Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

Cox Engine of The Month

Cylinder Performance Figures

Page 1 of 1

Cylinder Performance Figures

Cylinder Performance Figures

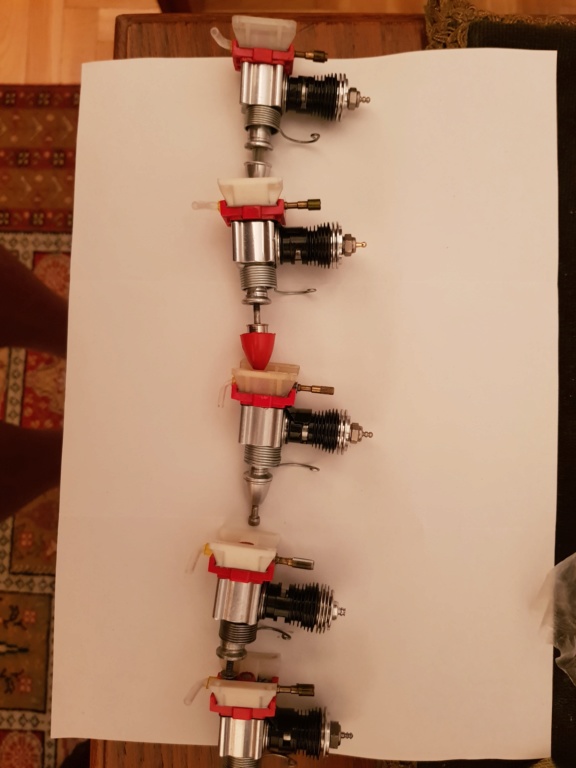

In looking at the various cylinders of the .049/.051

1-2-3-4-5-6-7-8-9-0

We all know the various differences.

#4 &5 2 bypass, 2 booster

#1 old widow 2 bypass

#3 some venom and others 2 bypass 1 booster

and so on and so on.....

Has anyone ever taken each cylinder with identical prop, fuel atmospheric conditions etc and tested each one for the actual performance? This is just curiosity. I know a #4 will kick but and top 19 k in a decent reed valve. Others skilled like Balogh can get mid 25+ with even a lesser cylinder. What are the factors to achieve this higher performance. We all stumble across a mix that does well from time to time. I have used #4 cylinders on reeds and they have really worked excellent. Shame all cylinders weren't that way!

However was really interested to see one by one what difference there REALLY is. If one like the #6 without sub induction what rpm loss would incur over a similar cylinder WITH SPI for example. Is there a chart or someone has stats that show these different performance findings?

Thanks!

Ice

1-2-3-4-5-6-7-8-9-0

We all know the various differences.

#4 &5 2 bypass, 2 booster

#1 old widow 2 bypass

#3 some venom and others 2 bypass 1 booster

and so on and so on.....

Has anyone ever taken each cylinder with identical prop, fuel atmospheric conditions etc and tested each one for the actual performance? This is just curiosity. I know a #4 will kick but and top 19 k in a decent reed valve. Others skilled like Balogh can get mid 25+ with even a lesser cylinder. What are the factors to achieve this higher performance. We all stumble across a mix that does well from time to time. I have used #4 cylinders on reeds and they have really worked excellent. Shame all cylinders weren't that way!

However was really interested to see one by one what difference there REALLY is. If one like the #6 without sub induction what rpm loss would incur over a similar cylinder WITH SPI for example. Is there a chart or someone has stats that show these different performance findings?

Thanks!

Ice

Iceberg- Gold Member

- Posts : 382

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: Cylinder Performance Figures

Re: Cylinder Performance Figures

Hi Darren thanks for referring to my "skills" but honestly I did nothing other than add a Kamtechnik turbo head to my 1974 red postage stamp 190 and it runs crazy rpm-s as seen on my Quickie100 maiden video and audiotached also by Brad aka 1/2A Nut with unloading speeds 28k+ and static 23k on the ground. I am puzzled because all my other 190-s with the same No1 cylinder, Kamtechnik turbo head, APC 4.5X3.5 prop and fuel (60×20×20) do only static 21k-ish on the ground. Rusty suggested the bypass ports on that champ 190 may be a tad deeper than others but my measurement did not show any difference.

All I know is the theory of reed float limiting reedie speeds near 20k does not seem to hold any longer. I have stock star copper reed in all of them.

All I know is the theory of reed float limiting reedie speeds near 20k does not seem to hold any longer. I have stock star copper reed in all of them.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cylinder Performance Figures

Re: Cylinder Performance Figures

Exhaust orientation makes a difference as they in turn positions the

bypass ports in their best arrangement.

If the exhaust ports are fore and aft the bypass ports line up with

the flywheel this helps to push / fling more fuel up thru the bypass

ports / past the piston with more force / flow.

Facing the front of the engine the port on the right gets the lions

share of the assisted flywheel driven fuel flow. If you have a single

bypass port cylinder if able have it on the right side to take advantage

of this secondary function of the flywheel.

Some may have seen enhanced competition car engine cranks have a

swepted channel milled into the flywheel to help guide the fuel / air flow

with more directive authority. With a dremel tool we could grind a bit of

a flow channel to a stock Cox TD crank.

bypass ports in their best arrangement.

If the exhaust ports are fore and aft the bypass ports line up with

the flywheel this helps to push / fling more fuel up thru the bypass

ports / past the piston with more force / flow.

Facing the front of the engine the port on the right gets the lions

share of the assisted flywheel driven fuel flow. If you have a single

bypass port cylinder if able have it on the right side to take advantage

of this secondary function of the flywheel.

Some may have seen enhanced competition car engine cranks have a

swepted channel milled into the flywheel to help guide the fuel / air flow

with more directive authority. With a dremel tool we could grind a bit of

a flow channel to a stock Cox TD crank.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cylinder Performance Figures

Re: Cylinder Performance Figures

I had an email conversation with Bernie at Cox International about this some time ago. He sent me this from Larry Renger, an engineer at Cox along with a follow up by Timothy D. Chapman. I bench tested both cylinder types on the same crankcase on the same day and found that they were right, the cylinder with two boost ports out performed the four boost port version by 500 to 800 rpm using a Cox gray 5-3 and 35% Sig fuel.

From Larry Renger -

"I don’t recall the alloy, but the pistons were hardened and I think the cylinders were not. We found the two boost port version ran higher rpm than four. The reason is that it introduces a swirl to the mix that enhances combustion. Four ports are too symmetrical. This trick was used in the Killer Bee, Tee Dee and Venom. I picked up the hint from the “Two Stroke Tuner’s Handbook”, a long out of print 2-stroke bible.

Larry Renger"

From Timothy D. Chapman -

"Hi,

I think I have it. The reason for the 4-boost port Tee Dees not making as much power as the 2-boost port Tee Dees is probably because the transfer ports expel out the air/fuel mix so close to the exhaust ports, so some of the un-burnt fuel goes straight out the exhaust. The Surestart has only 2 boost ports, AND the main port and the boost port is fairly centered. They (the transfer ports) have about .8 and 1mm on each side of the transfer ports before you run into the exhaust ports on either side. The Tee Dee has 4 boost ports, as well as the main port and it is perfectly centered between the exhaust port, leaving a very small amount of metal (about .4- .5mm) between the upper part of the boost port(s) and the exhaust port.

In the Two-Stroke Tuner's Handbook this is on page 118 and 119 (go by the number at the bottom of the page, not the PDF page numbers) and it is referred to as "short circuiting".

I hope this helps you.

Timothy D, Chapman"

From Larry Renger -

"I don’t recall the alloy, but the pistons were hardened and I think the cylinders were not. We found the two boost port version ran higher rpm than four. The reason is that it introduces a swirl to the mix that enhances combustion. Four ports are too symmetrical. This trick was used in the Killer Bee, Tee Dee and Venom. I picked up the hint from the “Two Stroke Tuner’s Handbook”, a long out of print 2-stroke bible.

Larry Renger"

From Timothy D. Chapman -

"Hi,

I think I have it. The reason for the 4-boost port Tee Dees not making as much power as the 2-boost port Tee Dees is probably because the transfer ports expel out the air/fuel mix so close to the exhaust ports, so some of the un-burnt fuel goes straight out the exhaust. The Surestart has only 2 boost ports, AND the main port and the boost port is fairly centered. They (the transfer ports) have about .8 and 1mm on each side of the transfer ports before you run into the exhaust ports on either side. The Tee Dee has 4 boost ports, as well as the main port and it is perfectly centered between the exhaust port, leaving a very small amount of metal (about .4- .5mm) between the upper part of the boost port(s) and the exhaust port.

In the Two-Stroke Tuner's Handbook this is on page 118 and 119 (go by the number at the bottom of the page, not the PDF page numbers) and it is referred to as "short circuiting".

I hope this helps you.

Timothy D, Chapman"

Dave P.- Gold Member

- Posts : 477

Join date : 2017-07-31

Age : 67

Location : Durham, NC

Re: Cylinder Performance Figures

Re: Cylinder Performance Figures

Now we're getting somewhere. Must even be some more stats out there.

Thank you!

Ice

Thank you!

Ice

Iceberg- Gold Member

- Posts : 382

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: Cylinder Performance Figures

Re: Cylinder Performance Figures

1/2A Nut wrote:Exhaust orientation makes a difference as they in turn positions the

bypass ports in their best arrangement.

If the exhaust ports are fore and aft the bypass ports line up with

the flywheel this helps to push / fling more fuel up thru the bypass

ports / past the piston with more force / flow.

Facing the front of the engine the port on the right gets the lions

share of the assisted flywheel driven fuel flow. If you have a single

bypass port cylinder if able have it on the right side to take advantage

of this secondary function of the flywheel.

Some may have seen enhanced competition car engine cranks have a

swepted channel milled into the flywheel to help guide the fuel / air flow

with more directive authority. With a dremel tool we could grind a bit of

a flow channel to a stock Cox TD crank.

Brad that theory makes a lot of sense..yet it is the one on the top with its exhaust ports almost sideways that runs 23k static/28k unloading while all others including the ones with exhaust at front and aft max out at 21k static.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cylinder Performance Figures

Re: Cylinder Performance Figures

It is based on feedback from a guy that worked at the Cox California location.

Something the engine guys would do when setting up customers TD's for more power.

Many factors influencing the power out of course. Plug type, compression, deck height,

piston and crank fit, heat, drag, reed type, well aligned prop etc. all adds up.

Something the engine guys would do when setting up customers TD's for more power.

Many factors influencing the power out of course. Plug type, compression, deck height,

piston and crank fit, heat, drag, reed type, well aligned prop etc. all adds up.

1/2A Nut- Top Poster

- Posts : 3537

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cylinder Performance Figures

Re: Cylinder Performance Figures

Sure Brad I have also read that cylinder orientation is a means of ramping up power. I am still wondering what may make that marked performance difference in my engines. Near 10% difference in rpm means more than 30% shaft power difference.

.

.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cylinder Performance Figures

Re: Cylinder Performance Figures

Just a question. If you want to orient the ports front to back to hopefully achieve higher flow what washer or spacer works to lock the cylinder when another 1/4 to 1/2 turn remains on thtreads?

. thanks

Ice

. thanks

Ice

Iceberg- Gold Member

- Posts : 382

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: Cylinder Performance Figures

Re: Cylinder Performance Figures

Cox Int'l and Ex Model Engines used to sell "Timing Shims" specifically for raising the cylinder when a muffler was used in an SPI engine. They were a set of three different thickness copper shims. I can't seem to find them currently.

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Cylinder Performance Figures

Re: Cylinder Performance Figures

I cant find the cylinder shims anymore either Oldenginerod. wish I could. I have several engines I need to shim.

Bob

Bob

Basswood- Gold Member

- Posts : 141

Join date : 2020-02-19

Age : 68

Location : Phoenix, Az.

Re: Cylinder Performance Figures

Re: Cylinder Performance Figures

I bought some a while back, not for shimming cylinders, but they were the only source of the correct size copper gaskets I could find to use as Gilbert 7 head gaskets.Basswood wrote:I cant find the cylinder shims anymore either Oldenginerod. wish I could. I have several engines I need to shim.

Bob

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Cylinder Performance Figures

Re: Cylinder Performance Figures

Basswood wrote:I cant find the cylinder shims anymore either Oldenginerod. wish I could. I have several engines I need to shim.

Bob

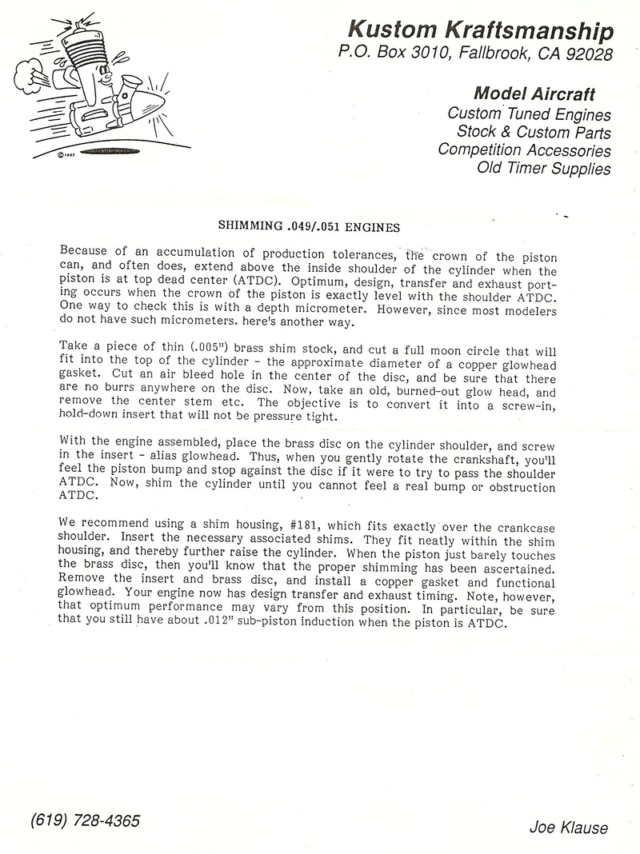

Kustom Kraftsmanship use to make a timing kit years ago. Along with the kit was an instruction sheet on how to use the kit.

I have one kit left that I keep (pristine) so that I can duplicate that same kit (when I need to).

If you look in the attached photo of the original KK kit, it has a brass ring to help installation of the shims onto the cylinder head.

The KK kit had two shims that were .003" thick, one .004" thick, and one .005" thick and were made from copper.

I make my own head shims from copper sheets and a purchased punch sets (english and metric.)

I don't know if I posted how I make my own here or not?

If I haven't, I should.

The punches (the good ones) cost about $200 a set. but you can use those punches to do more than head shims.

I have use then to make shims for the crankshaft to crank housing shims (copper).

Better to use the copper shims on my Tee Dee engines than the "steel" ones, or you can use the phenolic shims as well.

And other projects where I make my own shims for engines/ electric motors.

sosam117

Kustom Kraftsmanship Kit

Kuston Kraftsmanship Instructions

Punch and die for making cylinder head shims.

Punched out copper cylinder head shim

Punched out shim on Cylinder head.

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Cylinder head performance / Cylinder timing

Cylinder head performance / Cylinder timing

Hi Gents,

Some guys in previous posts wished to time there cylinders. I did a posting on how to make your own.

Here is the posting:

https://www.coxengineforum.com/t13946-shimming-cox-cylinder-for-transfer-and-exhaust-timing?highlight=shimming+cylinder+head

Like you, I wish someone would make the cylinder head kits like Kustom Kraftsmanship did years ago.

In the mean time I'll have to make my own.

sosam117

Some guys in previous posts wished to time there cylinders. I did a posting on how to make your own.

Here is the posting:

https://www.coxengineforum.com/t13946-shimming-cox-cylinder-for-transfer-and-exhaust-timing?highlight=shimming+cylinder+head

Like you, I wish someone would make the cylinder head kits like Kustom Kraftsmanship did years ago.

In the mean time I'll have to make my own.

sosam117

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Cylinder Performance Figures

Re: Cylinder Performance Figures

This is really good information. The original timing kits used copper. Is there a way to use maybe neoprene or another material? Where are the .003 .004 and .005 thickness copper and possibly neoprene available? This is to correct incorrect deck height do to running and crowning the piston.

However we were saying even on a new motor the port position and timing might have substantial performance increase?

Thanks

Ice

However we were saying even on a new motor the port position and timing might have substantial performance increase?

Thanks

Ice

Iceberg- Gold Member

- Posts : 382

Join date : 2018-11-03

Location : Suva Fiji Islands

Re: Cylinder Performance Figures

Re: Cylinder Performance Figures

Iceberg wrote:This is really good information. The original timing kits used copper. Is there a way to use maybe neoprene or another material? Where are the .003 .004 and .005 thickness copper and possibly neoprene available? This is to correct incorrect deck height do to running and crowning the piston.

However we were saying even on a new motor the port position and timing might have substantial performance increase?

Thanks

Ice

If you can't get the copper or brass or even aluminum (my Enya .049 / .06 / .08 and .10 use aluminum cylinder head shims).

You can cut them from heavy paper (gasket material).

Cutting the inside hole for the cylinder clearance. Then screw the cylinder onto the crank housing and cut the excess material off around the outside of the cylinder. I have done that as well. The down side is if you take it apart, you'll have to remake them with new ones.

I make my cylinder head shims out of .002", .003", .005", .010", .015", .020", and .025" from flat sheet of copper or brass.

The brass sheets I get at my local hobby shop. You can also get the flat aluminum sheets there as well.

The copper sheets I purchased off the internet.

sosam117

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Cylinder Performance Figures

Re: Cylinder Performance Figures

gtp reed valve engine is rated to 30 000 rpm just two boost port its exaust manifold is part of its performance just sayin cars engine spec ventury jet is capable of 22.000 with prop 6x3 on them no manifold direct exaust no test wit headers for now wil tes more stuf experiment wit cox cars engines

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Similar topics

Similar topics» Super bee rpm figures?

» Cox .010 rpm figures yours and mine

» Anyone know what this item is?

» WTB cox 051 TD cylinder

» i think i have a rare COX item

» Cox .010 rpm figures yours and mine

» Anyone know what this item is?

» WTB cox 051 TD cylinder

» i think i have a rare COX item

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules