Log in

Search

Latest topics

» Tee Dee .020 combat modelby roddie Today at 1:34 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

Cox Engine of The Month

My crank said No!

Page 1 of 1

My crank said No!

My crank said No!

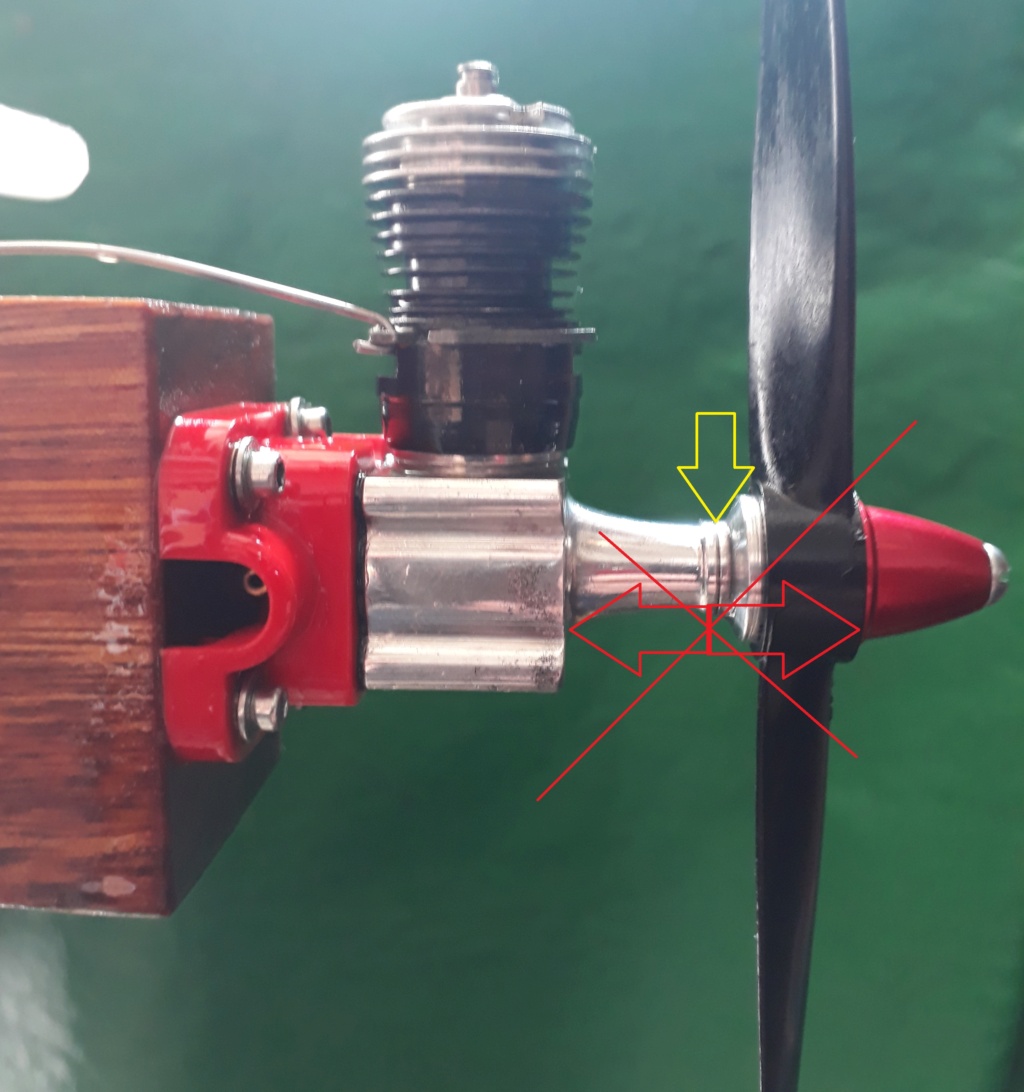

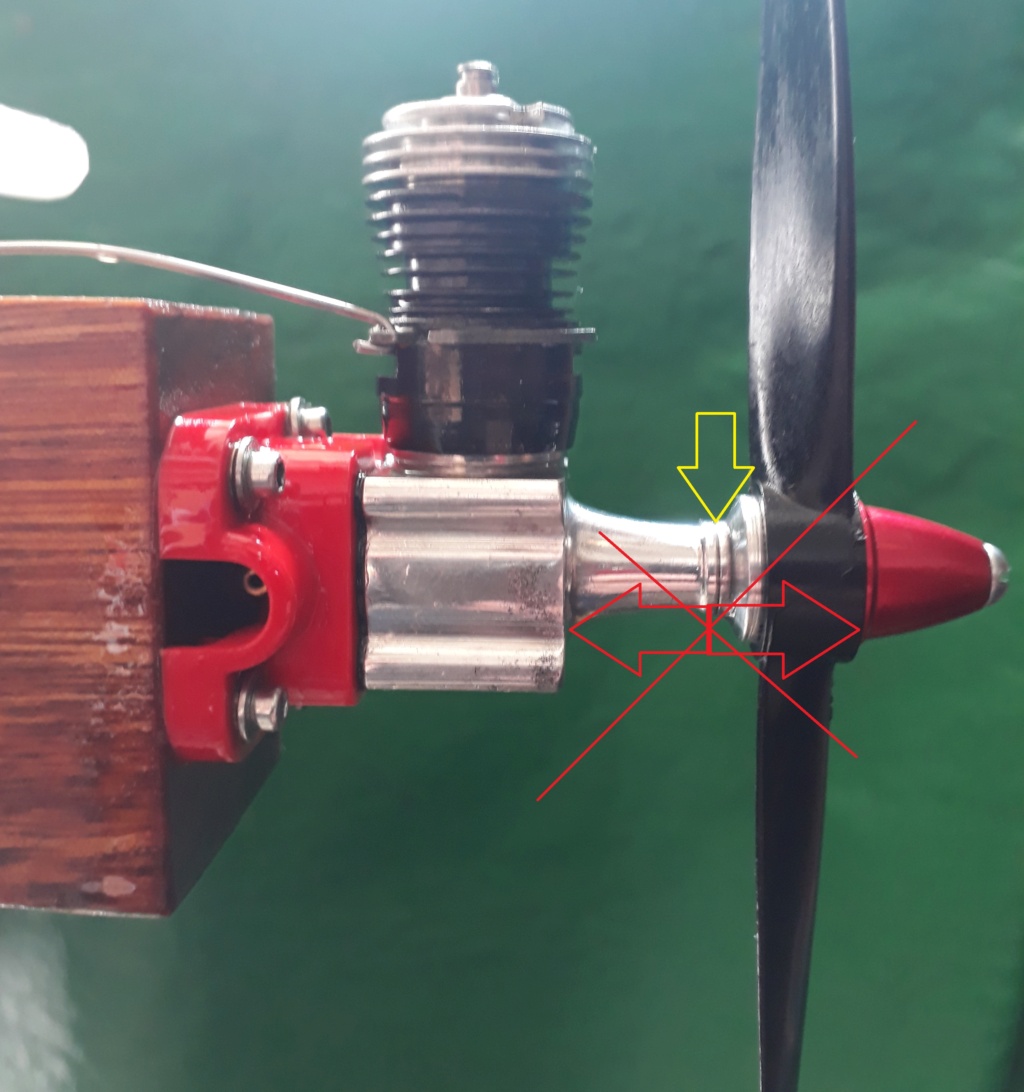

The crank of one of my red postage stamp backplate reedie surrendered mid-air today while spinning the APC 4.5x3.5 in the nose of the Quickie100 at higher than 24k rpm...Kamtechnik turbo head and 20% nitro tickled the engine to run so fast.

The exploded grits of the crank KO-d the reed and the backplate too. Luckily I have a few spare parts of such reedies in the waiting so I could quickly snap parts back and put the reedie on the plane.

The exploded grits of the crank KO-d the reed and the backplate too. Luckily I have a few spare parts of such reedies in the waiting so I could quickly snap parts back and put the reedie on the plane.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

rsv1cox- Top Poster

Posts : 11247

Join date : 2014-08-18

Location : West Virginia

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: My crank said No!

Re: My crank said No!

What method did you use to center the:

Prop

Stock spinner - tends to shift when tightened.

Prop

Stock spinner - tends to shift when tightened.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: My crank said No!

Re: My crank said No!

Hi Andras, I’m glad that your airplane wasn’t damaged as a result.. and I’m glad that you have spare-parts to rebuild the engine.

Was the crank a stock unit? I apologize if you outlined the engine-specs. in a previous thread. I’ve been absent from the attention that I’d been paying here.

28,000 RPM is really cookin’….. I hadn’t thought that the old-style beryllium star-shape reed would keep a beat to that tune! I have quite a few of those reeds. They’re all .049 size. I have not one Cox .020 engine.

Where the whole inner-journal separated; as opposed to the crank-pin.. it seems like a “fluke” (might never happen again..) rather than something that could have been prevented. On the other hand (she wore a glove..) the design-rpm of the engine is well below what you were achieving. We can only imagine what a near-perfectly balanced engine and flywheel could sustain.. but none of us want's to break parts.. just records.

Hey.. the best racing engines in the world blow-up sometimes.

Was the crank a stock unit? I apologize if you outlined the engine-specs. in a previous thread. I’ve been absent from the attention that I’d been paying here.

28,000 RPM is really cookin’….. I hadn’t thought that the old-style beryllium star-shape reed would keep a beat to that tune! I have quite a few of those reeds. They’re all .049 size. I have not one Cox .020 engine.

Where the whole inner-journal separated; as opposed to the crank-pin.. it seems like a “fluke” (might never happen again..) rather than something that could have been prevented. On the other hand (she wore a glove..) the design-rpm of the engine is well below what you were achieving. We can only imagine what a near-perfectly balanced engine and flywheel could sustain.. but none of us want's to break parts.. just records.

Hey.. the best racing engines in the world blow-up sometimes.

Re: My crank said No!

Re: My crank said No!

It died doing what it does best! Glad you have spares. With a stock crank it was bound to happen eventually. Hope you are back in the air soon!

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: My crank said No!

Re: My crank said No!

Thank you all!

Except for the Kamtechnik turbo head, all stock parts. Thin wall 2-bypass cylinder from the 1960's. I centered the prop with a piece of fuel line pulled over the prop stud and there was no vibration. I know this rpm was abusive to the stock crank but some reedies like the Black Widow generate more torque and do not break the crank..the flywheel that broke looks like that of a stock TeeDee which is a way more powerful engine...but thinner

Looks like a fatigue break of some brittle material..the way it broke simetrically on the 2 sides of the crankpin tells me the piston must have been at TDC with cylinder pressure at its peak.

Anyway I was kind of expecting this but as Cribbs74 said it died of what it is doing best: outstanding performance...

Here is the TeeDee flywheel that is much thicker..

Except for the Kamtechnik turbo head, all stock parts. Thin wall 2-bypass cylinder from the 1960's. I centered the prop with a piece of fuel line pulled over the prop stud and there was no vibration. I know this rpm was abusive to the stock crank but some reedies like the Black Widow generate more torque and do not break the crank..the flywheel that broke looks like that of a stock TeeDee which is a way more powerful engine...but thinner

Looks like a fatigue break of some brittle material..the way it broke simetrically on the 2 sides of the crankpin tells me the piston must have been at TDC with cylinder pressure at its peak.

Anyway I was kind of expecting this but as Cribbs74 said it died of what it is doing best: outstanding performance...

Here is the TeeDee flywheel that is much thicker..

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: My crank said No!

Re: My crank said No!

Thanks Brad I have this Killer Bee combo on my Lil Roughneck. It is really strong but I somehow find the anodized cases a bit loose on the shaft fit. New cases and cranks show a bit of wobble on the prop end..

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: My crank said No!

Re: My crank said No!

Yeah i know what your saying with the wobble got two CC,s new some time back that have soo much play they want run

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: My crank said No!

Re: My crank said No!

My anodized crankcases run but I see fuel squirting at the drive plate. I checked if it was some wear because of unbalanced props but even the anodization inside the crankcase front is untouched..so I believe the stock fit is loose, and the radially unsupported shaft may lead to constant vibration and self destruction even if the prop is balanced?

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: My crank said No!

Re: My crank said No!

balogh wrote:Thanks Brad I have this Killer Bee combo on my Lil Roughneck. It is really strong but I somehow find the anodized cases a bit loose on the shaft fit. New cases and cranks show a bit of wobble on the prop end..

They were designed by Cox to be a bit looser on the fit for the Killer Bee crank, but I have considered altering this on future production runs.

Re: My crank said No!

Re: My crank said No!

Thanks Matt..I could not agree more!

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: My crank said No!

Re: My crank said No!

Andras, how are you dear friend !?

I want to give you a little advice, when an engine is going to be subjected to many revolutions, even above the standard, you have to check the longitudinal displacement of the crankshaft.

If there is a minimum movement back and forth (in most there is), you must eliminate it by placing a supplement steel washer and make it NOT move more.

The high rpm plus that displacement, generate this type of risk to which your engine ended up damaged.

If you eliminate that offset and fit a perfectly balanced propeller, then that kind of breakage shouldn't occur.

I want to give you a little advice, when an engine is going to be subjected to many revolutions, even above the standard, you have to check the longitudinal displacement of the crankshaft.

If there is a minimum movement back and forth (in most there is), you must eliminate it by placing a supplement steel washer and make it NOT move more.

The high rpm plus that displacement, generate this type of risk to which your engine ended up damaged.

If you eliminate that offset and fit a perfectly balanced propeller, then that kind of breakage shouldn't occur.

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: My crank said No!

Re: My crank said No!

Thank you Mauricio. I fully agree with you the small axial and radial play of the shaft are important for the lasting performance of these engines. Once I see the castor carries aluminum particles, I immediately inspect the the engine.

The crank and the case on this vintage CoX was and -with the new shaft - is as new..I think that as Roddie pointed out, there may have been some internal material fault in the flywheel..the close up photo I posted a few entries up shows brittle surface with maybe some "flakes".

But I must admit the crank failure at 24k+ rpm in these stock engines should not surprise me as that us a real excessive load..

The crank and the case on this vintage CoX was and -with the new shaft - is as new..I think that as Roddie pointed out, there may have been some internal material fault in the flywheel..the close up photo I posted a few entries up shows brittle surface with maybe some "flakes".

But I must admit the crank failure at 24k+ rpm in these stock engines should not surprise me as that us a real excessive load..

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: My crank said No!

Re: My crank said No!

The main cause of this game is to use the starter at the beginning of the engines.

I generally start my engines by finger, that is to say by hand,

From my .020 to any engine displacement, I do it by hand.

I only use the original starter spring on the Cox .010.

I use the starter in case there is no other remedy for a casual matter. otherwise I do not recommend its use.

Note: that game is usually of origin, but it is further aggravated with the use of the starter.

I generally start my engines by finger, that is to say by hand,

From my .020 to any engine displacement, I do it by hand.

I only use the original starter spring on the Cox .010.

I use the starter in case there is no other remedy for a casual matter. otherwise I do not recommend its use.

Note: that game is usually of origin, but it is further aggravated with the use of the starter.

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: My crank said No!

Re: My crank said No!

Totally agree Mauricio. I use spring starter on 049 reedies. I start my 010 and 020 TeeDees by just bumping the crank with the electric starter, as it slows down after I disengaged the starter button. So I try to save the stock axial gap between the crankcase front and the drive plate as much as I can.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: My crank said No!

Re: My crank said No!

Here is a useful article about steel defects, such as carbide non uniformity:

https://www.machinemfg.com/types-of-steel-defects/

https://www.machinemfg.com/types-of-steel-defects/

Levent Suberk- Diamond Member

- Posts : 2265

Join date : 2017-12-24

Location : Türkiye

Re: My crank said No!

Re: My crank said No!

It hapen To me wit dieselised 049 tink its just To mutch presure on crank pin wit hd crank it last litle longer yes is litle loose in some crankcase try swan nek type wit hd crank aluminium tank Reed valve Reed valve clearence wit crank and rod is smaler gap bether score aluminium back plate wit piston rod plastiques back plate is very loose some crankcase made difrent

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: My crank said No!

Re: My crank said No!

Tink use of that deflector is just giving play and rod slip of is slot in crank case at tdc rod can slip of the track inside crank Not the crank play it self back plate have To retain rod on track next build watch for rod play wit inside back plate is wat it look To me

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: My crank said No!

Re: My crank said No!

Thanks David interesting observation about the deflector plate..but I believe the axial play of the shaft is determined by the position of the prop drive plate and not the position of the backplate, which in my opinion should not be reached by the crankpin. If the cranking touches the backplate then a washer must be placed between the drive plate and crankcase to reduce the play..

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: My crank said No!

Re: My crank said No!

Not the crank play is the conrod just To loose back and fort inside it can slip of the track inside crank case back plate have To retain conrod on its crank pin Not the crank pin it self lets say rod can go just litle of the crank pin and Not pas the grove inside and toutch back plate without faling of track or crank pin... crankchaft now som play is ok no play at al is just enlarge the gap inside plus use of schim like that deflector on back plate nead crankcase adjustment for right clerance with conecting rod.... note the swan neck crankcase is To be used wit aluminium tank wit thimbledrome righting on tink red postale back plate use difrent crankcase Bolt hole inside is deaper litle in som crankcase is wy som just cut Bolt right lenght after sanded down the crankcase To right back plate space wit con rod hope u figure litle bether m'y long explication sory is is stil hard wit m'y translate programme just want To help m'y best hope it work for u nex time

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: My crank said No!

Re: My crank said No!

Thank you Dave I got you!

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Similar topics

Similar topics» Wanted: Tee Dee .049 crank case and crank

» TD 049 crank mod

» 049 crank vs. 051 crank

» Finished cleaning the chopper engine (baby bee)

» Pee Wee 020 crank shafts the same?

» TD 049 crank mod

» 049 crank vs. 051 crank

» Finished cleaning the chopper engine (baby bee)

» Pee Wee 020 crank shafts the same?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules