Log in

Search

Latest topics

» Tee Dee .020 combat modelby getback Today at 7:14 am

» Free Flight Radio Assist

by getback Today at 7:02 am

» My latest doodle...

by batjac Yesterday at 9:47 pm

» My N-1R build log

by roddie Yesterday at 8:50 pm

» Purchased the last of any bult engines from Ken Enya

by getback Yesterday at 12:05 pm

» Funny what you find when you go looking

by rsv1cox Wed Nov 20, 2024 3:21 pm

» Landing-gear tips

by 1975 control line guy Wed Nov 20, 2024 8:17 am

» Cox NaBOO - Just in time for Halloween

by rsv1cox Tue Nov 19, 2024 6:35 pm

» Canada Post strike - We are still shipping :)

by Cox International Tue Nov 19, 2024 12:01 pm

» Duende V model from RC Model magazine 1983.

by getback Tue Nov 19, 2024 6:08 am

» My current avatar photo

by roddie Mon Nov 18, 2024 9:05 pm

» Brushless motors?

by rsv1cox Sun Nov 17, 2024 6:40 pm

Cox Engine of The Month

Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Page 21 of 30

Page 21 of 30 •  1 ... 12 ... 20, 21, 22 ... 25 ... 30

1 ... 12 ... 20, 21, 22 ... 25 ... 30

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Good progress Brad, looking forward to seeing it develop into a fully fledged bird.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thank you András

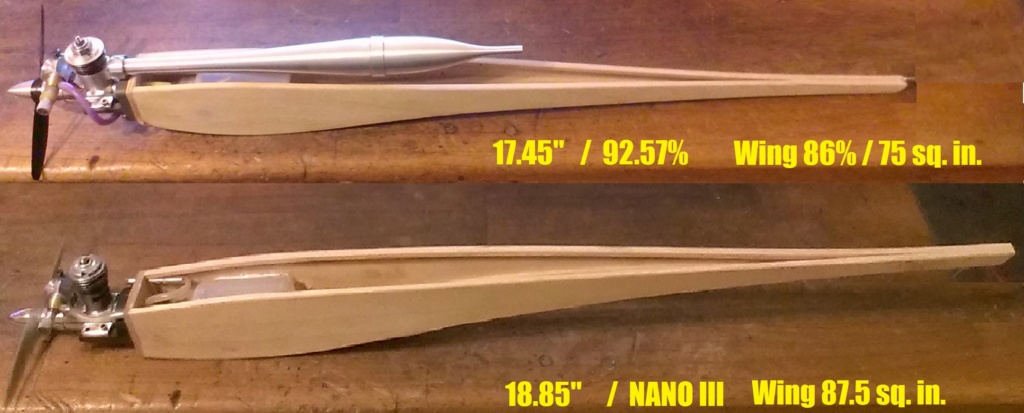

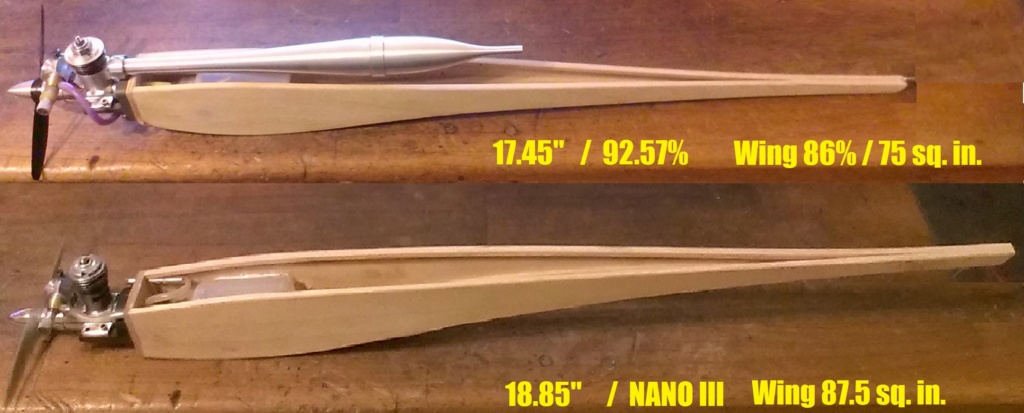

This one will be easy to compare to the NANO III it is 11% smaller. The servos

metal gear 5.8g vs 9g servos in the last build. Beyond that the other was 8oz

less fuel the goal is to loose 1oz and hit 7oz less fuel.

This one will be easy to compare to the NANO III it is 11% smaller. The servos

metal gear 5.8g vs 9g servos in the last build. Beyond that the other was 8oz

less fuel the goal is to loose 1oz and hit 7oz less fuel.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

I know I don’t comment much, but I do want to say I admire you for doing new and inventive things with these engines. You squeeze every last bit of power out of them and it’s impressive.

Cribbs74- Moderator

Posts : 11907

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thank you Eric much appreciated,

I get the fun out of pushing for performance. All came from the late 80's and 90's when I was wishing the RC gear would

get small enough to really do justice for the small Cox engine line. In the mid 90's the Futaba small servos made it happen

with the TD .09 extreme speed over 100 was possible and made good sport flying servos for the TD .049.

Comparison with the NANO that hit 139 mph prop pitch speed / some size reduction with the honed down version.

Smaller new metal gear servos make for room and weight savings will add up across the board. Imagine what will be

possible 10 yrs from now most likely solid state servos that do not use gears or motors yet put out more torque and

weigh / less than the counter parts today.

I get the fun out of pushing for performance. All came from the late 80's and 90's when I was wishing the RC gear would

get small enough to really do justice for the small Cox engine line. In the mid 90's the Futaba small servos made it happen

with the TD .09 extreme speed over 100 was possible and made good sport flying servos for the TD .049.

Comparison with the NANO that hit 139 mph prop pitch speed / some size reduction with the honed down version.

Smaller new metal gear servos make for room and weight savings will add up across the board. Imagine what will be

possible 10 yrs from now most likely solid state servos that do not use gears or motors yet put out more torque and

weigh / less than the counter parts today.

Last edited by 1/2A Nut on Wed Jan 02, 2019 2:47 am; edited 1 time in total

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Let's push it some more. Design a hot hell rider plane with a micro camera focused on a gerbil in a clear plastic pod mounted to plane.

ticomareado- Account Under Review

- Posts : 1089

Join date : 2013-10-03

Location : NC

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Ticomareado that's not a direction I would want to go lol!

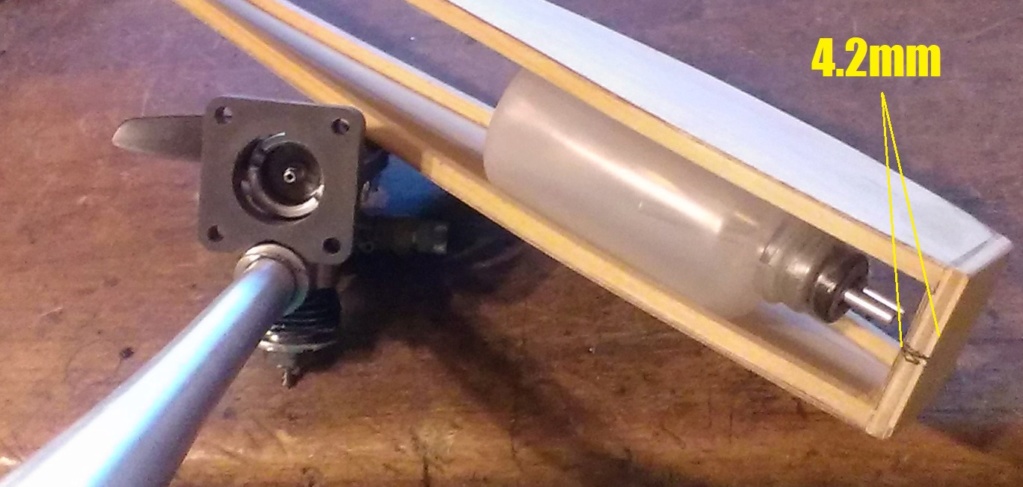

It took almost 2 hours messing around with different ways to secure the stinger, I wanted something that

was not bulky or heavy. Normally I make a aluminum bracket and polish it up but the drag is increased

for a fancy holder so this is was the most simple way to go and is field removable. The piano wire press fits

into a ply plate. The height is adjustable and can be removed in a flash to take the wing off when out flying.

Very secure no chance of loosing the pipe flying fast nor breaking the seal at the manifold. 128g as shown.

It took almost 2 hours messing around with different ways to secure the stinger, I wanted something that

was not bulky or heavy. Normally I make a aluminum bracket and polish it up but the drag is increased

for a fancy holder so this is was the most simple way to go and is field removable. The piano wire press fits

into a ply plate. The height is adjustable and can be removed in a flash to take the wing off when out flying.

Very secure no chance of loosing the pipe flying fast nor breaking the seal at the manifold. 128g as shown.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Some progress the wing servos have a home now, it dawned on me I can have flaps a big plus when forced

to land down wind. SIG airfoil core used has 6mm to 5.5mm depth to work with servo is 8.65mm. Span came

out to 25" and 78 sq/in. area should be blistering fast. 5.8oz thus far as shown nothing left but low weight

items to do yet should be close to the target weight of 7oz.

to land down wind. SIG airfoil core used has 6mm to 5.5mm depth to work with servo is 8.65mm. Span came

out to 25" and 78 sq/in. area should be blistering fast. 5.8oz thus far as shown nothing left but low weight

items to do yet should be close to the target weight of 7oz.

Last edited by 1/2A Nut on Wed Jan 02, 2019 1:45 am; edited 1 time in total

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Hey Brad I see you do not waste your time in the New Year holiday season..big advance on this new plane.

I was also wondering whether to use the Dubro tail mixer for flaperon function of the ailerons in my larger planes but so far have not used them..what is your design for flaps? Unless you have separate channels for the 2 aileron servos the only solution is the tail-mixer for flaperons?

https://rover.ebay.com/rover/0/0/0?mpre=https%3A%2F%2Fwww.ebay.co.uk%2Fulk%2Fitm%2F322336587562

I was also wondering whether to use the Dubro tail mixer for flaperon function of the ailerons in my larger planes but so far have not used them..what is your design for flaps? Unless you have separate channels for the 2 aileron servos the only solution is the tail-mixer for flaperons?

https://rover.ebay.com/rover/0/0/0?mpre=https%3A%2F%2Fwww.ebay.co.uk%2Fulk%2Fitm%2F322336587562

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thank you András

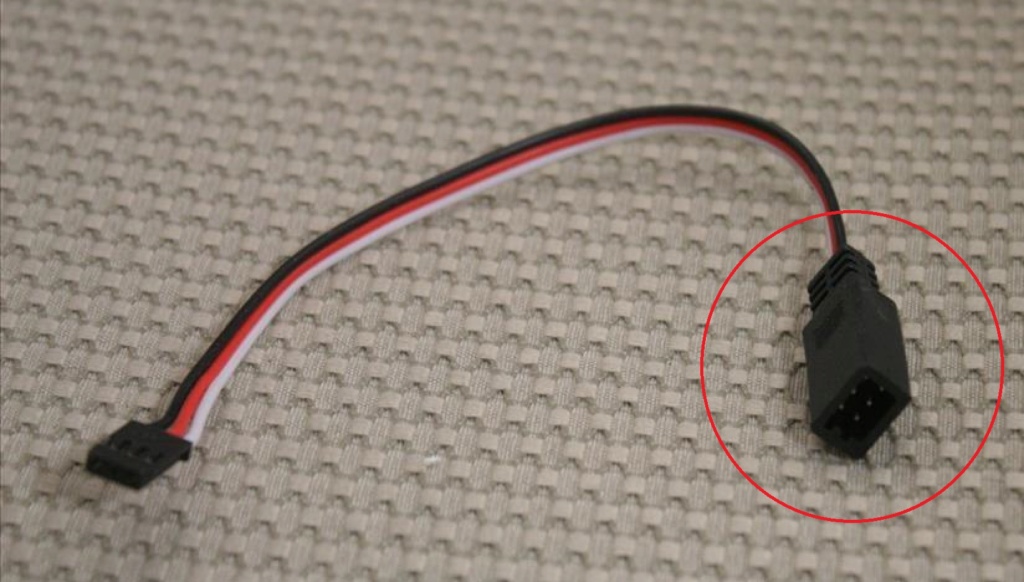

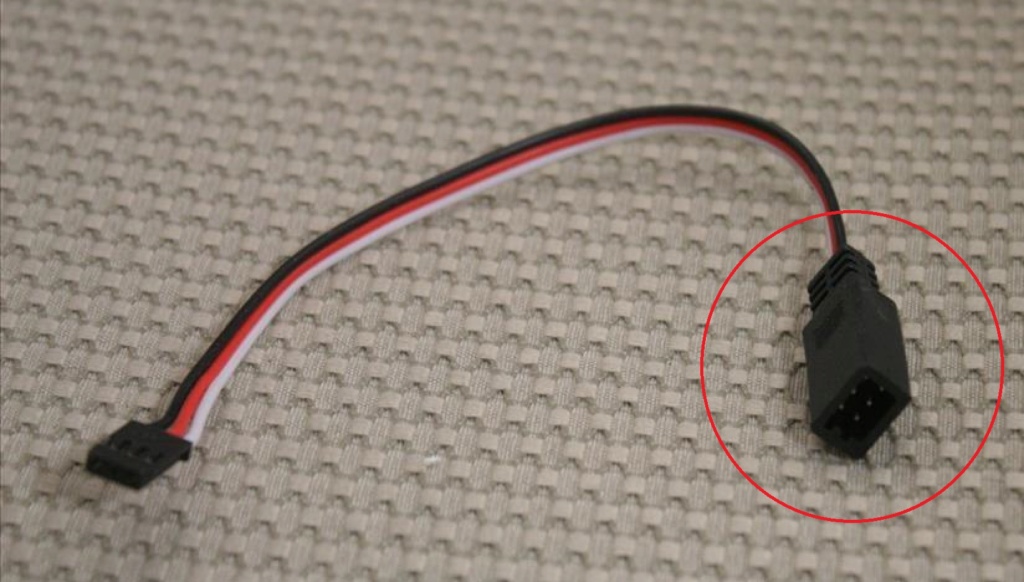

I do not have the room to use that but yes could be done with that hardware. The Skorch had a servo for flaps with the TD .049.

I had separate flaps though so no issues or need to mechanically gang them with the aileron servo. For this project of course

the computer radio will mix in flaps I will have high and low rates for that function via a toggle switch. You could mix in flaps

just by using two servos for future projects. With existing if there is room to have two servos side by side then it would be

a simple fix to mix in flaps with a modern radio. I bought this Y harness to use with this plan project unique single plug holds

two servo plugs, nice clean setup.

I do not have the room to use that but yes could be done with that hardware. The Skorch had a servo for flaps with the TD .049.

I had separate flaps though so no issues or need to mechanically gang them with the aileron servo. For this project of course

the computer radio will mix in flaps I will have high and low rates for that function via a toggle switch. You could mix in flaps

just by using two servos for future projects. With existing if there is room to have two servos side by side then it would be

a simple fix to mix in flaps with a modern radio. I bought this Y harness to use with this plan project unique single plug holds

two servo plugs, nice clean setup.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thanks Brad for the explanations. I also use the Y harness if have 2 separate servos for the ailerons like in my TeeDeeVooDoo, Denight 50 and SIG Wonder planes.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

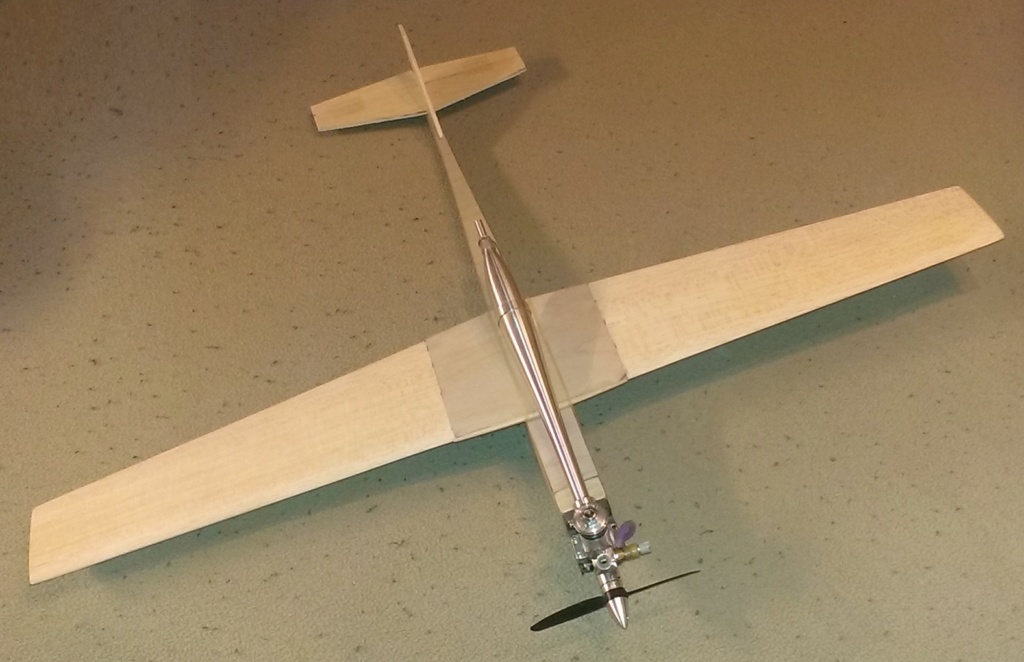

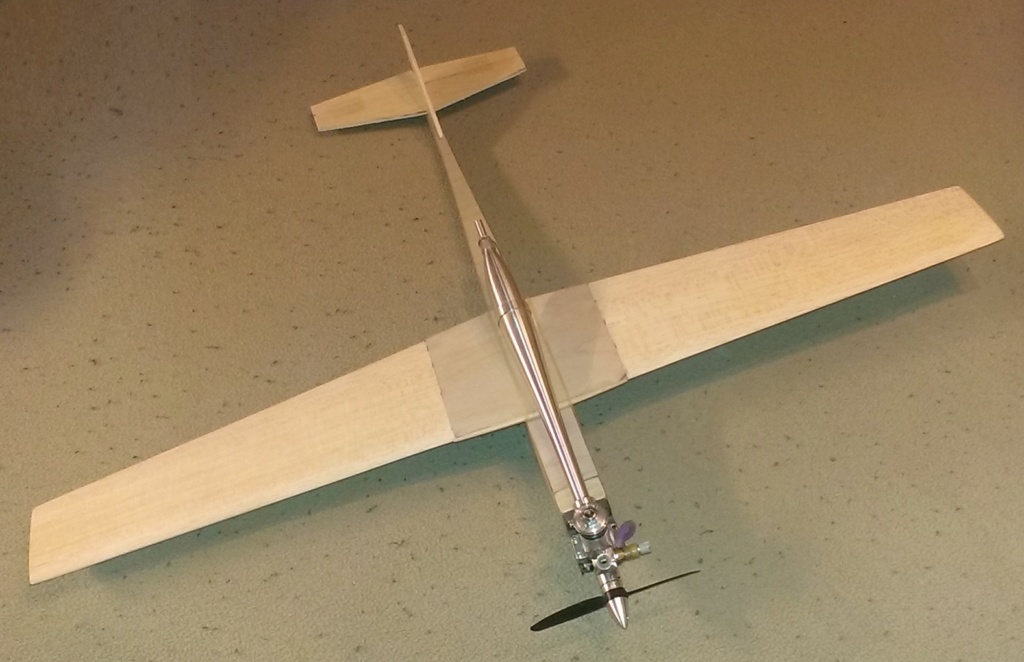

Some progress cut out the tail feathers out have not sanded in the airfoils yet.

Propped them up in place to see what the over all look of the design based on the drawing I did.

I did not deviate from the original drawing for this plane project, it's always interesting to see

a one dimensional drawing pop out into the physical world as shown below. Battery showed up

in the mail not bad at just 13g.

Ply footing to help keep the vertical stab in place at speed.

Propped them up in place to see what the over all look of the design based on the drawing I did.

I did not deviate from the original drawing for this plane project, it's always interesting to see

a one dimensional drawing pop out into the physical world as shown below. Battery showed up

in the mail not bad at just 13g.

Ply footing to help keep the vertical stab in place at speed.

Last edited by 1/2A Nut on Thu Jan 03, 2019 11:04 pm; edited 1 time in total

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Tell me more about that battery. What kind of charging equipment is needed? What does its discharge curve look like? Can it be used with older conventional digital proportional flight packs that would normally use a 4.8 to 6.0 volt battery pack?

ticomareado- Account Under Review

- Posts : 1089

Join date : 2013-10-03

Location : NC

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Brad the way it looks it is going to be a helluva fast plane!!

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Heheh yes András all engine up front!!

When they look like that typically you can expect power to weight ratio good to go!

I expect this will be the new fastest RC 3ch Cox .05 plane on the planet.

Has to beat my NANO III which is no slouch at 141 mph pitch speed thus far with the TD.

Doppler 136 mph as it passed 5 ft. in front of the video camera.

Hi Tico you need to read up on how to charge and care for LiFe batteries, the up swing is

after you charge them they hold their voltage for a long time very little loss. So you can

charge a week ahead and still have nearly full capacity after a week in fact after 4 weeks

a 100% charge LiFe pack will still have 96% capacity. Coreless motors can handle the volts.

Older bushed motors may not. The RX can least the one I am using is ok up to 9v. Today

may folks use 2 cell LiFe batteries for the RX and servos. Lipo cells start off at 3.7v nominal.

After they are fully charged they can hold up to 4.2v this is a bit much on servos in a 2S

configuration you can run the risk of reducing the life span of the servo. Generally there

will be warning (not to exceed volts) on some of the micro servos you have be aware of

the specs know what motor is in the servo. When in doubt use a 5v voltage regulator with

LiFe or LiPo 2S packs.

NiMh cells are 1.2v nominal when fully charge the cell can peak with a digital charger to 1.6v

4 cell pack will settle down to about 5.8v after charging they loose voltage and capacity hourly.

You can charge one day and have a 15% loss the next, I use them with my TD .010

and .020 projects and always peak the pack before I head out to the flying field as capacity

it set for 4 to 5 flights tops any more than that is dead weight when it comes to performance planes.

Much information throughout this thread all things fast.

When they look like that typically you can expect power to weight ratio good to go!

I expect this will be the new fastest RC 3ch Cox .05 plane on the planet.

Has to beat my NANO III which is no slouch at 141 mph pitch speed thus far with the TD.

Doppler 136 mph as it passed 5 ft. in front of the video camera.

Hi Tico you need to read up on how to charge and care for LiFe batteries, the up swing is

after you charge them they hold their voltage for a long time very little loss. So you can

charge a week ahead and still have nearly full capacity after a week in fact after 4 weeks

a 100% charge LiFe pack will still have 96% capacity. Coreless motors can handle the volts.

Older bushed motors may not. The RX can least the one I am using is ok up to 9v. Today

may folks use 2 cell LiFe batteries for the RX and servos. Lipo cells start off at 3.7v nominal.

After they are fully charged they can hold up to 4.2v this is a bit much on servos in a 2S

configuration you can run the risk of reducing the life span of the servo. Generally there

will be warning (not to exceed volts) on some of the micro servos you have be aware of

the specs know what motor is in the servo. When in doubt use a 5v voltage regulator with

LiFe or LiPo 2S packs.

NiMh cells are 1.2v nominal when fully charge the cell can peak with a digital charger to 1.6v

4 cell pack will settle down to about 5.8v after charging they loose voltage and capacity hourly.

You can charge one day and have a 15% loss the next, I use them with my TD .010

and .020 projects and always peak the pack before I head out to the flying field as capacity

it set for 4 to 5 flights tops any more than that is dead weight when it comes to performance planes.

Much information throughout this thread all things fast.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Painting a picture here will at some point bench test this setup to see what it can do.

Pipe length has been set at 7" ideal length for max rpm unknown.

Pipe is 8mm OD / 7mm ID should have a very steady idle.

Clears the wing so only the tail feathers will need cleaning off between flights.

Good goo control and noise suppression should sound great.

FYI on a nice 5g servo mount two per pack. Will use this for the throttle.

Pipe length has been set at 7" ideal length for max rpm unknown.

Pipe is 8mm OD / 7mm ID should have a very steady idle.

Clears the wing so only the tail feathers will need cleaning off between flights.

Good goo control and noise suppression should sound great.

FYI on a nice 5g servo mount two per pack. Will use this for the throttle.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Brad,

I spend most of my plane building time in mounting the servos on proper stands that I typically make from scrap plywood with more, but rather, less success.

Where did you find those aluminum mounts? The few hobby shops left standing in my hometown always stare at me with blue eyes when asked about servo mounts for micro servos.

Thanks, András.

I spend most of my plane building time in mounting the servos on proper stands that I typically make from scrap plywood with more, but rather, less success.

Where did you find those aluminum mounts? The few hobby shops left standing in my hometown always stare at me with blue eyes when asked about servo mounts for micro servos.

Thanks, András.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

These work very well you will appreciate how fast you can secure them to the plane, I have bought 10 of them thus far.

https://www.ebay.com/itm/Qty-2-Aluminum-Servo-Mount-for-5-Gram-5g-Micro-Servos/162603837782?hash=item25dbf1a956:g:GU8AAOSwNSxVNWRZ:rk:21 0

0

https://www.ebay.com/itm/Qty-2-Aluminum-Servo-Mount-for-9-Gram-9g-Micro-Servos/160427436842?hash=item255a386b2a:g:dmEAAOxyW1NREwTL:rk:1 1&frcectupt=true

1&frcectupt=true

Dry fit not sure if I will use the 9g servo yet just seeing whats possible.

Can confirm the mounts work on these:

This servo is metal gear with a top bearing almost the same size as the 3.7g which puts out 10oz of torque

with a 6.6v LiFe charged battery it would be lower in weight if not for the bearing and metal gears. The benefit

is it's small size and the torque it puts out with a 6.6v LiFe battery fully charged you start out with 26oz torque

this is why I have them for the wing ailerons. I am going to take a chance and use it for the elevator as well to

save weight as the 9g servo wires are heavy and longer than needed for a plane this size. Requires washers to

hold down the servo do to the slightly small size. Highly recommend 2-56 hex / socket head bolts over the stock screws.

Here is the size / weight /output comparison.

Elevator servo is in place now with the foam isolation tape the wood surface was sealed with wood sealing latex paint by doing

so the sticky tape has 3x better sticking grip and should last. The smooth aluminum surface of the mount seems to equally

have superior grip to that surface. Engine vibrations should be greatly reduced the servo floats 1mm off the floor of the fuselage.

I would not recommend ever attaching to bare wood without using some additional glue, it simply won't last heat of the summer

could loosen it off the surface. Here it gets over 100F in hindsite I redid mine and added glue to both sides.

https://www.ebay.com/itm/Qty-2-Aluminum-Servo-Mount-for-5-Gram-5g-Micro-Servos/162603837782?hash=item25dbf1a956:g:GU8AAOSwNSxVNWRZ:rk:21

https://www.ebay.com/itm/Qty-2-Aluminum-Servo-Mount-for-9-Gram-9g-Micro-Servos/160427436842?hash=item255a386b2a:g:dmEAAOxyW1NREwTL:rk:1

Dry fit not sure if I will use the 9g servo yet just seeing whats possible.

Can confirm the mounts work on these:

This servo is metal gear with a top bearing almost the same size as the 3.7g which puts out 10oz of torque

with a 6.6v LiFe charged battery it would be lower in weight if not for the bearing and metal gears. The benefit

is it's small size and the torque it puts out with a 6.6v LiFe battery fully charged you start out with 26oz torque

this is why I have them for the wing ailerons. I am going to take a chance and use it for the elevator as well to

save weight as the 9g servo wires are heavy and longer than needed for a plane this size. Requires washers to

hold down the servo do to the slightly small size. Highly recommend 2-56 hex / socket head bolts over the stock screws.

Here is the size / weight /output comparison.

Elevator servo is in place now with the foam isolation tape the wood surface was sealed with wood sealing latex paint by doing

so the sticky tape has 3x better sticking grip and should last. The smooth aluminum surface of the mount seems to equally

have superior grip to that surface. Engine vibrations should be greatly reduced the servo floats 1mm off the floor of the fuselage.

I would not recommend ever attaching to bare wood without using some additional glue, it simply won't last heat of the summer

could loosen it off the surface. Here it gets over 100F in hindsite I redid mine and added glue to both sides.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Much, much, much, dedication and your beautiful way of sharing experiences, make of my valuation towards you dear friend.

I keep your advances in mind!

Happy year, for you, friend !!!

I keep your advances in mind!

Happy year, for you, friend !!!

MauricioB- Top Poster

- Posts : 3712

Join date : 2016-02-16

Age : 53

Location : ARG

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

I had those DSM44 servos in one of my planes and they work well and last long. Congrats Brad for the fast advance and nice build.

balogh- Top Poster

Posts : 4958

Join date : 2011-11-06

Age : 66

Location : Budapest Hungary

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Thank you András, I have used those servos on the TD .020 version for the ailerons with no issues.

Going with the black carbon scheme for the fuselage, not sure on the rest yet will do the tail feathers next

and the wing last. Need to do some work yet on the wing ailerons need to be cut out and need to sort out

how I will finish off covering the servos up.

Going with the black carbon scheme for the fuselage, not sure on the rest yet will do the tail feathers next

and the wing last. Need to do some work yet on the wing ailerons need to be cut out and need to sort out

how I will finish off covering the servos up.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

The more I eyeball the dimensions and geometry of Nut's hell burners, it occurs to me that a scale ME-109E hell burner might be feasible.

ticomareado- Account Under Review

- Posts : 1089

Join date : 2013-10-03

Location : NC

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Patience is key on this effort not the covering per say it's a given more so the alignment of the horizontal and vertical stab.

At the speed this one will go I need solid ridged strength helped by the two stepped ply footings integrating the 3 components.

Another benefit it aided in quickly aligning the stabs at that crucial moment when using thick CA provided enough

working time to adjust all axis to perfection. I don't like using epoxy as it makes repairs harder to fix.

At the speed this one will go I need solid ridged strength helped by the two stepped ply footings integrating the 3 components.

Another benefit it aided in quickly aligning the stabs at that crucial moment when using thick CA provided enough

working time to adjust all axis to perfection. I don't like using epoxy as it makes repairs harder to fix.

1/2A Nut- Top Poster

- Posts : 3536

Join date : 2013-10-20

Age : 61

Location : Brad in Texas

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Re: Cox .01 /.02 /.05 /.09 /.15 Speed Planes

Nice job on cramming those servos in such a small space , and i do like that carbon covering  You really put some smoke on building this model ! Ordered some of those mounts i like the way there easy to work with and small enough for a couple models that need some new mounts and servos , If i may ask what RX do you use with your DX6I i need to get one or two . Thanks Brad .

You really put some smoke on building this model ! Ordered some of those mounts i like the way there easy to work with and small enough for a couple models that need some new mounts and servos , If i may ask what RX do you use with your DX6I i need to get one or two . Thanks Brad .

You really put some smoke on building this model ! Ordered some of those mounts i like the way there easy to work with and small enough for a couple models that need some new mounts and servos , If i may ask what RX do you use with your DX6I i need to get one or two . Thanks Brad .

You really put some smoke on building this model ! Ordered some of those mounts i like the way there easy to work with and small enough for a couple models that need some new mounts and servos , If i may ask what RX do you use with your DX6I i need to get one or two . Thanks Brad .

getback- Top Poster

Posts : 10441

Join date : 2013-01-18

Age : 67

Location : julian , NC

Page 21 of 30 •  1 ... 12 ... 20, 21, 22 ... 25 ... 30

1 ... 12 ... 20, 21, 22 ... 25 ... 30

Similar topics

Similar topics» CG on Speed Contest Planes

» Anyone here into Giant Scale R/C Planes? Post Pics of your Planes.

» Fellow speed freaks, help me build a pair of speed Bees.

» CL planes...

» How many cox planes do you have?

» Anyone here into Giant Scale R/C Planes? Post Pics of your Planes.

» Fellow speed freaks, help me build a pair of speed Bees.

» CL planes...

» How many cox planes do you have?

Page 21 of 30

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules