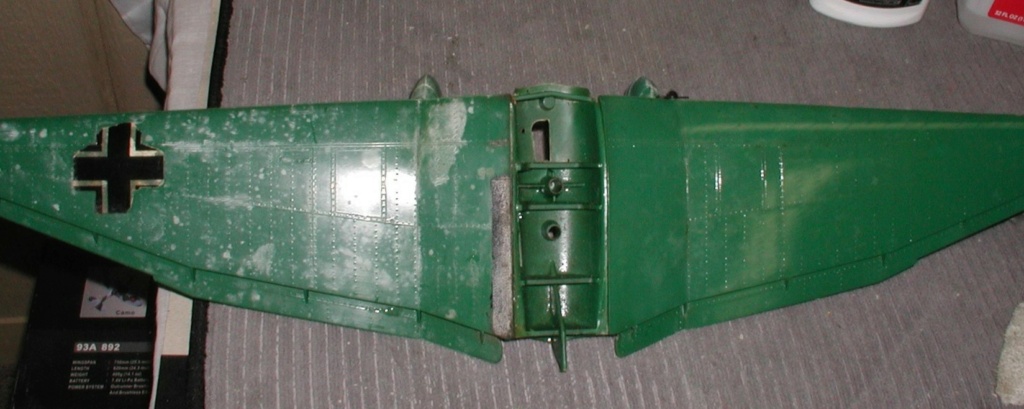

Also, not only is the left wing root cracked (repaired now) I discovered that the right wing is cracked mid-way too. Found it while cleaning it up. Did the worst wing first.

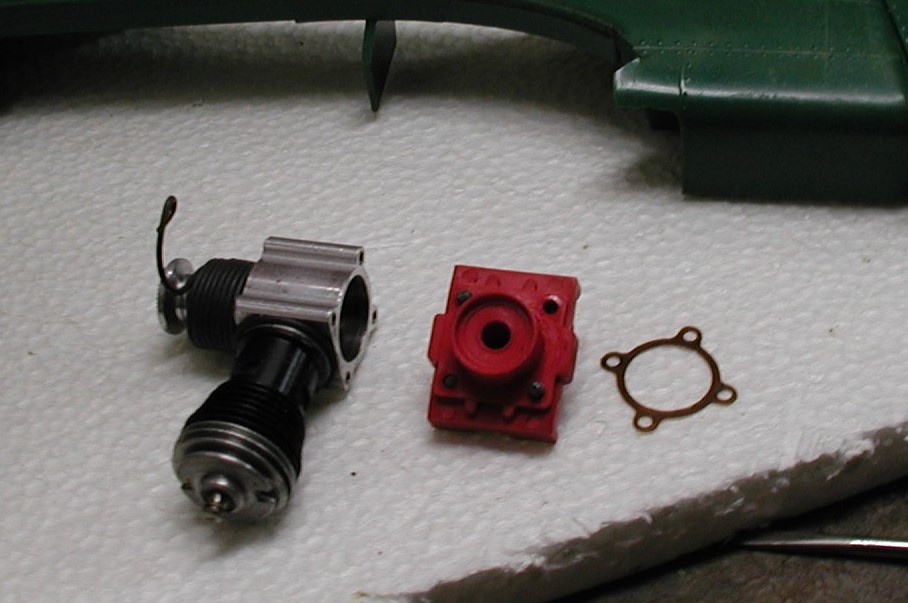

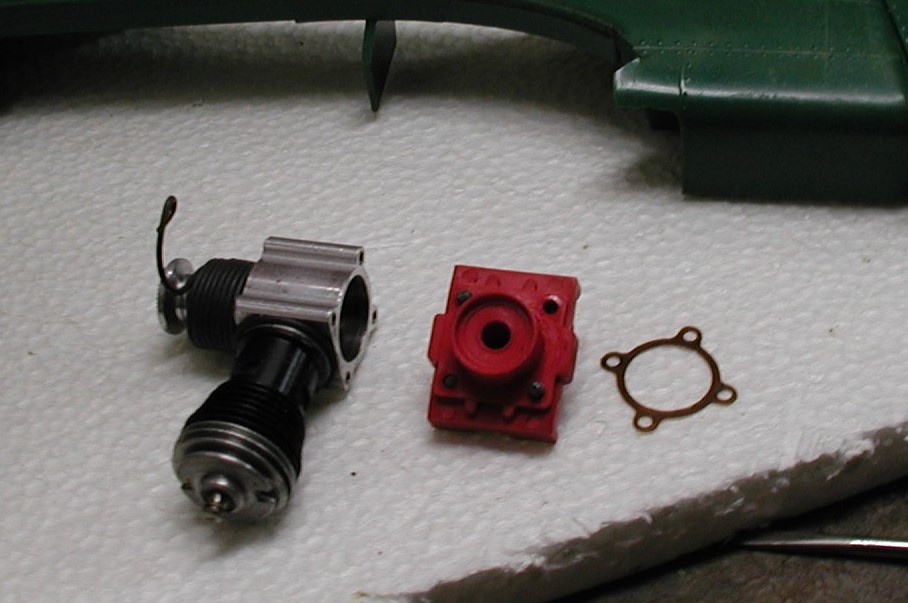

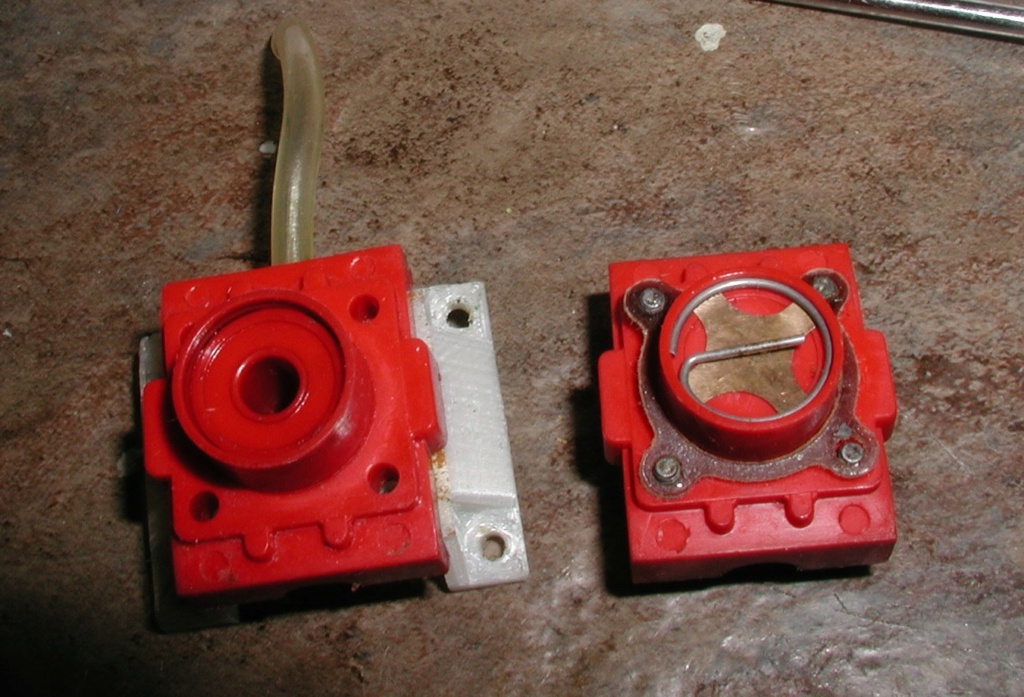

Engine looks great from the outside, opened it up and no reed or clip. Got one from parts, cleaned the reed fine steel wool and 91%. Someone's been in there before me!

I don't care for the Cox starter, bit me more times than just finger flipping. Got rid of it. Put the piston back in and got a bind, turned the connecting rod around and it eliminated it. I don't explain it, I just relate. Low time engine, beautiful piston and #1 cylinder. Perfect pop.

Casual photo, and I haven't even started to reassemble it yet.

Also, not only is the left wing root cracked (repaired now) I discovered that the right wing is cracked mid-way too. Found it while cleaning it up. Did the worst wing first.

Engine looks great from the outside, opened it up and no reed or clip. Got one from parts, cleaned the reed fine steel wool and 91%. Someone's been in there before me!

I don't care for the Cox starter, bit me more times than just finger flipping. Got rid of it. Put the piston back in and got a bind, turned the connecting rod around and it eliminated it. I don't explain it, I just relate. Low time engine, beautiful piston and #1 cylinder. Perfect pop.

Casual photo, and I haven't even started to reassemble it yet.

rsv1cox- Top Poster

Posts : 11245

Join date : 2014-08-18

Location : West Virginia

Re: Stuka woes, when the unthinkable becomes thinkable

Re: Stuka woes, when the unthinkable becomes thinkable

"not harvesting King Tut's Tomb"

that, sir --- is valuable advice for all of us. worry less, put together more!

that, sir --- is valuable advice for all of us. worry less, put together more!

cstatman- Platinum Member

Posts : 568

Join date : 2021-02-17

Age : 60

Location : San Jose, CA

Re: Stuka woes, when the unthinkable becomes thinkable

Re: Stuka woes, when the unthinkable becomes thinkable

cstatman wrote:"not harvesting King Tut's Tomb"

that, sir --- is valuable advice for all of us. worry less, put together more!

Yes, and knowing when your beat and accepting it!

This thing is more broken up than the seller acknowledged, maybe he didn't know it. The wing and fin/rudder tabs where the fuselage screws pass through are broken off and missing. Not good. Unless I can figure out a fix, I may have to tack cement this Stuka back together. It came (fell) apart real easy.

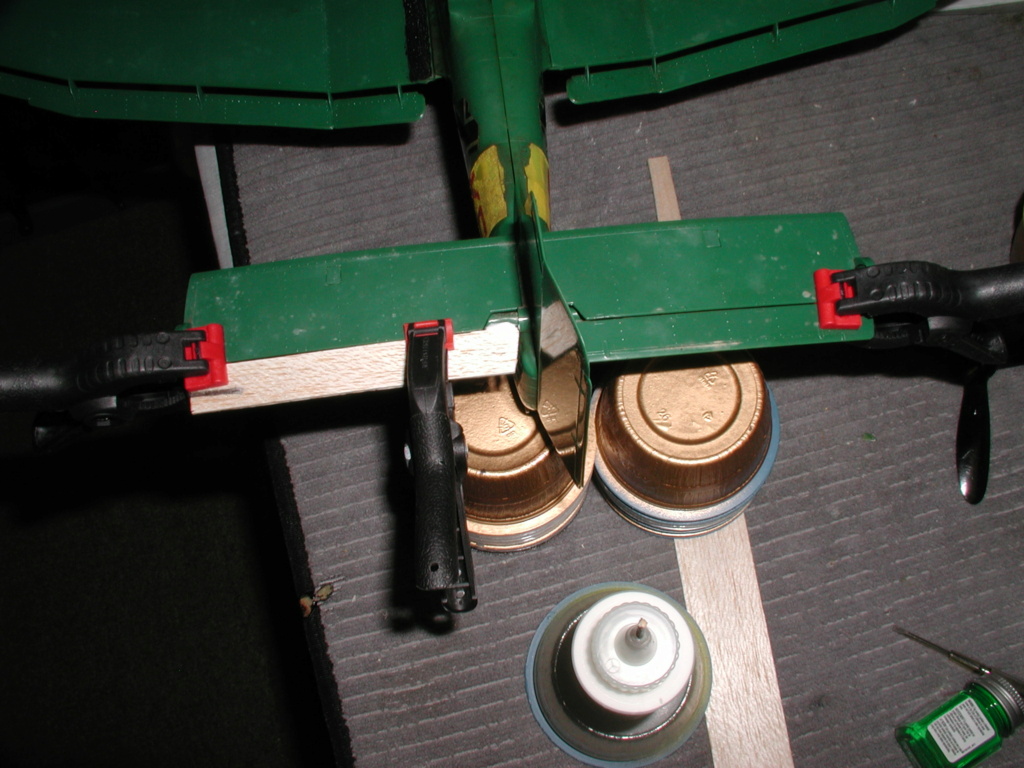

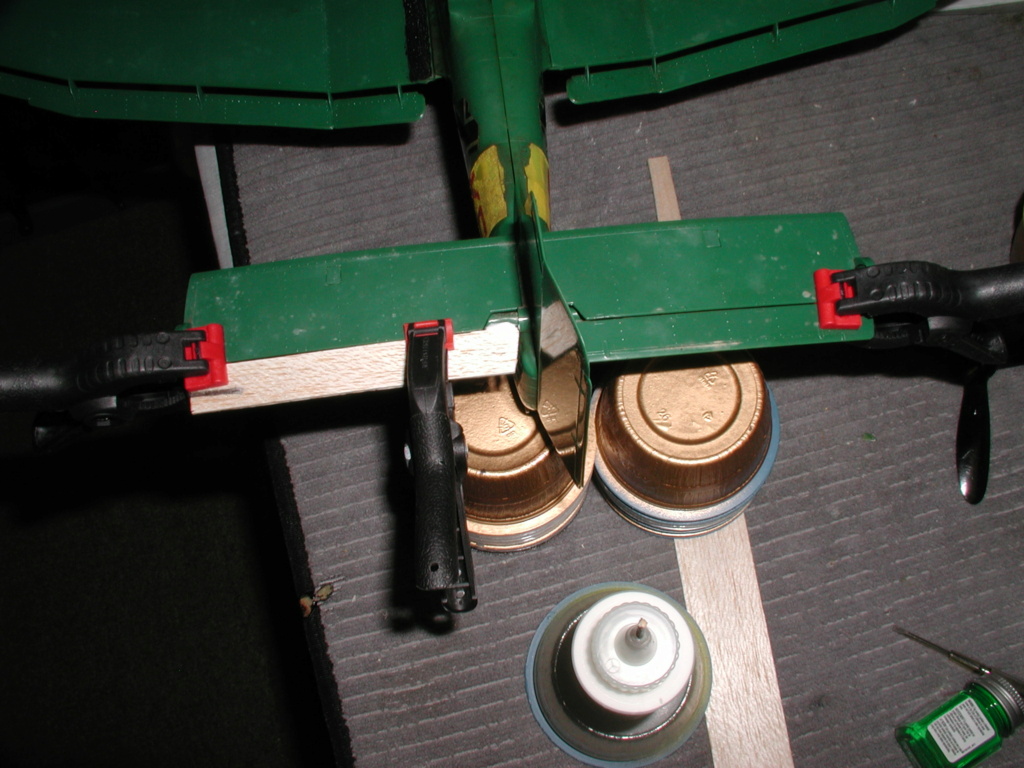

Cementing the other half of the wing. Crack ran right along the landing gear pylon. Broken tab is one half of the tail wheel bracket.

Test fitting.

rsv1cox- Top Poster

Posts : 11245

Join date : 2014-08-18

Location : West Virginia

Re: Stuka woes, when the unthinkable becomes thinkable

Re: Stuka woes, when the unthinkable becomes thinkable

Both Cox designers and subsequent owners have worked their deviltry on this thing.

I look at it, walk away only to return later and tinker a bit. A losing cause but I persist. Missing/broken parts, staining that will not come out despite my best efforts. Howard wax coverup. Not kosher. Waiting for Godot.

I look at it, walk away only to return later and tinker a bit. A losing cause but I persist. Missing/broken parts, staining that will not come out despite my best efforts. Howard wax coverup. Not kosher. Waiting for Godot.

rsv1cox- Top Poster

Posts : 11245

Join date : 2014-08-18

Location : West Virginia

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: Stuka woes, when the unthinkable becomes thinkable

Re: Stuka woes, when the unthinkable becomes thinkable

I have been close to caption #3 many times.

Just finished with more tinkering. Actually got it back together except the canopys which just snap on. Managed to capture the bellcrank on the wings post, no easy job as those that have messed with these know only to well. Engine still floats, If I want it to be flyable I will have to cement it in. no other practical choice.

Don't let the appearance fool, it's a mess. Other one will be the keeper.

Just finished with more tinkering. Actually got it back together except the canopys which just snap on. Managed to capture the bellcrank on the wings post, no easy job as those that have messed with these know only to well. Engine still floats, If I want it to be flyable I will have to cement it in. no other practical choice.

Don't let the appearance fool, it's a mess. Other one will be the keeper.

rsv1cox- Top Poster

Posts : 11245

Join date : 2014-08-18

Location : West Virginia

Re: Stuka woes, when the unthinkable becomes thinkable

Re: Stuka woes, when the unthinkable becomes thinkable

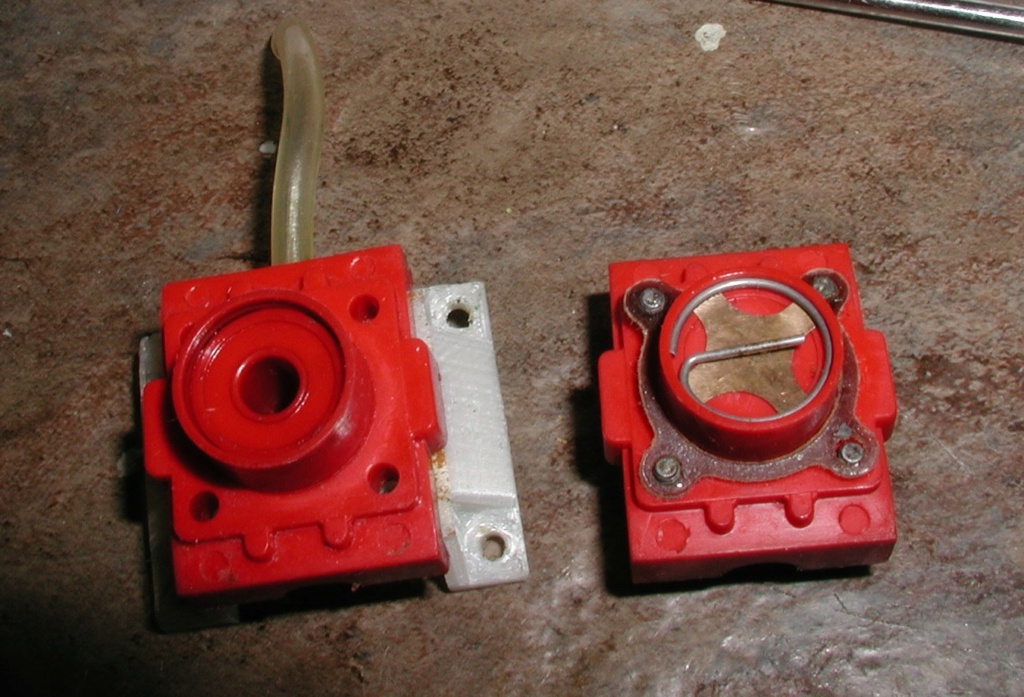

Last piece of the puzzle.

Engine cemented in, one side only can still be taken apart. Bell crank connected. Flyable if this holds. Formula 560 canopy cement - "Glues anything to anything" we will see. Could have used epoxy but it doesn't stick well to plastic, CA the same. Testors red tube - forget it.

Anyone have a better idea?

Engine cemented in, one side only can still be taken apart. Bell crank connected. Flyable if this holds. Formula 560 canopy cement - "Glues anything to anything" we will see. Could have used epoxy but it doesn't stick well to plastic, CA the same. Testors red tube - forget it.

Anyone have a better idea?

rsv1cox- Top Poster

Posts : 11245

Join date : 2014-08-18

Location : West Virginia

GallopingGhostler- Top Poster

Posts : 5721

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

rsv1cox- Top Poster

Posts : 11245

Join date : 2014-08-18

Location : West Virginia

Re: Stuka woes, when the unthinkable becomes thinkable

Re: Stuka woes, when the unthinkable becomes thinkable

Good methodology in hinging the replacement balsa elevator,

back in the old days as a flyer, I went a step further and covered the end with a strip of crinoline (same stuff used as cloth hinges 50 years ago, it was coated cloth strip used in sewing to stiffen clothing edges like pants cuffs, shirt collars). Once sealed along with balsa, it left a slight impression where you saw the material, but that was then called features of "flying scale".

back in the old days as a flyer, I went a step further and covered the end with a strip of crinoline (same stuff used as cloth hinges 50 years ago, it was coated cloth strip used in sewing to stiffen clothing edges like pants cuffs, shirt collars). Once sealed along with balsa, it left a slight impression where you saw the material, but that was then called features of "flying scale". Is the plastic factory painted, or is the white showing through the sanding just light reflection from camera flash?

It might be the way the engine "solidified" after being broke in. If it works by rotating the assembly, "if you don't mind, it don't matter", you're right, while question it?rsv1cox wrote:Engine looks great from the outside, opened it up and no reed or clip. Got one from parts, cleaned the reed fine steel wool and 91%. Someone's been in there before me!

I don't care for the Cox starter, bit me more times than just finger flipping. Got rid of it. Put the piston back in and got a bind, turned the connecting rod around and it eliminated it. I don't explain it, I just relate. Low time engine, beautiful piston and #1 cylinder. Perfect pop.

According to:

CEF: Cox .049 Cylinder Identification

You have a keeper, a prized engine. You could replace that with a Babe Bee styled (1 bypass) engine with postage stamp, and use that engine on another aircraft as a flyer, if this will only be for static display.CEF wrote: Number 1 : Used on early Black Widow and 290-291 series engines. 2 bypass, sub-piston induction, some cylinders had milled top fins and some older ones didn't.

But it does answer an earlier question I had, that the heavier than other Cox models, the earliest Cox green Stukas did have the more powerful dual port Black Widow styled cylinder.

GallopingGhostler- Top Poster

Posts : 5721

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Stuka woes, when the unthinkable becomes thinkable

Re: Stuka woes, when the unthinkable becomes thinkable

Yes, the hinge is epoxied in a slot cut in the balsa. Not going to move. Looked at bushing it. Can do but will have to drill out the plastic a bit. Cut out the end rotator, got to find out what it's for.

Yes, white seems to be dried fuel/castor that I haven't cleaned up yet. Still lot's of detailing still to do. When finished I will have a flyable glued together piece of crap. Never had to do one this way before but this Stuka was just to busted up internally to cope with. Previous owner even cut holes in the fuselage for inspection/repair.

Never had to do one this way before but this Stuka was just to busted up internally to cope with. Previous owner even cut holes in the fuselage for inspection/repair.

Yes, white seems to be dried fuel/castor that I haven't cleaned up yet. Still lot's of detailing still to do. When finished I will have a flyable glued together piece of crap.

rsv1cox- Top Poster

Posts : 11245

Join date : 2014-08-18

Location : West Virginia

Re: Stuka woes, when the unthinkable becomes thinkable

Re: Stuka woes, when the unthinkable becomes thinkable

You may not even need to bush it, if the plastic pin socket is in reasonably sound condition, although there is a touch of slop there with the improvised pin for hinge. Only reason for additional reinforcing with Crinoline was back in the days, to withstand engine vibration for a plane that would be flown often, like in the case of a balsa C/L. In your case, I doubt you'd accumulate sufficient hours to warrant it.rsv1cox wrote:Yes, the hinge is epoxied in a slot cut in the balsa. Not going to move. Looked at bushing it. Can do but will have to drill out the plastic a bit. Cut out the end rotator, got to find out what it's for.

Yes, white seems to be dried fuel/castor that I haven't cleaned up yet. Still lot's of detailing still to do. When finished I will have a flyable glued together piece of crap.Never had to do one this way before but this Stuka was just to busted up internally to cope with. Previous owner even cut holes in the fuselage for inspection/repair.

I wouldn't call it a piece of crap, it is a restoration to flyable condition. The previous owner, probably a teen, did what they knew with their limited knowledge of repairs, to make things work. One starts off as an apprentice, before they become a craftsman. I'm sure that model help to build for useful experiences and knowledge, to help that individual with greater things as an adult.

In reality I think we boomers were blessed to be in the world at the time we were growing up. Working on our own built a knowledge base, something today this world of so called professional educators and politicians have totally missed through their restrictive child rearing policies and new teaching methods.

The Cox models and engines were a training ground for future engineers, designers, repair and construction technicians, assembly workers and etc. It helped to train them in use of tools and techniques, visualize from drawings, descriptions, use of fasteners, etc.

GallopingGhostler- Top Poster

Posts : 5721

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Stuka woes, when the unthinkable becomes thinkable

Re: Stuka woes, when the unthinkable becomes thinkable

I built the elevator counter weight yesterday and epoxied it on. They actually sold these years ago as WW2 artifacts.

https://axis-militaria.com/product/ww-ii-german-hohenruder-gewichtausgleich-elevator-counter-weight-ju87-stuka/

Grooved it for the fixing pin.

and trimmed it to fit. My test mule, better Stuka will get a better fit as it's missing the same elevator half.

Some differences between green and black Stukas. Green used phillips head screws, black used fillister heads. Green used thin cylinders #1's, black used stepped #1's. White boarder insignias vs yellow for the black Stukas. Green used fixed landing gear, black flexible. Black took liberties with color while green did not.

Testors red tube is holding it together. That or the trash can.

https://axis-militaria.com/product/ww-ii-german-hohenruder-gewichtausgleich-elevator-counter-weight-ju87-stuka/

Grooved it for the fixing pin.

and trimmed it to fit. My test mule, better Stuka will get a better fit as it's missing the same elevator half.

Some differences between green and black Stukas. Green used phillips head screws, black used fillister heads. Green used thin cylinders #1's, black used stepped #1's. White boarder insignias vs yellow for the black Stukas. Green used fixed landing gear, black flexible. Black took liberties with color while green did not.

Testors red tube is holding it together. That or the trash can.

rsv1cox- Top Poster

Posts : 11245

Join date : 2014-08-18

Location : West Virginia

rsv1cox- Top Poster

Posts : 11245

Join date : 2014-08-18

Location : West Virginia

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules