Log in

Search

Latest topics

» Tee Dee .020 combat modelby rdw777 Today at 5:07 pm

» Free Flight Radio Assist

by rdw777 Today at 4:51 pm

» My N-1R build log

by akjgardner Today at 12:39 pm

» Purchased the last of any bult engines from Ken Enya

by getback Today at 12:05 pm

» Funny what you find when you go looking

by rsv1cox Yesterday at 3:21 pm

» Landing-gear tips

by 1975 control line guy Yesterday at 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» My latest doodle...

by TD ABUSER Mon Nov 18, 2024 11:30 am

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

Cox Engine of The Month

PeeWee .020 bent cylinder

Page 1 of 2

Page 1 of 2 • 1, 2

PeeWee .020 bent cylinder

PeeWee .020 bent cylinder

I bought this from the bay for reasonable buy it now price for a PeeWee….. It looked like it had a rough life but might be a good fixer upper project and I wanted an extra cylinder/piston set anyway…,, Looking back on the seller’s photos I could probably have noticed the bent cylinder with a little more scrutiny…. Lesson learned…,Photos above are mine…

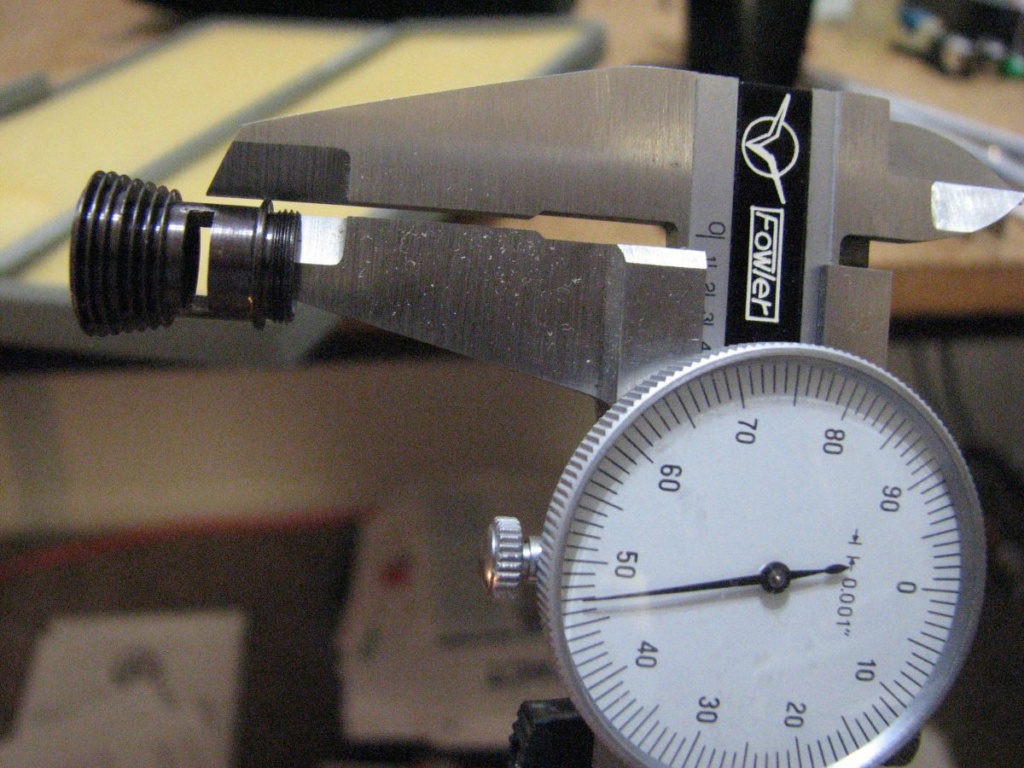

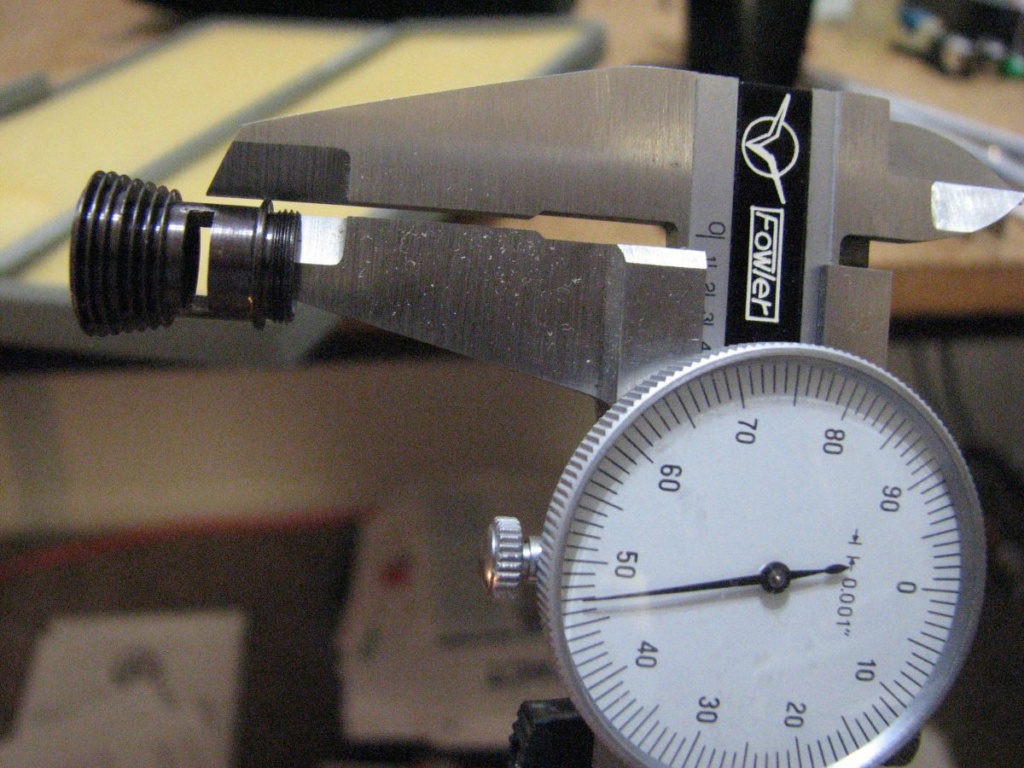

My first reaction is it’s toast and can’t be fixed due to the micro precision of these…. So I did check it best I could and will share what I found…. Cylinder assembly was cleaned dried and piston only will rise to the position in the photo…. The piston rotates freely in the lower part of the bore so it seems round….Piston crown inserted into the top of the bore only goes in about .030 but will rotate freely….. The skirt inserted in top will only barely start…. I think the top part of the bore is round and the assembly is probably tapered….. One exhaust port measures .095 and the other .078…., .017 difference…..It seems the bend is in the webs between the exhaust ports…

It’s no good like it is so I’m thinking IF I were to try to repair it what would that be…. I don’t have access to a lathe so have to think of something else….Maybe boring a piece of wood about the same od as the widest part of the cylinder about a foot long that could be used as a lever……Wrap the base of the cylinder to about the same od for something to bear against….. Heat the webs and try to pull back in place…. Touchy feely rotating the engine thru while trying….

Any other ideas?.,,, Again I realize this cylinder has little to no chance …. Thanks

Robert

rdw777- Diamond Member

Posts : 1716

Join date : 2021-03-11

Location : West Texas

Re: PeeWee .020 bent cylinder

Re: PeeWee .020 bent cylinder

Wow.  That is a serious bend. I bet that engine hit the floor just right from a good distance up... or it was in quite the crash.

That is a serious bend. I bet that engine hit the floor just right from a good distance up... or it was in quite the crash.

I'm not sure how successful of a save you can do on that cylinder other than trying to knock it back straight without over-bending it or cracking it. I've seen cylinders broken in two from a crash or some gorilla going at a stuck one with a wrench. It might have ovaled a bit from the bend too. Maybe try pounding a well fit wood dowel through it? The metal is quite thin at the bypass ports inside the cylinder.

It will be interesting to see if you can save it. Other than sending it back or getting a refund, what else do you have to lose?

If the backplate is in good shape, none of the lugs broken off, that would be a bonus!

I'm not sure how successful of a save you can do on that cylinder other than trying to knock it back straight without over-bending it or cracking it. I've seen cylinders broken in two from a crash or some gorilla going at a stuck one with a wrench. It might have ovaled a bit from the bend too. Maybe try pounding a well fit wood dowel through it? The metal is quite thin at the bypass ports inside the cylinder.

It will be interesting to see if you can save it. Other than sending it back or getting a refund, what else do you have to lose?

If the backplate is in good shape, none of the lugs broken off, that would be a bonus!

Re: PeeWee .020 bent cylinder

Re: PeeWee .020 bent cylinder

That engine has had a rough life even the lower lug is bent . I don't think you will ever get it straight without warping the cly.

getback- Top Poster

Posts : 10439

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: PeeWee .020 bent cylinder

Re: PeeWee .020 bent cylinder

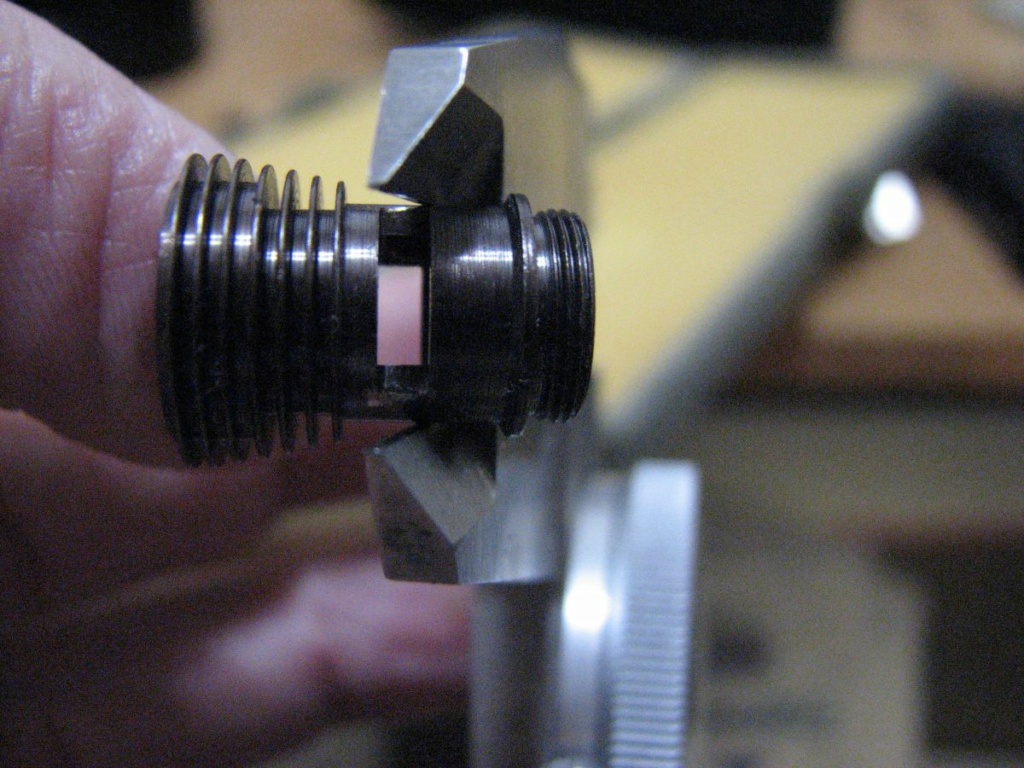

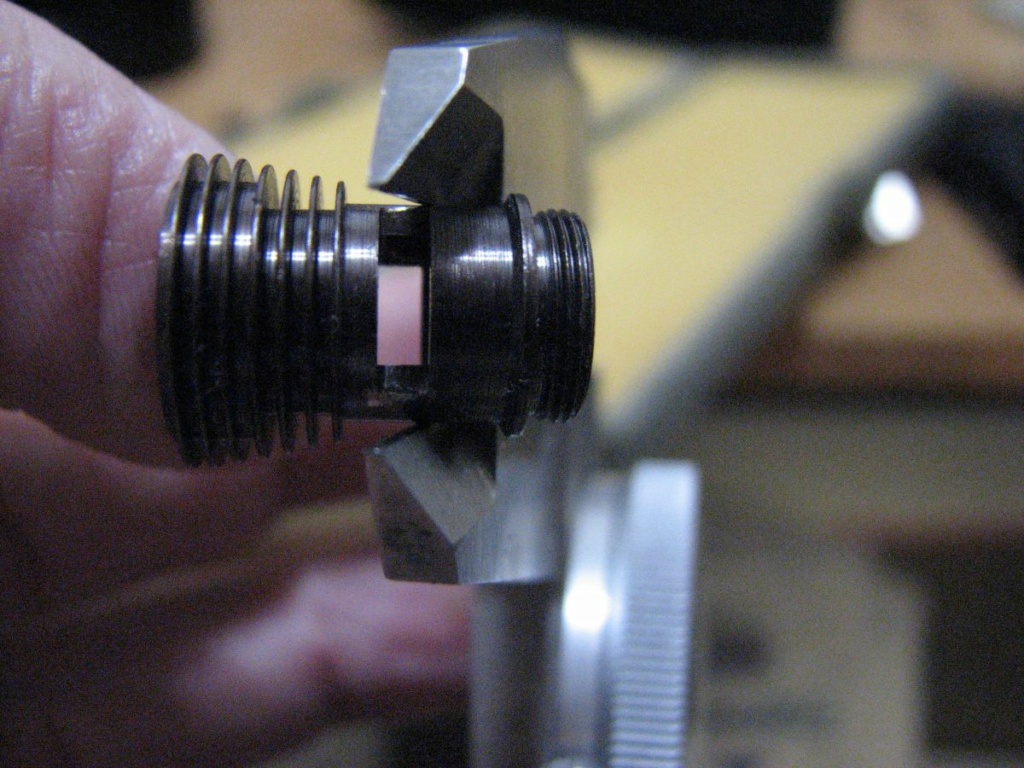

Just a thought! The cylinder is bent back towards the tank, so most likely it has been imacted on the front, causing the front exhaust port to stretch open. This, I believe, would be far more likely than the rear of the cylinder compressing.

There may be some chance of easing the front exhaust port closed a little by trying to compress the front part of the cylinder, closing up the exhaust port until it matches the rear or another known good cylinder. Did you compare the opening at the rear to another undamaged one?

My though is that you may be able to place the cylinder in a vise, compressing it ever so carefully with just the very edge of the stretched side of the cylinder clamped between the very edge of the jaws. It may work better (and be more secure) if you were to leave it screwed into the case, being sure to only put pressure on the stronger part of the case at the nose-end of the main case, maybe with a crankshaft inserted to give more strength. Maybe I should draw a picture?? I figure you have nothing to lose.

Rod.

Here you go!

There may be some chance of easing the front exhaust port closed a little by trying to compress the front part of the cylinder, closing up the exhaust port until it matches the rear or another known good cylinder. Did you compare the opening at the rear to another undamaged one?

My though is that you may be able to place the cylinder in a vise, compressing it ever so carefully with just the very edge of the stretched side of the cylinder clamped between the very edge of the jaws. It may work better (and be more secure) if you were to leave it screwed into the case, being sure to only put pressure on the stronger part of the case at the nose-end of the main case, maybe with a crankshaft inserted to give more strength. Maybe I should draw a picture?? I figure you have nothing to lose.

Rod.

Here you go!

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: PeeWee .020 bent cylinder

Re: PeeWee .020 bent cylinder

PeeWee bring crazy prices these days.

Ever try to straighten a piece of wire? This will be no different. On a lathe I might be tempted as an experiment, but have zero hope of a runner. The hard part is holding it. I suspect it will crack at the ports.

I didn't even know Ebay changed the condition in categories. Any "as-is, no returns" listing with no description of condition should be dirt cheap. I would say not as described even though there was no description at all.

Baby, Collectibles, Crafts, Dolls & Bears, Health & Beauty, Pet Supplies, Toys & Hobbies

New: The item is brand new, unused, unopened, and undamaged (including handmade items). See the seller's listing for full details.

Used: The item was previously used. See the seller's listing for full details and a description of any imperfections.

Ever try to straighten a piece of wire? This will be no different. On a lathe I might be tempted as an experiment, but have zero hope of a runner. The hard part is holding it. I suspect it will crack at the ports.

I didn't even know Ebay changed the condition in categories. Any "as-is, no returns" listing with no description of condition should be dirt cheap. I would say not as described even though there was no description at all.

Baby, Collectibles, Crafts, Dolls & Bears, Health & Beauty, Pet Supplies, Toys & Hobbies

New: The item is brand new, unused, unopened, and undamaged (including handmade items). See the seller's listing for full details.

Used: The item was previously used. See the seller's listing for full details and a description of any imperfections.

gkamysz- Gold Member

- Posts : 414

Join date : 2018-02-22

Location : Chicagoland

Re: PeeWee .020 bent cylinder

Re: PeeWee .020 bent cylinder

Nice diagnostics Rod, Thanks….. Looking at the enlarged photo again the lines on the rear port are a lot more parallel than the front so yes, Appears stretched on the front…. When I get home this weekend will measure a good cylinder for reference…..Do you think this attempt to re-compress would best be done warmed in the specific area with a micro torch or done cold?

If it doesn’t work out at least I’ll have a few parts for future others….

If it doesn’t work out at least I’ll have a few parts for future others….

rdw777- Diamond Member

Posts : 1716

Join date : 2021-03-11

Location : West Texas

Re: PeeWee .020 bent cylinder

Re: PeeWee .020 bent cylinder

.....DEE Dumm....Dee Dumm... Bumm BUM...Welcome to C.S.I. Crash Scene Investigation - Cylinder Damage COLD CASE. No information was provided so all results are assumed fictional and of Best Guess techknowlogy.

Yes, a close inspection of the sellers pictures may have indicated damage prior to purchase. Did the description indicate the condition: engine won't turn over or stuck?

To repair damage to engine, you would have to re=create the senerio in which it was damaged. Assuming it was being used as intended mounted on a model in flight operating at top adjustable RPM the cylinder would have been HOT, metal when HOT bends easily (ask any blacksmith). Due to Piolet error or Mother nature, if Flying FF, the Aircraft impacts the ground at a terminal velocity that forces the cylinder back towards the firewall and the lower tank mounted lugs bend backward in the effort to remain attached to the airframe.

SO, to reverse the damage you would heat the cylinder up to a Very Very Warm, Too Hot to touch temperature, then use a wooden dowel sized to closely fit the ID of the cylinder, inserted into the cylinder to just slightly above the exhaust ports and gently pull forward to return the bore of the cylinder to the fully upright position. Probably near impossible to return to OEM specifications, but Hey, what ya got to lose? The Mounting lugs are a lost cause, being cast of a Bizzare mixture of inexpensive metals they will only break if any force is used to attempt a return to a normal flat position as originally designed. Oh. looks like OER has beat me to the response. Shoot, time for a second cup-a-coffee..

Yes, a close inspection of the sellers pictures may have indicated damage prior to purchase. Did the description indicate the condition: engine won't turn over or stuck?

To repair damage to engine, you would have to re=create the senerio in which it was damaged. Assuming it was being used as intended mounted on a model in flight operating at top adjustable RPM the cylinder would have been HOT, metal when HOT bends easily (ask any blacksmith). Due to Piolet error or Mother nature, if Flying FF, the Aircraft impacts the ground at a terminal velocity that forces the cylinder back towards the firewall and the lower tank mounted lugs bend backward in the effort to remain attached to the airframe.

SO, to reverse the damage you would heat the cylinder up to a Very Very Warm, Too Hot to touch temperature, then use a wooden dowel sized to closely fit the ID of the cylinder, inserted into the cylinder to just slightly above the exhaust ports and gently pull forward to return the bore of the cylinder to the fully upright position. Probably near impossible to return to OEM specifications, but Hey, what ya got to lose? The Mounting lugs are a lost cause, being cast of a Bizzare mixture of inexpensive metals they will only break if any force is used to attempt a return to a normal flat position as originally designed. Oh. looks like OER has beat me to the response. Shoot, time for a second cup-a-coffee..

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: PeeWee .020 bent cylinder

Re: PeeWee .020 bent cylinder

Ha! I like the CSI approach  …. A bit more info detective, Right side mounting lugs are fairly straight, Left bottom bent as noted and left top separated but hanging on….(I did notice that in seller photos…. Was mainly wanting the cylinder/piston)….A missing chip out of the glow head….Whatever it was seemed to be rolled hard left when it hit…,

…. A bit more info detective, Right side mounting lugs are fairly straight, Left bottom bent as noted and left top separated but hanging on….(I did notice that in seller photos…. Was mainly wanting the cylinder/piston)….A missing chip out of the glow head….Whatever it was seemed to be rolled hard left when it hit…,

Seller description was “what you see is what you get, no returns….. Not a big deal…. I’ve gotten a lot of good deals there too….

Thanks for the repairs/expectations advise….

Seller description was “what you see is what you get, no returns….. Not a big deal…. I’ve gotten a lot of good deals there too….

Thanks for the repairs/expectations advise….

rdw777- Diamond Member

Posts : 1716

Join date : 2021-03-11

Location : West Texas

Re: PeeWee .020 bent cylinder

Re: PeeWee .020 bent cylinder

i'm loving the groups responses and attempts to help, yet I am ALSO reminded of the age old wisdom Butthead gave to Beavis once, about inability to polish feces.

i'd say its good for parts and or experimentation. or build it into a 'cut-a-way' for display.

a new cylinder/piston combo might work - i checked on our 2 friendly source/suppliers, and neither of them lists for sale for .020

I did ALSO look at that exact motor on eBay, thinking/ I need a backplate with all 4 mounting lugs...... I just couldn't add up the $$-to-abused looks.

good luck with it. AND? keep us all appraised.

i'd say its good for parts and or experimentation. or build it into a 'cut-a-way' for display.

a new cylinder/piston combo might work - i checked on our 2 friendly source/suppliers, and neither of them lists for sale for .020

I did ALSO look at that exact motor on eBay, thinking/ I need a backplate with all 4 mounting lugs...... I just couldn't add up the $$-to-abused looks.

good luck with it. AND? keep us all appraised.

cstatman- Platinum Member

Posts : 568

Join date : 2021-02-17

Age : 60

Location : San Jose, CA

Re: PeeWee .020 bent cylinder

Re: PeeWee .020 bent cylinder

That must have been a hard landing indeed

I would probably try to straighten the cylinder by inserting a wedge-shaped tool (like a flat screwdriver) in the narrower port, and with the cylinder mounted in a vise, possibly with the help of a crankcase, gently tap the wedge tool so that it widens the port and hopefully straightens the cylinder. Little by little... and testing with the piston after every few taps.

Not sure if it’s the camera optics, but it looks like the whole engine is bent Is the tank bowl deformed?

Is the tank bowl deformed?

I would probably try to straighten the cylinder by inserting a wedge-shaped tool (like a flat screwdriver) in the narrower port, and with the cylinder mounted in a vise, possibly with the help of a crankcase, gently tap the wedge tool so that it widens the port and hopefully straightens the cylinder. Little by little... and testing with the piston after every few taps.

Not sure if it’s the camera optics, but it looks like the whole engine is bent

Is the tank bowl deformed?

Is the tank bowl deformed?

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Re: PeeWee .020 bent cylinder

Re: PeeWee .020 bent cylinder

Good for you, trying to keep these little guys alive.

Go for it

That old college try

Nothing ventured, nothing gained.

Etc. Etc. Etc.

All above fixes may give positive results, but I like Rod's suggestion as you can control the pressure the vice exerts. Buffer both ends - A little at a time, check........check......check.

Go for it

That old college try

Nothing ventured, nothing gained.

Etc. Etc. Etc.

All above fixes may give positive results, but I like Rod's suggestion as you can control the pressure the vice exerts. Buffer both ends - A little at a time, check........check......check.

rsv1cox- Top Poster

Posts : 11245

Join date : 2014-08-18

Location : West Virginia

crankbndr- Top Poster

- Posts : 3109

Join date : 2011-12-10

Location : Homestead FL

Re: PeeWee .020 bent cylinder

Re: PeeWee .020 bent cylinder

That's too bad. Such a neat little engine. I see a pretty big dent dent on the left exhaust web from probably a standard Cox cylinder removal tool. And there looks to me like a bulge in the middle of that web also.

Some great ideas in possible fixes. My gut feeling is it's probably hopeless but nothing to loose if you try.

I have this cool little arbor press and I think if I were going to try I would lay the cylinder sideways on a couple of wood blocks maybe keeping the crankcase on would be good to help keep the cyl from warping, have the side long side up toward the plunger and use a piece of wood in there also and go slow trying the piston in the boar often as it looks better.

Can you get the head off and does the piston fit in the boar from the top? And if so how far down will the piston go, does it reach the top of the exhaust ports before hanging up?

Some great ideas in possible fixes. My gut feeling is it's probably hopeless but nothing to loose if you try.

I have this cool little arbor press and I think if I were going to try I would lay the cylinder sideways on a couple of wood blocks maybe keeping the crankcase on would be good to help keep the cyl from warping, have the side long side up toward the plunger and use a piece of wood in there also and go slow trying the piston in the boar often as it looks better.

Can you get the head off and does the piston fit in the boar from the top? And if so how far down will the piston go, does it reach the top of the exhaust ports before hanging up?

FlipStart- Gold Member

- Posts : 161

Join date : 2018-09-05

Location : Phoenix, Arizona

My Pee Wee bent cylinder story

My Pee Wee bent cylinder story

I built a Goldberg Swordsman 18 when I was a kid and powered it with a brand new Pee Wee 0.020.

The instructions specifically stated to wrap solder around the front of the Pee Wee as it was a very light engine and the plane would be too tail heavy if this advice wasn't followed.

I figured "Too ugly, can't spoil the looks of my brand new airplane with solder wrapped around the crankcase of a brand new engine."

So, took the plane out for its maiden flight and it immediately did an unintentional loop and smacked he cylinder into the only bit of pavement around.

Bent cylinder.

So my father brought it into work and one of his toolmaker buddies put it into a lathe and straightened it good enough that the engine would run on its prime. Not too shabby when you think of the clearances in that tiny cylinder.

I never could get the engine to run on anything but just the prime and suspect it was due to a broken off needle valve tip.

For anyone that might attempt this repair, I would fabricate a mandrel to fit the bore then gently tap the cylinder with a plastic hammer until a dial indicator nulled out.

The instructions specifically stated to wrap solder around the front of the Pee Wee as it was a very light engine and the plane would be too tail heavy if this advice wasn't followed.

I figured "Too ugly, can't spoil the looks of my brand new airplane with solder wrapped around the crankcase of a brand new engine."

So, took the plane out for its maiden flight and it immediately did an unintentional loop and smacked he cylinder into the only bit of pavement around.

Bent cylinder.

So my father brought it into work and one of his toolmaker buddies put it into a lathe and straightened it good enough that the engine would run on its prime. Not too shabby when you think of the clearances in that tiny cylinder.

I never could get the engine to run on anything but just the prime and suspect it was due to a broken off needle valve tip.

For anyone that might attempt this repair, I would fabricate a mandrel to fit the bore then gently tap the cylinder with a plastic hammer until a dial indicator nulled out.

706jim- Gold Member

- Posts : 472

Join date : 2013-11-29

Re: PeeWee .020 bent cylinder

Re: PeeWee .020 bent cylinder

Jim, Neat story and good advice, and a bit encouraging …. The school I work at has a machine shop but the instructor that I am friends with recently left so I don’t have that resource anymore….My home shop has drill press, dial indicator, dial calipers, vice, etc….. I do like Rod’s observation of “stretch” and approach to non machine shop attempt….. Maybe it’s a combination me making a hardwood mandrel on the drill press and using the vice to compress a bit….. Arbor press has been mentioned and I have one but I like the vice idea cause you could creep on it a tiny bit at a time….. I like the thinking thru process and am not in a hurry so will see what develops….

Love rsv’s optimism…. With you on that!!! I’d rather fail trying ….

A bit more info for other questions that were asked….The tank bowel is straight and the back plate mates to it and will turn all the way round… Tank mates to crank case fine… There was no tank gasket as received…. Needle is fine including tip… No spring….Fuel pick up was/is as shown….Very clean inside…. Nothing was gummed up hard in the engine…. Looks like it had a short, hard life…

Love rsv’s optimism…. With you on that!!! I’d rather fail trying ….

A bit more info for other questions that were asked….The tank bowel is straight and the back plate mates to it and will turn all the way round… Tank mates to crank case fine… There was no tank gasket as received…. Needle is fine including tip… No spring….Fuel pick up was/is as shown….Very clean inside…. Nothing was gummed up hard in the engine…. Looks like it had a short, hard life…

rdw777- Diamond Member

Posts : 1716

Join date : 2021-03-11

Location : West Texas

Re: PeeWee .020 bent cylinder

Re: PeeWee .020 bent cylinder

A little follow up info…. Rod suggest to measure the size of the ports on a known good engine which I did when I got home today…. Three other cylinders are at .087…. The bent one is at .078 and .095 so there’s both stretch and compression…. Nothing more than interesting data for comparison….

rdw777- Diamond Member

Posts : 1716

Join date : 2021-03-11

Location : West Texas

Re: PeeWee .020 bent cylinder

Re: PeeWee .020 bent cylinder

If you have a bench press, level it and make sure the ram is flat. Pressure plate too.

The ram should hit the high side first and should straighten it. Not too much pressure as it’s pretty soft metal. Maybe use a piece of hardwood for the plate instead of steel. Kind of the same thing Rod suggested just has better footing.

The ram should hit the high side first and should straighten it. Not too much pressure as it’s pretty soft metal. Maybe use a piece of hardwood for the plate instead of steel. Kind of the same thing Rod suggested just has better footing.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: PeeWee .020 bent cylinder

Re: PeeWee .020 bent cylinder

Listen you guys! Getting the exhaust gap the same is a poor way of getting the top and bottom of the cylinder to have concentric bores. Please try to find someone with a lathe to do this right.

706jim- Gold Member

- Posts : 472

Join date : 2013-11-29

Re: PeeWee .020 bent cylinder

Re: PeeWee .020 bent cylinder

Jim, I’m sure you’re right…., In the beginning I was looking for similar experiences and repairs but Im sure proper machine tools are the best to have remote chance of fixing it…. I’ll set it aside for now until better opportunities come along…..I’ve got other engines to play with and I need to finish SM 23… But!!…, It’s nearly worth what I paid to see all the support and ideas here…, I’m really enjoying the forum…And I’m learning alot… Sincerely

rdw777- Diamond Member

Posts : 1716

Join date : 2021-03-11

Location : West Texas

Straightening bent Pee Wee cylinder

Straightening bent Pee Wee cylinder

You could send the cylinder and piston to me. I have a high end tool makers lathe and 40 years of machining experience. And in the worst case scenario, a couple of used Pee Wee's in better condition than yours.

PM if you're interested.

PM if you're interested.

Last edited by 706jim on Fri Sep 24, 2021 8:54 pm; edited 1 time in total

706jim- Gold Member

- Posts : 472

Join date : 2013-11-29

Re: PeeWee .020 bent cylinder

Re: PeeWee .020 bent cylinder

Typical modeler kindness, Thanks…. I may PM you in a day or two and see what we can work out…. Thanks,

Robert

Robert

rdw777- Diamond Member

Posts : 1716

Join date : 2021-03-11

Location : West Texas

Re: PeeWee .020 bent cylinder

Re: PeeWee .020 bent cylinder

Did the head come off OK?

Maybe that's how the cylinder got bent, someone trying to remove a stuck head with the cylinder tool in the exhaust slots and twisting force applied to the head. Are there any nasty tool marks on the head?

If the piston doesn't fit in the top part of the cylinder the cylinder is ovaled and you would half to give it bore job to save it.

Maybe that's how the cylinder got bent, someone trying to remove a stuck head with the cylinder tool in the exhaust slots and twisting force applied to the head. Are there any nasty tool marks on the head?

If the piston doesn't fit in the top part of the cylinder the cylinder is ovaled and you would half to give it bore job to save it.

FlipStart- Gold Member

- Posts : 161

Join date : 2018-09-05

Location : Phoenix, Arizona

Re: PeeWee .020 bent cylinder

Re: PeeWee .020 bent cylinder

Hi Robert,

looks like the engine was dropped. If it was running when it got damaged most likely the piston would have jammed itself into the bent cylinder and ruined the piston/rod.

If you could size 2 aluminum rods to the bore you could use it to straighten the cylinder. You can size the rods with a drill press and a flat file. Insert each rod from either end until they meet at the bend. Hold one rod in a vice and apply pressure with the other rod in the proper direction. You can test your progress by seeing if the rod can go past the bend. Just an Idea.

looks like the engine was dropped. If it was running when it got damaged most likely the piston would have jammed itself into the bent cylinder and ruined the piston/rod.

If you could size 2 aluminum rods to the bore you could use it to straighten the cylinder. You can size the rods with a drill press and a flat file. Insert each rod from either end until they meet at the bend. Hold one rod in a vice and apply pressure with the other rod in the proper direction. You can test your progress by seeing if the rod can go past the bend. Just an Idea.

coxaddict- Gold Member

- Posts : 429

Join date : 2013-01-27

Location : north shore oahu, Hawaii

Re: PeeWee .020 bent cylinder

Re: PeeWee .020 bent cylinder

I was just checking this one. See if I got my math right. I'm terrible at math and spelling. That cylinder is only .020" at it's narrowest in the bottom of the half moon transfer port, and it has twin transfer ports, one in each exhaust web. Probably pretty easy to bend.

.020" looks a lot wider in the picture than in real life too.

.020" looks a lot wider in the picture than in real life too.

FlipStart- Gold Member

- Posts : 161

Join date : 2018-09-05

Location : Phoenix, Arizona

Re: PeeWee .020 bent cylinder

Re: PeeWee .020 bent cylinder

The cylinder is about .040" wall thickness in that area.

gkamysz- Gold Member

- Posts : 414

Join date : 2018-02-22

Location : Chicagoland

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Spacebug-Style Crankshaft Repair

» 049 backplate needle bent?

» TIEBREAKER-POLL **COX-ENGINE-OF-THE-MONTH** (December 2022)

» Cylinder Performance Figures

» Bent 049 conrod repaired

» 049 backplate needle bent?

» TIEBREAKER-POLL **COX-ENGINE-OF-THE-MONTH** (December 2022)

» Cylinder Performance Figures

» Bent 049 conrod repaired

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules