Log in

Search

Latest topics

» My N-1R build logby roddie Yesterday at 9:29 pm

» Funny what you find when you go looking

by rsv1cox Yesterday at 3:21 pm

» Landing-gear tips

by 1975 control line guy Yesterday at 8:17 am

» Purchased the last of any bult engines from Ken Enya

by sosam117 Yesterday at 7:45 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» My latest doodle...

by TD ABUSER Mon Nov 18, 2024 11:30 am

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

» Free Flight Radio Assist

by rdw777 Sun Nov 17, 2024 6:03 pm

» Tribute Shoestring build

by amurphy6812 Sun Nov 17, 2024 5:43 pm

Cox Engine of The Month

TD 09 Ducted Fan

Page 3 of 4

Page 3 of 4 •  1, 2, 3, 4

1, 2, 3, 4

Re: TD 09 Ducted Fan

Re: TD 09 Ducted Fan

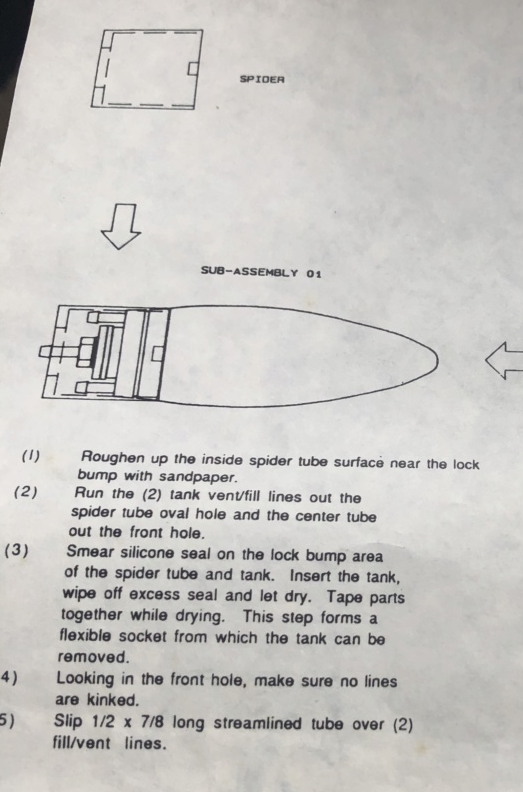

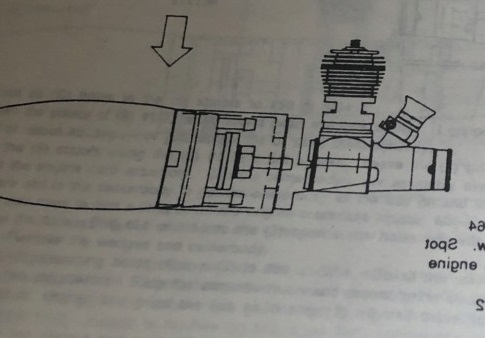

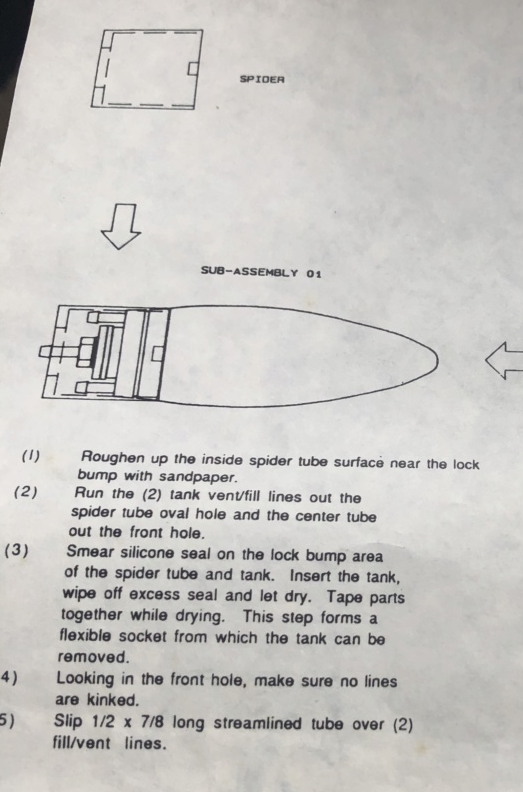

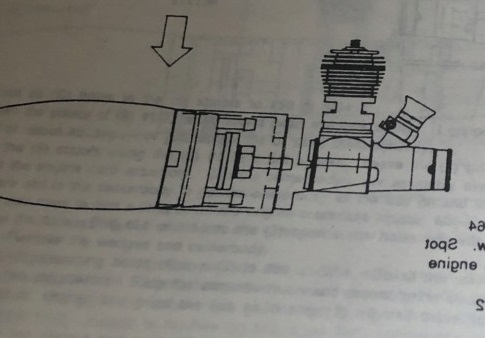

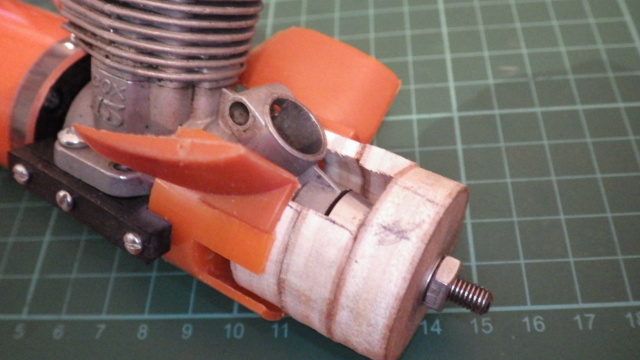

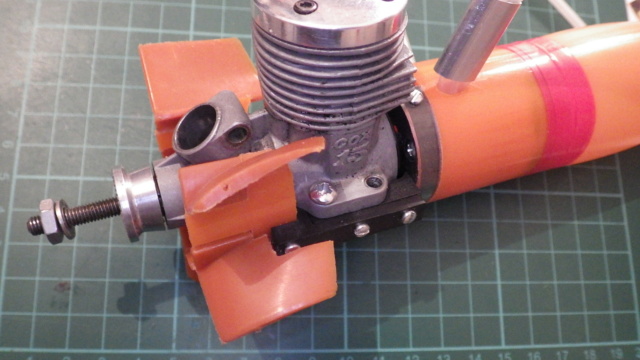

I'm at the point of fixing the spider tube to the tank. The spider tube also carries the engine mount + engine and is bolted to the outer tube. On top is an oval hole for exiting the filler and vent tubes.

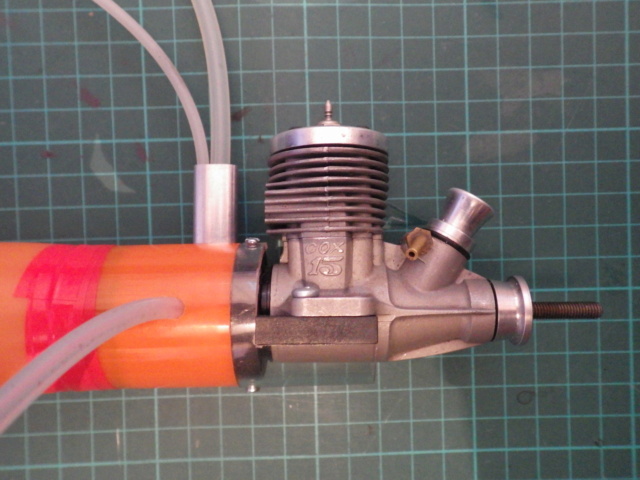

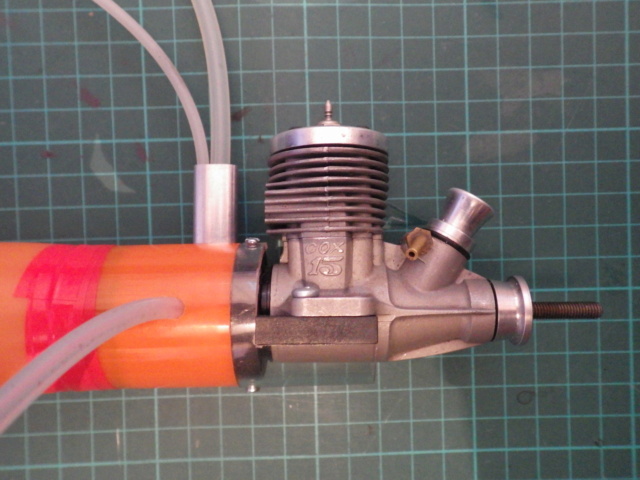

When using a TeeDee, the fuel feed tube exits through the hole in the engine mount and behind the engine. The Conquest, however needs to be mounted with the backplate against the motor mount ring. This means no space anymore for the fuel tube.

The only thing I can come up with is to drill a hole in the side to get this tube out. I looked at pictures on the web but cannot find any similar case. If some of you have another idea...

When using a TeeDee, the fuel feed tube exits through the hole in the engine mount and behind the engine. The Conquest, however needs to be mounted with the backplate against the motor mount ring. This means no space anymore for the fuel tube.

The only thing I can come up with is to drill a hole in the side to get this tube out. I looked at pictures on the web but cannot find any similar case. If some of you have another idea...

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: TD 09 Ducted Fan

Re: TD 09 Ducted Fan

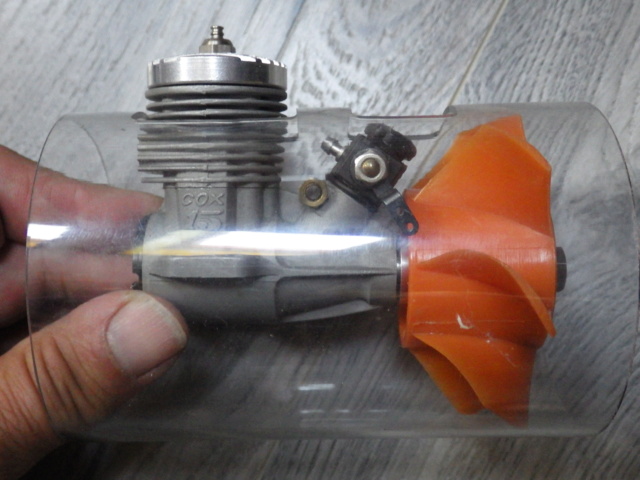

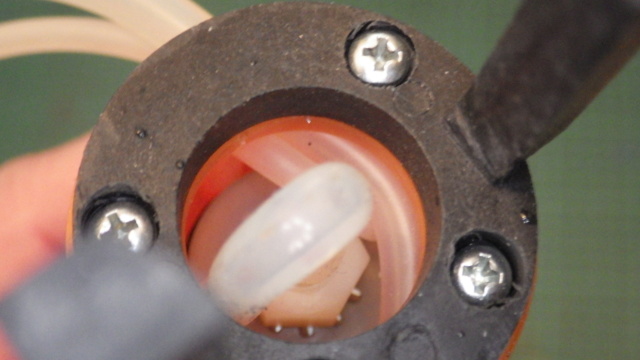

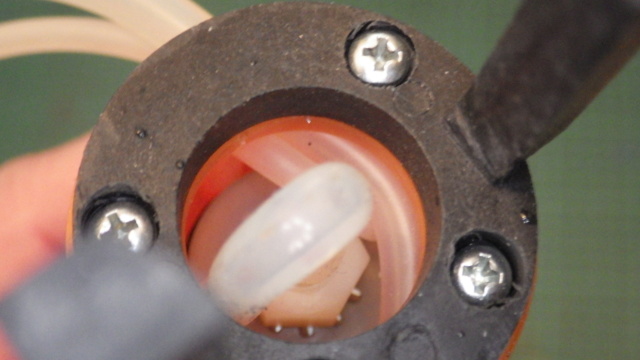

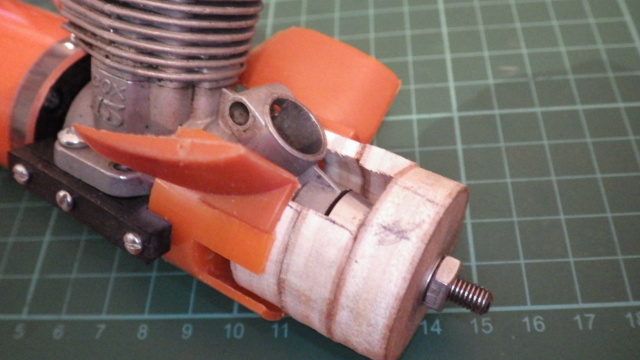

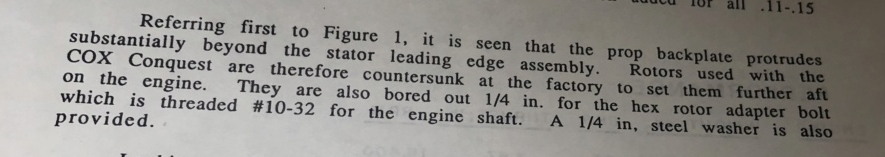

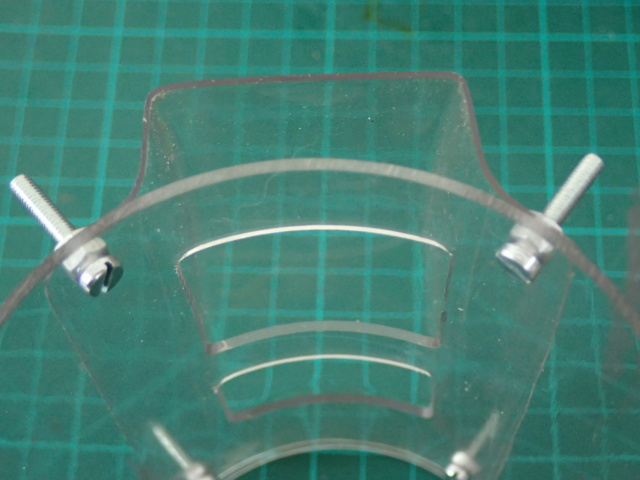

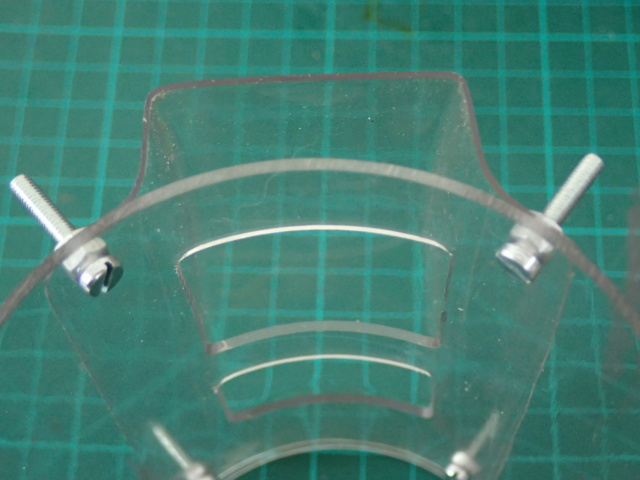

I started assembling parts. First, I attached the spider tube to the tank with a smear of silicon and tape. The silicon tubes must have no kinks. The feed tube has a loop that sits in the hollow backplate of the engine. Next, the motor mount was fixed. As the engine has to be mounted against the motor mount base, the holes have to be made countersunk with a drill. Because the screws go deeper in the spider tube, I filed off the points to protect the silicon tubes. Then the clear centerbody was checked for a good fit and fixed with 3 small screws.

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: TD 09 Ducted Fan

Re: TD 09 Ducted Fan

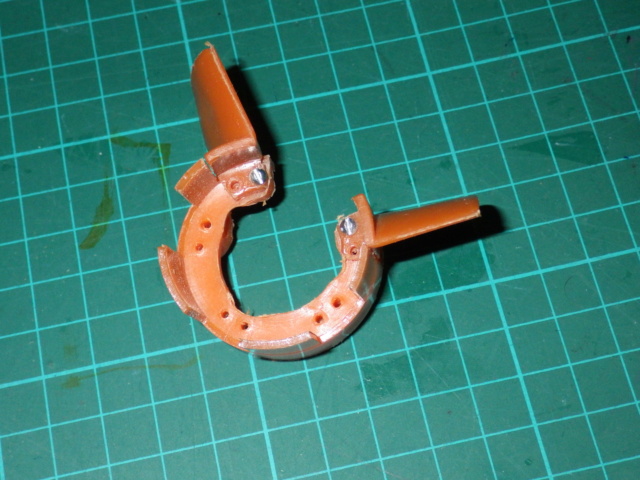

The .09 engine mount appears to be too weak for a .15 engine.

There is simply not enough meat on the beam to radial mount interface.

There is simply not enough meat on the beam to radial mount interface.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: TD 09 Ducted Fan

Re: TD 09 Ducted Fan

Brad, The engine mount is not for the 09. That one is narrower and fits into the stator tube. The motor mount I have is for the .11 - .15 engines. The whole kit was assembled like that. I don't have any specific 09 parts. By the way, the engine is also supported by the stator.

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: TD 09 Ducted Fan

Re: TD 09 Ducted Fan

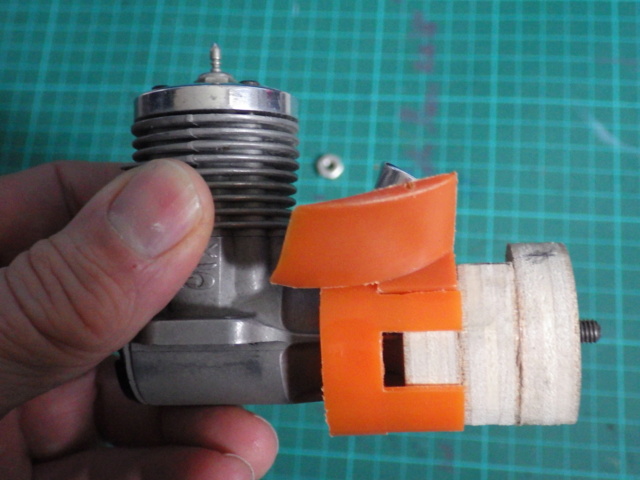

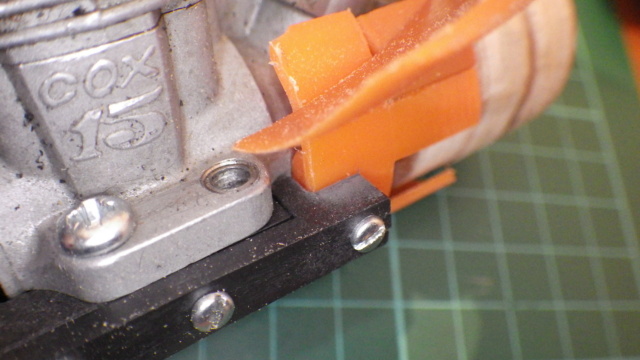

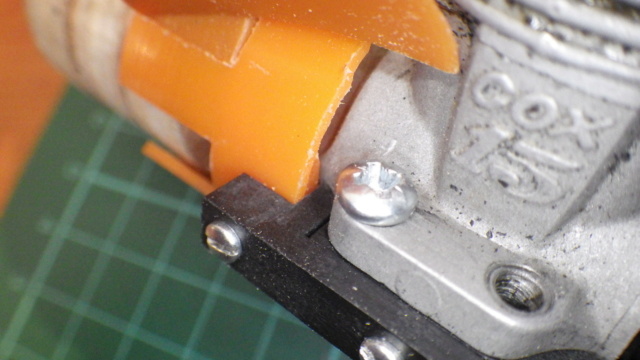

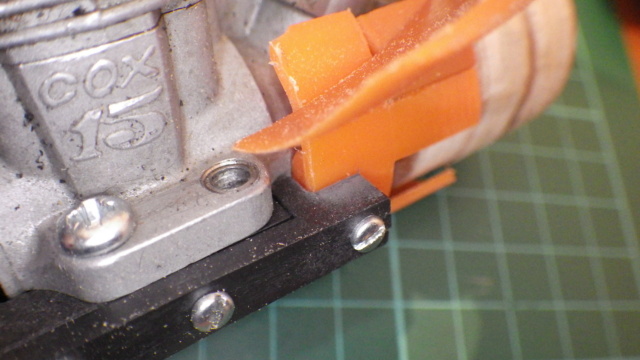

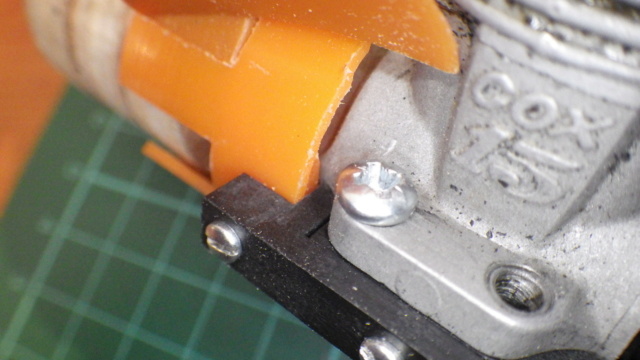

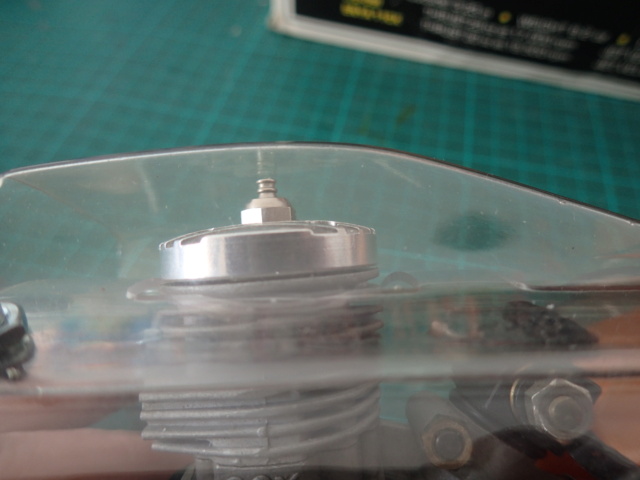

That's where I filed away the edge to make room for the crankcase.

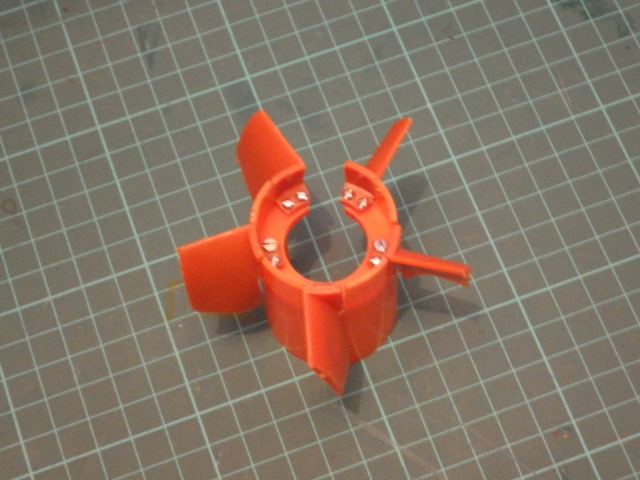

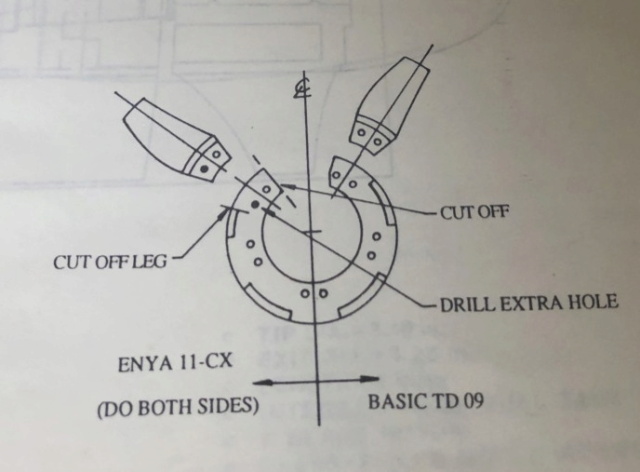

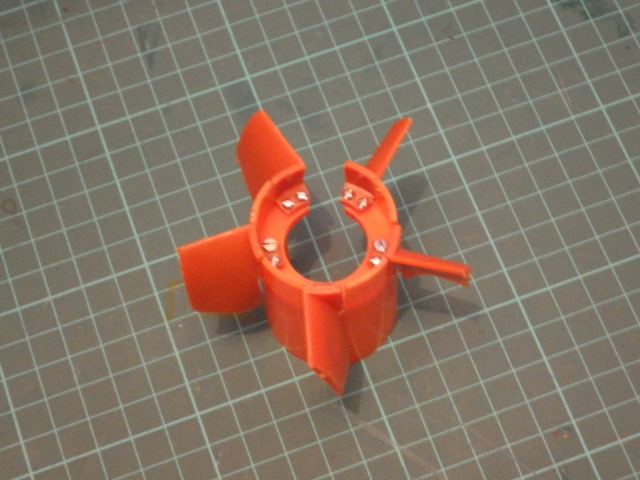

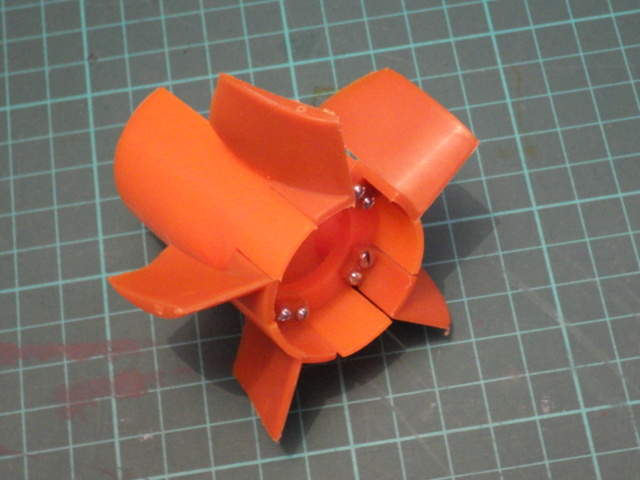

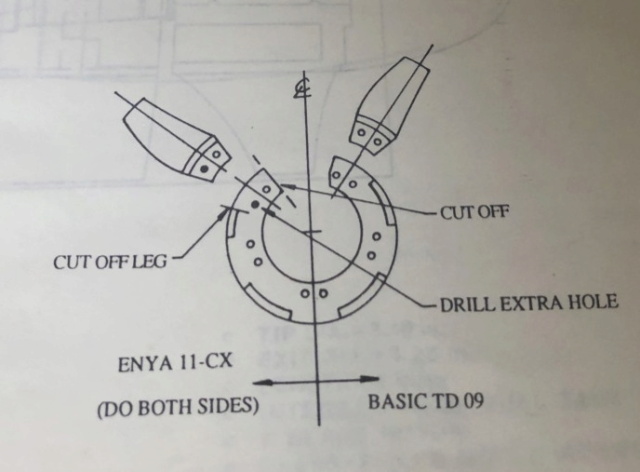

I hope to bring this to a good end. The most difficult part is yet to come: the stator. That piece was already assembled by the previous owner. I have to reposition the 2 upper blades and cut off the tube. The whole unit is too big in diameter to fit into the outer tube. I'll have to take some material off the blades and still make sure that it's still centered!

I hope to bring this to a good end. The most difficult part is yet to come: the stator. That piece was already assembled by the previous owner. I have to reposition the 2 upper blades and cut off the tube. The whole unit is too big in diameter to fit into the outer tube. I'll have to take some material off the blades and still make sure that it's still centered!

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

getback- Top Poster

Posts : 10436

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: TD 09 Ducted Fan

Re: TD 09 Ducted Fan

The stator is modified. I widened the gap and repositioned the 2 upper blades. The major part of the tube was cut off.

Now this is not the end (as Churchill said).

When holding the stator on the engine, the gap between the back of the stator tube end the engine bearers should be 1/8". I have to make notches in the stator hole to slide it further back on the engine.

Now this is not the end (as Churchill said).

When holding the stator on the engine, the gap between the back of the stator tube end the engine bearers should be 1/8". I have to make notches in the stator hole to slide it further back on the engine.

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: TD 09 Ducted Fan

Re: TD 09 Ducted Fan

Your doing a Fantastic job Overlord this is more of a DIY than a Kit , i hope it all turns out for the Best!!

getback- Top Poster

Posts : 10436

Join date : 2013-01-18

Age : 67

Location : julian , NC

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: TD 09 Ducted Fan

Re: TD 09 Ducted Fan

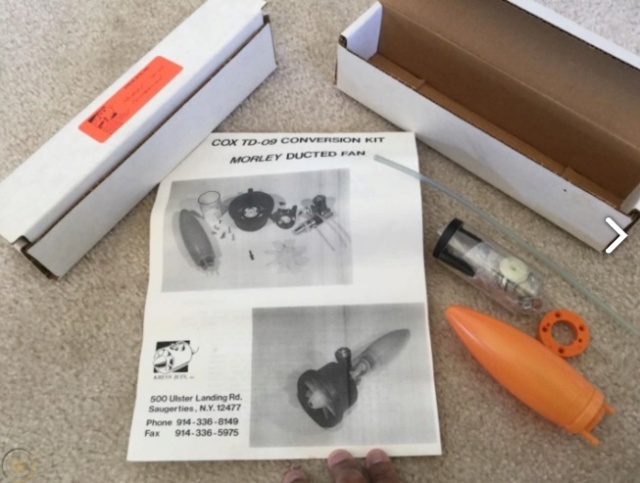

I have a couple electric Morley units. I've never seen this kit for the .09. I seem to remember from the magazines Kress himself built an airplane using one of these, maybe that V1? I doubt I've ever seen anything else.

gkamysz- Gold Member

- Posts : 414

Join date : 2018-02-22

Location : Chicagoland

Re: TD 09 Ducted Fan

Re: TD 09 Ducted Fan

getback wrote:Your doing a Fantastic job Overlord this is more of a DIY than a Kit , i hope it all turns out for the Best!!

More DIY.

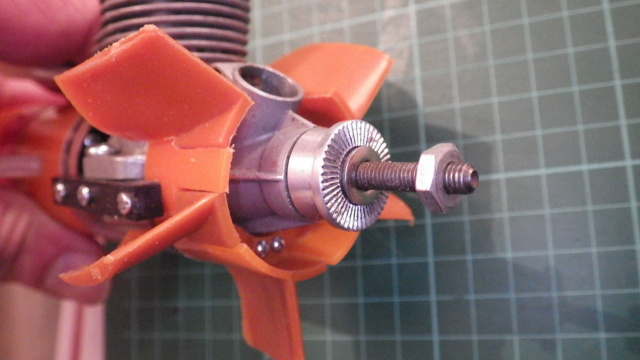

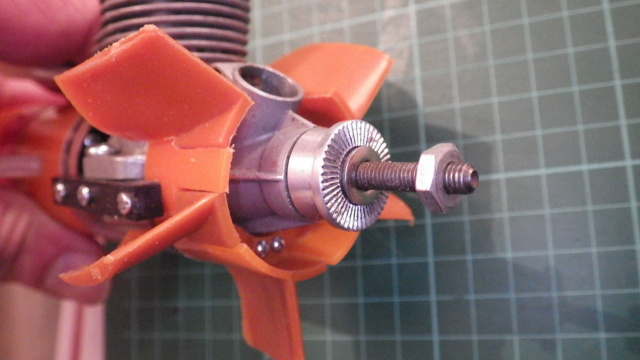

The stator will be bolted onto the engine mount but has remain centered at the same time. To do this by eye is rather difficult and not so precise. Therefore I made a little gizmo out of 3 pieces of plywood glued together. A first round piece fits the engine prop stud and 2 more C-shaped pieces are glued to that. The outer diameter is the inside diameter of the stator tube and can just slide into that. When done up against the prop washer, this piece sould determine the right position of the stator. At least, that's what I hope!

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: TD 09 Ducted Fan

Re: TD 09 Ducted Fan

After some more grinding, a bit of swearing, fitting and more grinding, I got the stator ring to fit. I fixed the engine mount braces to the engine bearers. The instructions say to drill with a 52 thou drill (1,3 mm) but I found that too small. When mounting the #2 screws, you have to put too much pressure on the head with the shallow split that things wear out fast. Therefore, I redrilled with 1,5mm.

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

gkamysz- Gold Member

- Posts : 414

Join date : 2018-02-22

Location : Chicagoland

Re: TD 09 Ducted Fan

Re: TD 09 Ducted Fan

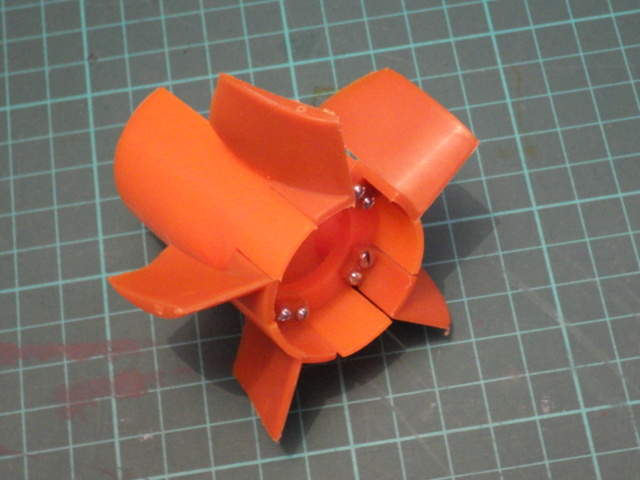

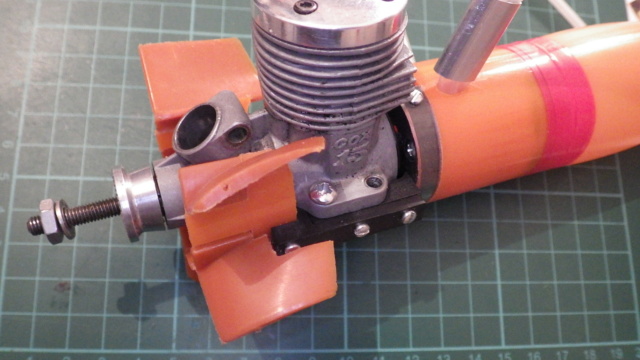

Today, I fitted the stator blades. On the left side, 1 blade needed a cut out to make room for the engine bearer.

I now have to fit this unit in the outer tube, but:

- the blades are too big

- the outer tube is not round

- the rotor has to be centered

- I have to find a way to insert the engine without taking it apart

The outer tube is made of Vivak which is a sort of PET like the plastic water bottles. This material seems to be stressed internally. When I cut the small tube that goes below the crankcase, the material folded back on itself. The outer tube has 2 holes, one for the cylinder head and one for the carb extension. These holes create unequal stresses, resulting in the tube not being round anymore.

I now have to fit this unit in the outer tube, but:

- the blades are too big

- the outer tube is not round

- the rotor has to be centered

- I have to find a way to insert the engine without taking it apart

The outer tube is made of Vivak which is a sort of PET like the plastic water bottles. This material seems to be stressed internally. When I cut the small tube that goes below the crankcase, the material folded back on itself. The outer tube has 2 holes, one for the cylinder head and one for the carb extension. These holes create unequal stresses, resulting in the tube not being round anymore.

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: TD 09 Ducted Fan

Re: TD 09 Ducted Fan

Damn , and wow non fit stuff ! Can you use a stiff bottle of todays plastics to replace the older and deformed ?

getback- Top Poster

Posts : 10436

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: TD 09 Ducted Fan

Re: TD 09 Ducted Fan

Eric, I have to keep the outer tube because that fits exactly around the rotor. I'm thinking of making wooden forms to keep the tube round while fixing the stator. Once that is done, the tube will hopefully keep its shape.

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: TD 09 Ducted Fan

Re: TD 09 Ducted Fan

Cool Kris to the rescue ! I was wondering what had happened to the thread , Good to see your back on it .

getback- Top Poster

Posts : 10436

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: TD 09 Ducted Fan

Re: TD 09 Ducted Fan

I'm glad to see that it worked out!

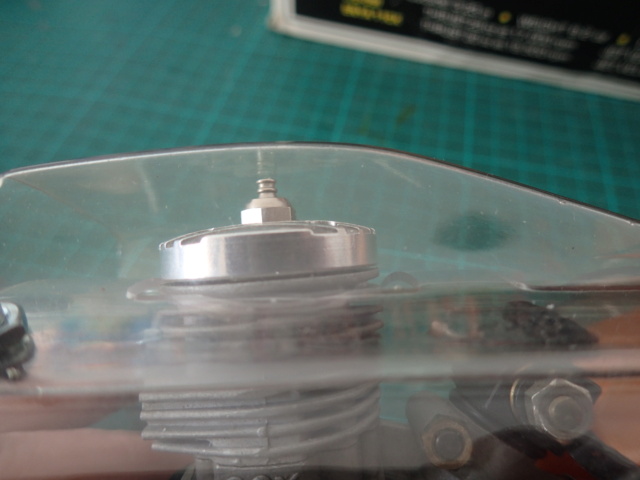

There is nothing "standard" about that that nut, it is about twice as long as any of the commercial ones that I have seen, and the diameter is also slightly larger. They really should have included one in the kit...

There is nothing "standard" about that that nut, it is about twice as long as any of the commercial ones that I have seen, and the diameter is also slightly larger. They really should have included one in the kit...

Surfer_kris- Diamond Member

- Posts : 1912

Join date : 2010-11-20

Location : Sweden

Re: TD 09 Ducted Fan

Re: TD 09 Ducted Fan

Surfer_kris wrote:I'm glad to see that it worked out!

There is nothing "standard" about that that nut, it is about twice as long as any of the commercial ones that I have seen, and the diameter is also slightly larger. They really should have included one in the kit...

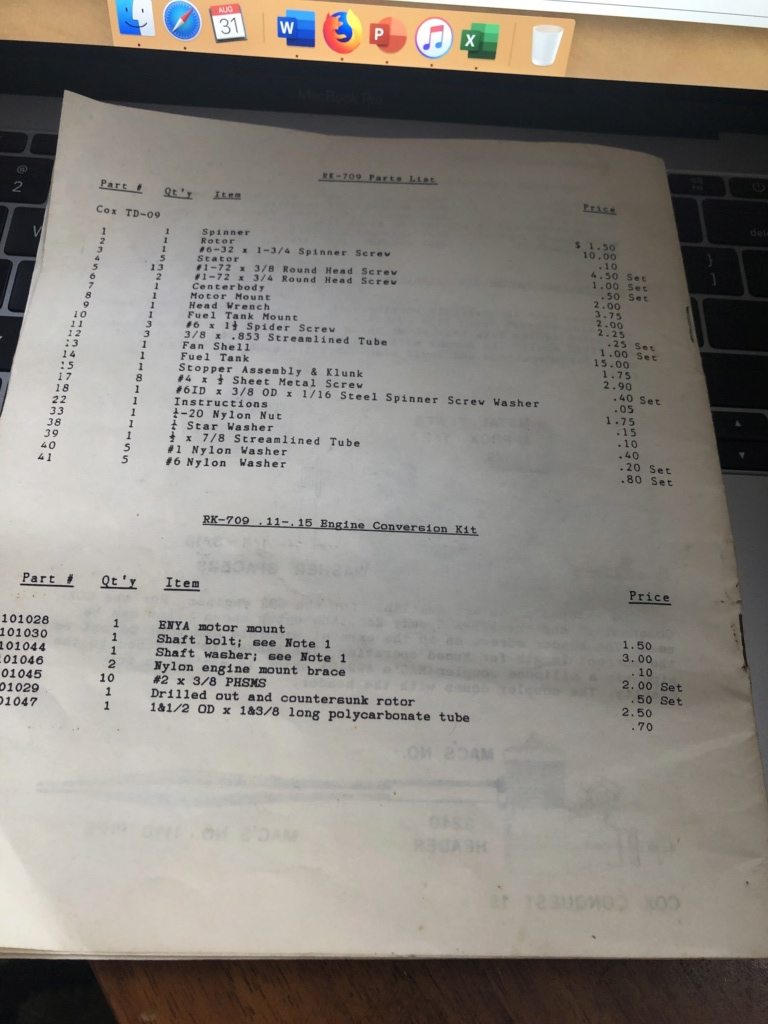

The standard Kress fan has the parts to fit a TeeDee 09. There was a conversion kit available for .11 and .15 engines. This kit had the countersunk fanss and also the nut and washer. In the box I got, This conversion kit was included but the nut got probably lost. I remember that the previous owner said on the phone he had a Webra or an Enya .11 for it and it might be that the nut is still on that engine right now!

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: TD 09 Ducted Fan

Re: TD 09 Ducted Fan

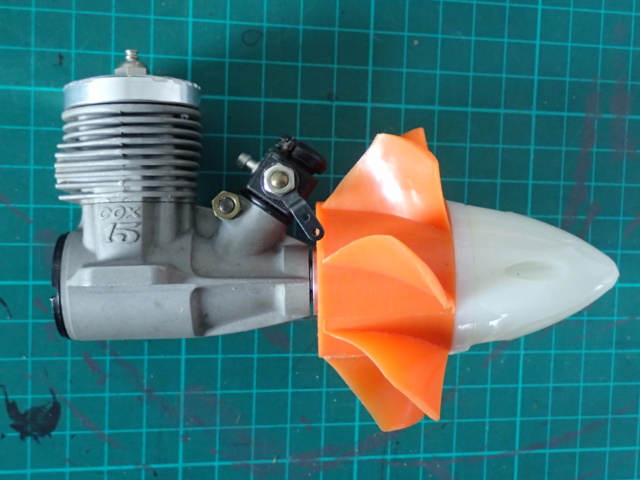

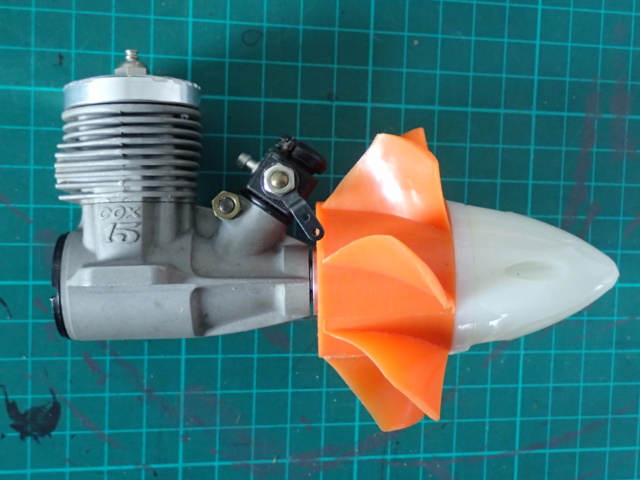

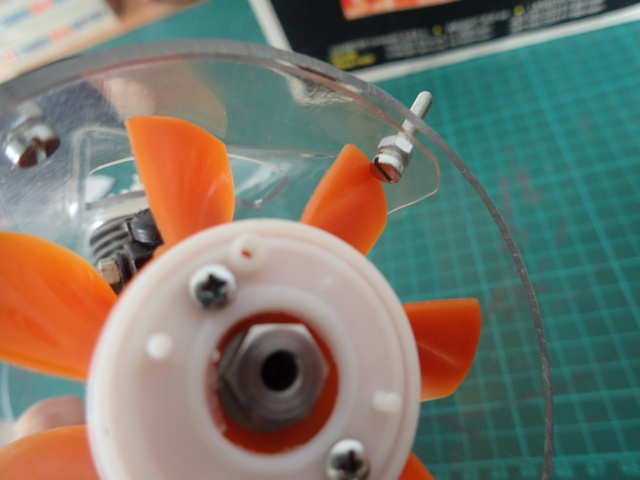

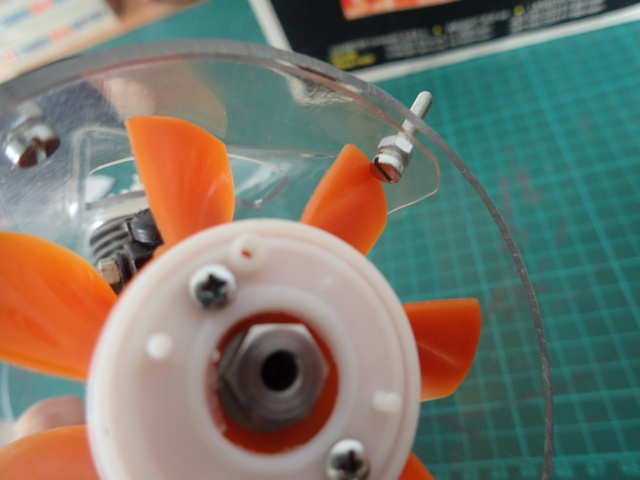

Today, I fitted the spinner to the rotor. The spinner base plate is not fixed by means of the central prop nut but is mounted onto the rotor with 2 1/2" screws. The centre of the spinner base has to be drilled out to make place for the rotor nut. Kress says there should be a 1/4" washer but I naven't got such a washer. I will try to find a M7 washer in my Citroën bolt stock and use that. The centre hole is drilled out big enough to fit the 10mm socket to do up the rotor nut.

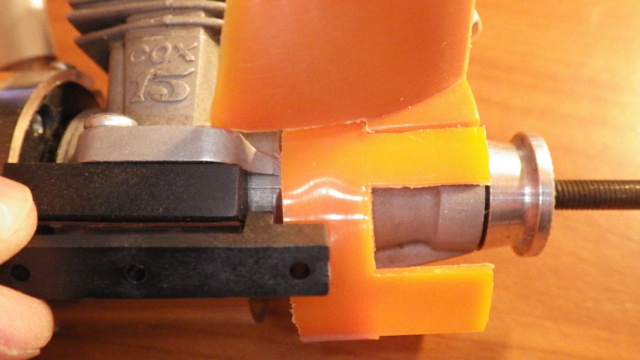

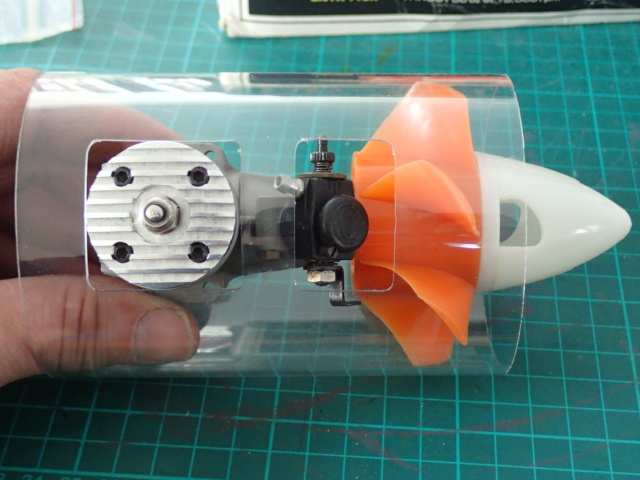

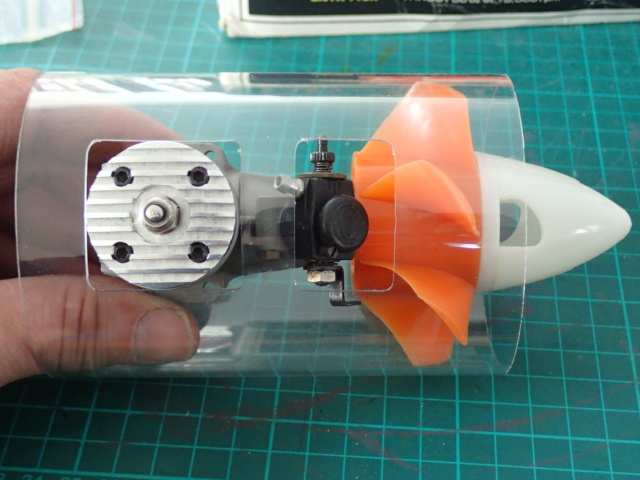

The rotor mounted on the engine and in the plastic tube. According to the instructions, the engine with tank, stator and rotor should slide in the tube from the rear. In order to be able to do that, I will have to cut the part behind the cylinder.

The rotor mounted on the engine and in the plastic tube. According to the instructions, the engine with tank, stator and rotor should slide in the tube from the rear. In order to be able to do that, I will have to cut the part behind the cylinder.

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

Re: TD 09 Ducted Fan

Re: TD 09 Ducted Fan

I fitted the cooling cap to the tube. This piece is, as the tube, made from PET. The cooling cap has to be cut out and made to size. It is fixed to the tube with 4 bolts an nyloc nuts. I don't know what size they are but they are a bit smaller than M3. The instructions don't mention anything about this sequence. For the moment I used M3 bolts and normal nuts as I still have to take it apart during assembly.

When inserting the engine with fan I found out that a hole has to be drilled in the cooling cap in way of the glow plug to mount the engine horizontally. This hole will have to be big enough for the glow starter. As mentioned above, the plastic part of the tube aft of the cylinder hole will have to be cut away otherwise it is not possible to slide the engine and stator into the tube. Also the unit has to be mounted a bit further back as the fan may not interfere with the bolt heads of the cooling cap.

When inserting the engine with fan I found out that a hole has to be drilled in the cooling cap in way of the glow plug to mount the engine horizontally. This hole will have to be big enough for the glow starter. As mentioned above, the plastic part of the tube aft of the cylinder hole will have to be cut away otherwise it is not possible to slide the engine and stator into the tube. Also the unit has to be mounted a bit further back as the fan may not interfere with the bolt heads of the cooling cap.

OVERLORD- Diamond Member

- Posts : 1807

Join date : 2013-03-19

Age : 58

Location : Normandy, France

getback- Top Poster

Posts : 10436

Join date : 2013-01-18

Age : 67

Location : julian , NC

Page 3 of 4 •  1, 2, 3, 4

1, 2, 3, 4

Similar topics

Similar topics» Help to ID: Glow Plugs & Ducted Fan Unit

» Tee dee .09 Ducted Fan R/C

» Cox/Testors ducted fan Star Wars plastic junque

» Ducted fan Shrike

» Cox powered "ducted fan"

» Tee dee .09 Ducted Fan R/C

» Cox/Testors ducted fan Star Wars plastic junque

» Ducted fan Shrike

» Cox powered "ducted fan"

Page 3 of 4

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules