Log in

Search

Latest topics

» Roger Harris revisitedby rsv1cox Today at 3:38 pm

» My N-1R build log

by GallopingGhostler Today at 3:04 pm

» Tee Dee .020 combat model

by 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

Cox Engine of The Month

Problems with a "used" Golden Bee -- purchased from RC Groups

Page 1 of 1

Problems with a "used" Golden Bee -- purchased from RC Groups

Problems with a "used" Golden Bee -- purchased from RC Groups

Purchased a good looking Golden Bee (original with #2 cylinder head) and metal backplate.

It looked like it was used very little. No screw/ screwdriver marks on the tank.

Still have a very "Yellow" anodized look to it.

It turned over, nothing was stuck, had a high compression glow head.

Looked at the screws in he back plate. Yes, the screw heads were buggered up, but for the age --ok?

Now, to take it apart to clean it up and rebuild it, cause it looked like it hasn't been apart for a while?

(this is where I should have started to photos of this teardown).

I tried to remove the screws. The wouldn't budge? O.K., I'll use some heat. I could smell the caster oil.

Ok, now try to remove the screws. The heads broke off.

Whom ever had this engine, used epoxy to help seal the holes around the screws.

The heads of these screws were not Cox engine type screws. Probably why epoxy was used?

(this is where the photos of this problem would have been useful)

Well the good part was with the heads of the screws broken off, I can just remove the tank.

The tank wasn't coming off, nor was it able to rotate?

Alright, maybe some more caster oil "goo" holding the tank onto the back plate?

I used heat again on the engine on the fuel tank. Started smelling that caster oil smell.

Using a pair of pliers on the backplate and a strap on the tank I was able to get them apart.

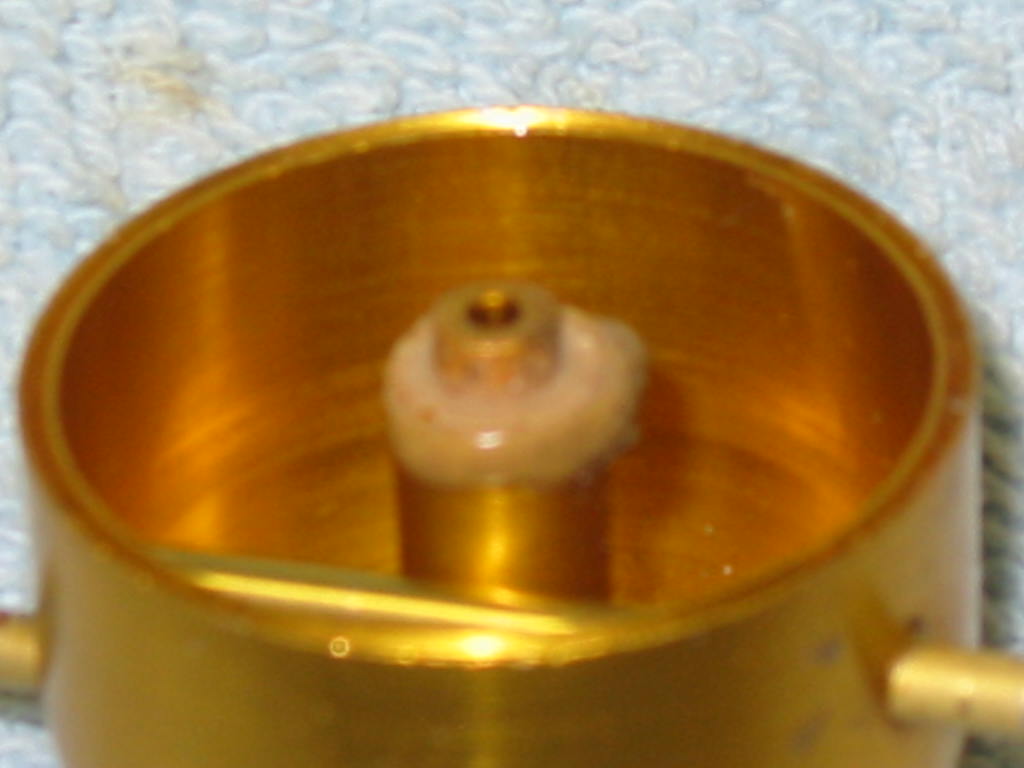

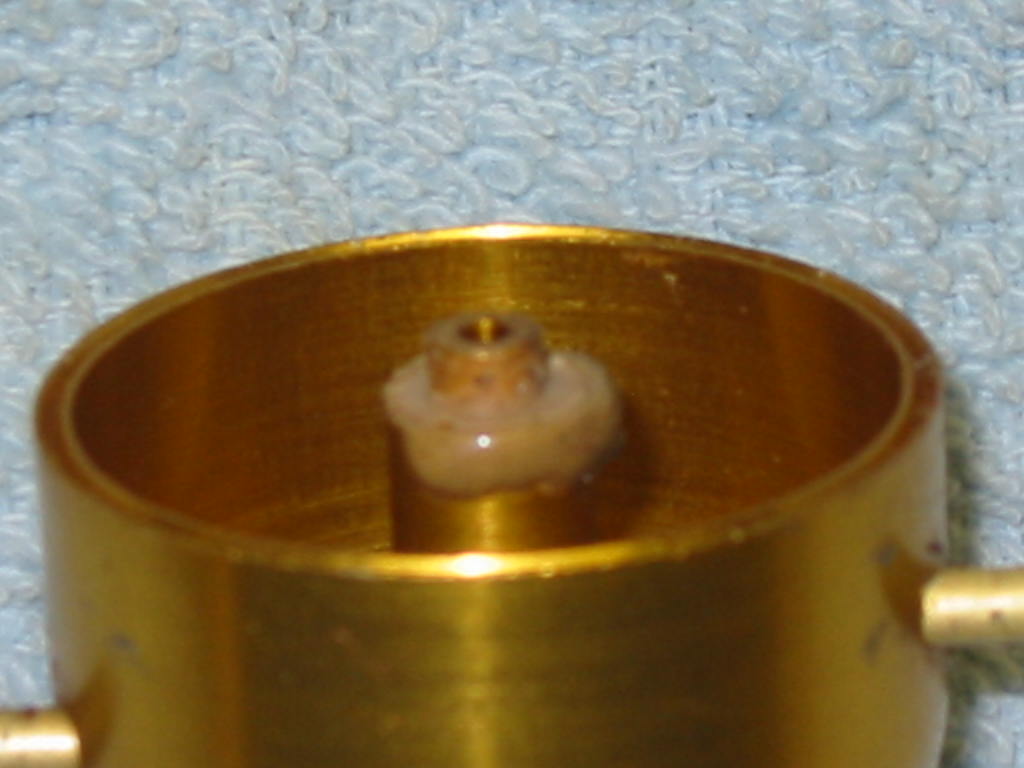

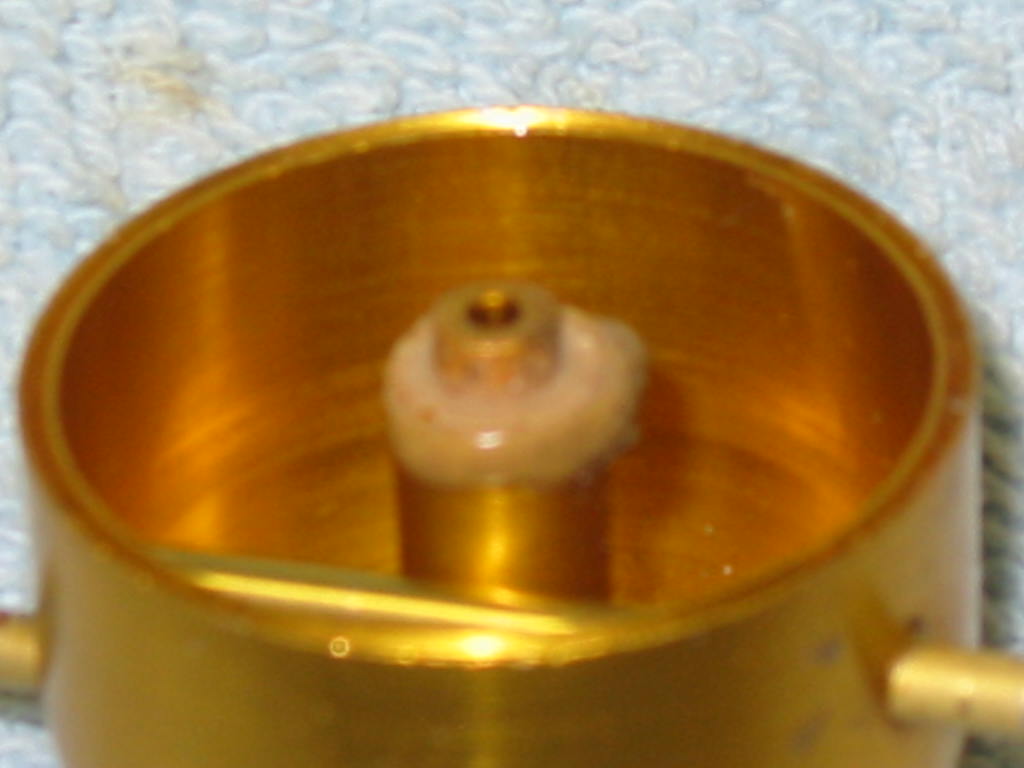

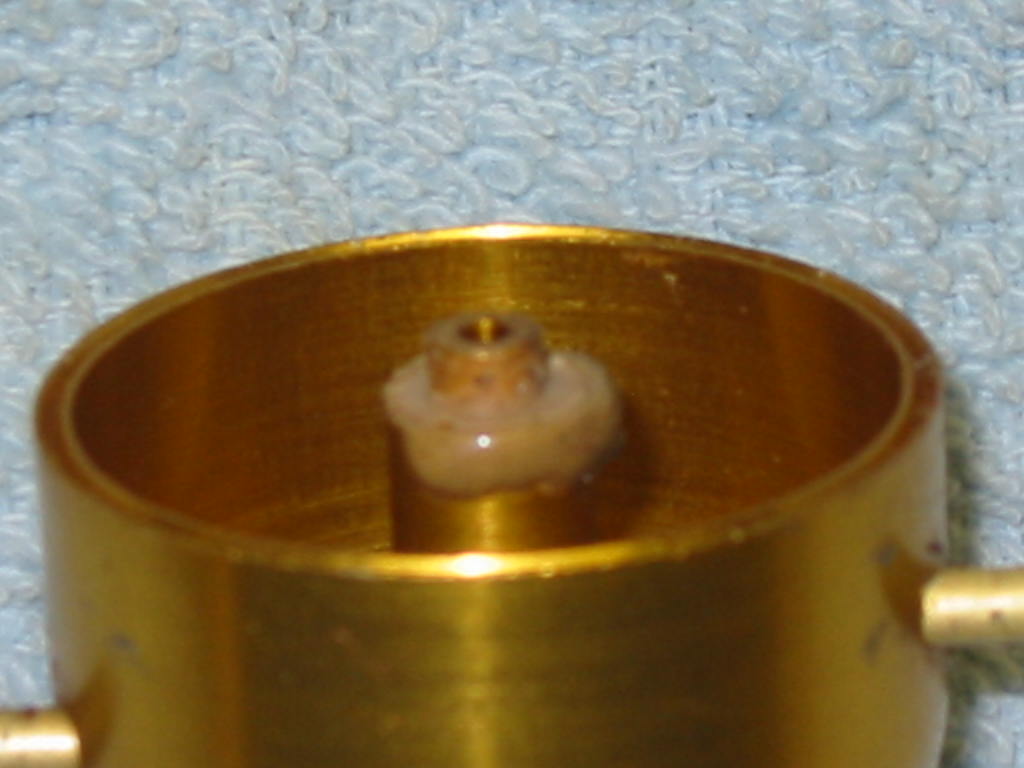

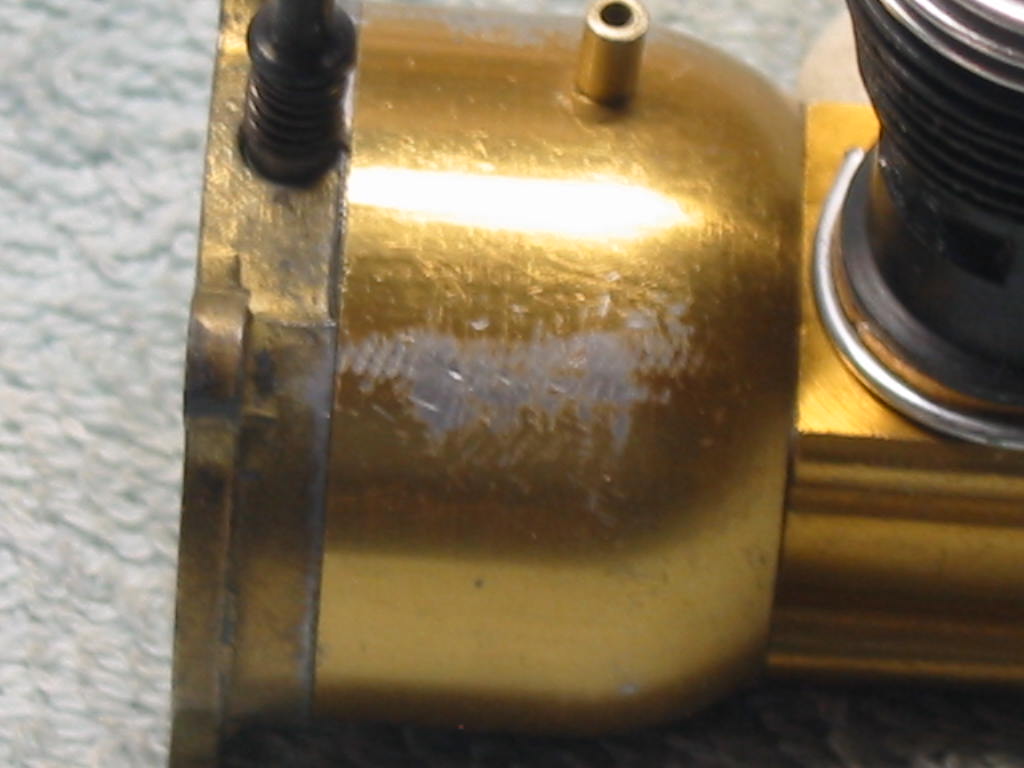

What I found amazed me. The previous owner used epoxy instead of the rubber gasket to seal the venturi tube to the backplate.

(this time I took the time to get the camera and take photos)

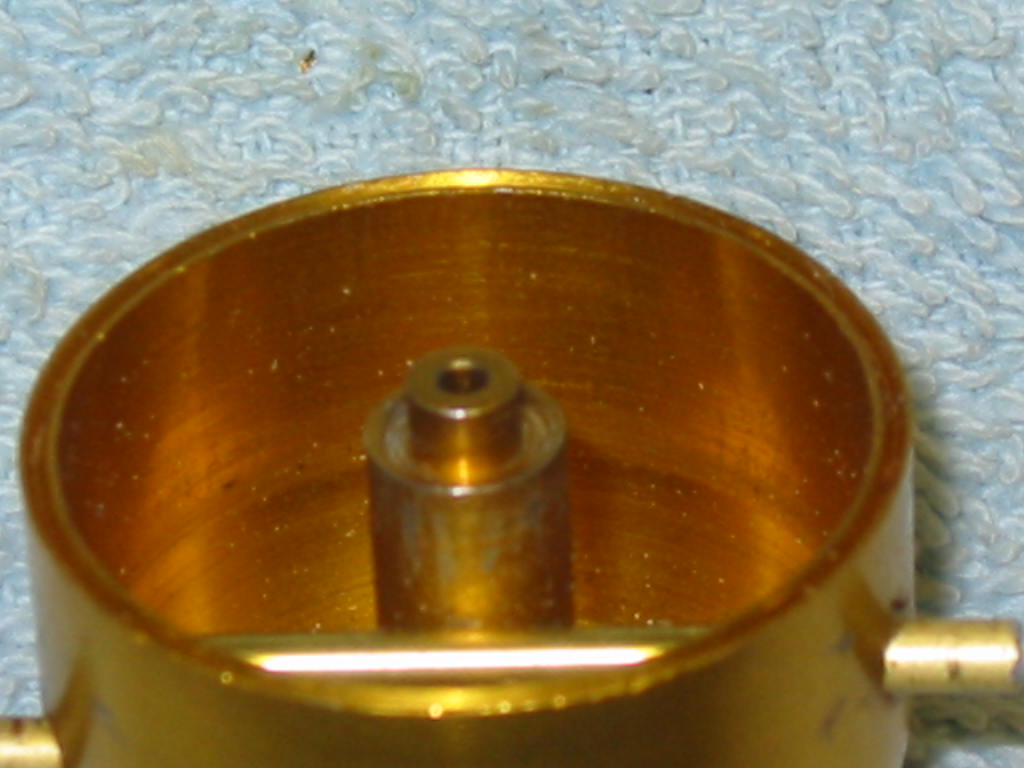

After about a 1/2 hour of work to carefully remove the epoxy from the venturi area. (not to create any burrs) I was able to remove all of the epoxy.

One thing I still had to address were the broken screws that were still sticking out of the crankcase.

Again using heat I was able to remove three of the four screws.

The 4th screw sheared off even with the crankcase.

What I did was to carefully (using my Dremel)cut the screw even with the back of the crankcase.

Using my MiniMax drill/lathe, drilled out the broken shaft of the screw so I can re-tap it.

Then, re-tapping the hole I was able to save the crankcase housing.

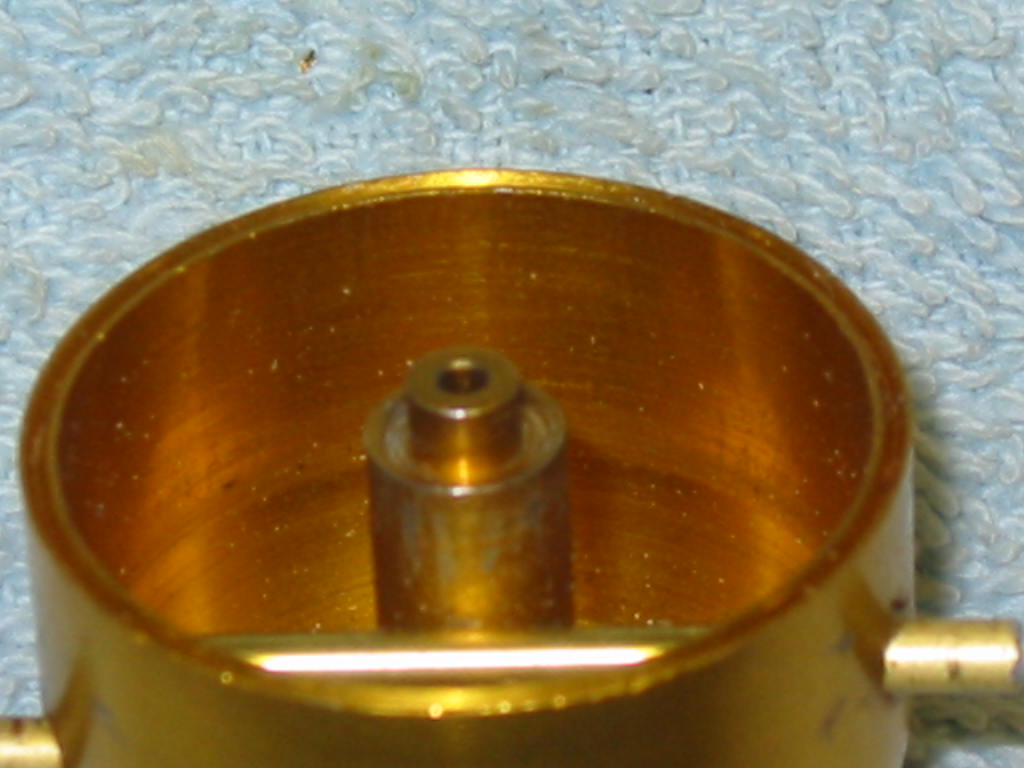

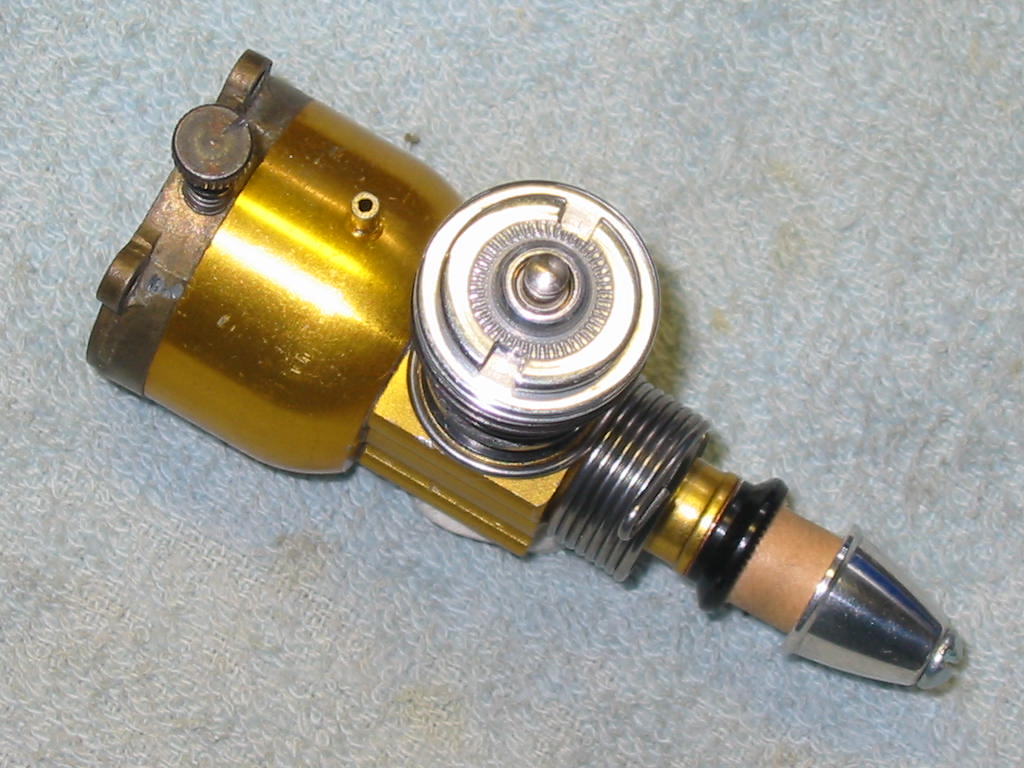

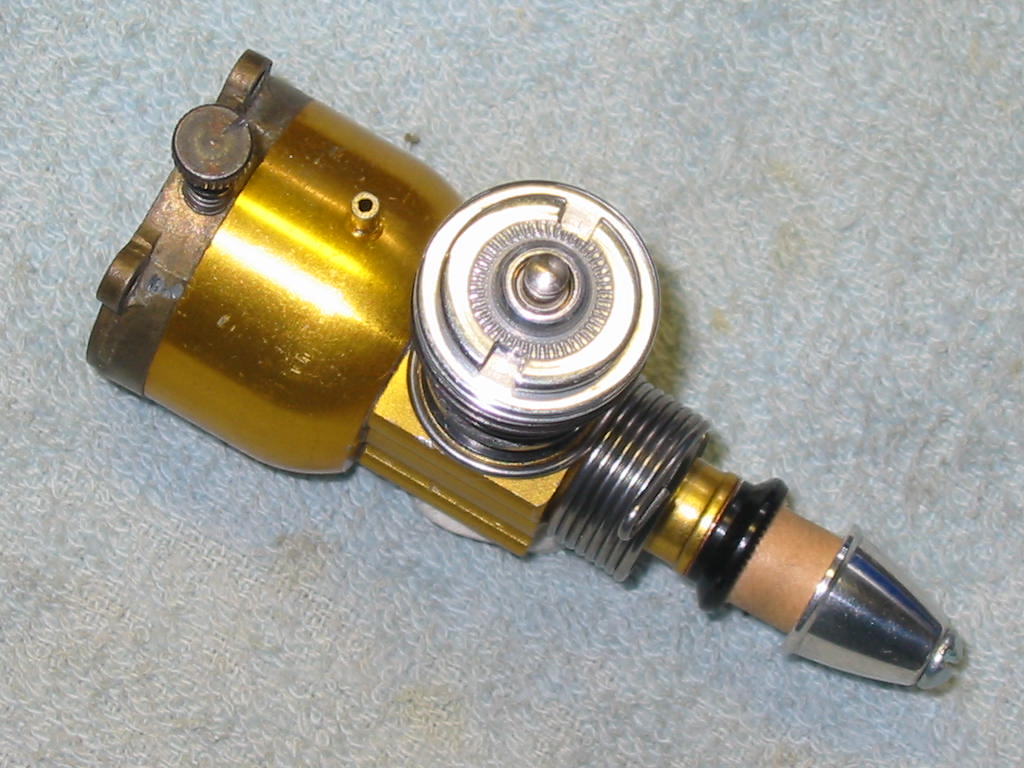

Here are the finished photos of the rebuilt Cox 049 Golden Bee.

It looked like it was used very little. No screw/ screwdriver marks on the tank.

Still have a very "Yellow" anodized look to it.

It turned over, nothing was stuck, had a high compression glow head.

Looked at the screws in he back plate. Yes, the screw heads were buggered up, but for the age --ok?

Now, to take it apart to clean it up and rebuild it, cause it looked like it hasn't been apart for a while?

(this is where I should have started to photos of this teardown).

I tried to remove the screws. The wouldn't budge? O.K., I'll use some heat. I could smell the caster oil.

Ok, now try to remove the screws. The heads broke off.

Whom ever had this engine, used epoxy to help seal the holes around the screws.

The heads of these screws were not Cox engine type screws. Probably why epoxy was used?

(this is where the photos of this problem would have been useful)

Well the good part was with the heads of the screws broken off, I can just remove the tank.

The tank wasn't coming off, nor was it able to rotate?

Alright, maybe some more caster oil "goo" holding the tank onto the back plate?

I used heat again on the engine on the fuel tank. Started smelling that caster oil smell.

Using a pair of pliers on the backplate and a strap on the tank I was able to get them apart.

What I found amazed me. The previous owner used epoxy instead of the rubber gasket to seal the venturi tube to the backplate.

(this time I took the time to get the camera and take photos)

After about a 1/2 hour of work to carefully remove the epoxy from the venturi area. (not to create any burrs) I was able to remove all of the epoxy.

One thing I still had to address were the broken screws that were still sticking out of the crankcase.

Again using heat I was able to remove three of the four screws.

The 4th screw sheared off even with the crankcase.

What I did was to carefully (using my Dremel)cut the screw even with the back of the crankcase.

Using my MiniMax drill/lathe, drilled out the broken shaft of the screw so I can re-tap it.

Then, re-tapping the hole I was able to save the crankcase housing.

Here are the finished photos of the rebuilt Cox 049 Golden Bee.

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

That’s a nice early 70’s GB, you did excellent work. That was quite a bodge done by some PO.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

Gives a new meaning to the concept of threadlocker.

Looks good.

Phil

Looks good.

Phil

pkrankow- Top Poster

- Posts : 3025

Join date : 2012-10-02

Location : Ohio

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

Cribbs74 wrote:That’s a nice early 70’s GB, you did excellent work. That was quite a bodge done by some PO.

Originally I payed $45.00 for it (plus shipping -- total= $53.00)

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

Fabulous recovery! I would love to see a picture of your milling machine just to see how you managed to fit a puny engine in it. Can you re-bush cases with it too?

_________________

Never enough time to build them all...always enough time to smash them all!

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

Great save on a pretty nice looking Golden Bee.

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

Great job on giving this engine a new chance at life!

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

944_Jim wrote:Fabulous recovery! I would love to see a picture of your milling machine just to see how you managed to fit a puny engine in it. Can you re-bush cases with it too?

It's a combination of a milling machine and a lathe.

The height is 14 inches (bed to mill head) and the length is 30 inches.

My dad had it before me. I inherit the MiniMax from him when he passed away in 2001.

In the photo you have the on/off switch. Top white button on, middle turns the spindle on, Red button emergency stop.

Below that is a toggle lever to increase or decrease the motor speed on both motors.

The long lever to the right is the "high/low" gear selector.

To turn on the milling head, there is a switch on the back of the motor. (square looking box on the back of the motor)

It is a good "hobby" lathe/mill for doing small stuff and some minor home repairs.

My dad and I have done interesting stuff on it and trying to get stuff done on it that probably shouldn't have?

We have had it for close to 40 years.

Down side is the dials don't "zero" out. It's in inch ( I like working in metric more --- 25.4mm= 1 inch)

The mill stop is just a threaded nut that you just screw down to where you think it should stop

and lock it with the other nut that is behind that nut. The tail stock is a guess as well. No measurements on the spindle.

One turn on the tail stock is approximately 1/4"

No way to do any threading on this. Everything is done by hand (hand feeding - turn the wheel)

Here is a photo of it.

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

Admin wrote:Great save on a pretty nice looking Golden Bee.

This Golden Bee will help out my original Golden Bee that I got for a Christmas present (back in 1972 -- I was 13 yrs. old)

along with a Carl Goldberg Lil' Jumpin Bean kit. (from my dad --rip)

Here's photos of my cleaned up 1972 Golden Bee.

It has been mounted into many planes over its life time.

Last plane it was in was an Airtronics S-Tee with an EK Logictrol radio.(a month ago -- stuck and dirty)

Notice the screw markings on the tank and scratches --- no yellow anodizing.

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

Good looking Golden Bees, the both of them. I especially

like the thin wall #2 on the second bee.

Thanks for sharing.

Bob

like the thin wall #2 on the second bee.

Thanks for sharing.

Bob

dckrsn- Diamond Member

- Posts : 2750

Join date : 2010-10-21

Age : 71

Location : Long Island, New York

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

Glad you were able to work things out with that engine. The Golden Bee's have always been a favorite of mine. I like your MiniMax machine. Nice to have that.. even with the shortcomings you pointed out. The Unimat and Smithy are machines that I believe are similar to yours.

Nice job on the engine. Do you plan to run it with that H/C glowhead?

Nice job on the engine. Do you plan to run it with that H/C glowhead?

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

Re: Problems with a "used" Golden Bee -- purchased from RC Groups

roddie wrote:Glad you were able to work things out with that engine. The Golden Bee's have always been a favorite of mine. I like your MiniMax machine. Nice to have that.. even with the shortcomings you pointed out. The Unimat and Smithy are machines that I believe are similar to yours.

Nice job on the engine. Do you plan to run it with that H/C glowhead?

The high compression head is what came with it when I purchased it.

I have always use a standard glow head (with no problems).

With the MinMax machine I have learned to work with and work around its short comings.

It gets the small jobs I want to do, get them done.

I have friends that come over and have "little projects" that they would like me to do on my MiniMax.

I've done replacement contra-pistons for diesel engines.

Bore out old engines crank cases to re-sleeve them with a new oil-lite bearing (and ream them to size to accept the old crankshaft.).

Made special venturi for engines (out of production). The latest, I made a fuel tank for an old McCoy 049 diesel from aluminum because the original was missing.

And many other projects.

They're luck I don't charge them like a small machine shop would? They supply the material, throw me some money or item that I like my way and I'll do the job (if I like it?)

sosam117- Diamond Member

- Posts : 1350

Join date : 2016-03-23

Location : Suburb of Chicago, Illinois

Similar topics

Similar topics» "Racket Is Golden" Bernie's Backplate on a Golden Bee

» Tee Dee flooding problems

» Test Report - Babe Bee & Golden Bee

» new reed fit problems

» Cox PeeWee .020 Problems

» Tee Dee flooding problems

» Test Report - Babe Bee & Golden Bee

» new reed fit problems

» Cox PeeWee .020 Problems

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules