Log in

Search

Latest topics

» Tee Dee .020 combat modelby 1/2A Nut Today at 2:43 pm

» Chocolate chip cookie dough.........

by roddie Today at 1:13 pm

» Purchased the last of any bult engines from Ken Enya

by sosam117 Today at 11:32 am

» Free Flight Radio Assist

by rdw777 Today at 9:24 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

Cox Engine of The Month

Broken needle, any ideas?

Page 1 of 2

Page 1 of 2 • 1, 2

Broken needle, any ideas?

Broken needle, any ideas?

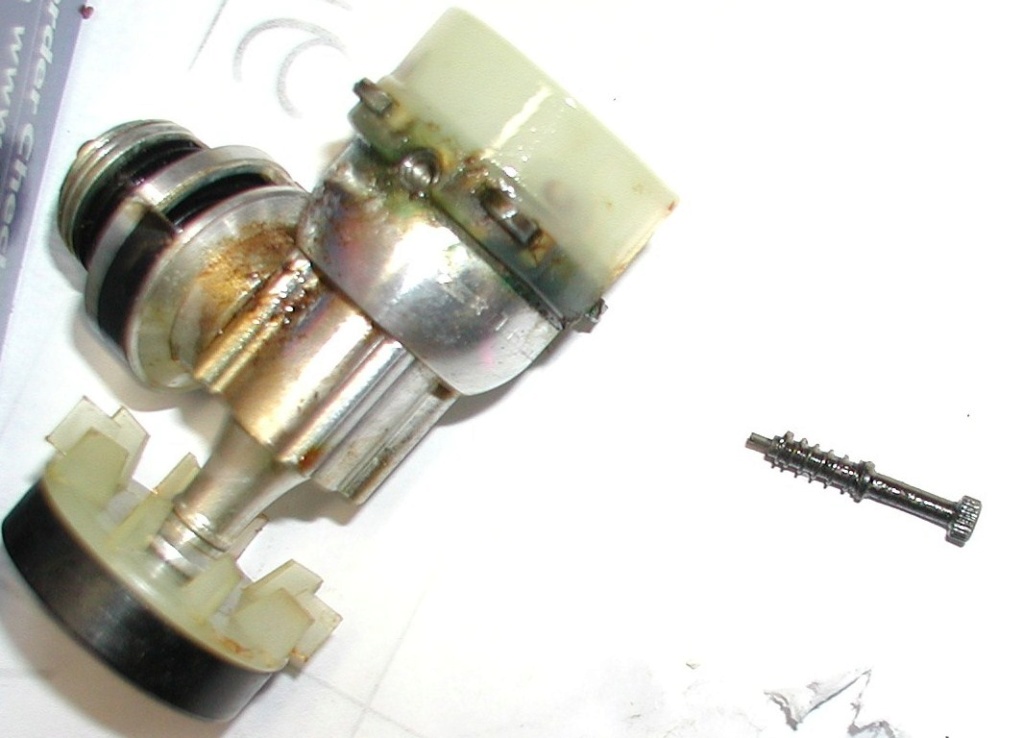

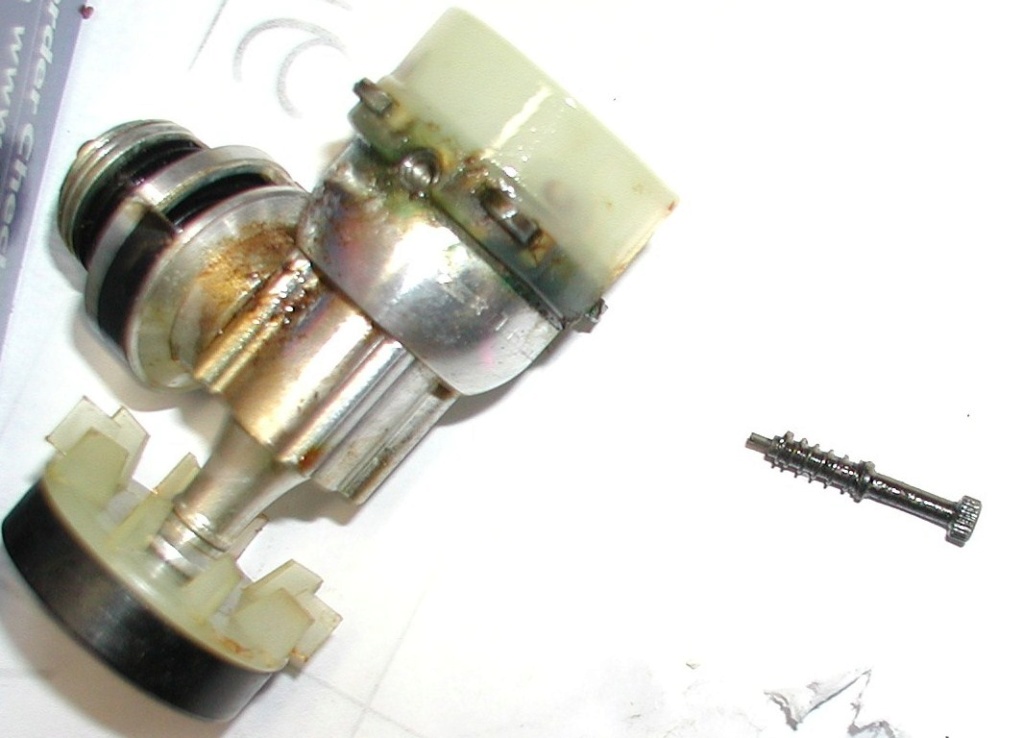

The needle is toast, but I would like to save the back plate. Never had this happen before and it would be the long shank needle peculiar to the Cox W-196.

The tip of the needle is stuck in the back plate. I have tried heat, compressed air, and a fine wire up though the venturi hole attempting to push it out to no happiness.

Bob

The tip of the needle is stuck in the back plate. I have tried heat, compressed air, and a fine wire up though the venturi hole attempting to push it out to no happiness.

Bob

rsv1cox- Top Poster

Posts : 11247

Join date : 2014-08-18

Location : West Virginia

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

rsv1cox wrote:The needle is toast, but I would like to save the back plate. Never had this happen before and it would be the long shank needle peculiar to the Cox W-196.

The tip of the needle is stuck in the back plate. I have tried heat, compressed air, and a fine wire up though the venturi hole attempting to push it out to no happiness.

Bob

friend, this has happened to me once ... well hot automotive coolant, which contains ethylene glycol in its composition, when the liquid starts to evaporate, turn off the flame (can ignite) and immerse the entire engine there in half an hour, Repeat the operation until the engine dirt easily detaches with a toothbrush.

Take the back plate and clean it perfectly with that brush and do the cleaning operation several times.

It is very possible that the tip of the needle is stuck with the oil.

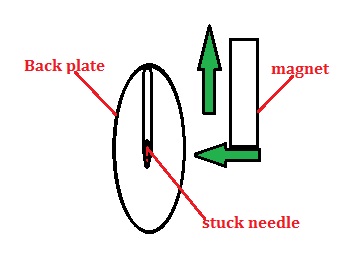

Take a very powerful magnet of those used in computer drives, and place the magnet making tours from the bottom up, stop magic, but leave without ruining anything!

Last edited by MauricioB on Sun Jan 20, 2019 8:12 am; edited 1 time in total

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

I had one of these i never did get out and another that i boiled the crap out of to clean REAL good so it would finally unlodge itself ! Before that i even tried spraying carb. cleaner (with the extended nozzle ) right into the ventura hole (the little one ) Good Luck !

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

Are you 100% sure it’s still in there?

I liked Mauricio’s idea of cleaning all the crap out of it. It should dislodge quite easily once clean with a sharp tap or compressed air.

I liked Mauricio’s idea of cleaning all the crap out of it. It should dislodge quite easily once clean with a sharp tap or compressed air.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

.

Last edited by Mudhen on Wed Nov 17, 2021 9:07 am; edited 1 time in total

Mudhen- Gold Member

- Posts : 489

Join date : 2011-09-19

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

The threaded insert that's in the backplate can be removed. I save most of my old backplates that have cracks or ears broken. Pull the insert out of a old one and insert it back into the desired one with a little JB weld.

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

I would bee interested in how to do this Ken , you say threaded ?Ken Cook wrote:The threaded insert that's in the backplate can be removed. I save most of my old backplates that have cracks or ears broken. Pull the insert out of a old one and insert it back into the desired one with a little JB weld.

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

getback wrote:I would bee interested in how to do this Ken , you say threaded ?Ken Cook wrote:The threaded insert that's in the backplate can be removed. I save most of my old backplates that have cracks or ears broken. Pull the insert out of a old one and insert it back into the desired one with a little JB weld.

By ”threaded” I assume Ken means the inside thread where the needle threads into and the outside of that insert is probably smooth or maybe knurled

This is probably how KK made their special bee backplates... I wonder if a 128tpi postage stamp NVA could be made to fit a bee backplate?

KariFS- Diamond Member

- Posts : 2044

Join date : 2014-10-10

Age : 53

Marleysky- Top Poster

Posts : 3618

Join date : 2014-09-28

Age : 72

Location : Grand Rapids, MI

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

The only thing I can think of is a nice long hot soak in a Crock-Pot with antifreeze in it and air or a fine pick to remove it after a while. I wonder if the previous owner possibly tightened teh bejesus out of it and it may be slightly stuck under pressure and not by castor or fuel? Hope you can get her out soon.

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

you can't use the 128 spraybar in a integral tank backplate. The KK assemblies for the integral tank backs were a custom part. Darren Albert purchased the last of those assemblies and sold them on Ebay years ago. He had hundreds of needles and spraybars. I probably should've bought a few. I passed and it was a good decision as I rarely use integral bees anymore. The postage stamp spraybar will not work due to a smaller diameter and the hole is in a different location where the fuel exits. I highly doubt your going to be able to remove the broken piece as it doesn't just remove itself.I've had this occur dozens of times. It jams into the bottom and all the prodding and prying usually doesn't offer much success. The outside of the insert is different depending on years made. Some have knurls, some have flutes. I wouldn't be overly concerned about damaging what you have, it's already damaged therefore you have nothing to lose. Pull it out and replace it, you could of had it done already it's that easy.

Last edited by Ken Cook on Sun Jan 20, 2019 12:28 pm; edited 1 time in total

Ken Cook- Top Poster

- Posts : 5637

Join date : 2012-03-27

Location : pennsylvania

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

Yes, I know the broken tip is still in there. I can't pass a fine wire down into the screened opening like I can with another back plate.

The W-196 engine is the same as any other tapered case early engine. Only thing different is the longer shaft needle necessary to extend above the closed hood for external adjustment. My bad, I should have applied heat before trying to unscrew it.

I robbed the unvented back plate from that scored anodized Golden Bee and used that. I ordered an unvented plastic back plate from Matt this morning along with other things to replace it. But Ugh, plastic.

I did not know the NVA could be pried out. The hammer thing looks to be quite aggressive, but I'm game.

Thanks to all for your comments.

Bob

The W-196 engine is the same as any other tapered case early engine. Only thing different is the longer shaft needle necessary to extend above the closed hood for external adjustment. My bad, I should have applied heat before trying to unscrew it.

I robbed the unvented back plate from that scored anodized Golden Bee and used that. I ordered an unvented plastic back plate from Matt this morning along with other things to replace it. But Ugh, plastic.

I did not know the NVA could be pried out. The hammer thing looks to be quite aggressive, but I'm game.

Thanks to all for your comments.

Bob

rsv1cox- Top Poster

Posts : 11247

Join date : 2014-08-18

Location : West Virginia

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

Is there a way you could bend a very fine piece of wire or sewing needle (of the same size of the piont on the needle stem) into an L shape and use a small flat blade screwdriver to lever it up into the hole?

If you can't get it out. I'm sure someone on here has a non-vented black widow or golden bee backplate in their parts stash they can spare.

There's this slightly overpriced but NOS Golden Bee tank kit:

https://www.etsy.com/listing/194336856/cox-parts-tank-front-back-for-golden-bee

Or you could try to win a Black Widow: https://www.ebay.com/itm/COX-049-BLACK-WIDOW-model-airplane-engine/163485818956

What might be fun is getting another long stem needle.

If you can't get it out. I'm sure someone on here has a non-vented black widow or golden bee backplate in their parts stash they can spare.

There's this slightly overpriced but NOS Golden Bee tank kit:

https://www.etsy.com/listing/194336856/cox-parts-tank-front-back-for-golden-bee

Or you could try to win a Black Widow: https://www.ebay.com/itm/COX-049-BLACK-WIDOW-model-airplane-engine/163485818956

What might be fun is getting another long stem needle.

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

Admin wrote:Is there a way you could bend a very fine piece of wire or sewing needle (of the same size of the piont on the needle stem) into an L shape and use a small flat blade screwdriver to lever it up into the hole?

What might be fun is getting another long stem needle.

One of the first things I tried Jacob. Tried fine wire up through the screened venturi opening, then a stiffer safety pin, neither worked.

Next time I do an engine crock pot boil I'll toss it in and try again.

Yeah Hen's teeth on that needle.

Bob

rsv1cox- Top Poster

Posts : 11247

Join date : 2014-08-18

Location : West Virginia

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

Ok, I'll bite. What do you exactly mean by a long shanked needle? In that type of needle, I am aware of the ones with larger and smaller knobs on top. And for the horseshoe type needles, I do know there are long and short needles. If indeed there is a long shanked needle, would the backplate for it be specifically for it?

NEW222- Top Poster

- Posts : 3896

Join date : 2011-08-13

Age : 46

Location : oakbank, mb

chevyiron420- Gold Member

- Posts : 251

Join date : 2015-01-28

Age : 66

Location : Barney Georgia

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

Consider a sewing needle or pin again...maybe an uphosltery pin.

But this time grind the tip square. Your needle tip may be wedging or jambing off to one side of the fuel needle instead if pushing square on the end.

Hopefully a ground-off needle tip (no longer sharp) will sit on the end of the fuel needle, and give you good purchase to TAP it out with a small jeweler's hammer. No SMALL hammer? Then a 5"-6" long 5/8" bolt.will do. The idea is lots of little taps versus a big wallop.

Also, heat the plate with a heavy soldering iron or very small butane torch to quickly heat the area...hopefully fast enough to expand the plate before the needle expands too!

But this time grind the tip square. Your needle tip may be wedging or jambing off to one side of the fuel needle instead if pushing square on the end.

Hopefully a ground-off needle tip (no longer sharp) will sit on the end of the fuel needle, and give you good purchase to TAP it out with a small jeweler's hammer. No SMALL hammer? Then a 5"-6" long 5/8" bolt.will do. The idea is lots of little taps versus a big wallop.

Also, heat the plate with a heavy soldering iron or very small butane torch to quickly heat the area...hopefully fast enough to expand the plate before the needle expands too!

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

I would do that and then tap the backplate heavily on an anvil/vise, straight down onto the top. The inertia may jar the needle loose and pop it right out.944_Jim wrote:

Also, heat the plate with a heavy soldering iron or very small butane torch to quickly heat the area...hopefully fast enough to expand the plate before the needle expands too!

Otherwise, I would agree that it has most likely been screwed down way too hard. If it's tight enough to snap when unscrewed, I doubt anything will shift it.

Oldenginerod- Top Poster

- Posts : 4018

Join date : 2012-06-15

Age : 62

Location : Drouin, Victoria

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

The more I think of this problem, the more ideas too in my head.

The following is just to hold the backplate firmly:

Screw the back olate.to a chunk of wood. Chuck the wood/backplate in your vice such that the wood is clamoed by the jaws, and the backplate is resting on top if the jaw edge.

Or cut two pieces of wood (plywood, for instance). Drill or machine reliefs in one to clear the delicate parts of the backplate...the venturi, the filler tubes.

Then use both pieces of wood to clamp the backplate in the vice. Again to hold the backplate...just not by the delicate mounting ears.

I suspect the mating hole in the backplate is a tapered hole as is the needle valve tip. Tapered machined mating surfaces are some of the strongest connections in this world! Look at lawn mower engine flywheel/cranks...or TR6 rear axles/bearings...the stub axle is tapered. In particular, the TR6 stub axle will be ruined by banging, but will pop apart if done by a custom press.

The following is just to hold the backplate firmly:

Screw the back olate.to a chunk of wood. Chuck the wood/backplate in your vice such that the wood is clamoed by the jaws, and the backplate is resting on top if the jaw edge.

Or cut two pieces of wood (plywood, for instance). Drill or machine reliefs in one to clear the delicate parts of the backplate...the venturi, the filler tubes.

Then use both pieces of wood to clamp the backplate in the vice. Again to hold the backplate...just not by the delicate mounting ears.

I suspect the mating hole in the backplate is a tapered hole as is the needle valve tip. Tapered machined mating surfaces are some of the strongest connections in this world! Look at lawn mower engine flywheel/cranks...or TR6 rear axles/bearings...the stub axle is tapered. In particular, the TR6 stub axle will be ruined by banging, but will pop apart if done by a custom press.

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

I have had many tanked bees won from the 'bay with broken needle tips stuck in the body. Removing the body is easy. I stack small washers that have a larger diameter than the needle body and use an old needle valve with a broken tip. Screw the broken needle (I actually grind the needle down taking all the needle off leaving only the threads) against the washers adding washers as the needle pulls the body out. Use pliers to screw the needle. Once its out you can clear the hole or replace the body. Clean the mating surfaces and use JB weld only on the top of the body knurling or groove as Ken stated. Make sure to align the fuel inlet hole with the fuel nipple. I put the modified needle back in and use small clamp to hold the body down as the epoxy dries. The epoxy also seals against any air leaks between the back plate and the needle body.

I posted this procedure a while back and the only drawback is that spare needles and bodies are not always available.

I actually do this to all my metal tank back plates when rebuilding engines as the epoxy sealing actually helps the engine run better.

I posted this procedure a while back and the only drawback is that spare needles and bodies are not always available.

I actually do this to all my metal tank back plates when rebuilding engines as the epoxy sealing actually helps the engine run better.

Last edited by coxaddict on Sun Jan 20, 2019 9:09 pm; edited 1 time in total (Reason for editing : add info)

coxaddict- Gold Member

- Posts : 429

Join date : 2013-01-27

Location : north shore oahu, Hawaii

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

I've learned something new tonight...this is a surprise that there is a "removable" piece in there...now if I could find my warped Golden Bee backplate!

Thisbitnof knowledge is going into my Model airplane note book. Thanks guys.

Thisbitnof knowledge is going into my Model airplane note book. Thanks guys.

944_Jim- Diamond Member

Posts : 2022

Join date : 2017-02-08

Age : 59

Location : NE MS

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

Chevyiron, the short needles are used on some Cox powered cars. I like the short needles as they are less prone to vibration, wearing the threads and causing the engine to run erratic. I sometimes cut the head off the long needle and epoxy a bead that was drilled out to fit the stub. Got that idea from a Leo Squire engine and it looks cool! That along with the tried and true fuel tubing/washer combination can only help the engine run more consistent.

coxaddict- Gold Member

- Posts : 429

Join date : 2013-01-27

Location : north shore oahu, Hawaii

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

Wow, lot's of good idea's. I like squaring off the pins end. The problem is that angle.

The tragedy is losing that long shaft needle, the only place I have ever seen it is on the 5cc vented tanked Babe Bee engine used in the Cox Mercedes. But any BB needle will work.

Pictures show a Cox Riviera with the short needle required to avoid contact with the Rivieras back window, the long Mercedes needle needed to clear the closed hood for external adjustment and two standard BB/BW/GB needles with small and large heads.

The tragedy is losing that long shaft needle, the only place I have ever seen it is on the 5cc vented tanked Babe Bee engine used in the Cox Mercedes. But any BB needle will work.

Pictures show a Cox Riviera with the short needle required to avoid contact with the Rivieras back window, the long Mercedes needle needed to clear the closed hood for external adjustment and two standard BB/BW/GB needles with small and large heads.

rsv1cox- Top Poster

Posts : 11247

Join date : 2014-08-18

Location : West Virginia

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

Bob , how long is that needle you need ? i have one thats 1" over all

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Re: Broken needle, any ideas?

Re: Broken needle, any ideas?

If it were mine, I would be trying to get it out using an ultrasonic bath, a good solvent, and a really strong magnet to help it along in the right direction.

jarboy- Moderate Poster

- Posts : 16

Join date : 2017-01-05

Location : Minnesota

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Out of ideas - Help :(

» Any ideas for a TD 020 muffler?

» Looking for ideas. How would you repair this?

» All-Star Biplane for .020

» McCutchen Wing AKA Charibdis

» Any ideas for a TD 020 muffler?

» Looking for ideas. How would you repair this?

» All-Star Biplane for .020

» McCutchen Wing AKA Charibdis

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules