Log in

Search

Latest topics

» TEE DEE Having issuesby balogh Today at 7:42 am

» Retail price mark-up.. how much is enough?

by rsv1cox Today at 7:36 am

» Cox films/videos...

by Coxfledgling Today at 4:46 am

» Purchased the last of any bult engines from Ken Enya

by Coxfledgling Today at 4:18 am

» My N-1R build log

by roddie Today at 12:32 am

» Happy 77th birthday Andrew!

by akjgardner Today at 12:27 am

» Landing-gear tips

by roddie Yesterday at 6:17 pm

» Roger Harris revisited

by TD ABUSER Yesterday at 2:13 pm

» Tee Dee .020 combat model

by Ken Cook Yesterday at 1:41 pm

» My latest doodle...

by roddie Yesterday at 10:43 am

» Chocolate chip cookie dough.........

by roddie Fri Nov 22, 2024 1:13 pm

» Free Flight Radio Assist

by rdw777 Fri Nov 22, 2024 9:24 am

Cox Engine of The Month

Bent 049 conrod repaired

Page 1 of 1

Bent 049 conrod repaired

Bent 049 conrod repaired

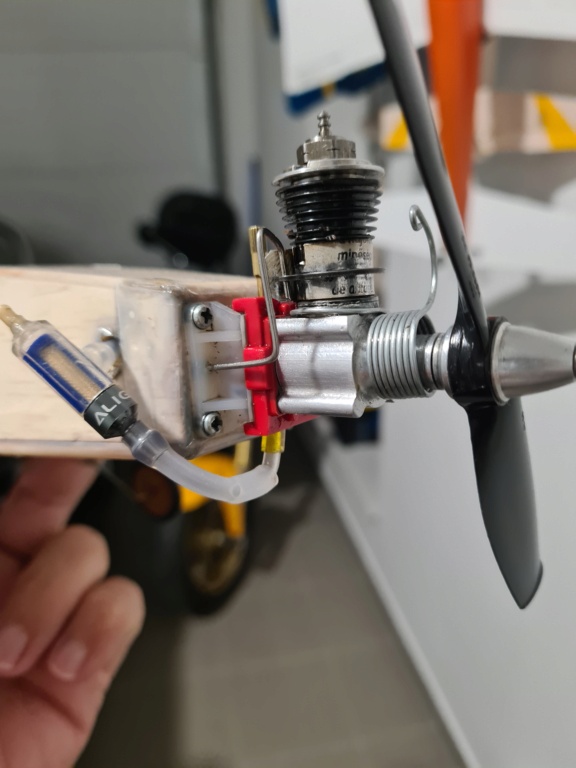

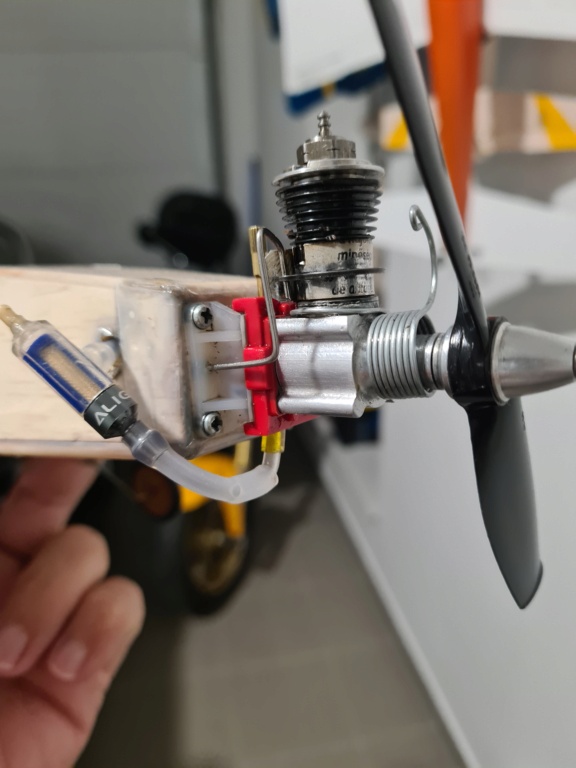

Now that I enjoy the access to a small airfield owned by a friendly family whose son happens to be a pilot and a modeler too, I am flying the heck out of my COX RC planes including the Quickie100, and no matter how hard I press it, neither the plane nor the red postage backplate 049 bee seem to be complaining.

Except for one hydraulic lock that the starter spring drove the piston into when I started the engine..may have primed the beast a bit too much..I would not expect hydro-lock damage from a starter spring, fatal hydro-locks are more likely to occur with electric starters as far as I know...I immediately knew something was wrong and did not force the crank around..when disassembled, the engine showed a bent conrod..while I have spare cylinder & piston combos on stock, this thin wall tapered bore cylinder has such a superb compression after so many hours of run near its limits with a high compression Galbreath head and Nelson plug, that I simply did not want to replace the piston . So I decided to give it a try, and with the bent conrod section between the jaws of a flat nose pliers, pressing and turning and pressing and turning the rod, I managed to press the conrod visually straight...a couple years ago I did that to a 051 TeeDee conrod that was bent in an electric starter driven hydro-lock, and the piston could be saved.

With these tiny components a small curl left in the conrod can easily lead to another rod buckling. In addition, if the hole in the conrod big end and the crankpin are not parallel, the big end will not function as a journal bearing where the oil separates the mating parts, and the pin and the big end will soon destroy each other.

But the straightening of this conrod with the flat pliers was successful. I tested the Quickie in the field again and the engine was just as good as before..

No photos unfortunately, only the plane after the field test...

My takeaway: you can make it if you try...a piston in the COX heyday was a throw-away consumable with abundance of replacements..I want to sustain authenticity of my old stock workhorse COX engines by trying to repair rather than replace the repairable parts..

Except for one hydraulic lock that the starter spring drove the piston into when I started the engine..may have primed the beast a bit too much..I would not expect hydro-lock damage from a starter spring, fatal hydro-locks are more likely to occur with electric starters as far as I know...I immediately knew something was wrong and did not force the crank around..when disassembled, the engine showed a bent conrod..while I have spare cylinder & piston combos on stock, this thin wall tapered bore cylinder has such a superb compression after so many hours of run near its limits with a high compression Galbreath head and Nelson plug, that I simply did not want to replace the piston . So I decided to give it a try, and with the bent conrod section between the jaws of a flat nose pliers, pressing and turning and pressing and turning the rod, I managed to press the conrod visually straight...a couple years ago I did that to a 051 TeeDee conrod that was bent in an electric starter driven hydro-lock, and the piston could be saved.

With these tiny components a small curl left in the conrod can easily lead to another rod buckling. In addition, if the hole in the conrod big end and the crankpin are not parallel, the big end will not function as a journal bearing where the oil separates the mating parts, and the pin and the big end will soon destroy each other.

But the straightening of this conrod with the flat pliers was successful. I tested the Quickie in the field again and the engine was just as good as before..

No photos unfortunately, only the plane after the field test...

My takeaway: you can make it if you try...a piston in the COX heyday was a throw-away consumable with abundance of replacements..I want to sustain authenticity of my old stock workhorse COX engines by trying to repair rather than replace the repairable parts..

balogh- Top Poster

Posts : 4959

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Bent 049 conrod repaired

Re: Bent 049 conrod repaired

Congrats on the straightening con rod repair, András.

Similar but slightly different repair, a while back I purchased a used Enya .19-VI TV engine cheap. It had very good compression but, did not know it had a bent threaded crankshaft prop shaft. Using a nut to protect threaded end, I smacked it a couple times with my autobody hammer. Used a good nut and fender washer from my motorcycle parts bin, for the missing ones.

Lo and behold, after a couple iterations, I actually straightened it. Ran perfectly on a test stand with a 9x4 prop.

It is always a good feeling to repair something thought to be otherwise irreparable.

Similar but slightly different repair, a while back I purchased a used Enya .19-VI TV engine cheap. It had very good compression but, did not know it had a bent threaded crankshaft prop shaft. Using a nut to protect threaded end, I smacked it a couple times with my autobody hammer. Used a good nut and fender washer from my motorcycle parts bin, for the missing ones.

Lo and behold, after a couple iterations, I actually straightened it. Ran perfectly on a test stand with a 9x4 prop.

It is always a good feeling to repair something thought to be otherwise irreparable.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Bent 049 conrod repaired

Re: Bent 049 conrod repaired

Andras, at your age 64, your enthusisum for flying these little devils reminds me of myself back when I was 14-17 flying Walt's hollow logs powered by Space Bug Jr.s and the early Babe Bees. I couldn't wait to get out there. Keeps you thinking young.

Bob

Bob

rsv1cox- Top Poster

Posts : 11251

Join date : 2014-08-18

Location : West Virginia

Re: Bent 049 conrod repaired

Re: Bent 049 conrod repaired

Thanks George and Bob...indeed. The hobby has burnt into my everydays, and I feel somehow empty if I have not dealt with my engines and planes in some way for a few days or shorter. But repairing a wounded engine gives me a special satisfaction that you Bob may also feel when completing one of your refurbishment projects.

balogh- Top Poster

Posts : 4959

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Bent 049 conrod repaired

Re: Bent 049 conrod repaired

Great story Andras, I’m glad you were able to save it! I too have a once bent engine that was repaired by a kind forum member and still going strong …Let us know how it holds up for you in the future….Your reports on high time engines have been encouraging as well… I really like running them so it’s good to know they can have a long service life if treated well…

Robert

Robert

rdw777- Diamond Member

Posts : 1718

Join date : 2021-03-11

Location : West Texas

Re: Bent 049 conrod repaired

Re: Bent 049 conrod repaired

Thank you Robert. I bought this red postage backplate engine in already used condition, and it has had some heavy runtimes since then. I do not expect its hand-straightened rod to buckle in normal running conditions, but the recognition that a starter spring can also drive it into a harmful hydraulic lock just taught me that no matter what, the first flips and cranks should always be by hand. With its excellent compression still retained I expect many hours of dependable performance still waiting of us.

balogh- Top Poster

Posts : 4959

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Bent 049 conrod repaired

Re: Bent 049 conrod repaired

While you have straightened it, those rods aren't ductile enough to bend and re bend. When it bends it microscopically cracks and when you straighten it, you work harden it even more making it even more brittle.

Ken Cook- Top Poster

- Posts : 5641

Join date : 2012-03-27

Location : pennsylvania

Re: Bent 049 conrod repaired

Re: Bent 049 conrod repaired

Ken, you bring up an interesting topic. I remember at McDonnell Douglas, watching on Test Hangar 41, we had million pound hydraulic jacks applying pressure on a C-17 main wing spar. Using a spectrum tape from the structural design engineers, would detail the load profile to be applied in our test rig, read in by our multi-tasking load servo controlling and data acquisition Perkin-Elmer 3220 test minicomputer, that we had in an enclosed trailer next to the test fixture.Ken Cook wrote:While you have straightened it, those rods aren't ductile enough to bend and re bend. When it bends it microscopically cracks and when you straighten it, you work harden it even more making it even more brittle.

It ran for a number of months, basically at an accelerated rate, to find out when it would start to fail (shut down at periodic intervals for inspection) and final failure through cyclic fatigue. When it did break, there was a huge explosive sound in the hangar (ear protection nearby a requirement), our computer would immediately terminate the test. (I could even hear such an event in the adjacent 41A office/flight test control room/simulations lab annex building where my desk was.)

Engineers wanted to know ahead of time to predict signs of failure, to see if redesign was needed, also to develop the criteria required to adequately inspect the spar so that the plane could be safely be safely withdrawn from service if need be, repaired / replaced so the plane could remain airworthy and prevent accidents.

I think the beauty of this type of repair on a venerable Cox 190 or 290 postage stamp engine, is that if the connecting rod did fracture and separate, from what others have shared in similar instances, worst case is the engine is rendered non-repairable. Sometimes, may be the worst hasn't happened and one can replace worn/damaged parts. It's not like destroying an expensive hard to replace, say, OS .30 Wankel.

Would one act of straightening a mild bent connecting rod cause a problem? Can't say. They do afterall from what I've heard, do a certain amount of rehardening (re-tempering) in the manufacturing process after forming when ductile, so the part can withstand higher strain without failing.

András is safety minded, and in case say there was a failure, given his mode of flying, even if the conrod separated, worst that could happen is loss of the engine. However, the nice thing about these engines is availability of replacement parts from Cox International, Ex Model Engines and his various other sources in his area.

Personally, my gut level feeling is that he probably won't have problems here on out, but that is just my personal impression. If it does, he'll have another story to share.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Bent 049 conrod repaired

Re: Bent 049 conrod repaired

Yes, Ken and George, a bend means a permanent change of shape of the material, that was stressed beyond the yield strength, yet I hope this will not cause a fatigue break to come soon. This engine with the Kamtechnik or Galbreath head spins well over 20k rpm when unloads in the air (its brother was audiotached at over 28k when I maidened the Quickie100, see the video in that thread), and after straightening the rod I already had a terrific test flight back in the field with the 290 screaming as usual, and the rod survived. Providing the rod is indeed straight, it is mainly exposed to pressing, and not to pulling forces or bending moments that would widen the micro cracks. So those intercrystalline cracks that may have developed when the rod got bent, will hopefully not, or not too soon propagate deeper into the material to lead to a break of the rod..I repaired a 051 rod with a similar rudimentary method (pliers, what else?) and so far that engine thanks for the question, but feels OK.

balogh- Top Poster

Posts : 4959

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Bent 049 conrod repaired

Re: Bent 049 conrod repaired

Thanks András for the logical explanation.

- One recent incident:

- I am reminded of is the implosion of the Titanic site seeing submersible vessel, the Titan, with loss of all occupants including the owner/operator. (My condolences)

As scientists are able to examine the wreckage and deduce probable cause, first thing that crossed my mind was, given the ultra high psi at the extreme depths it encountered, were the nonmetalic carbon fibre pressure vessel main body tube cyclic fatigue resistance exceeded?

Appears there may not be much cyclic fatigue test data available on such a new material yet, as there are with other materials.

Carbon fibre has tremendous strength, but considering the matrix used, is it limited to a small number of cycles, then must be retired?

Answers should be forthcoming sometime future.

GallopingGhostler- Top Poster

Posts : 5724

Join date : 2013-07-13

Age : 70

Location : Clovis NM or NFL KC Chiefs

Re: Bent 049 conrod repaired

Re: Bent 049 conrod repaired

Yes George the carbon fiber pressure bearing parts of the Titan were certainly less elastic than the metal parts, which, under a stress below the yield strength of the material will elastically elongate and regain their original shape when the stress or load is removed. The carbon fiber material is more brittle and if not designed for proper thickness/strength, will crack rather than bend elastically.. I have observed this also with the carbon fiber tubes that I substitute for hardwood or balsa wing spars in most of my planes. They take more load than balsa but if bent beyond a point will crack or buckle sooner than the bend radius a wooden spar will endure.

I read the Titan displayed micro cracks in its carbon fiber pressure bearing parts after a few dives, that finally may have led to the catastrophic propagation of the cracks leading to the implosion of the vessel on its final lethal dive.

I read the Titan displayed micro cracks in its carbon fiber pressure bearing parts after a few dives, that finally may have led to the catastrophic propagation of the cracks leading to the implosion of the vessel on its final lethal dive.

balogh- Top Poster

Posts : 4959

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Bent 049 conrod repaired

Re: Bent 049 conrod repaired

Andrew,

I use medium hot turbo plugs in the Kamtechnik head. No special brand preference, whatever I find in the few hobbyshops that still exist here.

I use medium hot turbo plugs in the Kamtechnik head. No special brand preference, whatever I find in the few hobbyshops that still exist here.

balogh- Top Poster

Posts : 4959

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Bent 049 conrod repaired

Re: Bent 049 conrod repaired

Good work Andras. It is better to try fixing a conrod than paying 19.95 Dollars. I think that conrod didn't bend too much, so no cracks any. Most materials can bend a little amount without any crack.

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Similar topics

Similar topics» B-25 repaired

» Engines repaired

» Can a .049 piston be repaired?

» How I repaired sized engines

» Spacebug-Style Crankshaft Repair

» Engines repaired

» Can a .049 piston be repaired?

» How I repaired sized engines

» Spacebug-Style Crankshaft Repair

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules