Log in

Search

Latest topics

» Tee Dee .020 combat modelby roddie Today at 1:34 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

Cox Engine of The Month

Cylinder Porting

Page 1 of 2

Page 1 of 2 • 1, 2

Cylinder Porting

Cylinder Porting

I have a few blank cylinders that need porting. Waiting listening and learning before I attempt cutting the ports. I do have the capability and tools to machine the ports. Any one with experience with the Kustom Kraftsmanship single port Tee Dees? How well do they perform?

coxaddict- Gold Member

- Posts : 429

Join date : 2013-01-27

Location : north shore oahu, Hawaii

Re: Cylinder Porting

Re: Cylinder Porting

Uaooo! This a very interesting question also from my side! I hope for detailed answer from cox engine experts

franzkleber- Moderate Poster

- Posts : 24

Join date : 2016-01-29

Age : 60

Re: Cylinder Porting

Re: Cylinder Porting

I will add something until an expert answers. My flying buddy had a shnuerle TD motor made. Not KK brand though. An exhaust tube was brazed on the back for a pipe. Pretty sure he had the Canadian record for 1/2A control line speed for a while. Over 100 mph with lots of nitro at that time. From what I recall, the cylinder wore out fairly fast, and a new piston was installed to get the compression back for a short time. The cylinder is what wore out. It was revving fairly high for a steel piston. We then went to ABC motors which were coming out at that time. Stels, VA, Norvels and CS. I have been thinking of blocking the exh. port of a B Bee cylinder and making it into a schneurle. Something just to try. I doubt there would be much if any boost in power. Another friend machined a few spare cylinders with a bunch of shapes and sizes and they all performed similarly. IIRC he used an indexing fixture and screwed the cylinder on to another cylinder with the fins turned down to fit accurately in the 5C collet. We had some cylinders that were already turned down for some tight cowls on some speed models.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Cylinder Porting

Re: Cylinder Porting

hi y have particular cylinder prototype in mind can draw a raw picturs of wat tink can work lets start explain how and wy tink 3 bypas single exaust port on bypas is it posible for u too machine to make boost port on eatch bypas mesurments of inside is hard for me to mesur use spec from venom bypas boost port not sur 3or 6 boost port like idea of 1 eatch

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Cylinder Porting

Re: Cylinder Porting

very crude way to explain my desing just copy inside venom boost port hight lenght size then copy 3 of them inside no spi for tuned pipe with spi for direct exaust use wasp .074 carb to get right fuel ratio hope u made som insane fast setup

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Cylinder Porting

Re: Cylinder Porting

I have practiced milling a second port on number 2 cylinders varying port timing with mixed results I also used carbide bits with 30 degree chamfer whereas the stock port seems to be made with a ball mill. Maybe this would create more swirl in the combustion chamber. I planned on welding one exhaust port and have some carbon rods to insert into the bore to prevent the weld material from entering the bore. Don't know if the cylinder would warp from the heat. Silver solder would be used. This all got put in the back burner when I became ill six months ago.

I have practiced milling a second port on number 2 cylinders varying port timing with mixed results I also used carbide bits with 30 degree chamfer whereas the stock port seems to be made with a ball mill. Maybe this would create more swirl in the combustion chamber. I planned on welding one exhaust port and have some carbon rods to insert into the bore to prevent the weld material from entering the bore. Don't know if the cylinder would warp from the heat. Silver solder would be used. This all got put in the back burner when I became ill six months ago.

coxaddict- Gold Member

- Posts : 429

Join date : 2013-01-27

Location : north shore oahu, Hawaii

Re: Cylinder Porting

Re: Cylinder Porting

just use piston inside cylinder after from outside exaust place som material prior the weld then heat cylinder befor weld use mig witout gas very low amp tic tac not continous weld dont go to far just block heather wil retain rest

davidll1984- Diamond Member

- Posts : 2327

Join date : 2020-02-12

Age : 39

Location : shawinigan

Re: Cylinder Porting

Re: Cylinder Porting

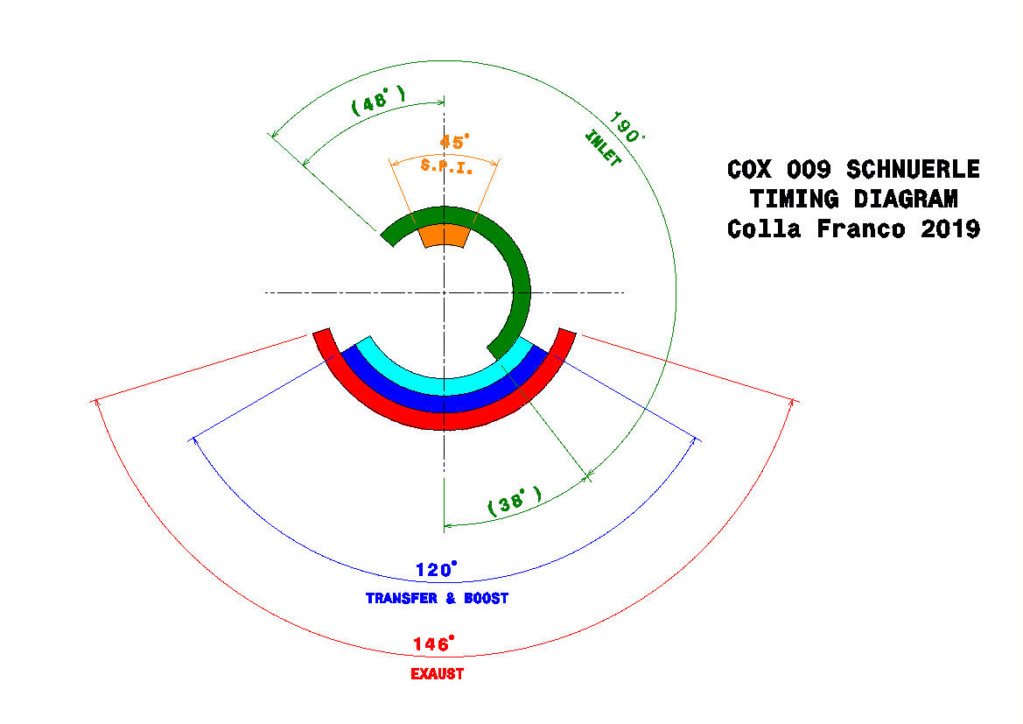

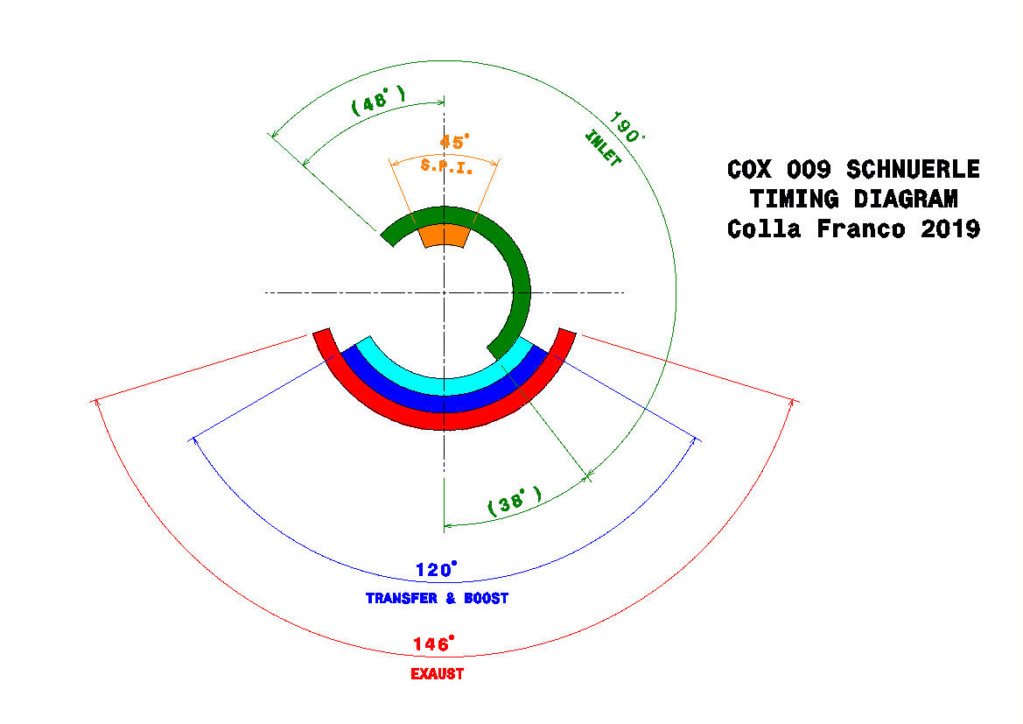

Hi everyone

I have always been interested in this topic on engines, it would be great to see the original construction drawings of the TD models .

I started a job last year but I was unable to carry it out , i had measured a TD 009 and drawn it as faithfully as possible in 3D.

Then taken from the impetus I designed a schnuerle variant based on the few fragmentary news and blurred photos that I found on the net adding something of my personal taste.

The result is what you can see in the attached images, only that making drawings is easy, building the pieces is a whole other story and of course I'm not sure this cylinder works properly.

I hope sooner or later to find the time to complete this small project , the displacement of 1.5 cc is my favorite but I must confess that for some time now I have been thinking of going down to 1 / A because these small 0.049 wasps impress me with their specific power.

I have always been interested in this topic on engines, it would be great to see the original construction drawings of the TD models .

I started a job last year but I was unable to carry it out , i had measured a TD 009 and drawn it as faithfully as possible in 3D.

Then taken from the impetus I designed a schnuerle variant based on the few fragmentary news and blurred photos that I found on the net adding something of my personal taste.

The result is what you can see in the attached images, only that making drawings is easy, building the pieces is a whole other story and of course I'm not sure this cylinder works properly.

I hope sooner or later to find the time to complete this small project , the displacement of 1.5 cc is my favorite but I must confess that for some time now I have been thinking of going down to 1 / A because these small 0.049 wasps impress me with their specific power.

franzkleber- Moderate Poster

- Posts : 24

Join date : 2016-01-29

Age : 60

Re: Cylinder Porting

Re: Cylinder Porting

franzkleber wrote:Hi everyone

I have always been interested in this topic on engines, it would be great to see the original construction drawings of the TD models .

I started a job last year but I was unable to carry it out , i had measured a TD 009 and drawn it as faithfully as possible in 3D.

Then taken from the impetus I designed a schnuerle variant based on the few fragmentary news and blurred photos that I found on the net adding something of my personal taste.

The result is what you can see in the attached images, only that making drawings is easy, building the pieces is a whole other story and of course I'm not sure this cylinder works properly.

I hope sooner or later to find the time to complete this small project , the displacement of 1.5 cc is my favorite but I must confess that for some time now I have been thinking of going down to 1 / A because these small 0.049 wasps impress me with their specific power.

So it looks like what you are showing is the cuts need to be made at an angle? I no speak Italiano. No disrespect meant. The drawings are in Italian, I presume, and I am guessing at what they say. Length, width measurements speak for themselves.

I hope that the members with the proper tools respond to your post. Very interesting.

Happydad

sorry I don’t see your flag.

sorry I don’t see your flag.

happydad- Rest In Peace

- Posts : 1592

Join date : 2012-05-28

Age : 79

Location : Escondido, CA

Re: Cylinder Porting

Re: Cylinder Porting

hi happydad

Y

es i am Italian , i live in the northem of Italy near Monza and you are right , the ports are angled machined .

The idea was to give a direction to the transfer fuel to get them as far away from the outlet port as possible.

I practically tried to copy the solution adopted by COX on its latest versions of 015.

Y

es i am Italian , i live in the northem of Italy near Monza and you are right , the ports are angled machined .

The idea was to give a direction to the transfer fuel to get them as far away from the outlet port as possible.

I practically tried to copy the solution adopted by COX on its latest versions of 015.

franzkleber- Moderate Poster

- Posts : 24

Join date : 2016-01-29

Age : 60

Re: Cylinder Porting

Re: Cylinder Porting

Wow franzkleber, your drawings and renditions are awesome! Is your cylinder design based on factory style cylinders or custom made cylinders. I see port bumps on the outside of your cylinder drawings.

coxaddict- Gold Member

- Posts : 429

Join date : 2013-01-27

Location : north shore oahu, Hawaii

Re: Cylinder Porting

Re: Cylinder Porting

It is a bit hard to get an angle without a CNC. Some of the old TD cylinders would be a bit faster if the bypass ports were machined a bit deeper right into the threads. I don't think the bulge is needed. Here is a pic of an AP .09. The AP .15 is a bigger bore, and then the slots are cut right through the sleeve to the piston. Kind of backwards from the TDs. The boost port is usually a more gradual angle than the side ones.

The Fora .049 is fairly similar to the AP, but has no boost port at all. A bit like the old Supertigers.

The Fora .049 is fairly similar to the AP, but has no boost port at all. A bit like the old Supertigers.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

You guys can figure this out

You guys can figure this out

coxaddict wrote:Wow franzkleber, your drawings and renditions are awesome! Is your cylinder design based on factory style cylinders or custom made cylinders. I see port bumps on the outside of your cylinder drawings.

Coxaddict: I was hoping you were following all this porting stuff. Didn’t I see you mention you have an a NC machine and could do your own porting? Or was it someone else.

If only we could find some blank cylinders. Hmmm.

Happydad

real old

real old

happydad- Rest In Peace

- Posts : 1592

Join date : 2012-05-28

Age : 79

Location : Escondido, CA

Re: Cylinder Porting

Re: Cylinder Porting

happydad, How are you? Yes I am eagerly following this thread as I have some blank cylinders that I purchased a while ago. They are of the stepped wall style and have been bored and honed I think by Cox. Just need to match the piston to the cylinder for the right fit. I'll make a leak down gage to find the best piston fit something like Cox used to air gage the piston to cylinders during assembly. Come to think about it I could probably use the gage on my other engines  I currently own a Sherline mini lathe and a mini mill that has digital read outs. No NC although I could outfit them if needed. (Kinda costly)

I currently own a Sherline mini lathe and a mini mill that has digital read outs. No NC although I could outfit them if needed. (Kinda costly)

I currently own a Sherline mini lathe and a mini mill that has digital read outs. No NC although I could outfit them if needed. (Kinda costly)

I currently own a Sherline mini lathe and a mini mill that has digital read outs. No NC although I could outfit them if needed. (Kinda costly)

coxaddict- Gold Member

- Posts : 429

Join date : 2013-01-27

Location : north shore oahu, Hawaii

Re: Cylinder Porting

Re: Cylinder Porting

aspeed, Thanks for the good info. Does the Fora use SPI? As I learn more I am leaning towards cutting the ports on the outside of the cylinder then shrink fitting a tube to the cylinder to seal the ports. This would allow for a better port window shape. Just a brainstorm  I think I'll practice on a single port cylinder first. The sleeve would also allow blocking off one of the exhaust ports. Just need to find the right material with same expansion rate as the cylinder.

I think I'll practice on a single port cylinder first. The sleeve would also allow blocking off one of the exhaust ports. Just need to find the right material with same expansion rate as the cylinder.

coxaddict- Gold Member

- Posts : 429

Join date : 2013-01-27

Location : north shore oahu, Hawaii

Nice machine I hear

Nice machine I hear

coxaddict wrote:happydad, How are you? Yes I am eagerly following this thread as I have some blank cylinders that I purchased a while ago. They are of the stepped wall style and have been bored and honed I think by Cox. Just need to match the piston to the cylinder for the right fit. I'll make a leak down gage to find the best piston fit something like Cox used to air gage the piston to cylinders during assembly. Come to think about it I could probably use the gage on my other enginesI currently own a Sherline mini lathe and a mini mill that has digital read outs. No NC although I could outfit them if needed. (Kinda costly)

Seems like you and BB, mr. Beeson, have a lot in common. Seems like someone else just purchased a new Sherline. I hope you two can communicate some day. He has been very busy lately and asked not to be bothered for a while. We both have a magic birthday soon. I never thought I would make 50 and now....

Happydad

happydad- Rest In Peace

- Posts : 1592

Join date : 2012-05-28

Age : 79

Location : Escondido, CA

Re: Cylinder Porting

Re: Cylinder Porting

Haven't had a chance to work on my projects in a while, all I can do is look at them. Last project I worked on was cutting the slit exhaust and lowering the port to create SPI on surestart cylinders. I used a 3"x .081" slotting saw on my mill. That was 8 months ago.

coxaddict- Gold Member

- Posts : 429

Join date : 2013-01-27

Location : north shore oahu, Hawaii

Oh, I see

Oh, I see

coxaddict wrote:Haven't had a chance to work on my projects in a while, all I can do is look at them. Last project I worked on was cutting the slit exhaust and lowering the port to create SPI on surestart cylinders. I used a 3"x .081" slotting saw on my mill. That was 8 months ago.

I see why you want help. In that case. Yes. BTW how’s the surf? North Sore, Hawaii. C’mon. You gotta be a surfer.

Or you could be one of the only guys who owns Cox engines that HAS to go to work every day. UGG.

Hd

happydad- Rest In Peace

- Posts : 1592

Join date : 2012-05-28

Age : 79

Location : Escondido, CA

Re: Cylinder Porting

Re: Cylinder Porting

Ha Ha! North shore flat, South side 2-5 ft. Last time I surfed was when I taught my son when he was 9. He's 41 now

Mostly fishing from shore nowadays. Haven't worked since 2012 got my Medicare card last year

Mostly fishing from shore nowadays. Haven't worked since 2012 got my Medicare card last year

Beautiful weather with a few showers and lots of trade winds.

Beautiful weather with a few showers and lots of trade winds.  Downside hard to fly control line with such windy weather.

Downside hard to fly control line with such windy weather.

Beautiful weather with a few showers and lots of trade winds.

Beautiful weather with a few showers and lots of trade winds.  Downside hard to fly control line with such windy weather.

Downside hard to fly control line with such windy weather.

coxaddict- Gold Member

- Posts : 429

Join date : 2013-01-27

Location : north shore oahu, Hawaii

Re: Cylinder Porting

Re: Cylinder Porting

Very windy here too on the north shore. (Lake Erie) The Fora does have SPI. Have a pic here. http://aerohobby.ca/store/index.php?main_page=product_info&cPath=19&products_id=176&zenid=a8bi83gkjauqfs2i52u8svj1d6 I have a Taig lathe, although I seldom use it except for angles. My Hardinge chucker can not do angles other than form tools unless i buy an expensive attachment. Yes I passed the 60 mark as well. Retired 10 years ago after noticing that many of my friends were gone at 50.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

How did that 3inch blade clear the rest of the cylinder

How did that 3inch blade clear the rest of the cylinder

happydad wrote:coxaddict wrote:Haven't had a chance to work on my projects in a while, all I can do is look at them. Last project I worked on was cutting the slit exhaust and lowering the port to create SPI on surestart cylinders. I used a 3"x .081" slotting saw on my mill. That was 8 months ago.

I see why you want help. In that case. Yes. BTW how’s the surf? North Sore, Hawaii. C’mon. You gotta be a surfer.

Or you could be one of the only guys who owns Cox engines that HAS to go to work every day. UGG.

Hd

I can’t imagine how a 3inch blade cut out the slit in the exhaust without hitting the cylinder walls. I have been tinkering with the idea for a while. Do you think the cheap harbor freight tools metal working lathe would hold the Dremel tool steady enough to do the cutting? Macgrubber style? It’s a thought. The metal lathe is about $300 last time I thought about it, maybe more now.

Wow, I guess I miss surfing as much as you do and I live 40 to 60 miles away from my old surfing spots.

Happydad

happydad- Rest In Peace

- Posts : 1592

Join date : 2012-05-28

Age : 79

Location : Escondido, CA

Re: Cylinder Porting

Re: Cylinder Porting

$300 is a great deal for the Harbor Freight lathe. I think the mill is better for cutting the slots though. That lathe has a lot of followers that like it after a good cleaning and adjusting mods.

aspeed- Platinum Member

- Posts : 796

Join date : 2013-01-18

Location : Leamington Ont. Can.

Re: Cylinder Porting

Re: Cylinder Porting

I own one of the TD's that was originally mentioned at the start of the thread. I believe this is also what David was trying to show as well. The cylinder has one exhaust port and three bypasses. My engine has a welded aluminum header which fits around the perimeter of the cylinder which is setup for a tuned pipe. I don't own the pipe. I've run the engine which is a chore in itself. I have a sewer pipe venturi which is essentially more or less a brass ring around the plastic carb body. This will not run on anything but pressure. The cylinder is not blued it appears to be nickel. When I've run this engine, I wasn't overly excited. I'm either trying to use too large of a prop or the timing requires the pipe or both. My engine has no needle valve so a remote setup is a must. In addition, the engine absolutely requires a bladder or it will not run. I hope to have it out again for a more secure rpm number.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Anyone know what this item is?

» Cox .020 cylinder tap 25/64-48

» SPI or Free Porting

» Cylinder Performance Figures

» All silver late late version TD 049 porting

» Cox .020 cylinder tap 25/64-48

» SPI or Free Porting

» Cylinder Performance Figures

» All silver late late version TD 049 porting

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules