Log in

Search

Latest topics

» Tee Dee .020 combat modelby getback Today at 7:14 am

» Free Flight Radio Assist

by getback Today at 7:02 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Purchased the last of any bult engines from Ken Enya

by getback Yesterday at 12:05 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

Cox Engine of The Month

Piston reset.

Page 1 of 2

Page 1 of 2 • 1, 2

Piston reset.

Piston reset.

Fellow .049ers,

I was resetting some .049 pistons yesterday and I was having a little trouble with one. So I took it into the light and I compared it with a TD one that I had just reset. I noticed that the ball cups were different. The TD one had a bevel on the cup and the one I was having trouble with had a flat edge on the cup. I always assumed the ball cups were the same. Is this piston an anomally or is it something standard? And no it's not a 3 piece piston.

The trouble piston is the one out of my Tach race engine. I will post up some pics later.

I was resetting some .049 pistons yesterday and I was having a little trouble with one. So I took it into the light and I compared it with a TD one that I had just reset. I noticed that the ball cups were different. The TD one had a bevel on the cup and the one I was having trouble with had a flat edge on the cup. I always assumed the ball cups were the same. Is this piston an anomally or is it something standard? And no it's not a 3 piece piston.

The trouble piston is the one out of my Tach race engine. I will post up some pics later.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Piston reset.

Re: Piston reset.

I promise that I DIDN'T swap it out !!!!!!!!!!!!!!!!!!!

Kim- Top Poster

Posts : 8625

Join date : 2011-09-06

Location : South East Missouri

Re: Piston reset.

Re: Piston reset.

TD, Medallion and reed valve engine pistons are indentical with only a few exceptions (Venom, Killer Bee, 051 Medallion).

Over the past 50 years Cox did manufacture a few different versions (tapered, thin-walled) but essentially 95% of pistons made in the last 50 years are the same.

However, Cox used different manufacturers for the blanks and they may have changed the ball-joint design over time.

Over the past 50 years Cox did manufacture a few different versions (tapered, thin-walled) but essentially 95% of pistons made in the last 50 years are the same.

However, Cox used different manufacturers for the blanks and they may have changed the ball-joint design over time.

Re: Piston reset.

Re: Piston reset.

Kim wrote:I promise that I DIDN'T swap it out !!!!!!!!!!!!!!!!!!!

Sure Kim I believe you.........

You saw what an awesome engine it was and just had to have that piston!

Nah, it was the same piston with the sloppy ball socket.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Piston reset.

Re: Piston reset.

I have seen a QB piston with a square look to the ball join. That engine was used (and abused) and I thought perhaps they had used a poor piston reset tool and deformed the ball joint...

Has the piston been reset before by someone else?

I'll see if I can find the QB piston again...

Has the piston been reset before by someone else?

I'll see if I can find the QB piston again...

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Piston reset.

Re: Piston reset.

Cox International wrote:TD, Medallion and reed valve engine pistons are indentical with only a few exceptions (Venom, Killer Bee, 051 Medallion).

Over the past 50 years Cox did manufacture a few different versiouns (tapered, thin-walled) but essentially 95% of pistons made in the last 50 years are the same.

However, Cox used different manufacturers for the blanks and they may have changed the ball-joint design over time.

Ok, thanks Bernie. That makes sense. I did manage to remove most of the play using your tool. It took a little more effort but, it is much better. I probably could get rid of all the slop if needed, I was being cautious as this was my first attempt at resetting an .049 piston. I didn't want to create a domed piston.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Piston reset.

Re: Piston reset.

Surfer_kris wrote:I have seen a QB piston with a square look to the ball join. That engine was used (and abused) and I thought perhaps they had used a poor piston reset tool and deformed the ball joint...

Has the piston been reset before by someone else?

I'll see if I can find the QB piston again...

I don't think it was reset before, I got that engine in trade when I was a young teen and it was in a box of HO trains. So I doubt that kid even knew anything about it.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Piston reset.

Re: Piston reset.

Ok, it probably wasen't reset then after reading above. You can square that edge if it is smacked way off center or the reset tool bounces and then comes back down while doing it's thing. A person usually mashes one side or the other of the cup flat with the rod cutout area of the tool if it is done incorrectly and allowed to bounce. Then it's basically trash.

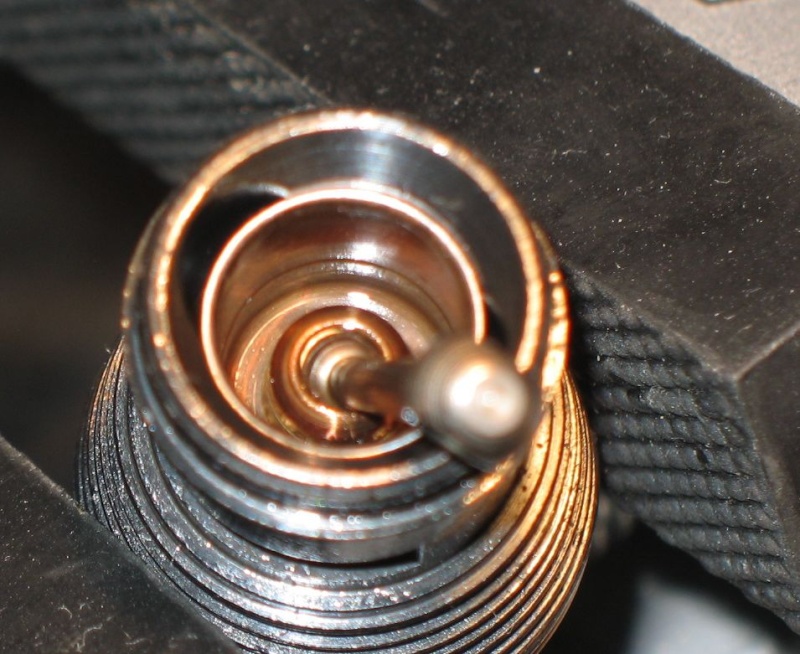

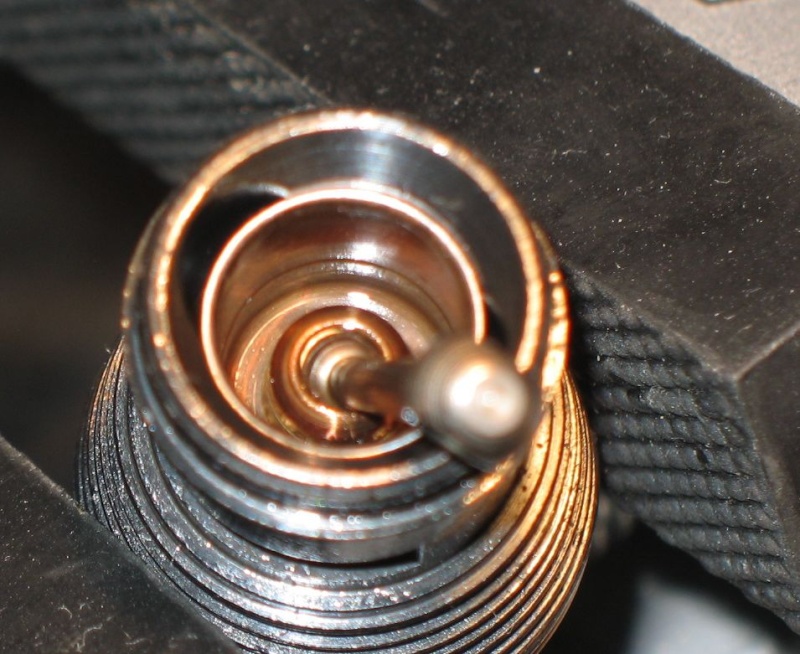

A pic of a NIP TD piston and rod area I snapped last weekend under the microscope. 60X magnification.

A pic of a NIP TD piston and rod area I snapped last weekend under the microscope. 60X magnification.

PV Pilot- High Tech Balsa Basher

- Posts : 1854

Join date : 2011-08-11

Age : 57

Location : The ragged end of the Universe.

Re: Piston reset.

Re: Piston reset.

It really depends upon how they were swaged on different production runs. The tooling may have been slightly different during the piston/connecting rod assembly process.

I have seen some with a larger bulge than others, as well as some that appeared to have a flared edge. If you are resetting, I would just be cautious and tap lightly first. Once you get a feel for the individual piston, it will be easier to 'tighten' up.

Matt

I have seen some with a larger bulge than others, as well as some that appeared to have a flared edge. If you are resetting, I would just be cautious and tap lightly first. Once you get a feel for the individual piston, it will be easier to 'tighten' up.

Matt

Re: Piston reset.

Re: Piston reset.

PV Pilot wrote:Ok, it probably wasen't reset then after reading above. You can square that edge if it is smacked way off center or the reset tool bounces and then comes back down while doing it's thing. A person usually mashes one side or the other of the cup flat with the rod cutout area of the tool if it is done incorrectly and allowed to bounce. Then it's basically trash.

A pic of a NIP TD piston and rod area I snapped last weekend under the microscope. 60X magnification.

Ok, I get what you are saying. I am unable to open that pic up for a visual though.

When I get home tonight I will post a couple pics. Thank you!

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Piston reset.

Re: Piston reset.

It wont click open Ron, all my pics are hosted on photobucket and I edit them to fit if needed. Still working on my lighting under the scope and I think I have found a nice fiber optic light source used in gunsmithing to clear the next batch of pics up a bit.

PV Pilot- High Tech Balsa Basher

- Posts : 1854

Join date : 2011-08-11

Age : 57

Location : The ragged end of the Universe.

Re: Piston reset.

Re: Piston reset.

Here is a picture of the QB piston with a "square" fitting over the rod. It did reset fairly okay but one can see that the reset tool has only touched the outer rim.

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Piston reset.

Re: Piston reset.

It looks like the reset tool might have nicked the edge on the right side there, pushing a little more material tabbed inward.

Either that or it's some gunk sitting there.

Either that or it's some gunk sitting there.

PV Pilot- High Tech Balsa Basher

- Posts : 1854

Join date : 2011-08-11

Age : 57

Location : The ragged end of the Universe.

Re: Piston reset.

Re: Piston reset.

It is the different shape that was trying to show, but it does not show that well in the image. Here is an image of the more common shape, they are clearly machined differently from the start;

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Piston reset.

Re: Piston reset.

Surfer_kris wrote:Here is a picture of the QB piston with a "square" fitting over the rod. It did reset fairly okay but one can see that the reset tool has only touched the outer rim.

It looks like your making Witches Brew... AHAAAAAAAA Some Frogs Breath, Eye of Newt! LOL (NMB4Christmas)

Re: Piston reset.

Re: Piston reset.

Slightly off this topic, i found the conrods to be hardened on some older piston, while they are soft on the surestarts.

I was building a "V-Bee" and was experimenting with some cylinder sets when i noticed that.

Regards

Thomas

I was building a "V-Bee" and was experimenting with some cylinder sets when i noticed that.

Regards

Thomas

altidsulten- Gold Member

- Posts : 179

Join date : 2011-12-03

Location : Hjørring, Denmark

Re: Piston reset.

Re: Piston reset.

Surfer_kris wrote:Here is a picture of the QB piston with a "square" fitting over the rod. It did reset fairly okay but one can see that the reset tool has only touched the outer rim.

That's what it looked like! Kinda like not enough material was removed from around the socket.

The reset tool will only reset a piston like that so far before it bottoms due to the conical shape of the tool. That's not an .09/.15 cylinder clamped in a vice is it?

Thank you for the pictures.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Piston reset.

Re: Piston reset.

Don't worry, that's very soft rubber jays on a hobby vice, held only to enable a picture...

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: Piston reset.

Re: Piston reset.

While we're on the subject, I want to ask, how many taps/rotations on average does it take for you to tighten up a piston?

Maybe someday I'll try again.

Maybe someday I'll try again.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Piston reset.

Re: Piston reset.

RknRusty wrote:While we're on the subject, I want to ask, how many taps/rotations on average does it take for you to tighten up a piston?

Maybe someday I'll try again.

Varies Rusty, for me it was like 3-4 taps with my son's tiny hammer. That was for the TD piston. It took quite a few more taps with the other piston.

Upon further inspection I see that both my TD and proddy engine shared the same style piston cup. So that throws out that theory!

So now I am not sure why it was tougher on the one.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Piston reset.

Re: Piston reset.

I'm up to 50 taps/rotations and never see a change. If I increase the force of my taps I usually mushroom the piston. I use the tool on a clean flat 50lb anvil on the concrete shop floor. All the ones I've done have the "regular" rounded ball cup. Since I have yet to ever successfully reset one, I think I'll back up and re-think my whole method. Or I could blame my tool... yeah that! That damn tool.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Piston reset.

Re: Piston reset.

i think your hammer might be too big. i always use a very light hammer for Cox engine matters,

i think it weighs around 5 ounces or something.

i think it weighs around 5 ounces or something.

GermanBeez- Platinum Member

- Posts : 1167

Join date : 2011-06-15

Location : Bavaria, Germany

Re: Piston reset.

Re: Piston reset.

I use a tack hammer too. I don't know the weight, but it's a fairly big tack hammer. It has a nice flat face, good quality. I was kidding about blaming the tool, but it's possible it could be deformed. Next time I try resetting a piston, I will video it for CEF expert analysis. Y'all can tell me what my problem is. It's actually kind of embarrassing, as I consider myself a good technician/mechanic.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Piston reset.

Re: Piston reset.

i bet you are

GermanBeez- Platinum Member

- Posts : 1167

Join date : 2011-06-15

Location : Bavaria, Germany

Re: Piston reset.

Re: Piston reset.

There shouldn't really be any problem with resetting the piston. If you use 50 strokes and cannot see a difference, then you are not hitting hard enough. If an increased force then deforms the piston itself, it sounds like something is wrong with the tools. Check the center part of the little anvil and also have a look at the end surface of the tool itself. The end should only be slightly hemispherical in order to shrink the piston part around the conrod. If the end is too flat you might actually hit the conrod itself and if it is curved too much it will not apply the force correctly. There might then be nothing that will give, hence the piston itself gets deformed.

The picture with a cut-up engine from "Altid sulten" (means "Always hungry" I believe...) shows the piston part quite well.

There is also the TD image at Aerotools;

The picture with a cut-up engine from "Altid sulten" (means "Always hungry" I believe...) shows the piston part quite well.

There is also the TD image at Aerotools;

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Page 1 of 2 • 1, 2

Similar topics

Similar topics» What causes a piston head to mushroom when you reset the piston rod?

» 09 piston reset

» .049 wrench, piston reset; help

» Piston reset tool worked

» Cox 09 and 15 piston reset tool.

» 09 piston reset

» .049 wrench, piston reset; help

» Piston reset tool worked

» Cox 09 and 15 piston reset tool.

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules